Modified asphalt with high ultraviolet aging resistance

A modified asphalt and UV technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of not being able to significantly improve the low-temperature crack resistance of asphalt pavement, effectively solving the problems of asphalt UV aging, and asphalt inhibition is not obvious, etc. Achieve the effects of improving the anti-ultraviolet aging ability, prolonging the maintenance cycle and service life, and facilitating the processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Modified asphalt with high UV aging resistance

[0032] The present embodiment provides a modified asphalt with high anti-ultraviolet aging function, which is composed of the following raw materials in terms of weight fraction: matrix asphalt is 75.4%, obsidian is 11.2%, bauxite is 6.9%, hydrogenated castor Sesame oil is 4.0%, aluminum-zirconium coupling agent is 2.5%.

[0033] The above-mentioned base asphalt adopts 90# base asphalt, which can be replaced by other types of asphalt.

[0034] The above-mentioned obsidian and bauxite are both 2000 mesh, and can also be replaced by other suitable mesh, such as 600 mesh or 5000 mesh.

[0035] The preparation method of the modified asphalt with high anti-ultraviolet aging function as described above comprises the following steps:

[0036] Step 1, weighing matrix pitch, obsidian, bauxite, hydrogenated castor oil and aluminum-zirconium coupling agent according to the proportion of raw materials, and set aside.

...

Embodiment 2

[0041] Example 2: Modified asphalt with high UV aging resistance

[0042] This embodiment provides a modified asphalt with high UV aging resistance, which is composed of the following raw materials in terms of weight fraction: 76.9% of matrix asphalt, 9.8% of obsidian, 7.6% of bauxite, hydrogenated castor Sesame oil is 3.7%, aluminum zirconium coupling agent is 2.0%.

[0043] This embodiment is the same as that of embodiment 1 to the requirement of raw material and preparation method.

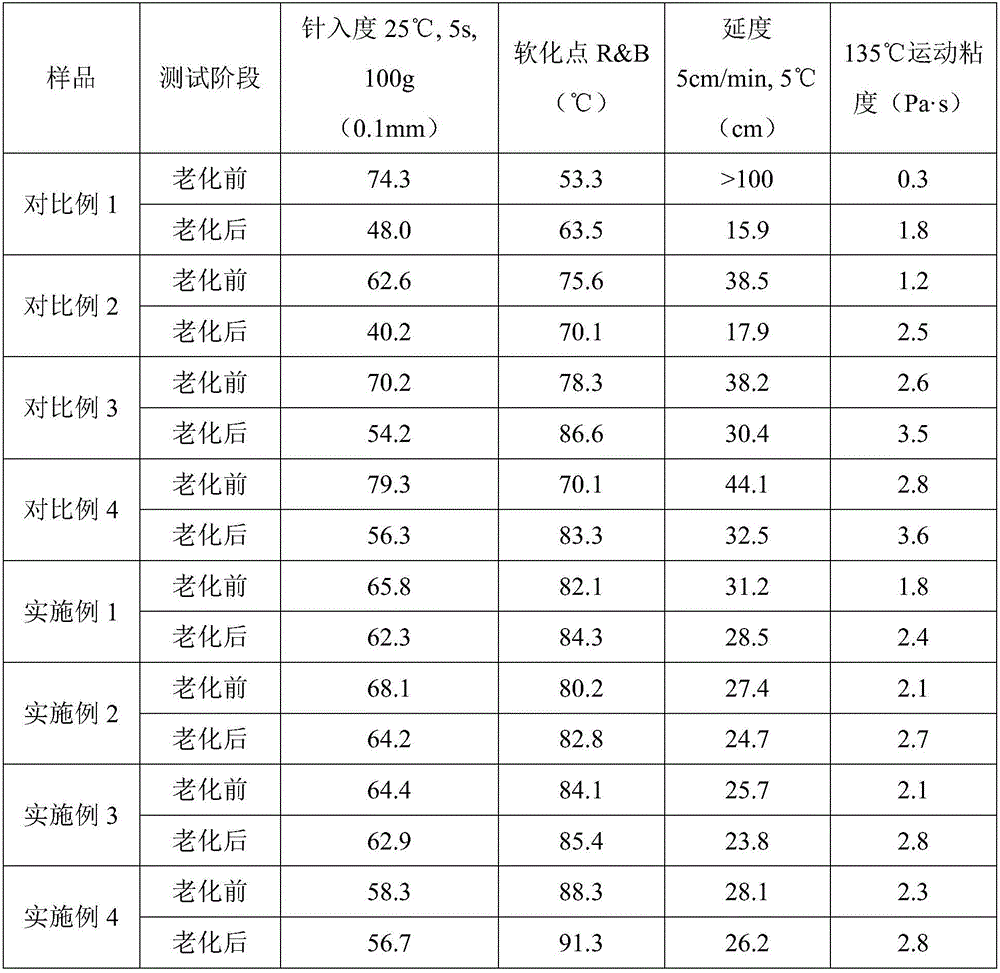

[0044] Table 1 shows the performance test results of the modified asphalt with high anti-ultraviolet aging function in this embodiment.

Embodiment 3

[0045] Example 3: Modified asphalt with high UV aging resistance

[0046] This embodiment provides a modified asphalt with high UV aging resistance, which is composed of the following raw materials in terms of weight fraction: 76.5% of matrix asphalt, 11.8% of obsidian, 6.1% of bauxite, hydrogenated castor Sesame oil is 3.0%, aluminum zirconium coupling agent is 2.6%.

[0047] This embodiment is the same as that of embodiment 1 to the requirement of raw material and preparation method.

[0048] Table 1 shows the performance test results of the modified asphalt with high anti-ultraviolet aging function in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com