Macromolecule uniform distribution and adding technology

A polymer and process technology, applied in the field of polymer uniform distribution adding technology, can solve the problems of easy generation of dust, polymer aggregation, affecting product performance, etc., and achieve the effect of increasing adding capacity, improving efficiency and adding uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

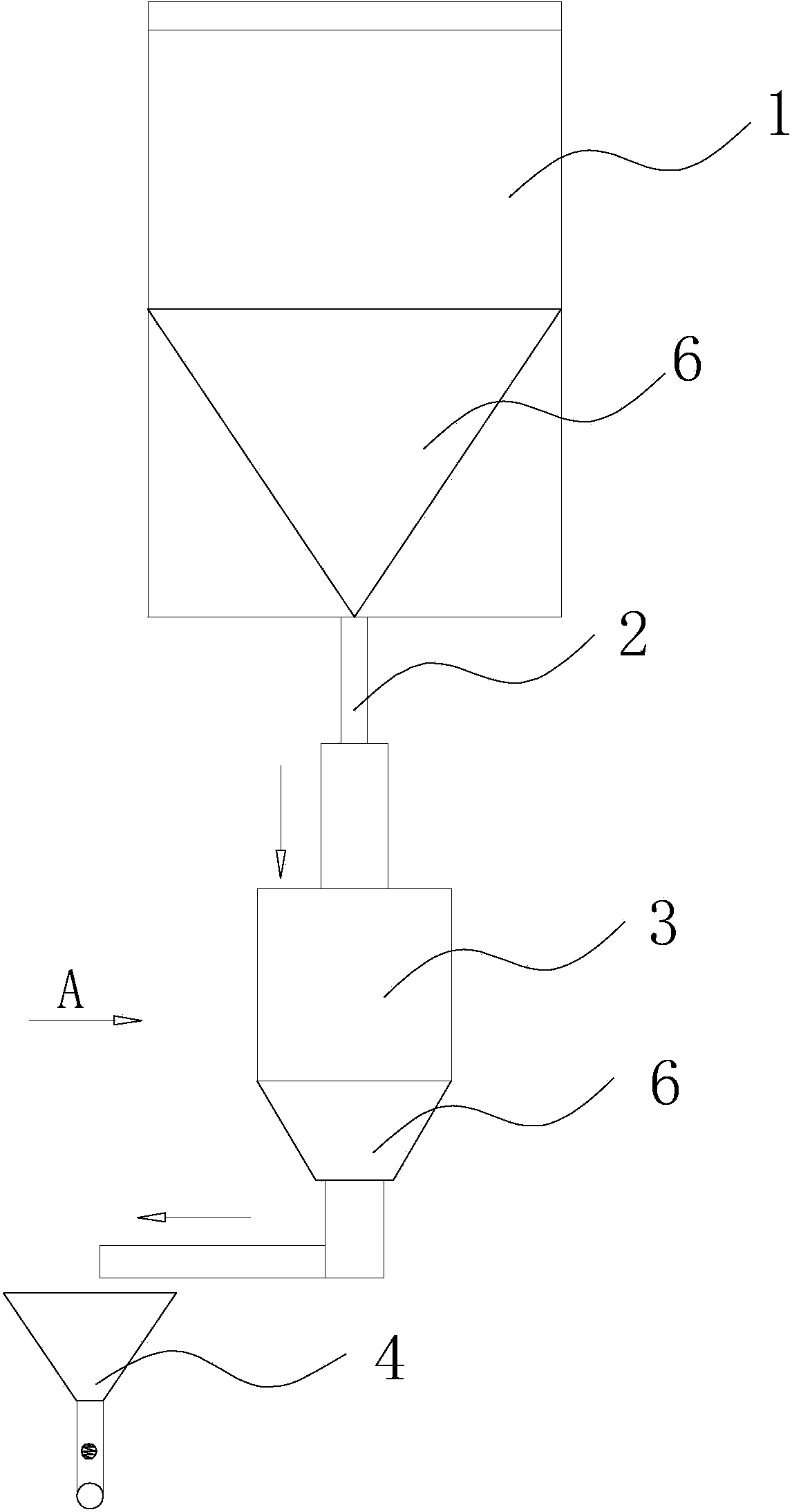

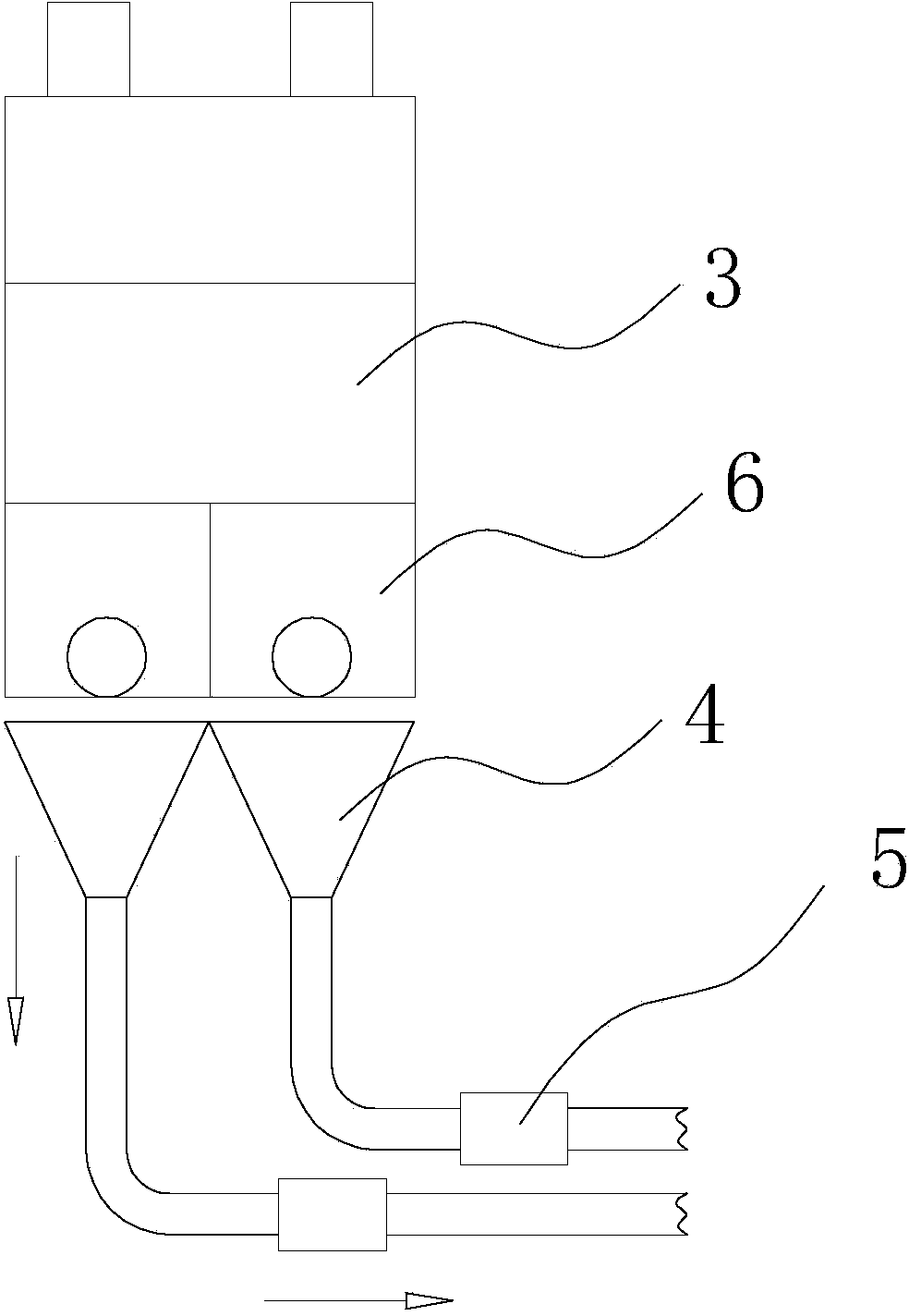

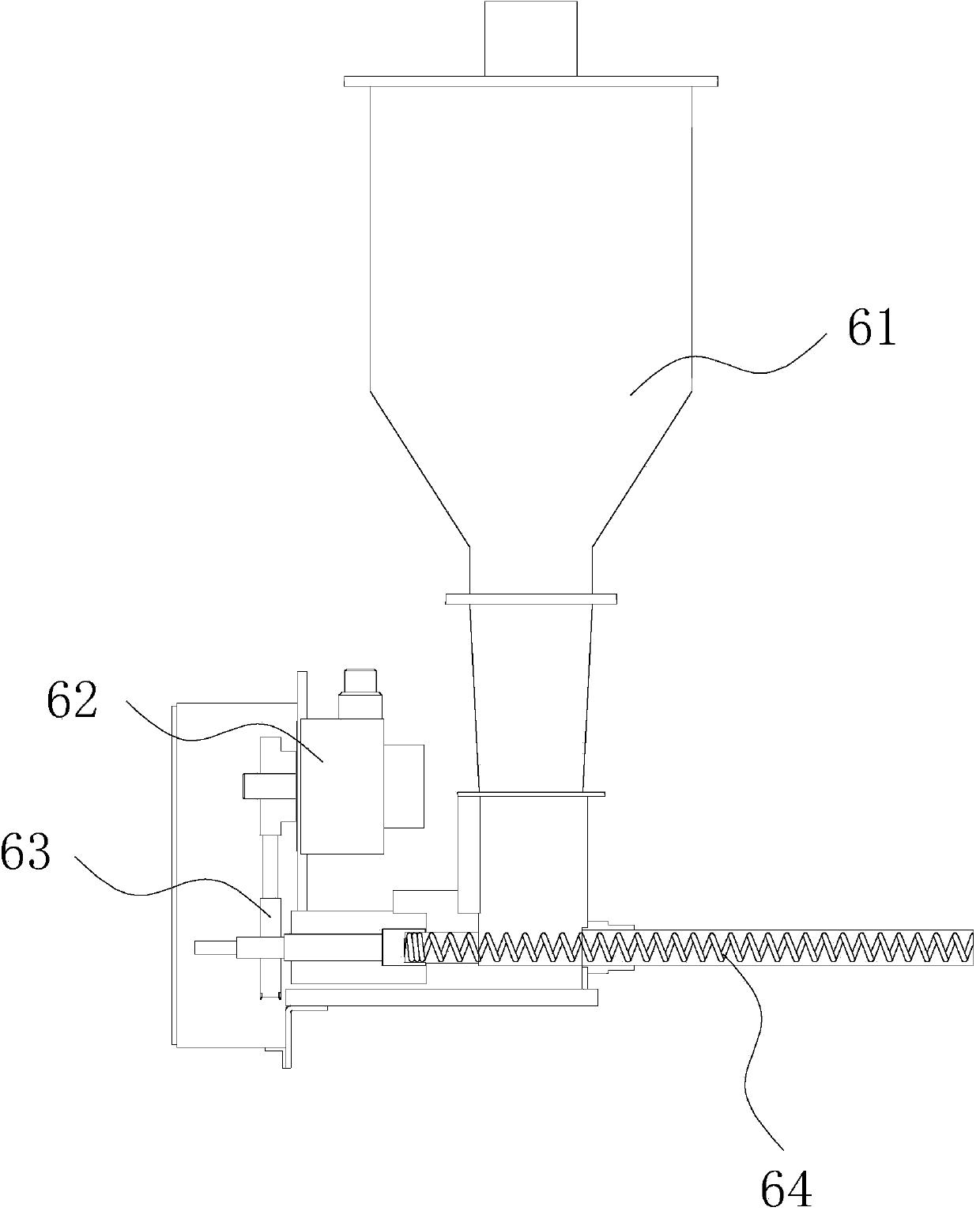

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] A process for uniformly distributed polymer addition, comprising the following steps:

[0018] The first step is to store the polymer in the polymer storage mechanism, and at the same time, it is equipped with an automatic heating device to keep the temperature at 50°C and ensure the dryness of the polymer at 5%, so as to provide polymer materials for machine production at any time;

[0019] In the second step, use a high-speed air spray gun to spray the polymer in the polymer storage mechanism into the polymer feeding mechanism, and transport it into the polymer quantitative mechanism;

[0020] In the third step, according to the requirements of the product on the weight of the polymer, the servo motor is used to control the vibration of the high-precision spring, so that the high-precision spring is used to send the polymer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com