Light jogging shoe sole preparation method

A lightweight technology for running shoes, applied in the field of organic polymer compounds, can solve problems such as poor sole performance and environmental pollution of EVA leftovers, and achieve high rebound rate, avoid large dust, and good rebound performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the present embodiment, described light jogging shoe sole comprises the following steps:

[0035] In order to achieve the above object, the present invention adopts following technical scheme, comprises the steps:

[0036] Step 1: Prepare and recycle EVA film, crush the scraps, defective products, waste products, and scraps produced in the process of producing EVA soles through a crusher; then crush 75 parts by weight of crushed material, 2 parts of mineral oil, and 4 parts of EVA 7870S , banbury in the internal mixer, then open the kneading, and finally calender into a recycled EVA film with a thickness of 0.02mm;

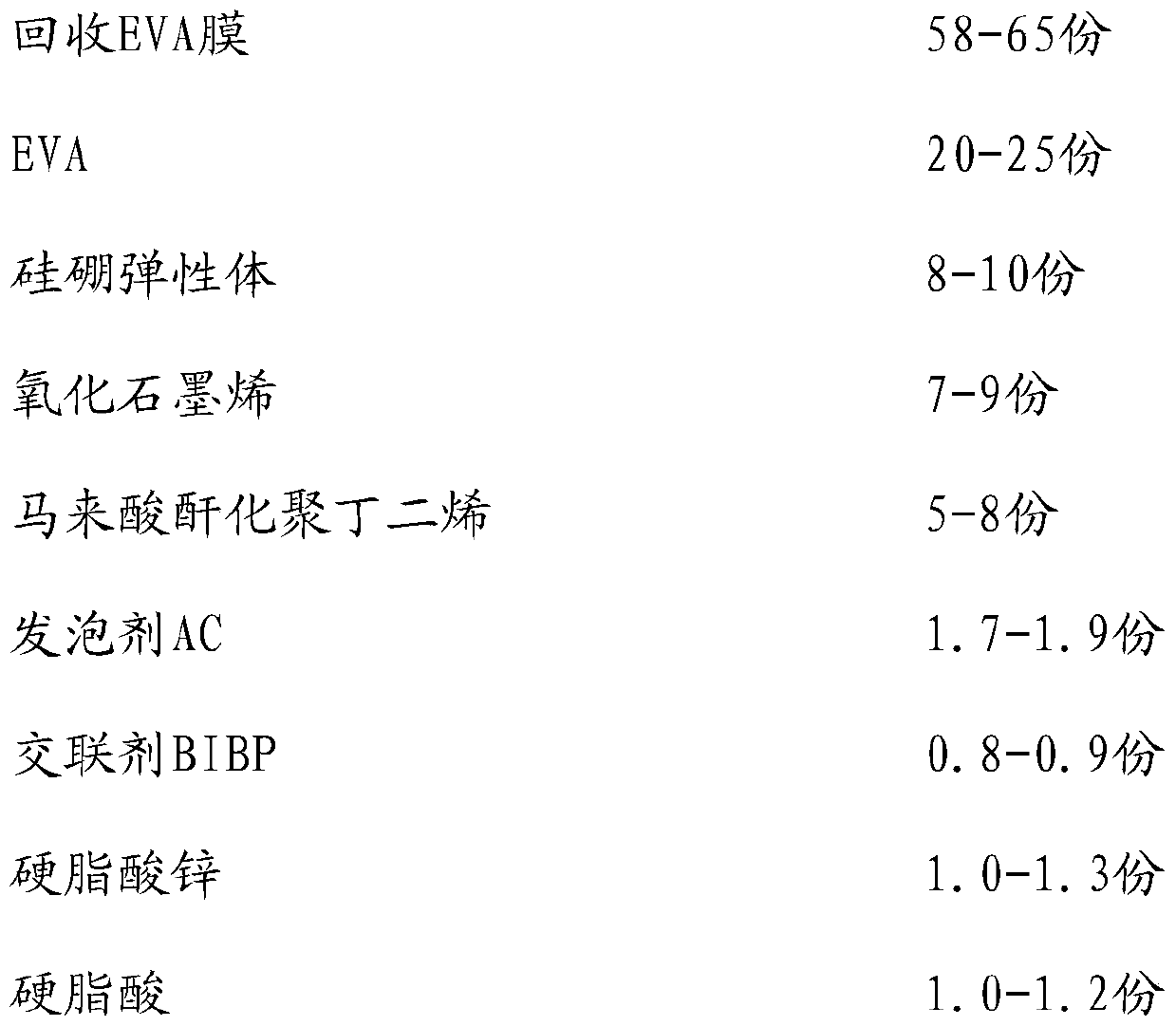

[0037] Step 2: prepare the rice for the sole of the light jogging shoes, the rice for the sole of the light jogging shoes is prepared from the following components in the following parts by weight:

[0038]

[0039] Among them, the preparation method of the silicon-boron elastomer: 140g of hydroxyl silicone oil with a viscosity range of 1500cs and a ...

Embodiment 2

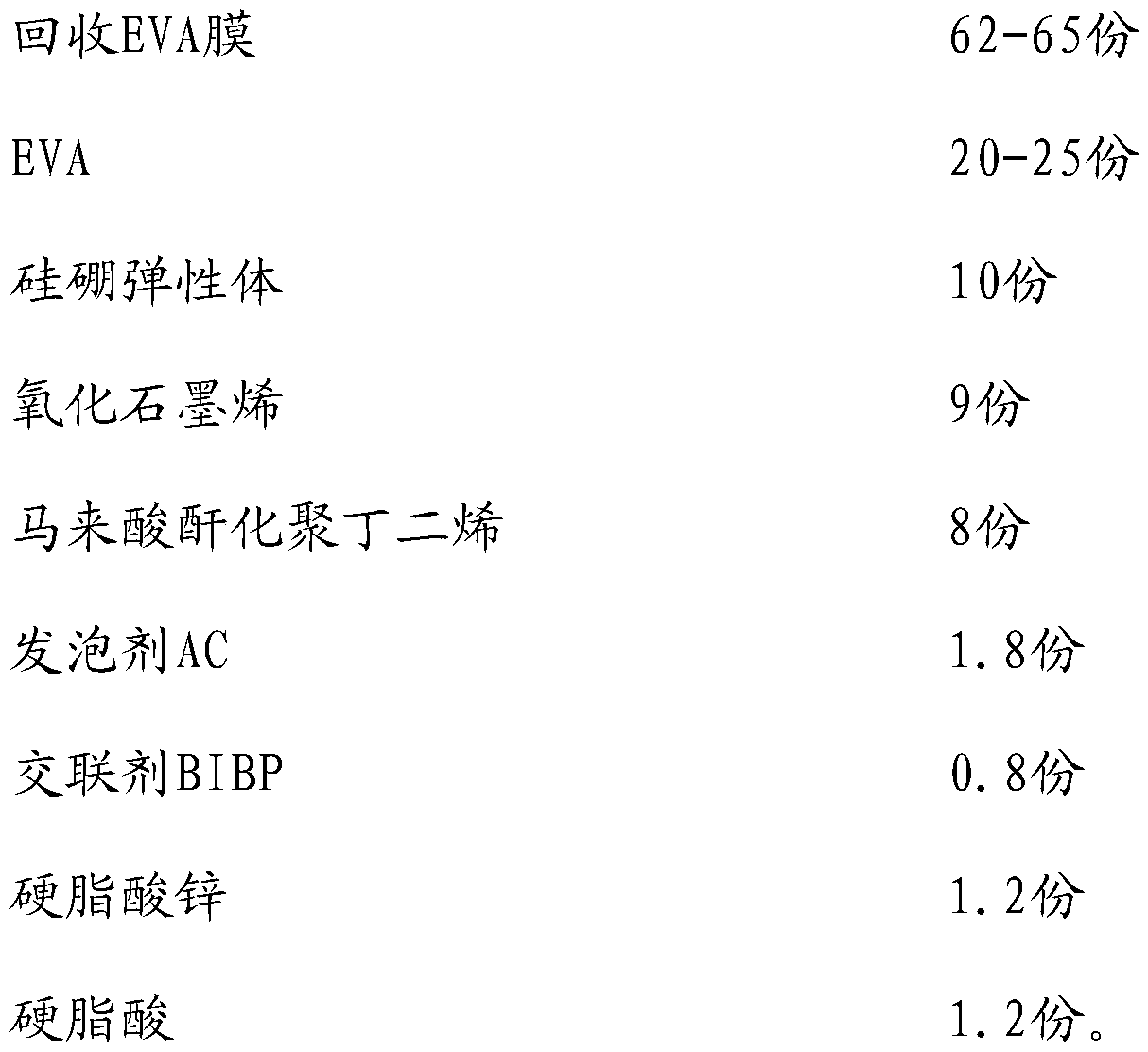

[0044] In the present embodiment, the preparation method of the sole of the light jogging shoes is basically the same as that in Example 1, except that:

[0045] In step 2: the composition of raw materials is different (see Table 1 for details).

[0046]In step 3: mold temperature 180°C, time 140 seconds.

[0047] The light jogging shoe sole that above-mentioned preparation obtains, density 0.22g / cm 3 , hardness 63C, tear strength 7.4N / mm, rebound rate 56%, dimensional shrinkage 1.0%.

Embodiment 3

[0049] In the present embodiment, the preparation method of the sole of the light jogging shoes is basically the same as that in Example 1, except that:

[0050] In step 2: the composition of raw materials is different (see Table 1 for details).

[0051] The light jogging shoe sole prepared above has a density of 0.21g / cm 3 , hardness 61C, tear strength 7.8N / mm, rebound rate 52%, dimensional shrinkage 0.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com