Integrated ClO2 preparation system with relatively independent processes of electrolysis and ClO2 preparation

A chlorine dioxide and preparation system technology, applied in the direction of chlorine dioxide, chlorine oxide, hydrogen chloride preparation, etc., can solve the problems of pure water entering, concentration reduction of weak sodium chlorate solution, affecting the normal operation of the electrolysis system and hydrochloric acid synthesis furnace, etc. , to achieve the effect of improving reaction efficiency and reducing decomposition times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

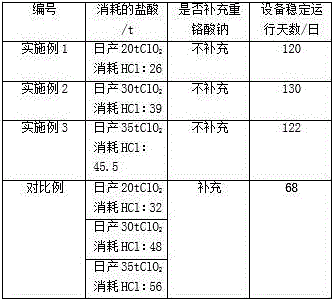

Embodiment 1

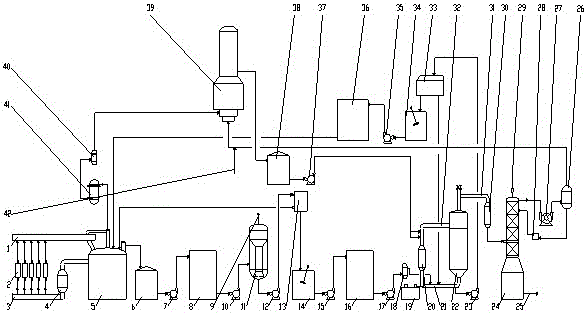

[0040] A comprehensive chlorine dioxide preparation system that is relatively independent of electrolysis and chlorine dioxide preparation, made of NaClO 3 Electrolysis and crystal preparation unit, ClO 2 Generation and HCl synthesis unit composition.

[0041] The operating process of the inventive method is as follows:

[0042] 1) First use refined salt water to electrolyze in the sodium chlorate electrolytic cell (2), the electrolyte enters the degasser (1) along with the gas along the pipeline to realize gas-liquid separation, the gas enters the hydrogen cooler (41), and then passes through the hydrogen Enter the hydrochloric acid synthesis furnace (39) behind the mist eliminator (40), and finally generate concentrated NaClO after the liquid flows into the sodium chlorate reactor (5) for reaction 3 Solution electrolyte, containing a concentration of 550g / L sodium chlorate solution and a concentration of 110g / L sodium chloride solution;

[0043] 2) The obtained electrolyt...

Embodiment 2

[0047] A comprehensive chlorine dioxide preparation system that is relatively independent of electrolysis and chlorine dioxide preparation, made of NaClO 3 Electrolysis and crystal preparation unit, ClO 2 Generation and HCl synthesis unit composition.

[0048] The operating process of the inventive method is as follows:

[0049] 1) First use refined salt water to electrolyze in the sodium chlorate electrolytic cell (2), the electrolyte enters the degasser (1) along with the gas along the pipeline to realize gas-liquid separation, the gas enters the hydrogen cooler (41), and then passes through the hydrogen Enter the hydrochloric acid synthesis furnace (39) behind the demister (40), and finally generate concentrated NaClO after the liquid flows into the sodium chlorate reactor reaction 3 Solution electrolyte, containing a concentration of 600g / L sodium chlorate solution and a concentration of 100g / L sodium chloride solution;

[0050] 2) The obtained electrolyte overflows to ...

Embodiment 3

[0054] A comprehensive chlorine dioxide preparation system that is relatively independent of electrolysis and chlorine dioxide preparation, made of NaClO 3 Electrolysis and crystal preparation unit, ClO 2 Generation and HCl synthesis unit composition.

[0055] The operating process of the inventive method is as follows:

[0056] 1) First use refined salt water to electrolyze in the sodium chlorate electrolytic cell (2), the electrolyte enters the degasser (1) along with the gas along the pipeline to realize gas-liquid separation, the gas enters the hydrogen cooler (41), and then passes through the hydrogen Enter the hydrochloric acid synthesis furnace (39) behind the demister (40), and finally generate concentrated NaClO after the liquid flows into the sodium chlorate reactor reaction 3 Solution electrolyte, containing a concentration of 650g / L sodium chlorate solution and a concentration of 90g / L sodium chloride solution;

[0057] 2) The obtained electrolyte overflows to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com