Preparation method of non-porous or porous polymer microsphere of surface function

A polymer microsphere and surface functional technology, applied in the field of functional polymer materials, can solve problems such as application limitations, and achieve the effects of controllable particle size, uniform particle size distribution, and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

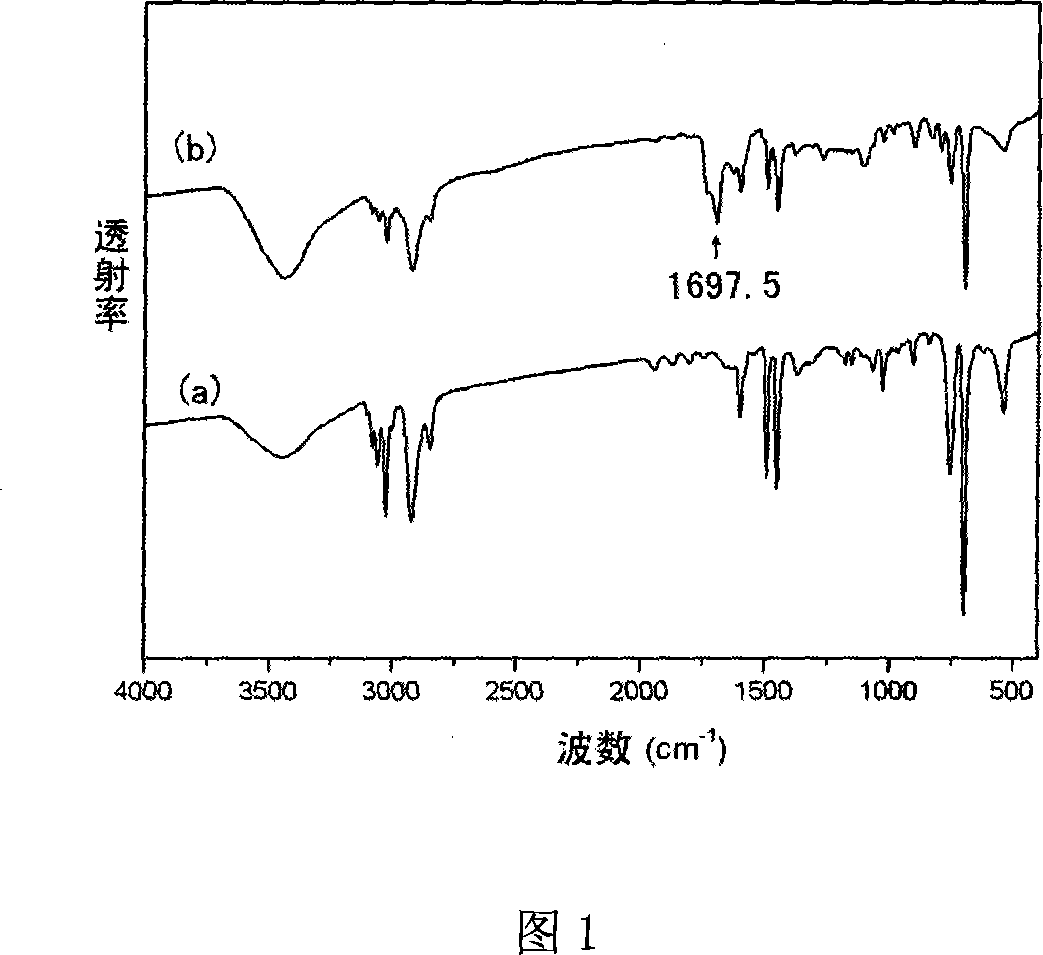

Image

Examples

Embodiment 1

[0029] This embodiment 1 is implemented under the following conditions of implementation and technical requirements:

[0030] (1) After styrene and methacrylic acid are subjected to reduced pressure distillation, the divinylbenzene is washed with a 10% NaOH aqueous solution by mass percentage, and then dried with anhydrous magnesium sulfate;

[0031] (2) Mix 30g of the above-mentioned treated styrene monomer, 0.06g of azobisisobutyronitrile, 2.0g of polyvinylpyrrolidone, 60g of ethanol and 8g of water, stir evenly, pass nitrogen for 15 minutes, and use under nitrogen protection It was heated up to 65°C and reacted at a constant temperature for 24 hours. After the reaction, the reaction solution was centrifuged at high speed to obtain polymer microspheres. The microspheres were washed with absolute ethanol for 3 times and then dried to obtain seed polymer microspheres. The number-average particle diameter Dn of the seed polymer microspheres is 2.1 μm, and the variation coeffici...

Embodiment 2

[0037] This embodiment 2 is implemented under the following conditions of implementation and technical requirements:

[0038] (1) Methyl methacrylate and acrylic acid are distilled under reduced pressure for use, and the ethylene glycol di(methacrylate) ester is first washed with an aqueous NaOH solution with a mass percent concentration of 1%, and then dried with anhydrous magnesium sulfate ,stand-by;

[0039] (2) Mix 15g of the above-mentioned treated methyl methacrylate monomer, 0.15g of azobisisobutyronitrile, 1.55g of polyvinylpyrrolidone, 120g of methanol and 35g of water, stir well, pass nitrogen for 15 minutes, and Under protection, heat up to 80°C, react at a constant temperature for 12 hours, centrifuge the reaction solution at high speed after the reaction to obtain polymer microspheres, wash them with absolute ethanol for 3 times, and then dry them to obtain seed polymer microspheres. The number-average particle diameter Dn of the molecular microspheres is 1.8 μm,...

Embodiment 3

[0045] This embodiment 3 is implemented under the following conditions of implementation and technical requirements:

[0046] (1) After styrene and methacrylic acid are subjected to vacuum distillation treatment, the divinylbenzene is washed with an aqueous NaOH solution with a mass percent concentration of 20%, and then dried with anhydrous magnesium sulfate, and then used;

[0047] (2) Mix 10 g of the above-mentioned treated styrene monomer, 0.5 g of azobisisobutyronitrile, 2.0 g of polyvinylpyrrolidone, 30 g of ethanol and 70 g of ethylene glycol methyl ether, stir well, and pass nitrogen for 5 minutes. Under the protection of nitrogen, the temperature was raised to 65°C, and the reaction was carried out at a constant temperature for 48 hours. After the reaction, the reaction solution was centrifuged at high speed, and the obtained polymer microspheres were washed with absolute ethanol for 3 times and dried to obtain seed polymer microspheres. The number-average particle di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com