Fully automatic bean milk machine and bean milk making method

A soybean milk machine, fully automatic technology, applied in the field of kitchen utensils, can solve the problems of low concentration, uncontrollable pulping volume, bad taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

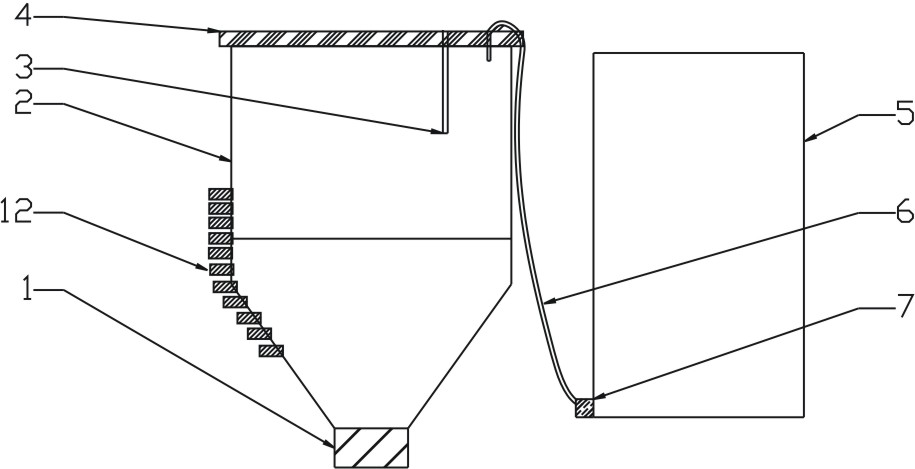

[0031] as attached figure 1 As shown, the installation of the device for detecting the input amount of materials on the soymilk machine is to install the infrared position measuring device on the hopper 2 to detect the information of the device for detecting the amount of materials to detect the amount of materials. The specific implementation method can be to install an infrared emitting and receiving array 12 on the side wall of the hopper to measure the amount of beans. When the beans are put into the hopper 2, the beans will block a part of the infrared rays of the infrared emitting and receiving array 12, thereby Affect the reflection or transmission of infrared rays, so that the size of the material volume can be judged, and the bean material put into the hopper 2 can be calculated.

Embodiment 2

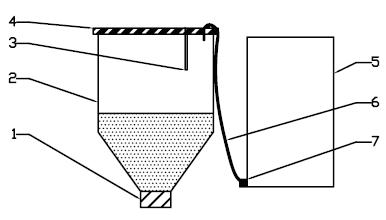

[0033] as attached figure 2 As shown, the device for detecting the input amount of materials is installed on the soybean milk machine to indirectly detect the amount of materials by measuring the relationship information between the water supply flow rate of the water pump 7 and the water supply time. The specific implementation method is that there is a water level electrode 3 above the hopper 2. When the beans are put into the hopper 2, since the volume of the hopper 2 is given, water is supplied through the water pump 7 until the water level reaches the water level electrode 3, and the water pump 7 is turned off. Calculate the time for the upper water to pass through the water pump 7 to convert the water injection amount, so as to calculate the amount of bean material put into the hopper 2 .

Embodiment 3

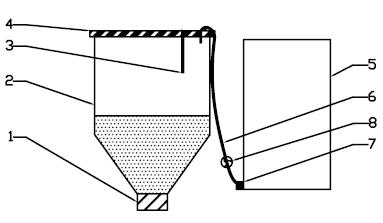

[0035] as attached image 3 As shown, the device for detecting the input amount of materials is installed on the soymilk machine to indirectly detect the amount of materials by setting the information of the flow meter 8 on the upper water pipe 6 . The specific implementation method can be to install a flowmeter 8 on the upper water pipe, reach the water level electrode 3, and close the flowmeter 8; since the volume of the hopper 2 has been given, the amount of soybeans in the hopper 2 is converted according to the water injection volume information measured by the flowmeter 8 information.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com