Inverse Y-shaped ventilation method for coal mining working face

A technology of coal mining face and ventilation method, which is applied to the ventilation of mines/tunnels, mining equipment, and earth-moving drilling, etc., can solve the problem of large roadway expansion and brushing repair works, long service time of mining roadway, and difficulty of gob-side road protection. It can reduce maintenance difficulty and support cost, achieve significant social and economic benefits, and solve the effect of gas accumulation in corners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

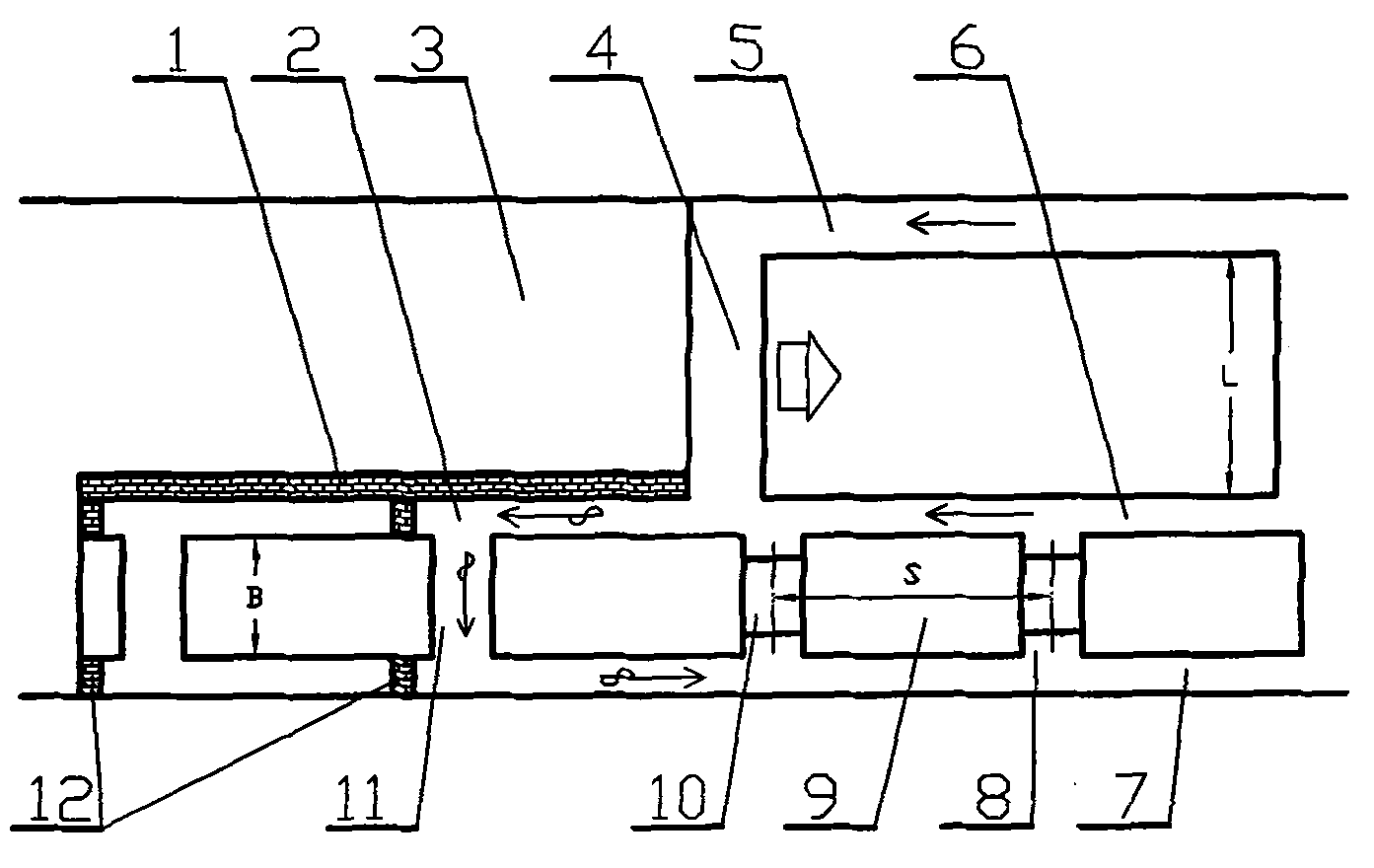

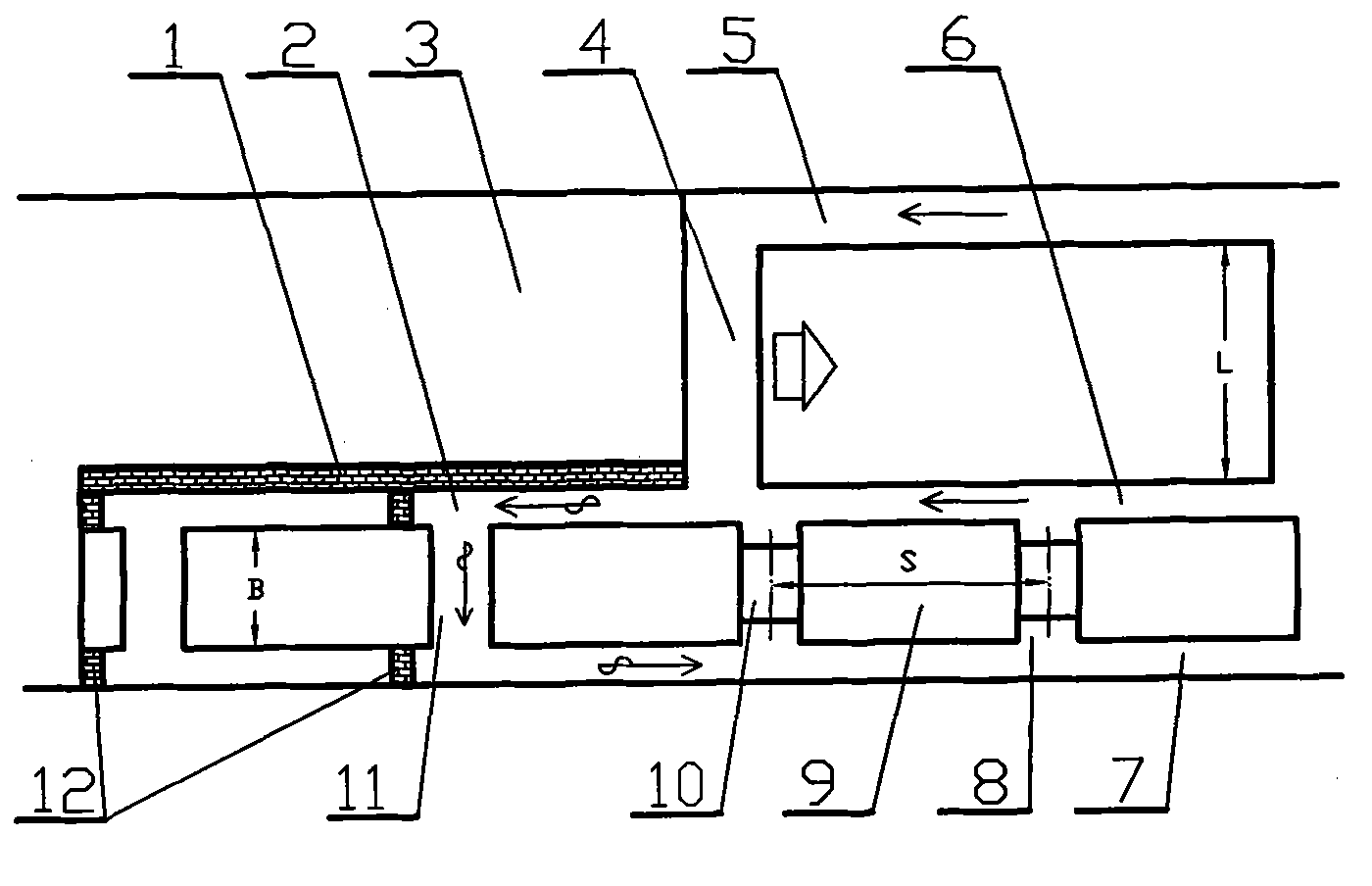

[0015] in the attached figure 1 In the reverse Y-shaped ventilation method of the coal mining face, it designs a roadway that can realize reverse Y-shaped ventilation, including gobside retention lane 2, transportation lane 5, track lane 6, return air lane 7, and connection lane 8 and return air connection lane 11; a transport lane 5 is provided on one side of the coal mining face 4; the other side of the coal mining face 4 is arranged with parallel track lanes 6 and return air lanes 7 in sequence; the track lane 6 It is also used as the air inlet roadway together with the transportation lane 5; there is a coal pillar 9 between the track lane 6 and the return air lane 7, and a connecting lane 8 is opened at a certain distance to connect the track lane 6 and the return air lane 7; the connecting lane 8 A sealed partition wall 10 is built in the middle to prevent air leakage; before the working face is recovered, the connection lane 8 near the coal mining face 4 is opened to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com