Carbon fiber sizing method

A carbon fiber and sizing agent technology, applied in the field of fiber manufacturing, can solve the problems of easy adhesion and curing of resin components, and the reduction of carbon fiber sizing amount, etc., to reduce the adhesion and curing phenomenon of sizing agent, control the concentration easily, and improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

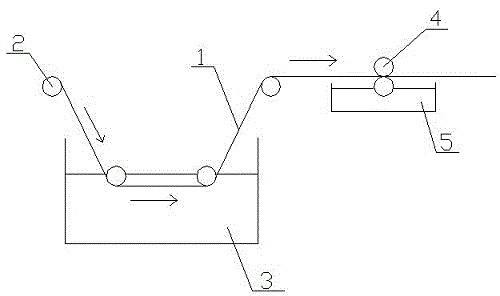

[0032] 40 bundles of unsized carbon fibers (the number of filaments per bundle is 12,000) are evenly arranged and run on the roller surface with an interval of 10mm. fiber bundles through figure 1 The sizing tank of the sizing system shown performs sizing. The sizing agent in the sizing tank is a sizing agent emulsion, and its main active ingredients are liquid-phase epoxy resin and solid-phase epoxy resin, and the concentration of the active ingredients is 4.5%.

[0033] The steps of the sizing method are as follows:

[0034] Step 1: Dip the carbon fiber into the sizing tank through the guide roller for sizing;

[0035] Step 2: Conducting the sized carbon fiber through the guide roller to the pressure roller partially immersed in the sizing agent for extrusion;

[0036] Step 3: Conveying the extruded carbon fiber to the next process.

[0037] In the second step, a liquid return tank is arranged under the pressure roller, and the lower half of the pressure roller is immers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com