Graphene oxide solution for wet spinning and preparation method thereof, graphene fiber and preparation method of graphene fiber

A graphene solution and graphene fiber technology, applied in spinning solution preparation, wet spinning method, inorganic raw material rayon, etc., can solve the problem that the steps of wet spinning graphene oxide solution are cumbersome and difficult to realize large-scale production and technology. Complexity and other problems, to achieve the effect of controllable concentration, easy size adjustment and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a kind of preparation method of graphene oxide solution for wet spinning, comprising the following steps:

[0039] The graphene oxide solution is centrifugally concentrated to obtain a graphene oxide solution for wet spinning.

[0040] The present invention uses the graphene oxide solution as a raw material, and the graphene oxide solution for wet spinning can be obtained through centrifugal concentration.

[0041] In the present invention, the graphene oxide solution is preferably prepared by a modified Hummers method. The modified Hummers method is

[0042] A) dissolving graphite and nitrate in concentrated sulfuric acid and mixing and stirring, adding potassium permanganate, stirring and standing to obtain an intermediate reaction solution;

[0043] B) adding deionized water and hydrogen peroxide to the intermediate reaction liquid for reaction, followed by centrifugal washing to obtain a graphene oxide solution.

[0044] In the present inve...

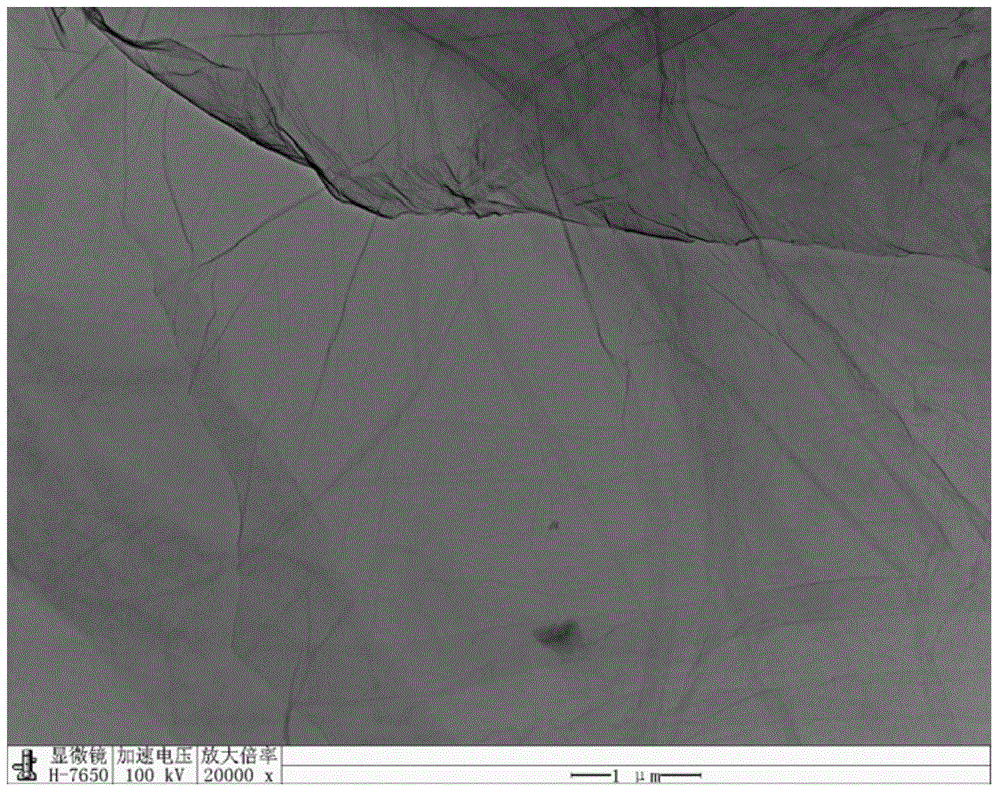

Embodiment 1

[0064] Dissolve 5g of graphite and 3.75g of sodium nitrate in 160ml of 98% sulfuric acid solution, mechanically stir at 200 rpm for 30min, slowly add 20g of potassium permanganate gradually, the addition time is about 40min, continue to stir for 20h, stand still for 7 days, slowly add 300ml Deionized water and 20ml hydrogen peroxide (added while stirring), repeated centrifugation and water washing (10000 rpm, 10min) until a brown layer of graphene oxide appeared (this process kept the total volume of the solution constant), poured off the supernatant and collected In the middle brown graphene oxide layer (without bright crystal particles), the bottom layer was precipitated and combined and continued to be centrifuged and washed 3 times to obtain an undialyzed graphene oxide solution, which was further centrifuged and concentrated (14000 rpm, 30min, poured out The supernatant and the low-viscosity upper layer of small pieces of graphene oxide solution are taken out of the lower ...

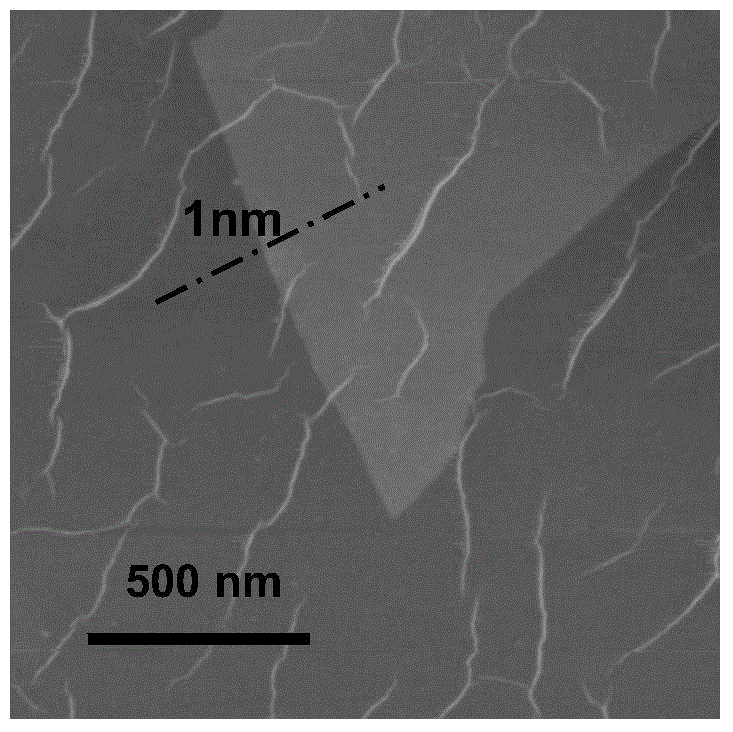

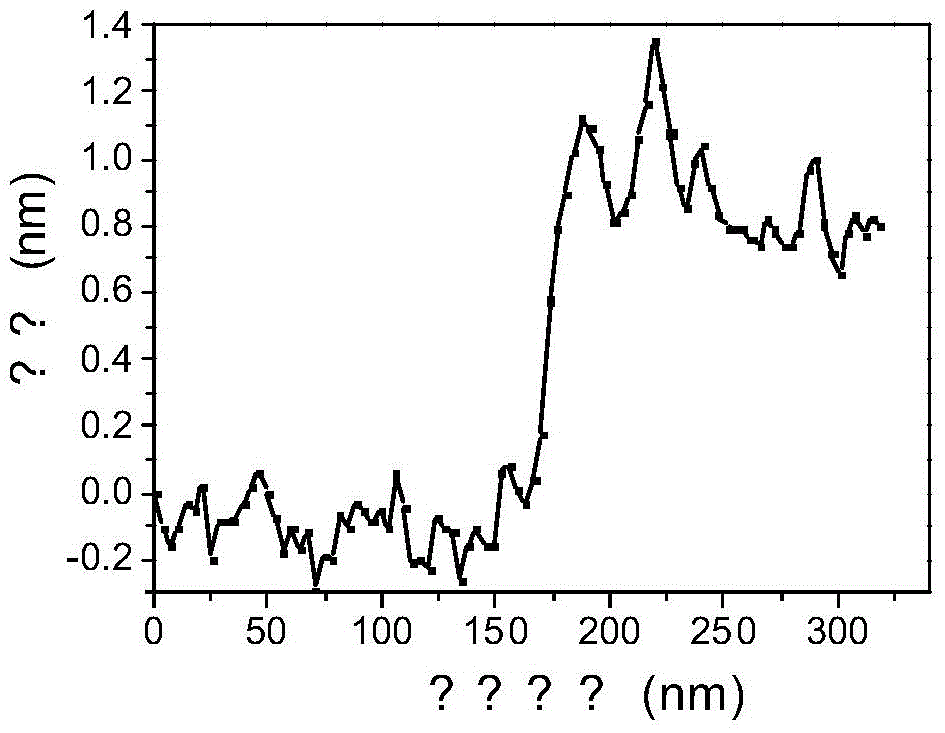

Embodiment 2

[0068] Dissolve 5g of graphite and 4g of potassium nitrate in 180ml of 98% sulfuric acid solution, mechanically stir at 200rpm for 25min, slowly add 20g of potassium permanganate gradually for about 40min, continue stirring for 20h, stand still for 5 days, slowly add 400ml to Ionized water and 30ml hydrogen peroxide (adding while stirring), repeated centrifugation and water washing (8000 rpm, 10min) until a brown layer of graphene oxide appeared (this process kept the total volume of the solution unchanged), poured off the supernatant and pipetted to collect the middle Brown graphene oxide layer (no bright crystal-colored particles), the bottom layer was precipitated and combined and continued to be centrifuged and washed 3 times, and then a non-dialyzed graphene oxide solution was initially obtained, which was further concentrated by centrifugation (14000 rpm, 30min, and poured out) Clear liquid and low-viscosity upper layer of graphene oxide solution, take out the lower layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com