Device for recycling nitric acid from waste liquor containing copper nitrate and use method of device

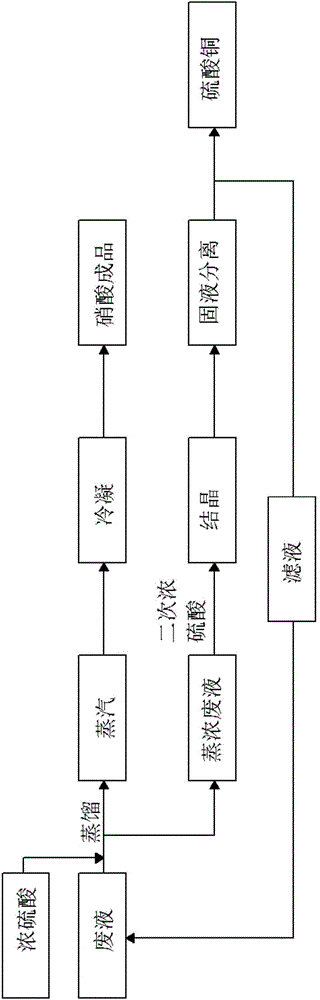

A technology of copper nitrate and pickling waste liquid, which is applied in the direction of nitric acid, copper sulfate, chemical instruments and methods, etc., can solve the problems of large space occupation, cumbersome operation steps, difficult control of evaporation process conditions and optimal crystallization conditions, etc. Achieve the effects of saving equipment space, simplifying operation steps, and controlling concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

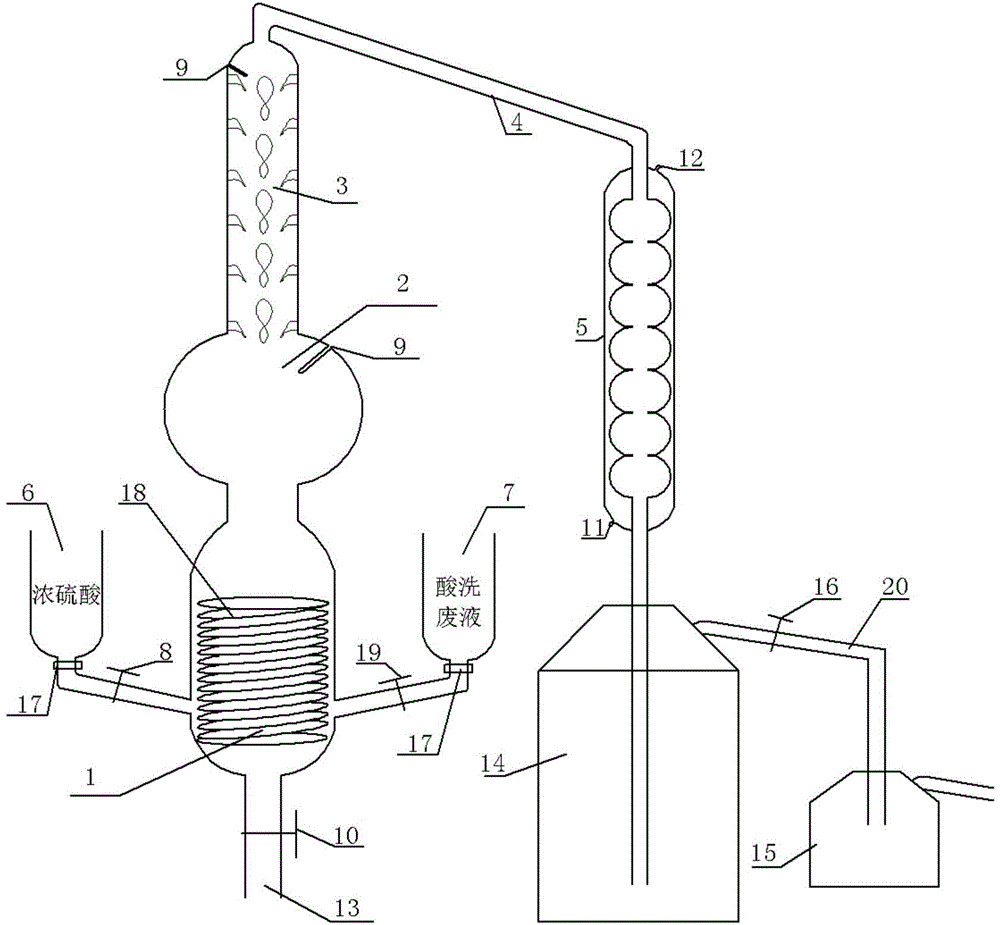

[0027] A kind of device that reclaims nitric acid from copper nitrate waste liquid, see figure 2 : It includes concentrated sulfuric acid storage tank 6, pickling waste liquid storage tank 7, the bottom outlets of concentrated sulfuric acid storage tank 6 and pickling waste liquid storage tank 7 are respectively provided with quantitative pump 17, and connected to the inner cavity of heating unit 1 On both sides, a heating wire 18 is arranged in the inner cavity of the heating unit 1, a crystallization product outlet pipe 13 is arranged at the bottom of the heating unit 1, and a retort 2, a rectification unit 3, and a retort are arranged in sequence at the upper outlet of the heating unit 1. The upper outlet of 2 is connected with the lower inlet of rectification unit 3, and the upper outlet of rectification unit 3 is externally connected to the upper inner cavity inlet of condensing unit 5, and the lower conduit of the inner cavity of condensing unit 5 is connected to the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com