Gallium oxide crystals with thermoluminescence performance and preparation method thereof

A gallium oxide and thermoluminescence technology, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems affecting the consistency of detectors, difficulty in controlling the amount of carbon doping, and uneven distribution of carbon, etc., to achieve Reduce the probability of cleavage cracking, stabilize the thermoluminescent performance, and inhibit the effect of decomposition and volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

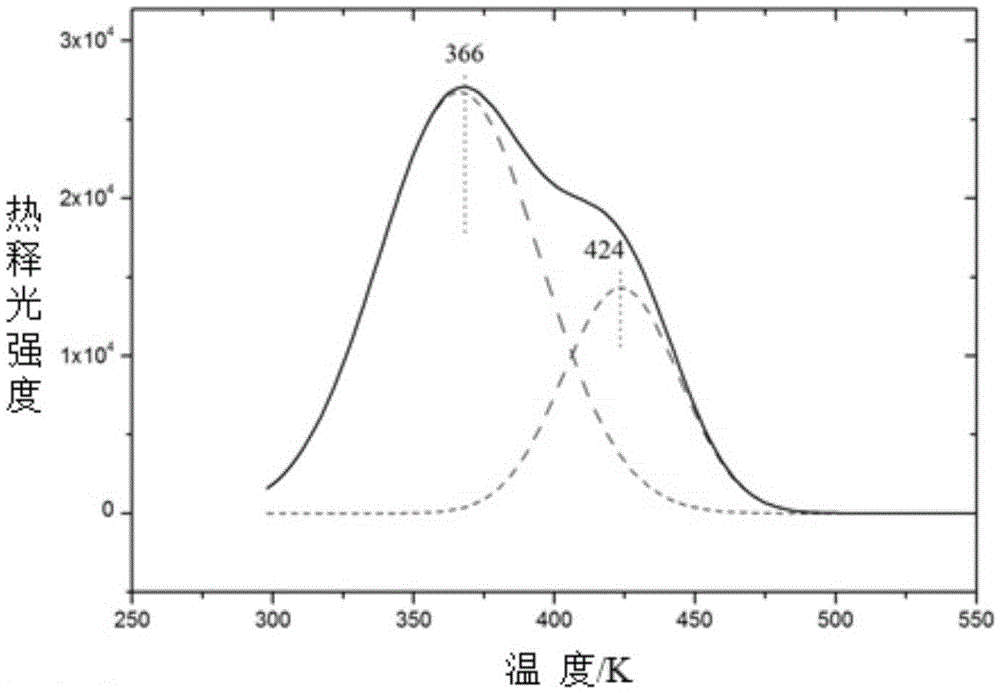

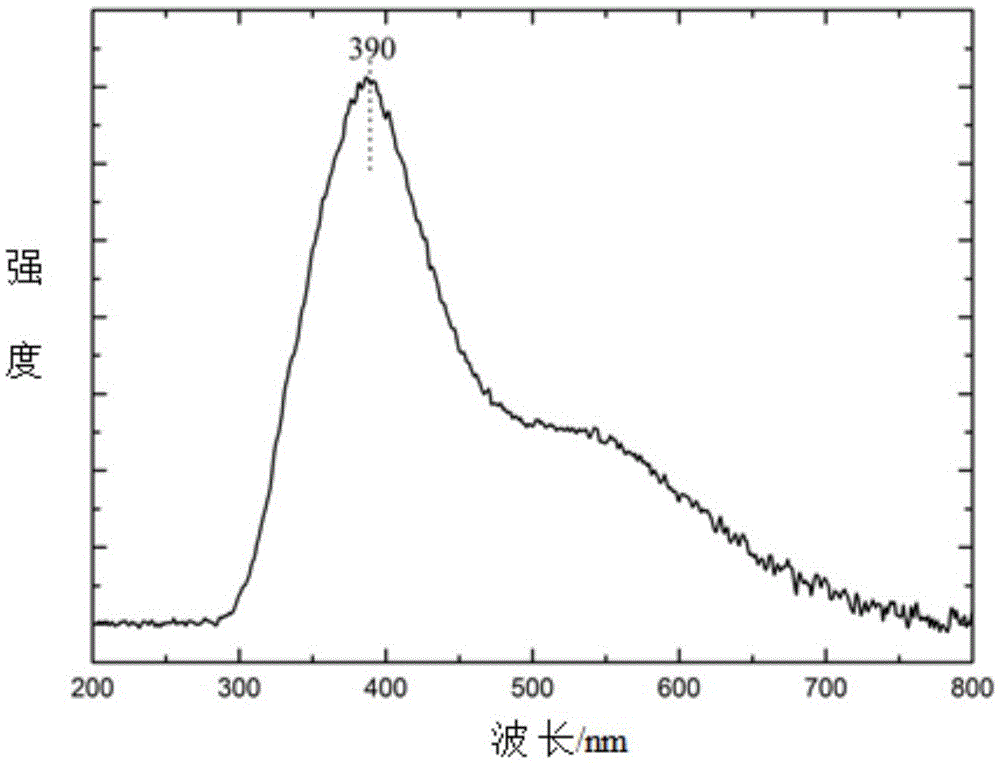

Embodiment 1

[0033] With high purity β-Ga2O 3 (99.999%) powder and doping amount 0.2mol% high purity GeO 2 (99.99%) powder is used as raw material, all raw materials are mixed and ground on a planetary ball mill at 95r / min for 24 hours, taken out, isostatically pressed, and sintered at 1450°C for 15 hours in an air atmosphere to make polycrystalline ceramic raw materials. Put the polycrystalline ceramic raw material into the iridium gold crucible of the guided mode method, β-Ga2O 3 The single crystal is placed in the iridium seed crystal fixture, and the crystal growth direction is parallel to the (100) cleavage plane. After evacuating to 5Pa in the furnace, fill with Ar gas, continue to heat up to 1400°C, keep the temperature constant for 0.5h, and then fill with CO 2 Gas, continue to heat up to 1850 ° C until the raw materials are completely melted and rise to the top of the mold along the mold slit, keep the temperature for 1 hour, and ensure the final gas ratio Ar:CO in the furnace ...

Embodiment 2

[0035] With high purity β-Ga 2 o 3 (99.999%) powder and doping amount 2mol% high purity GeO 2 (99.99%) powder is used as raw material, all raw materials are mixed and ground on a planetary ball mill at 95r / min for 24 hours, taken out, isostatically pressed, and sintered at 1450°C for 15 hours in an air atmosphere to make polycrystalline ceramic raw materials. Put the polycrystalline ceramic raw material into the iridium gold crucible of the guided mode method, β-Ga2O 3 The single crystal is placed in the iridium seed crystal fixture, and the crystal growth direction is parallel to the (100) cleavage plane. After evacuating to 5Pa in the furnace, fill it with Ar gas, continue to heat up to 1400°C, keep the temperature constant for 0.5h, and then fill it with CO 2 Gas, continue to heat up to 1850 ° C until the raw materials are completely melted and rise to the top of the mold along the mold slit, keep the temperature for 1 hour, and ensure the final gas ratio Ar:CO in the fu...

Embodiment 3

[0037] With high purity β-Ga 2 o 3 (99.999%) powder and doping amount 5mol% high purity GeO 2 (99.99%) powder is used as raw material, all raw materials are mixed and ground on a planetary ball mill at 95r / min for 24 hours, taken out, isostatically pressed, and sintered at 1450°C for 15 hours in an air atmosphere to make polycrystalline ceramic raw materials. Put the polycrystalline ceramic raw material into the iridium gold crucible of the guided mode method, β-Ga 2 o 3 The single crystal is placed in the iridium seed crystal fixture, and the crystal growth direction is parallel to the (100) cleavage plane. After evacuating to 5Pa in the furnace, fill it with Ar gas, continue to heat up to 1400°C, keep the temperature constant for 0.5h, and then fill it with CO 2 Gas, continue to heat up to 1850 ° C until the raw materials are completely melted and rise to the top of the mold along the mold slit, keep the temperature for 1 hour, and ensure the final gas ratio Ar:CO in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com