Compound annular electrode electrostatic spinning device

A ring-shaped electrode, electrospinning technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc. Effective protection of the solution, etc., to reduce high-voltage damage to the instrument or cause harm to the human body, avoid direct contact, and have a reliable principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

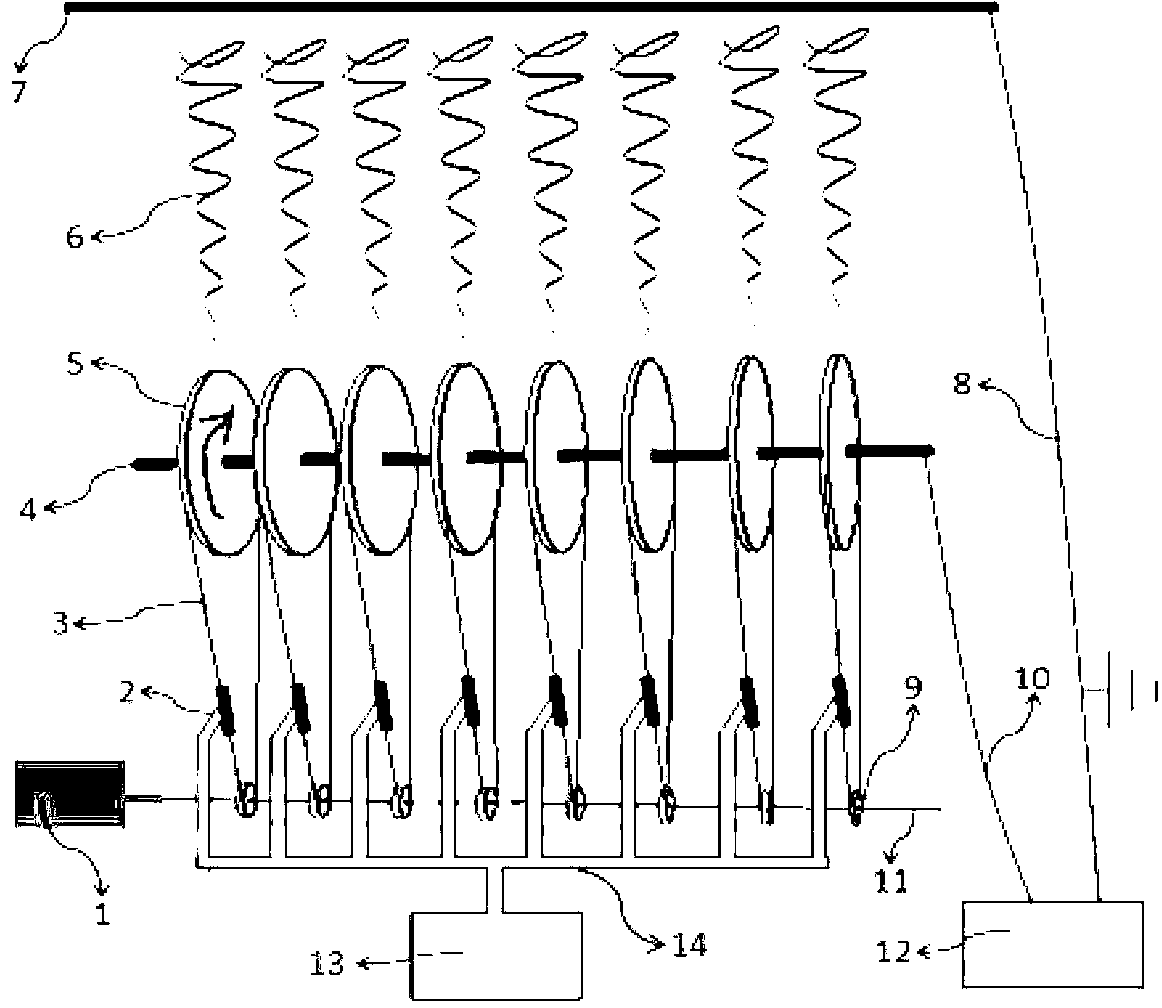

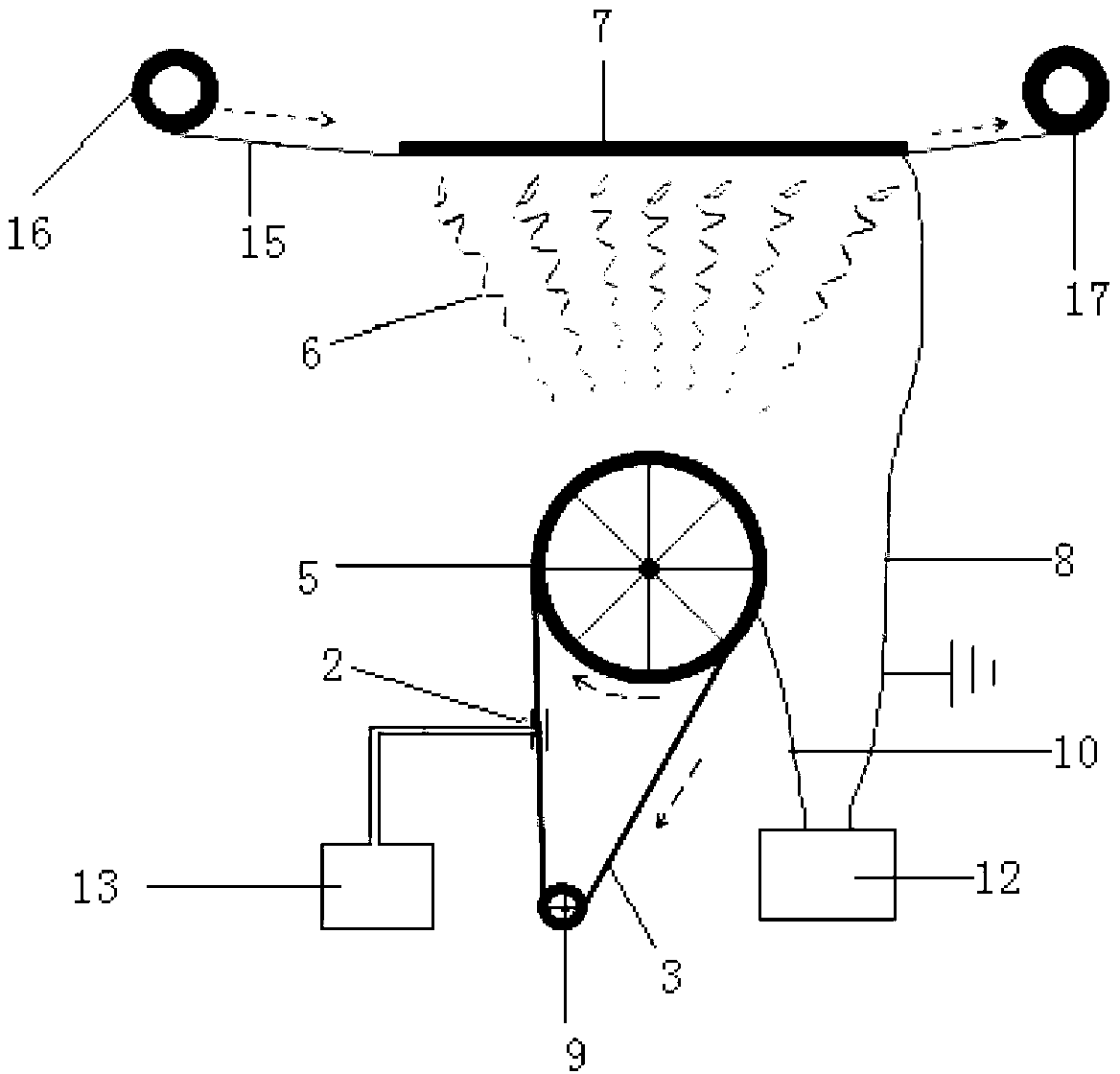

[0011] The main structure of this embodiment includes a motor 1, a liquid brush 2, an insulating tape 3, a metal shaft 4, a metal ring electrode 5, micro-nano fibers 6, a metal collector 7, a high-voltage power supply negative pole 8, an insulating pulley 9, and a high-voltage power supply positive pole 10 , insulating shaft 11, high voltage power supply 12, liquid supply system 13, shunt pipe 14, collecting substrate 15, feeding drum 16 and discharging drum 17; round hanging metal shaft 4 is fixedly installed with 4-8 groups of concentric metal The ring electrode 5 and one end of the metal shaft 4 are electrically connected to the high voltage power supply 12 through the positive pole 10 of the high voltage power supply; 4-8 sets of concentric insulating pulleys 9 are fixedly installed on the insulating shaft 11, and the output shaft of the motor 1 is linked with the insulating shaft 11 and drives All the insulated pulleys 9 rotate, and the insulated pulleys 9 rotate through t...

Embodiment 2

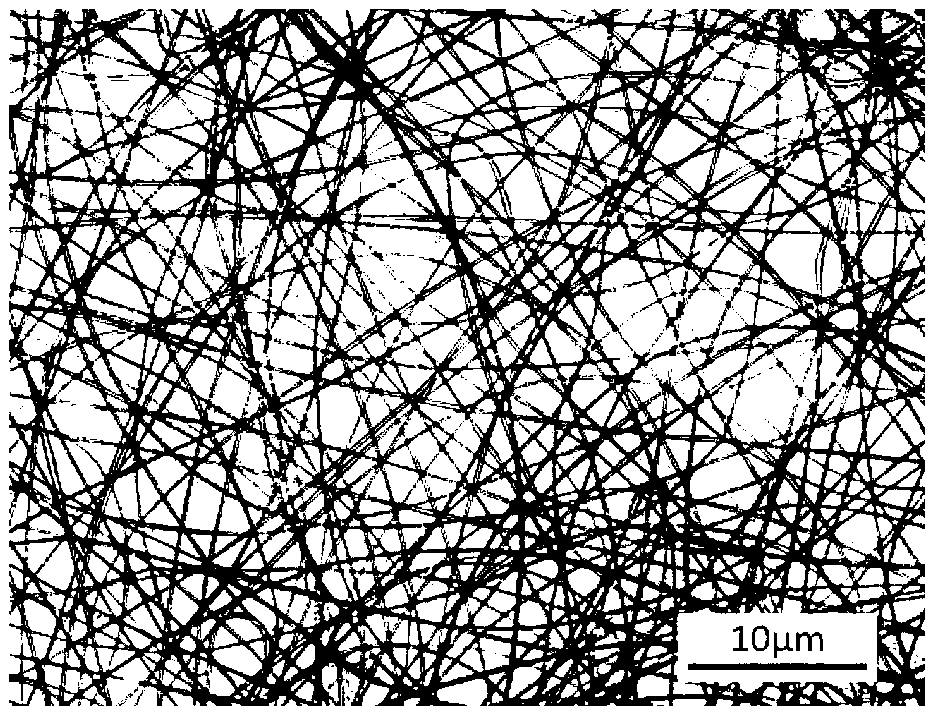

[0013] The present embodiment takes the polyvinylpyrrolidone PVP solution as an example to describe in detail, setting the ambient temperature to be 24.5°C, and the relative humidity of the environment is 43%RH, and selecting the polyvinylpyrrolidone PVP solution with a mass percentage of 13% as the spinning solution; 13 grams of polyvinylpyrrolidone (PVP, its molecular weight is 1.3 million) particles are slowly added to 87 grams of absolute ethanol under magnetic stirring, magnetic stirring at room temperature for 4-5 hours and then standing for 0.5-1 hour to obtain a uniform The transparent mass percentage is the PVP electrospinning precursor solution of 13%; Then put the prepared PVP solution into the liquid supply system 13, turn on the motor 1 that controls the rotation of the insulating pulley 9, and make the insulating pulley 9 start to rotate and pass through the insulating pulley. Driven by the belt 3, the metal ring electrode 5 is rotated; then the high-voltage power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com