Device and method for preparing gel microspheres with uniform grain sizes

A technology for gel microspheres and preparation devices, which is applied in the preparation of microspheres and microcapsule preparations. It can solve the problems of adverse effects on the activity of embedding objects, difficulty in meeting actual needs, and high cost of preparation processes, and reduce the application of external forces. Equipment requirements, good permeability, and the effect of stable preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

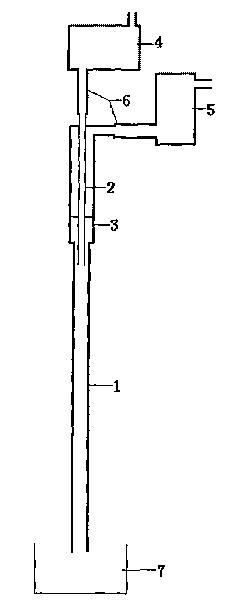

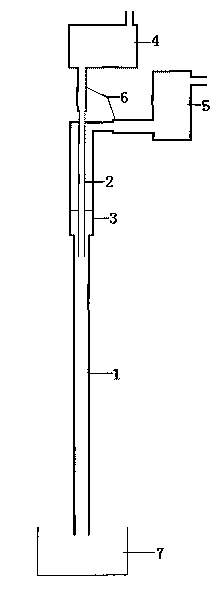

[0017] The specific preparation method of the microspheres includes the following steps: connect the container containing the oil phase to the inlet port of the constant flow pump 5 and set the flow rate of the constant flow pump, the oil phase passes through the hose 6 into the support tube 3 and flows into the capillary glass In the tube 1; the dispersed phase is loaded into the syringe of the micro-injection pump 4 and the flow rate of the micro-injection pump 4 is set, and the dispersed phase is passed through the flexible pipe 6 into the stainless steel needle 2 and flows into the capillary glass tube 1; the two-phase liquid flow is in the After the capillary glass tubes meet, the dispersed phase is pulled into a thin stream by the oil phase, and the end of the thin stream breaks periodically to form droplets with uniform particle size, and the oil containing the dispersed phase droplets is collected at the end of the capillary glass tube 1 with a glass container 7 phase, ...

Embodiment 1

[0023] Microsphere preparation device among the present invention: select the capillary glass tube of length 30cm (inner diameter 940 micron, outer diameter 1250 micron) and the needle head of 8cm (inner diameter 270 micron, outer diameter 600 micron).

[0024] The outlet ends of the micro injection pump 4 and the constant flow pump 5 are respectively connected to the stainless steel needle 2 and the bracket tube 3 through flexible tubes, and the bracket in the bracket tube 3 inserts the stainless steel needle 2 and fixes it on the central axis of the capillary glass tube 1 , and make the support tube 3 communicate with the capillary glass tube 1, and the oil phase containing the dispersed phase droplets with uniform particle size flowing out from the end of the capillary glass tube 1 is collected by the glass container 7.

Embodiment 2

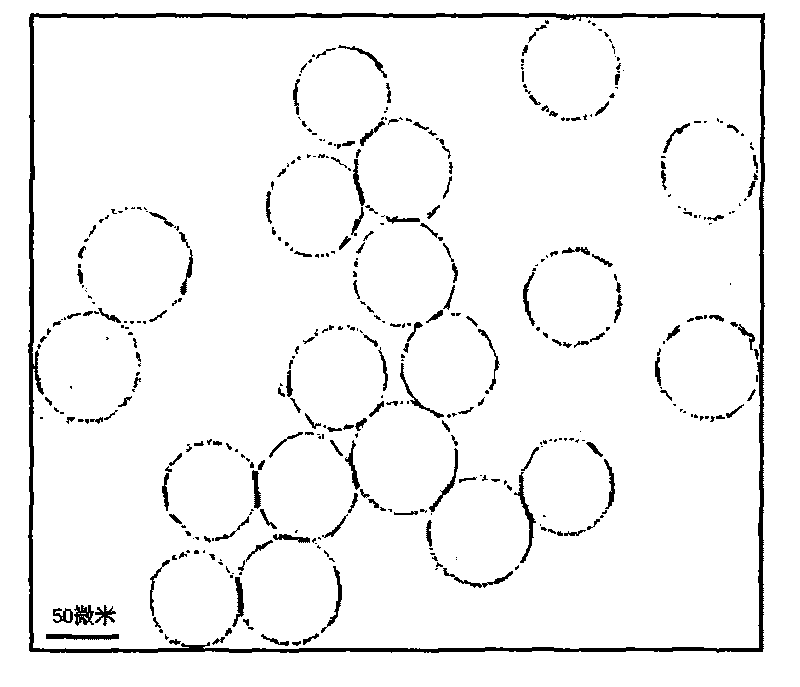

[0026] Using the natural polysaccharide sodium alginate as the material of the dispersed phase and paraffin oil as the oil phase, the preparation process of the microspheres is described in detail by using the device prepared in Example 1.

[0027] Sodium alginate with a viscosity of 125cps was used to prepare a sodium alginate aqueous solution with a concentration of 4% as the dispersed phase; paraffin oil was used as the oil phase, and Span 80 with a concentration of 1% was added to the paraffin oil as an emulsifier.

[0028]Connect the container containing 1% Span 80 paraffin oil to the inlet of the constant flow pump 5, set the flow rate of the constant flow pump to 70rpm, pass the oil phase through the hose 6 into the support pipe 3 and flow into the capillary glass Tube 1: Put the sodium alginate solution as the dispersed phase into the syringe of the micro-injection pump 4, set the flow rate of the micro-injection pump 4 to 0.3ml / h, pass the dispersed phase into the stai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com