Patents

Literature

98results about How to "Good particle size uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

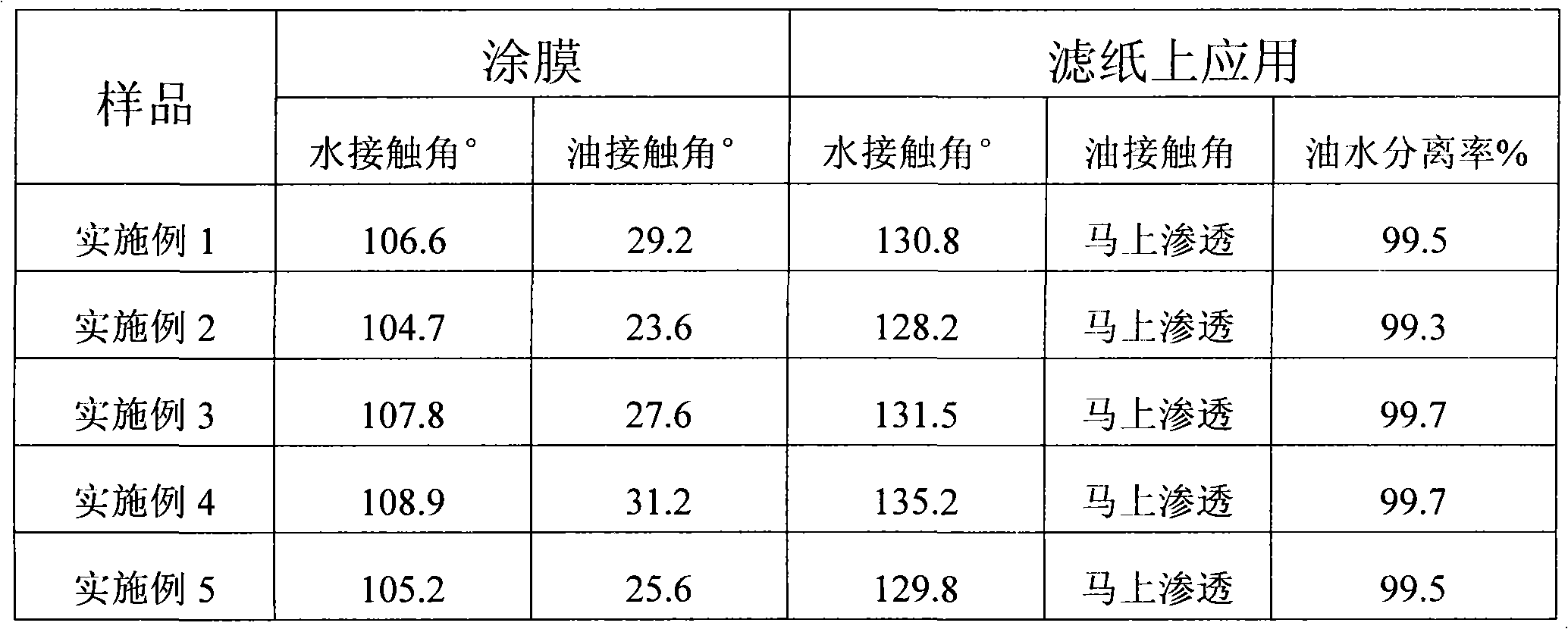

Styrene-acrylate emulsion with hydrophobic oleophylic fluorine-silicon-modified nuclear shell structure and preparation method thereof

InactiveCN102060952AGood hydrophobic and lipophilic effectGood particle size uniformityLiquid separationSurface energyEmulsion

The invention discloses a preparation method of styrene-acrylate emulsion with hydrophobic oleophylic fluorine-silicon-modified nuclear shell structure. The preparation method comprises the following step of: preparing fluorine-silicon-modified styrene-acrylate emulsion which has a nuclear shell structure and takes a styrene-acrylate polymer as a nucleus and a fluorine-silicon-modified styrene-acrylate polymer as a shell from a monomer, a cross-linking agent, an emulsifier, an initiator, a pH regulator and water by a room temperature pre-emulsification and seed emulsion polymerization process. The styrene-acrylate emulsion with the nuclear shell structure comprises a nucleus layer and a shell layer, wherein the nucleus layer is a copolymer of polymerizable monomers which does not contain fluorine and silicon; the shell layer is a copolymer of polymerizable monomers which contains a fluorine-silicon monomer; and the mass ratio of the nucleus to the shell is 1:4 to 4:1. The fluorine-silicon monomer is positioned in the shell layer, so that high performance of the fluorine-silicon polymer is kept, the using amount of the fluorine-silicon monomer is reduced and cost is saved; and a crosslinkable monomer is introduced and a film is formed by the reaction and crosslinking of radicals in an emulsion film forming process, so that the water resistance of the film is enhanced, and hydrophobic and oleophylic effects are enhanced; simultaneously, the phenomenon of possible migration of the fluorine-silicon monomer with low surface energy into latex particles is avoided.

Owner:SOUTH CHINA UNIV OF TECH

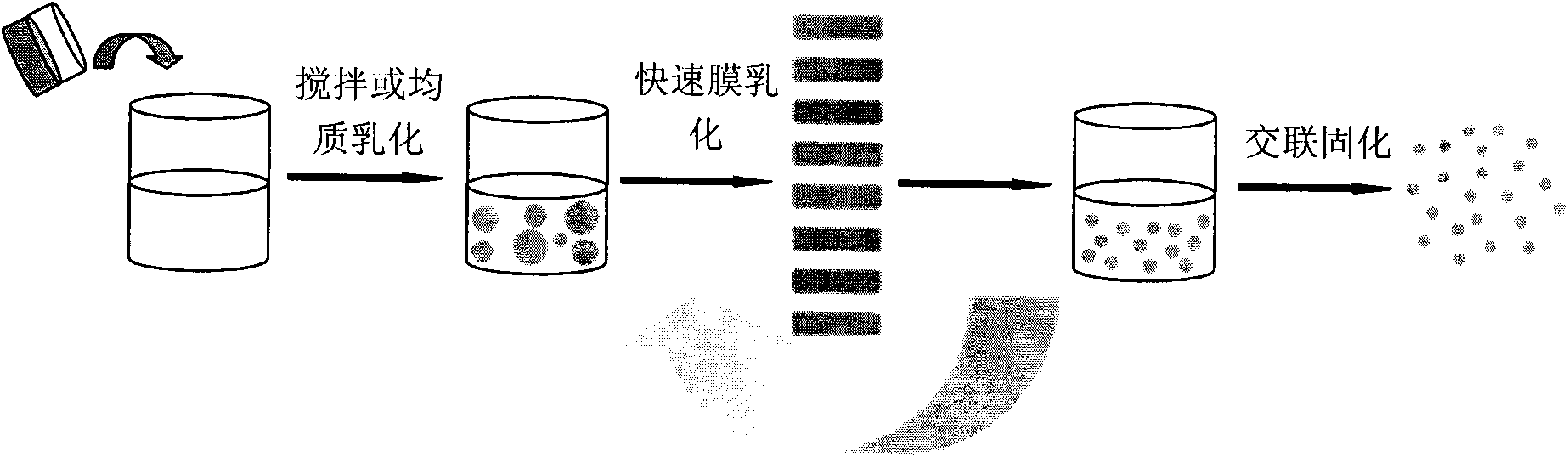

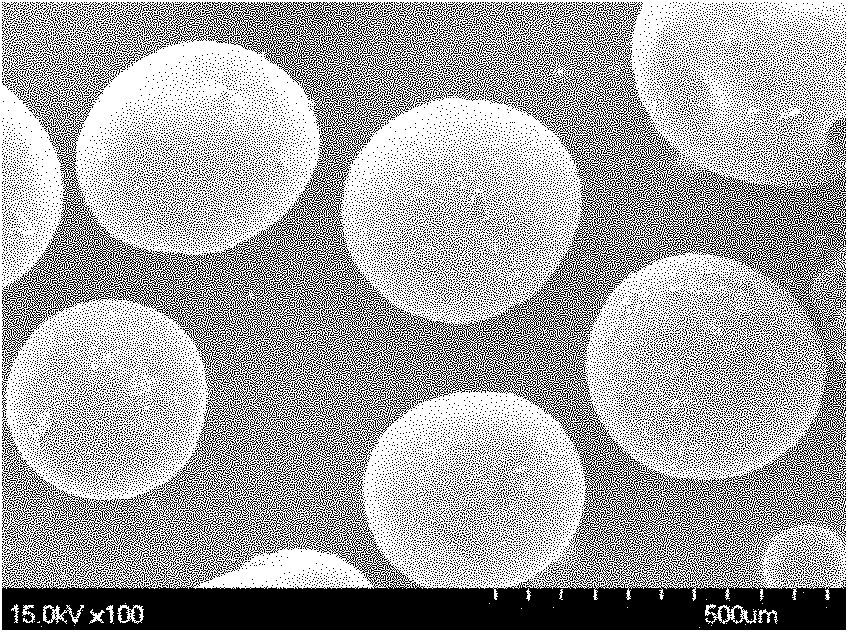

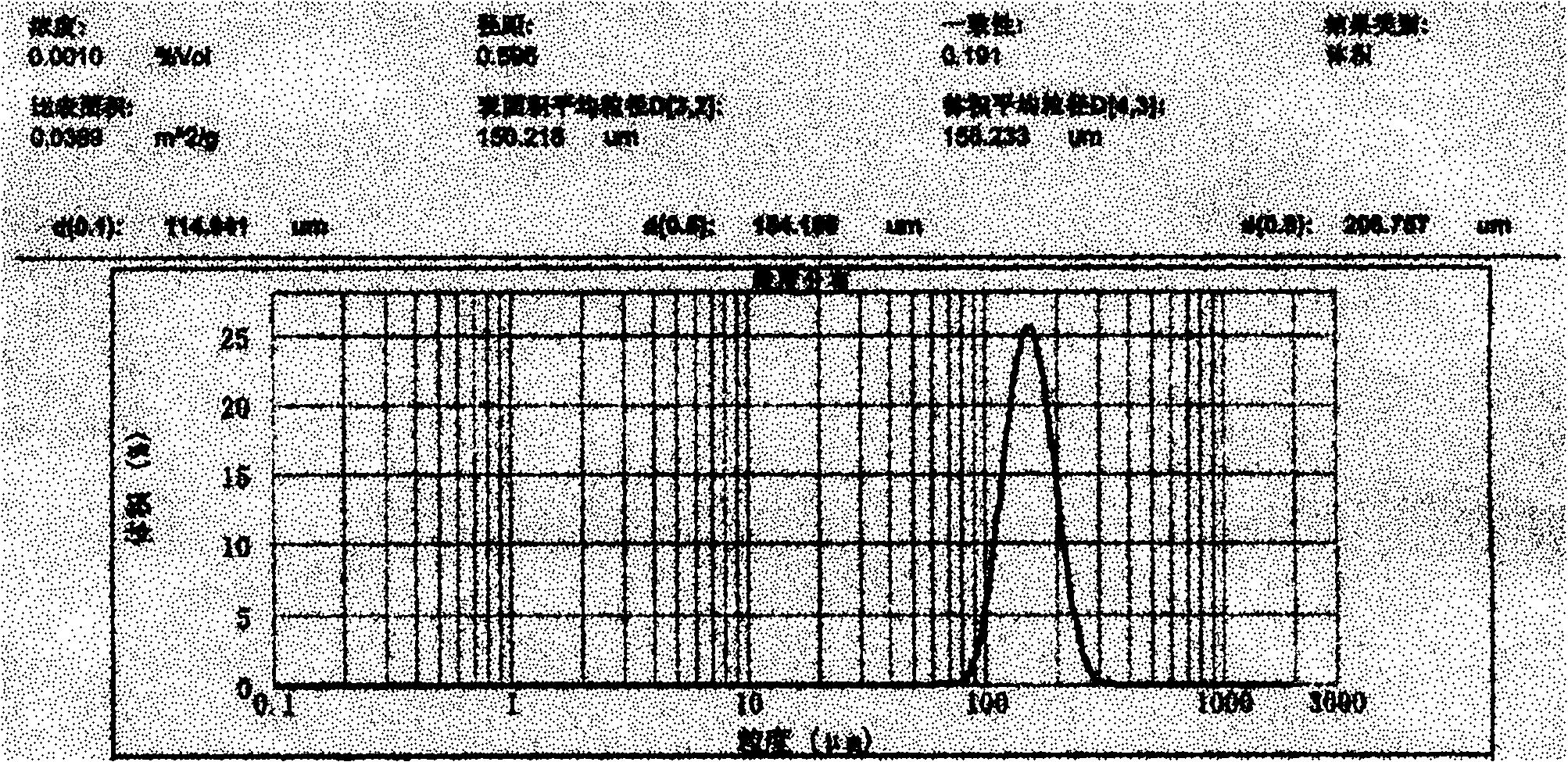

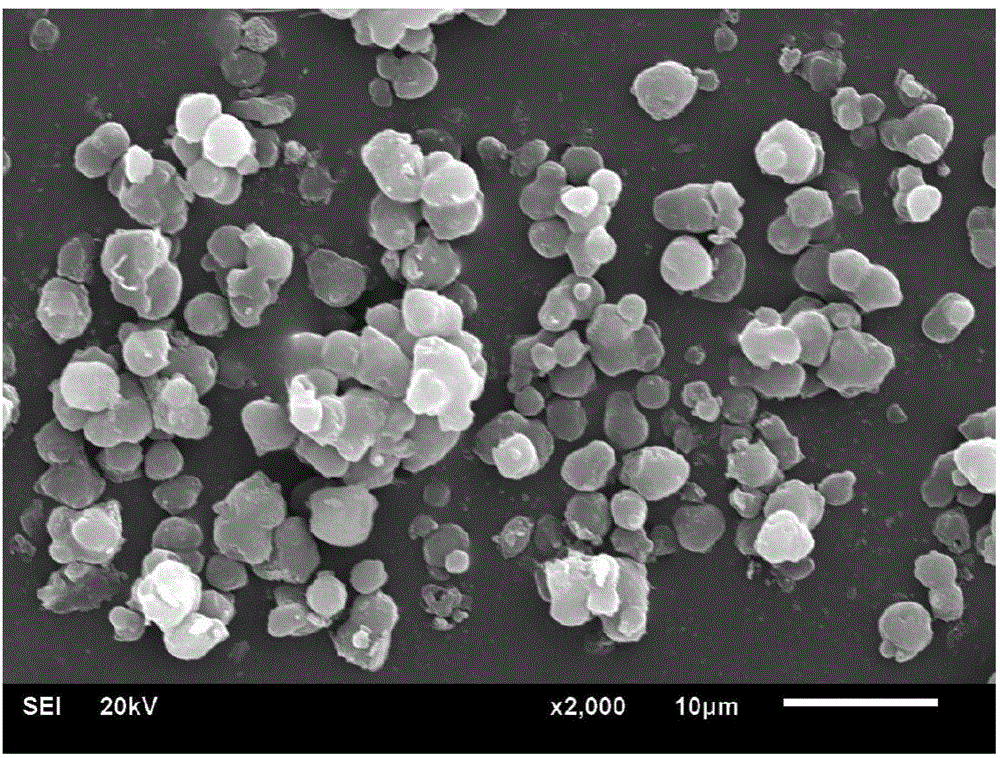

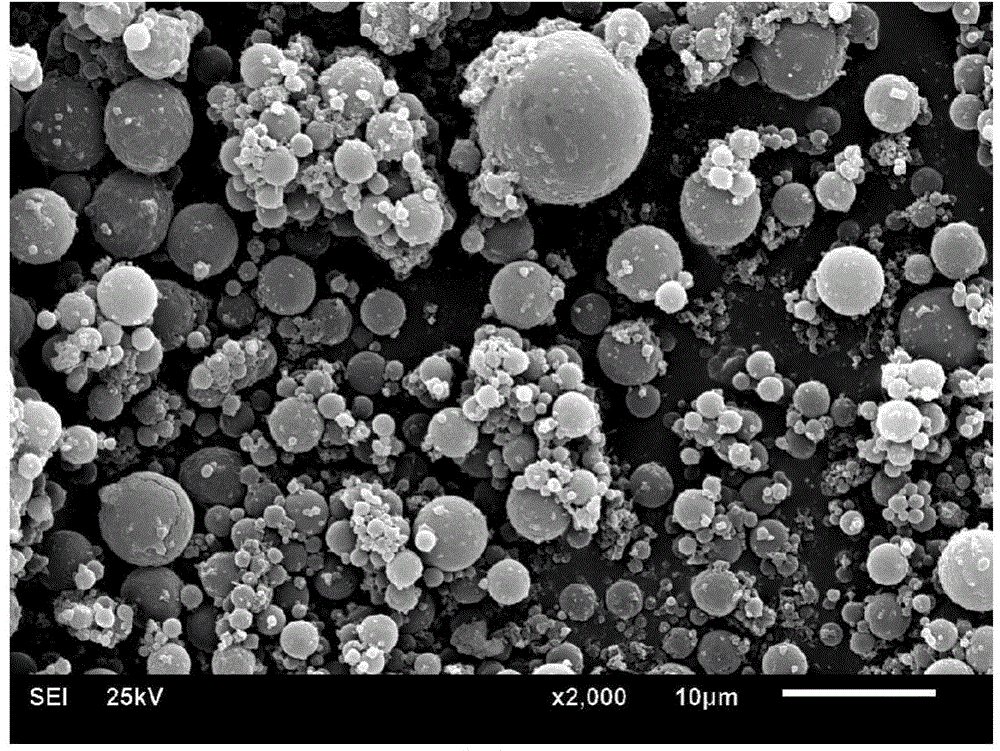

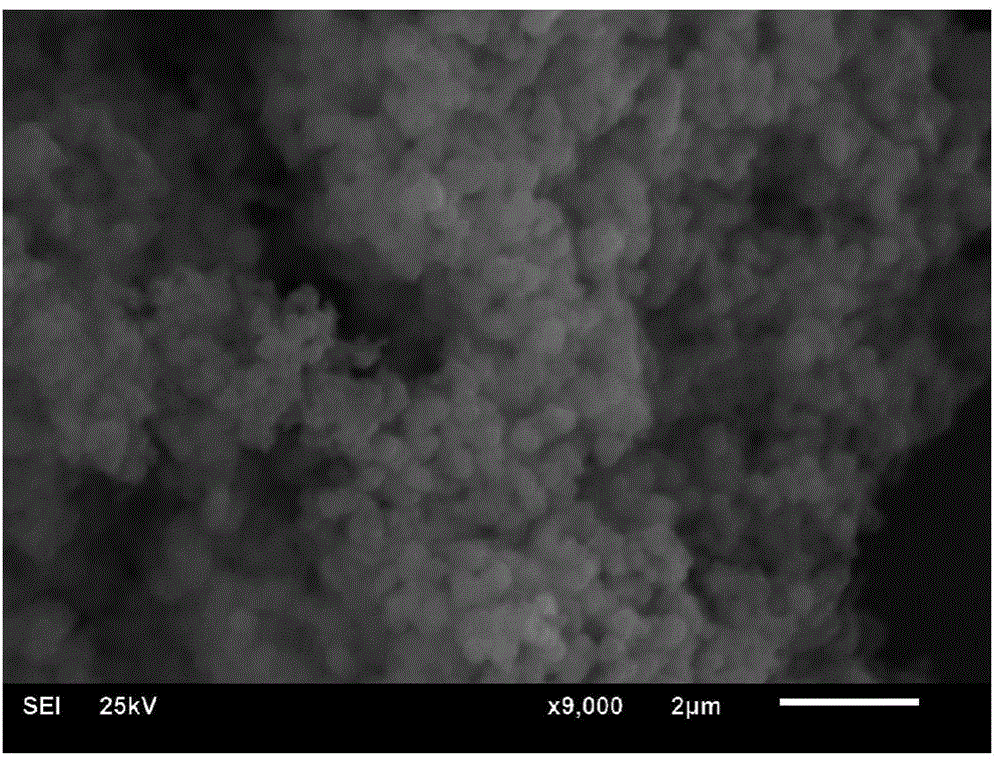

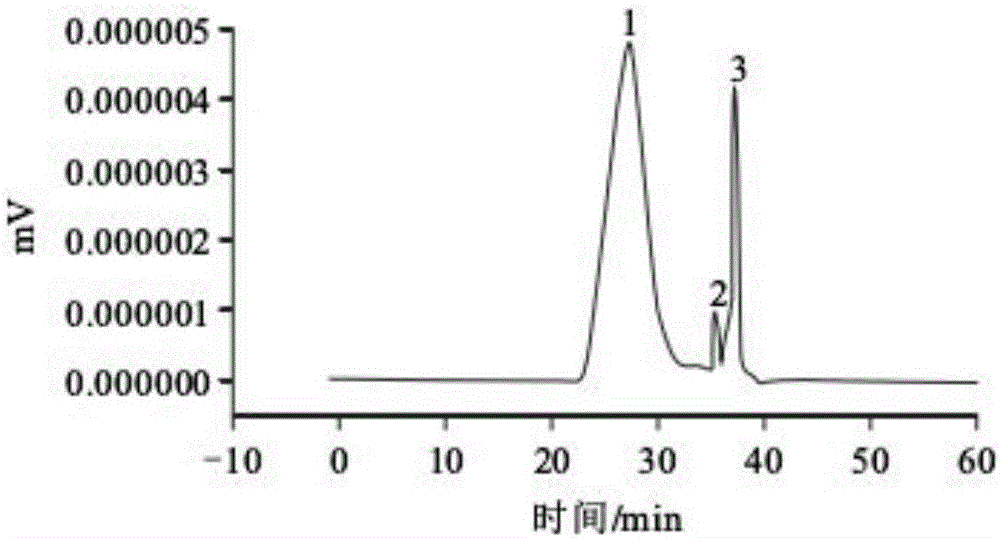

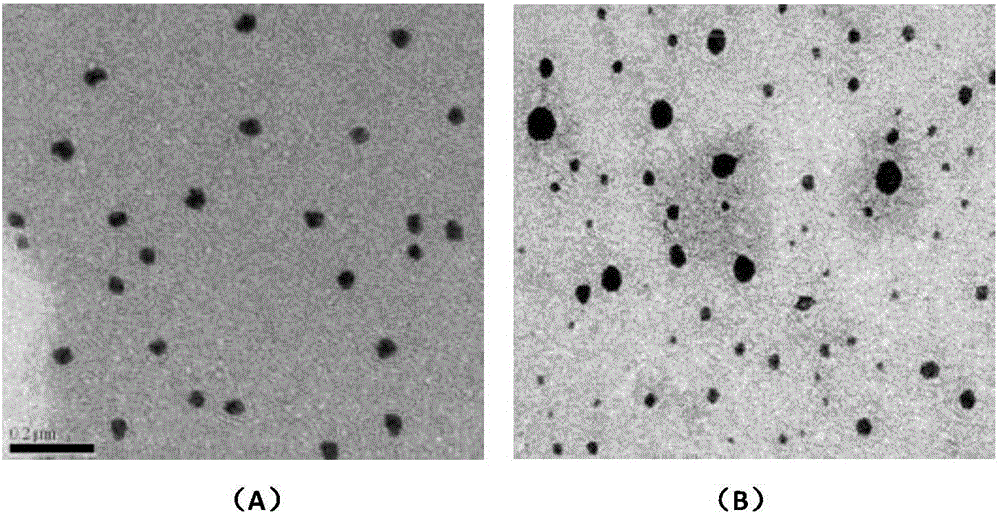

Chitosan nano-microspheres product and preparation method thereof

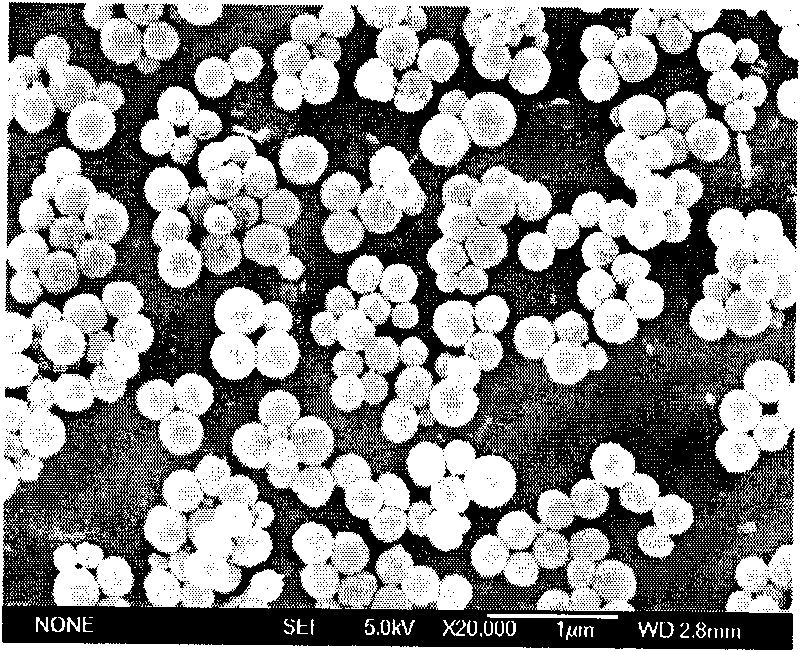

ActiveCN101675996AUniform sizeGood dispersionPharmaceutical product form changePharmaceutical non-active ingredientsChemistryNanometre

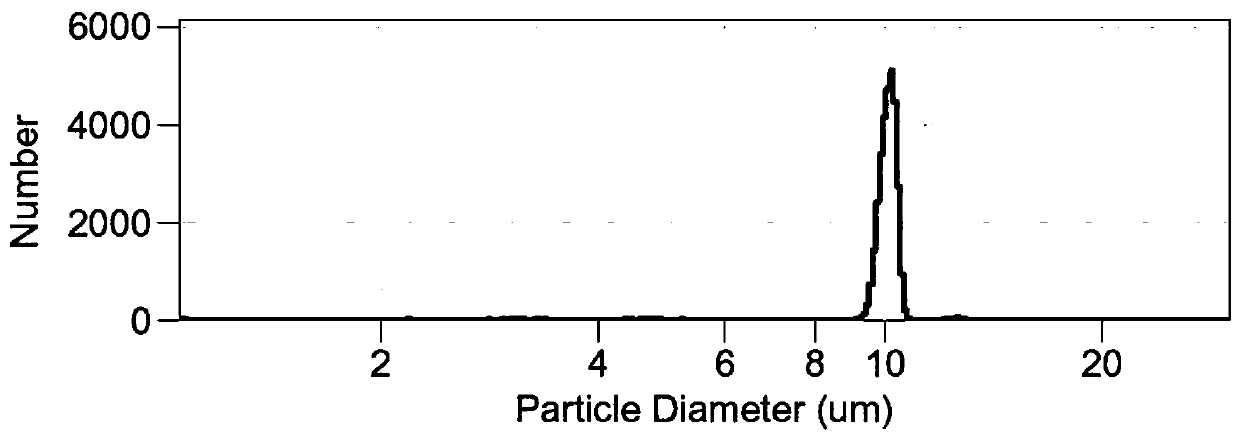

The invention provides a chitosan nano-microspheres product in which the average grain size of the chitosan nano microspheres is from tens of nanometers to ten micrometers and the grain size distribution coefficient C.V. is less than 20%. The invention also provides a preparation method and an application of the chitosan nano microspheres.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

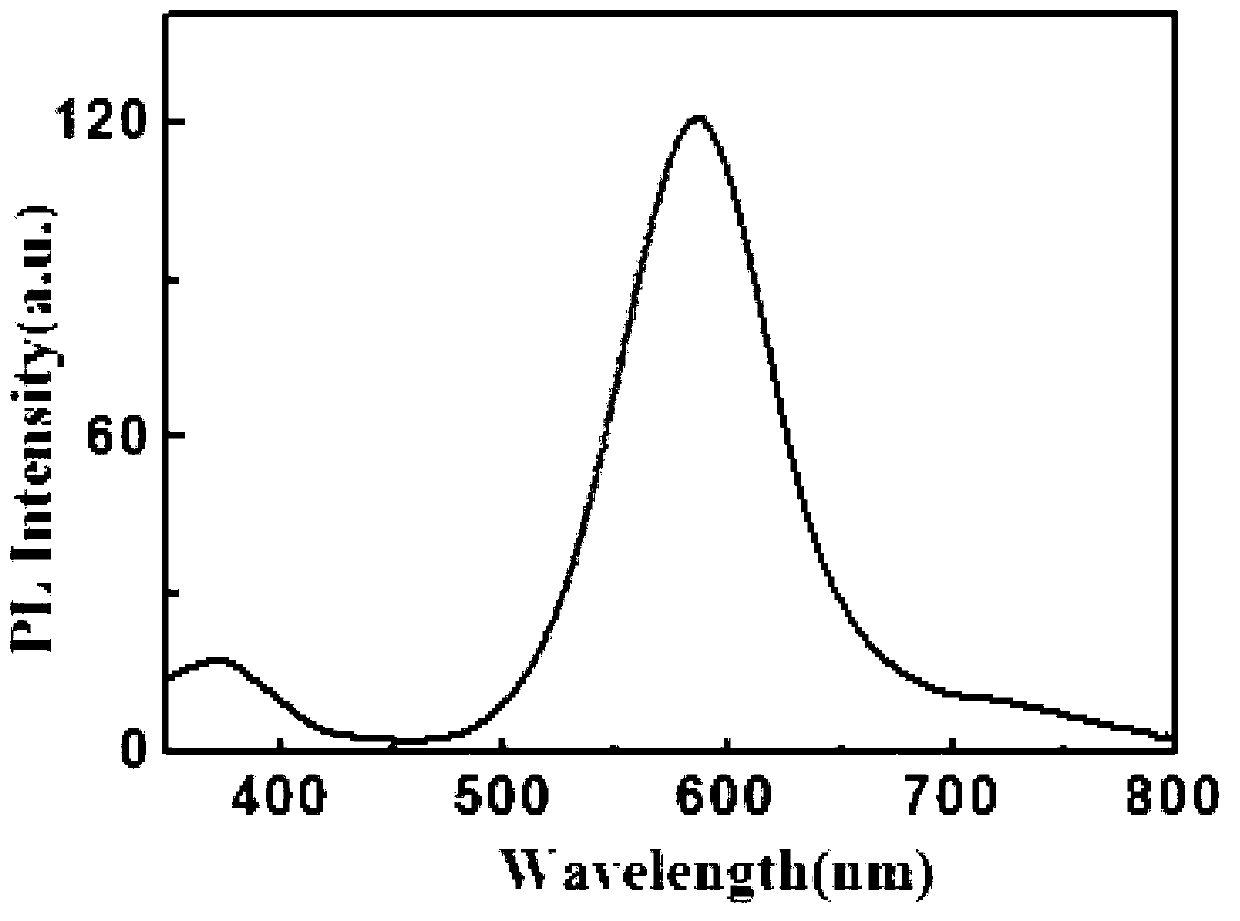

Method for preparing polymer fluorescent microsphere

InactiveCN103275700AReduce dosageReduce volumeLuminescent compositionsMicroballoon preparationPolymer dissolutionPolymer science

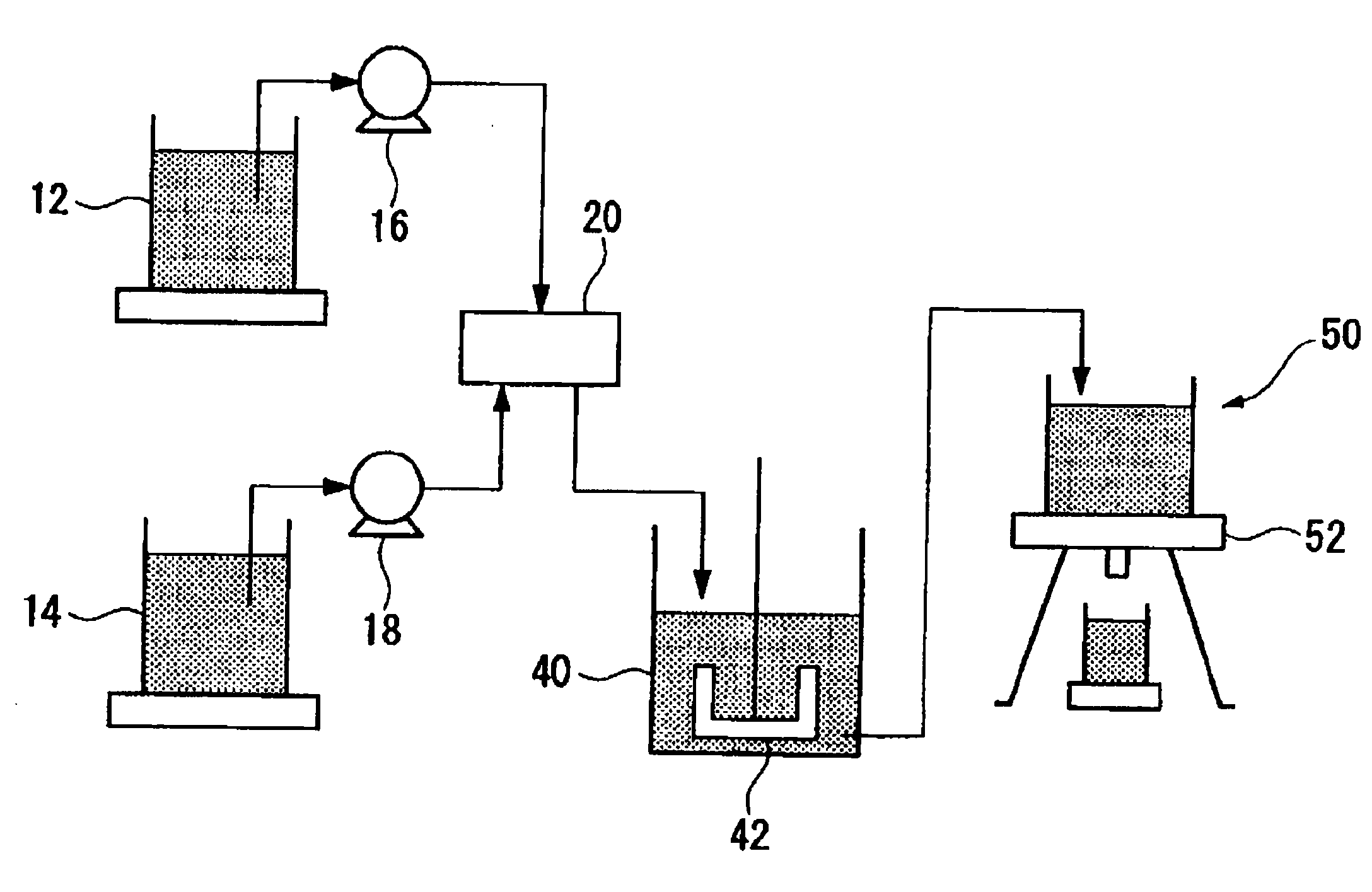

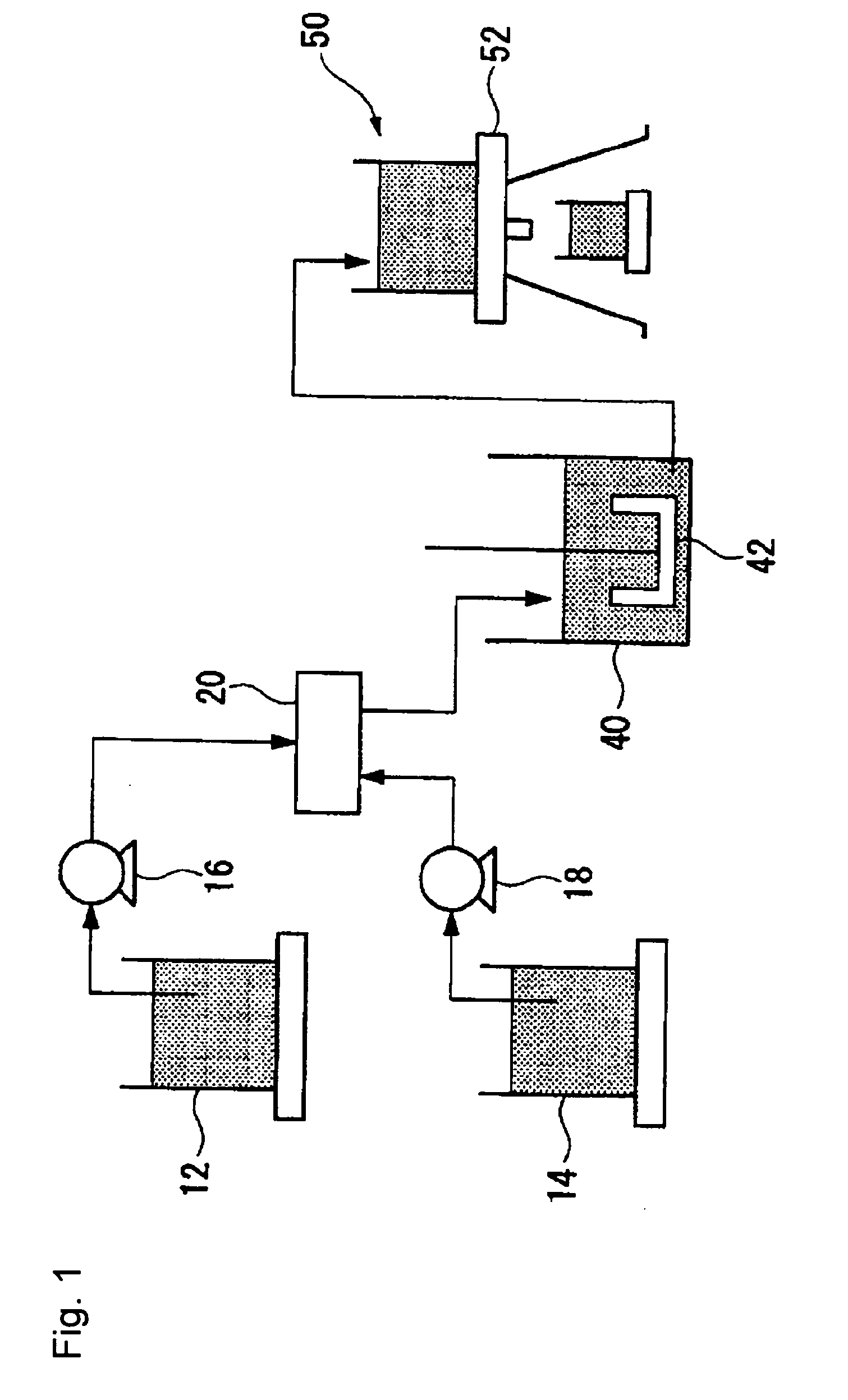

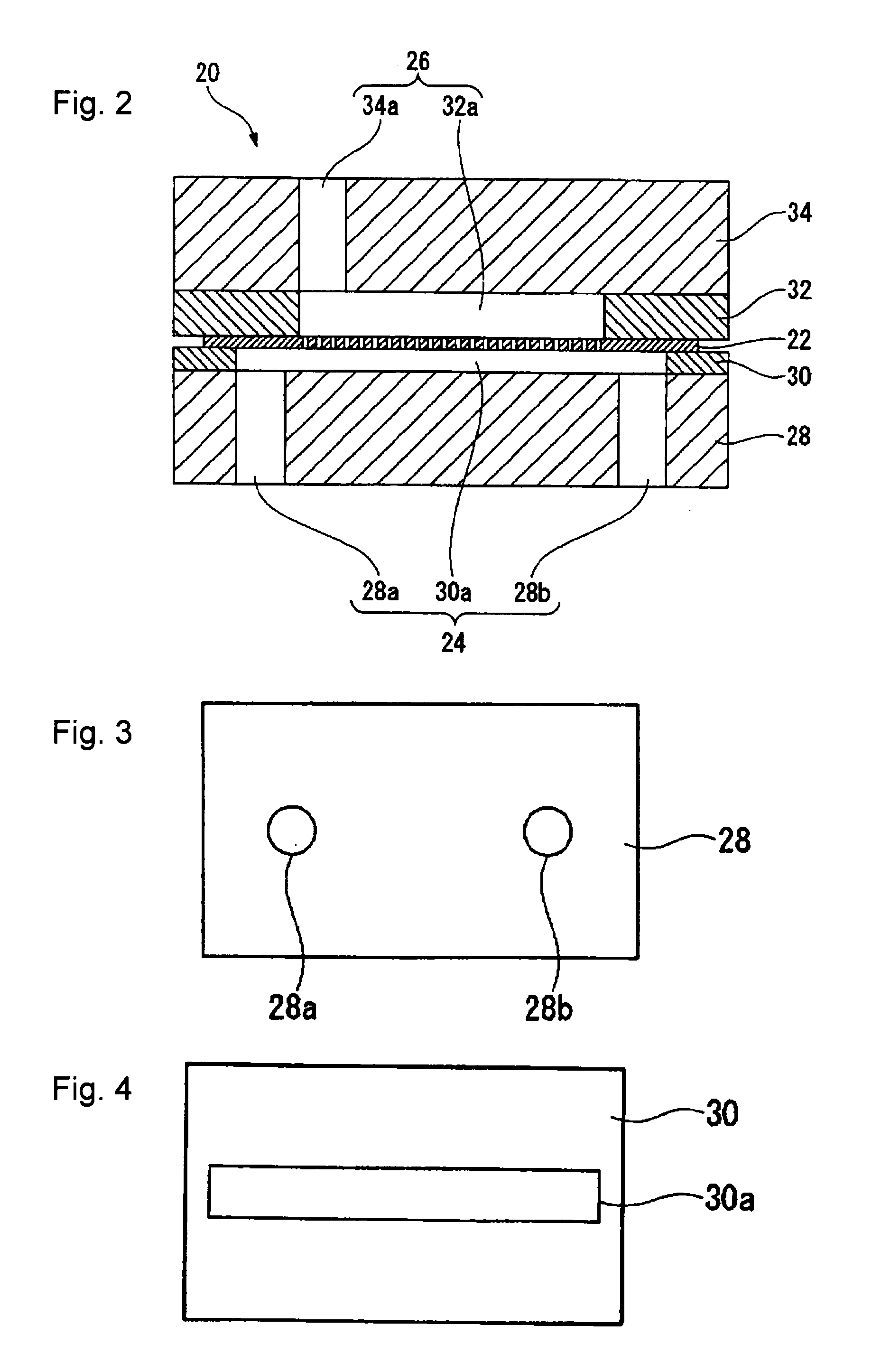

The invention relates to a method for preparing a polymer fluorescent microsphere. The method comprises the following steps of: 1, preparing polymer fluorescent microsphere liquid drops, namely dissolving a first polymer into a solvent, adding a fluorescent material into the solvent, magnetically and uniformly stirring the fluorescent material and the first polymer in the solvent to prepare a non-continuous phase, respectively putting the non-continuous phase and a continuous phase into injectors connected with a non-continuous phase inlet and a continuous phase inlet of a microfluid device, adjusting the flowing speeds of the two phases of solutions through a trace sample injection pump, so as to obtain the fluorescent microsphere liquid drops, and at a microfluid outlet, collecting the fluorescent microsphere liquid drops into a fluorescent microsphere receiving device; and 2, preparing the polymer fluorescent microsphere, namely drying the fluorescent microsphere liquid drops until the solvent is completely volatilized, then washing the fluorescent microsphere liquid drops by a washer, and cleaning the continuous phase of solution to finally obtain the polymer fluorescent microsphere. Equipment used by the method is simple and convenient to operate; the particle size of the microsphere can be adjusted by adjusting the flowing speeds of the continuous phase and the non-continuous phase; and the uniformity of the particle sizes of the prepared microspheres is high.

Owner:NANJING UNIV OF TECH

Double metal cyanide complex catalyst having organic ligand, process for its production and method for producing polyether polyol

InactiveUS20100041864A1Improve particle size uniformitySmall particle sizeOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationCyanideCompound (substance)

To provide a process for producing, simply and with high reproducibility, a double metal cyanide complex catalyst having an organic ligand, which has a high catalytic activity, a small particle size and a high particle size uniformity.A process for producing a double metal cyanide complex catalyst having an organic ligand, comprising (a) a step of contacting an aqueous metal halide compound solution and an aqueous transition metal cyanide compound solution in a laminar flow state to obtain a liquid containing a double metal cyanide complex, and (b) a step of mixing the liquid containing a double metal cyanide complex, and an organic ligand, to obtain a dispersion containing a double metal cyanide complex catalyst having an organic ligand.

Owner:ASAHI GLASS CO LTD

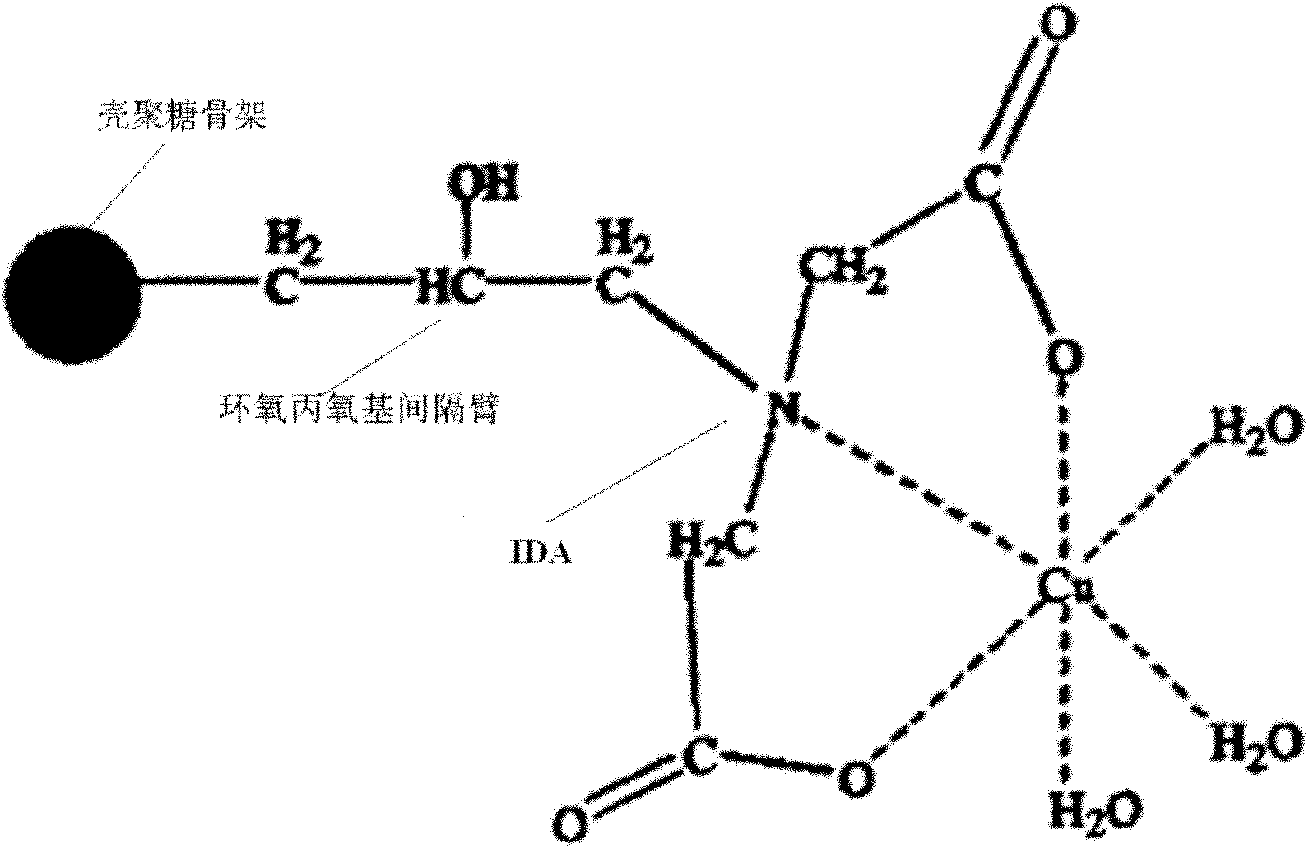

Method for preparing chitosan separation medium suitable for protein purification

ActiveCN102068965AEasy to operateGood particle size uniformityOther chemical processesPeptide preparation methodsCross-linkEpoxy

The invention relates to a method for preparing a chitosan separation medium suitable for protein purification, which comprises the following steps of: (1) dispersing acetic acid solution of chitosan into liquid paraffin with stirring to form chitosan particles in the presence of cyclohexane serving as a porogen and a small amount of span80, and further cross-linking the chitosan particles to form a chitosan skeleton under the action of glutaraldehyde serving as a cross-linking agent; (2) swelling the chitosan skeleton, and reacting a hydroxyl group on the chitosan skeleton with epoxy chloropropane in dimethyl sulfoxide (DMSO) / NaOH mixed solution to introduce an epoxy group into the chitosan skeleton so as to obtain a grafted chitosan skeleton; and (3) adding iminodiacetic acid (IDA) / NaOHmixed solution into the grafted chitosan skeleton, reacting at the temperature of between 20 and 80 DEG C for 1 to 10 hours, and performing suction-filtration to obtain the chitosan separation medium. The chitosan separation medium solves the leakage problem of metal ions to a large extent, has the advantages of process stability, high repeatability and the like, and is suitable for mass production.

Owner:ZHEJIANG UNIV OF TECH

Polyvinyl alcohol mircrobubbles and preparing method thereof

The invention provides polyvinyl alcohol mircrobubbles and a preparing method thereof. The method includes the following steps: firstly, dissolving polyvinyl alcohol in a solvent to obtain a polyvinyl alcohol water solution; then adding an oxidizing agent in the polyvinyl alcohol water solution and fully heating and stirring the mixture to enable hydroxide radicals in two vinyl alcohol units connected head to head to be oxidized into formyl groups and enable the formyl groups to be subjected to chain scission, so as to prepare a water solution containing polyvinyl alcohol chain scission products; then adding acid in the water solution containing the polyvinyl alcohol chain scission products and adjusting the pH value to 1-4, so as to obtain a mixed solution; stirring; enabling cross-linking reaction to occur between the polyvinyl alcohol chain scission products in the mixed solution to form microbubble films, so as to obtain polyvinyl alcohol mircrobubbles, as the solvent, wrapped by the microbubble films.

Owner:SHENZHEN INST OF ADVANCED TECH

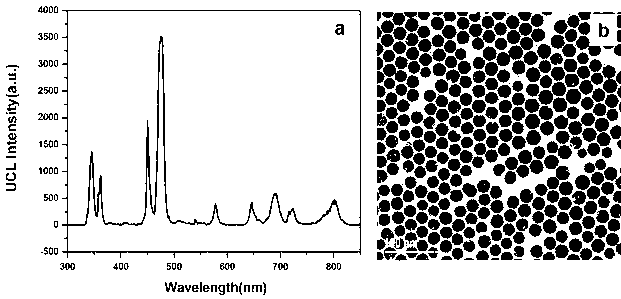

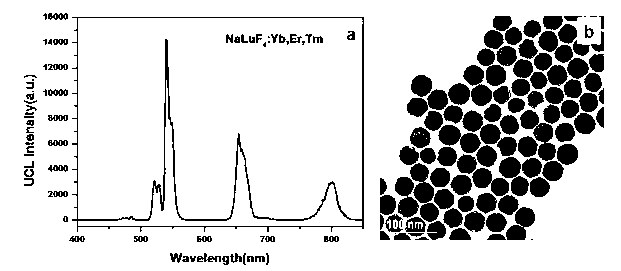

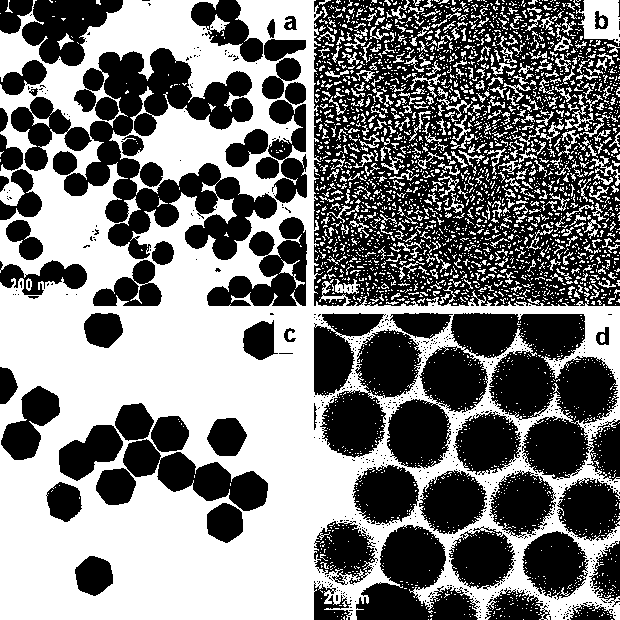

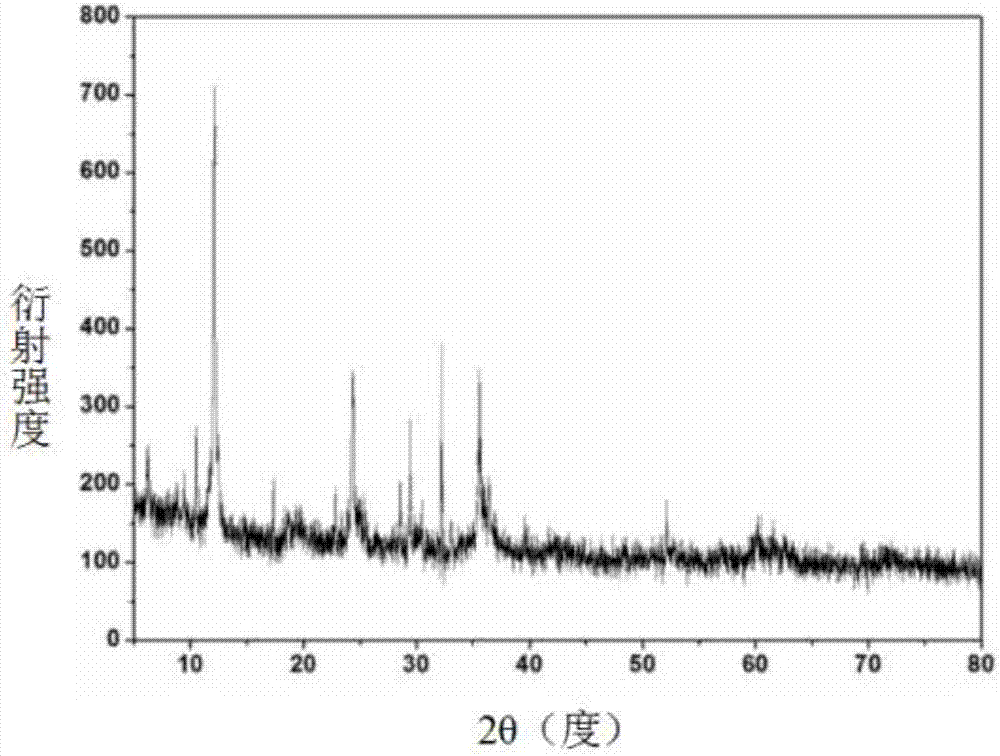

Nanoparticles used for biological detection with fluoride lutecium as main component

InactiveCN102735659AGood particle size uniformityGood biocompatibilityFluorescence/phosphorescenceNanoparticleBiological imaging

The invention relates to an application of nanoparticles with fluoride lutecium as a main component in biological detection and preparation of a reagent for biological detection. Furthermore, the invention also relates to the nanoparticles used in the above application and a preparation method thereof. The dimension of the material is less than 200nm. The material has an excellent luminescence property and can be used in bioimaging and biodetection as a luminescent probe.

Owner:FUDAN UNIV

Preparation method of silicon carbide micro-powder used in silicon carbide crystal growth

ActiveCN103058192AGood particle size uniformityHeating evenlyCarbon compoundsMicrowaveCrystal growth

The invention relates to a preparation method of silicon carbide micro-powder used in silicon carbide crystal growth. The method comprises the steps that: carbon powder and silicon powder are uniformly mixed, such that a mixture is obtained; and the mixture is added into a heating chamber, and is heated by using microwaves, such that the silicon carbide micro-powder used in silicon carbide crystal growth is obtained. According to the invention, microwave heating is adopted, and heating is uniform. The synthesized silicon carbide particles have good particle size homogeneity. The obtained product does not need to be crushed by using a traditional ball mill, such that secondary pollution is prevented, and product purity is ensured. Also, a single-time synthesizing amount is high, and efficiency is high.

Owner:HEBEI SYNLIGHT CRYSTAL CO LTD

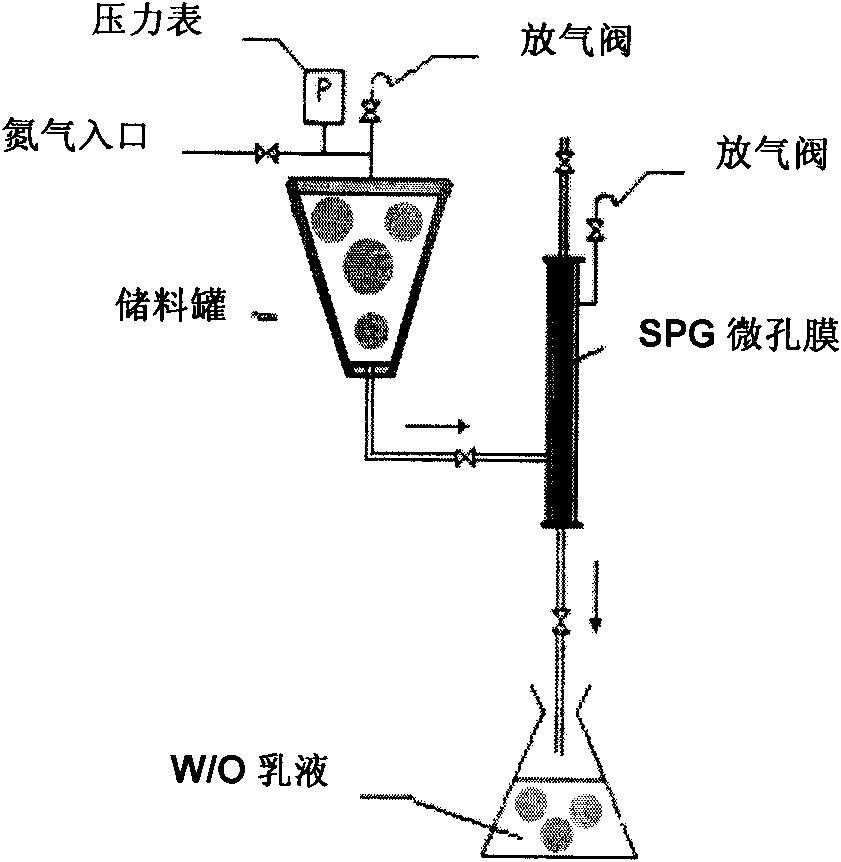

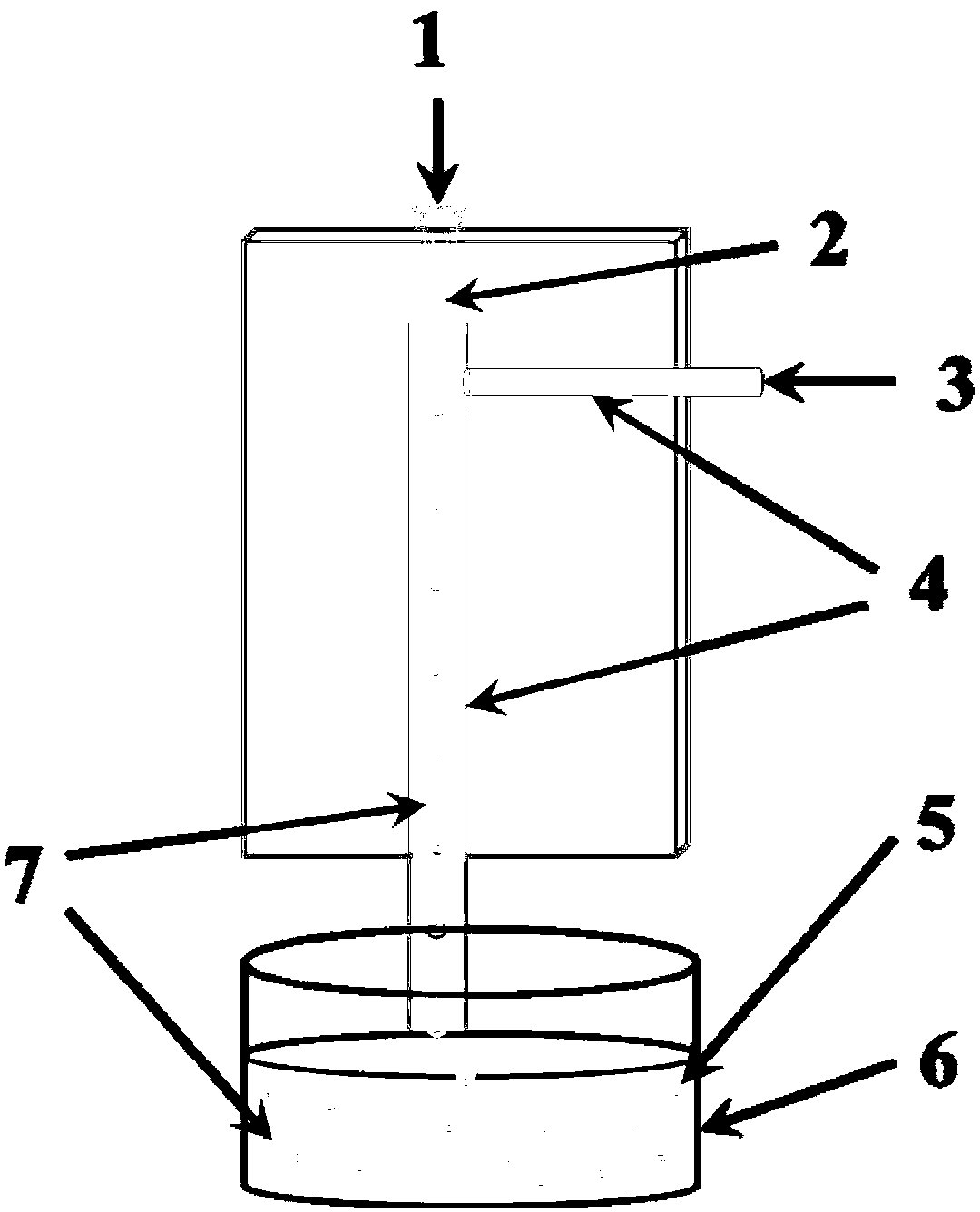

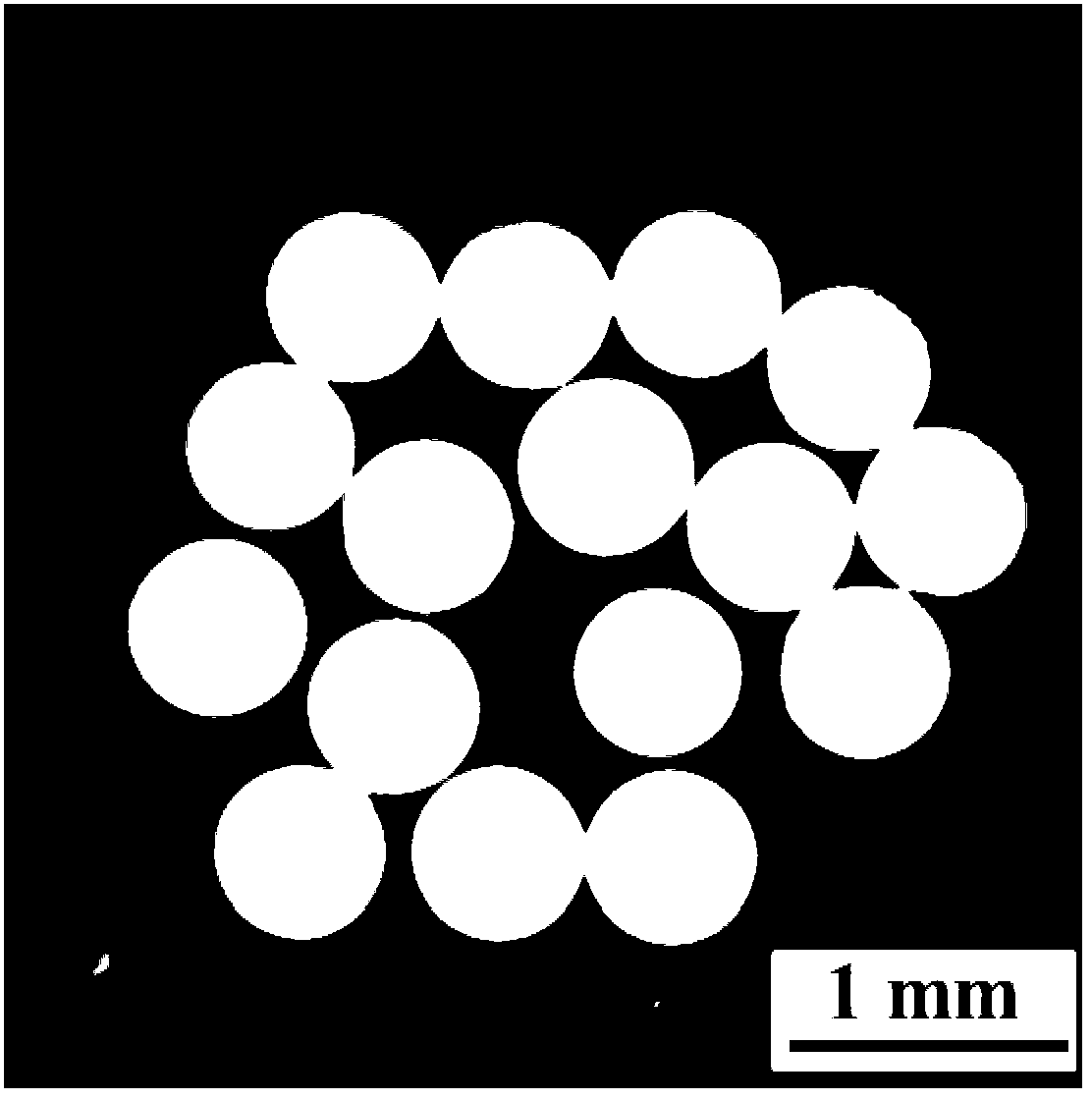

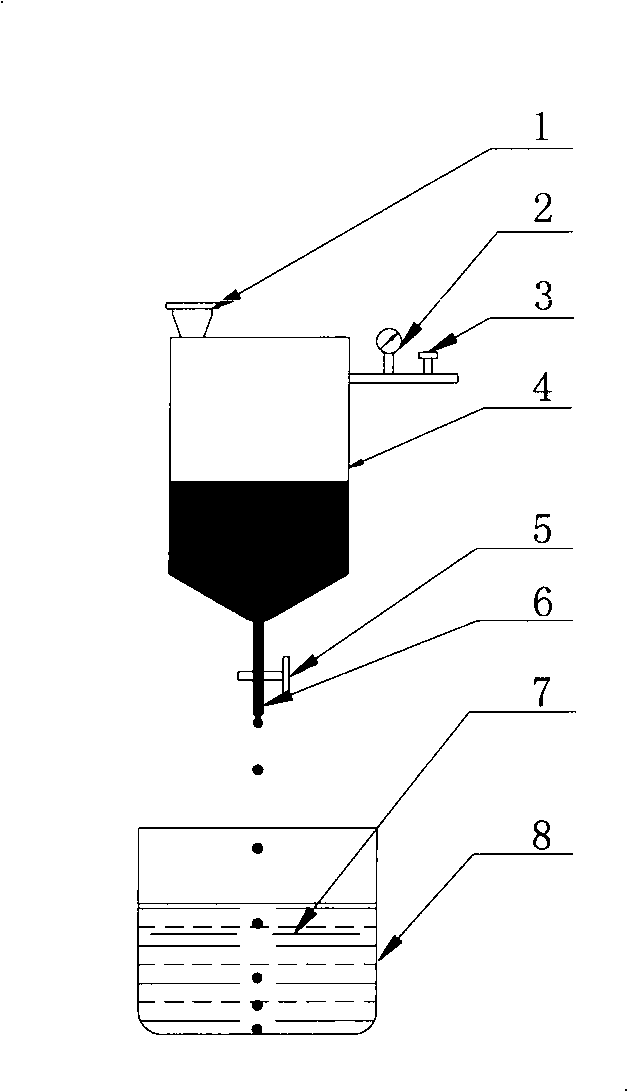

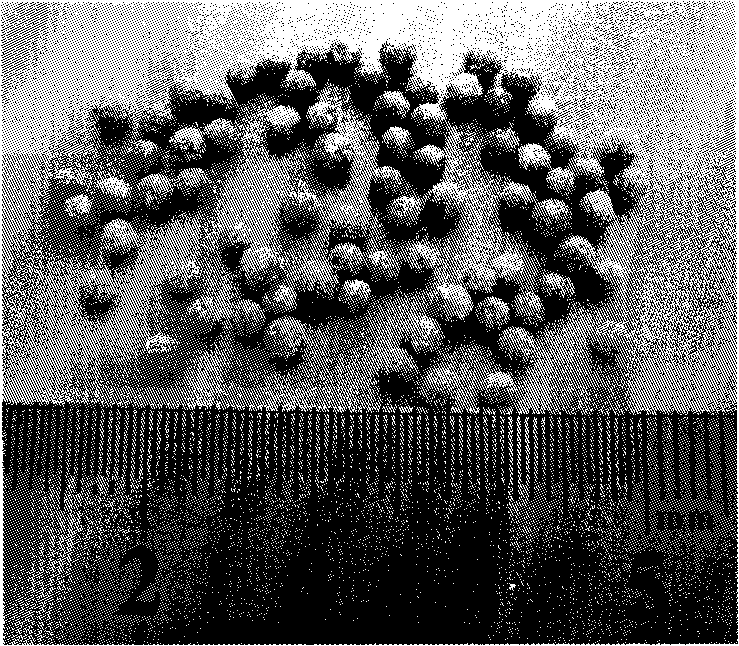

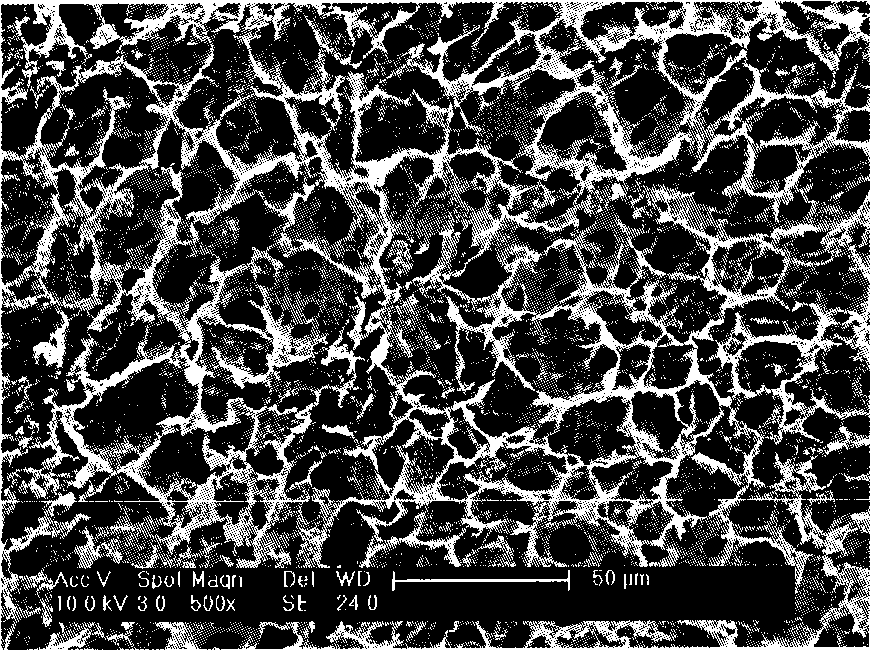

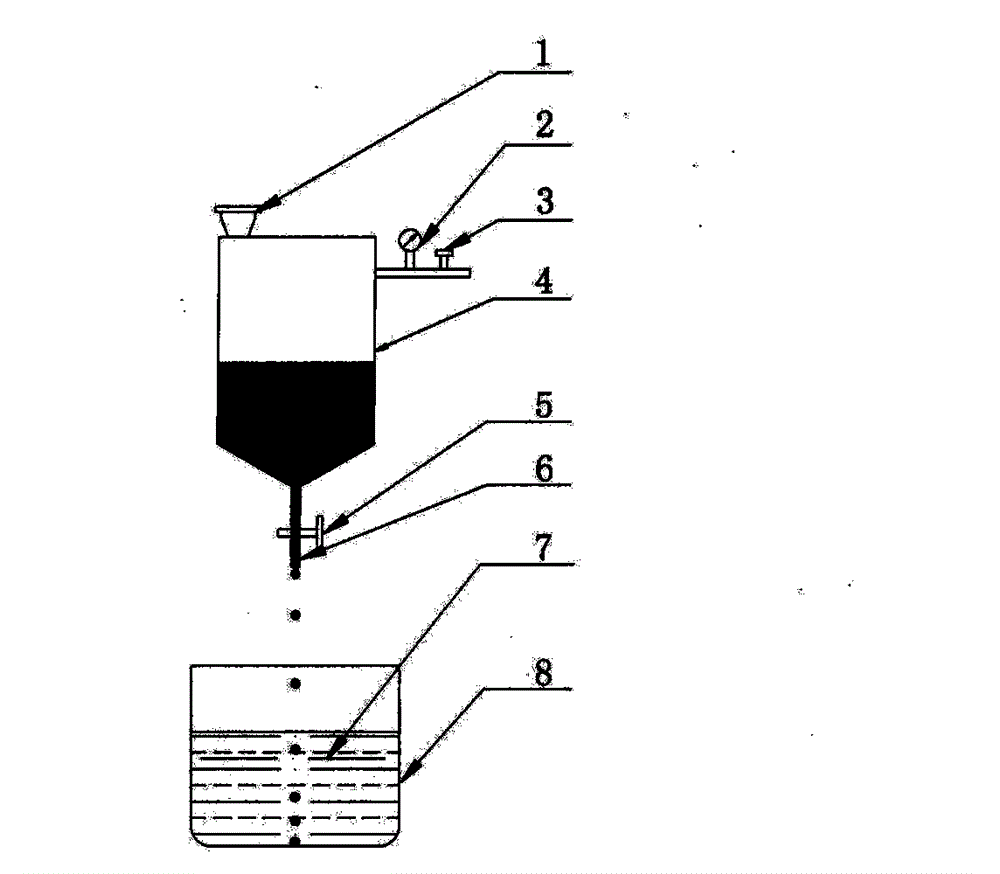

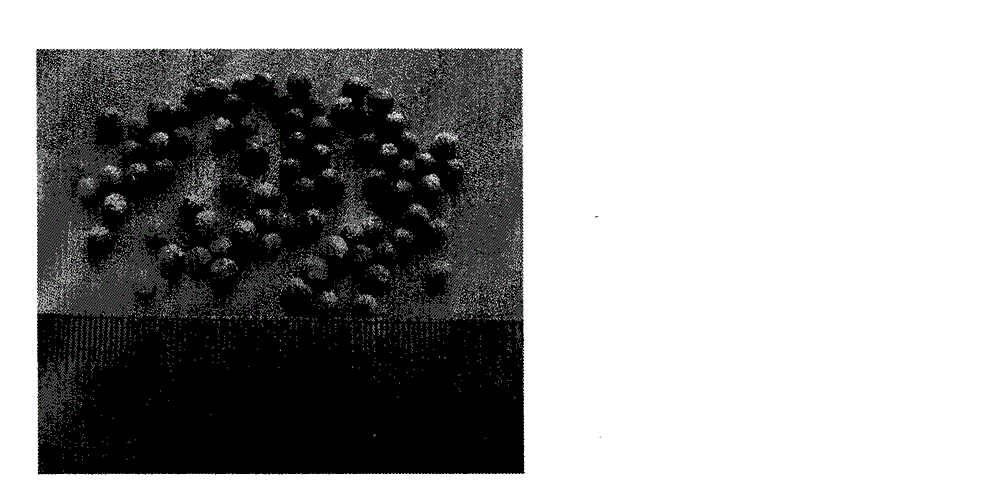

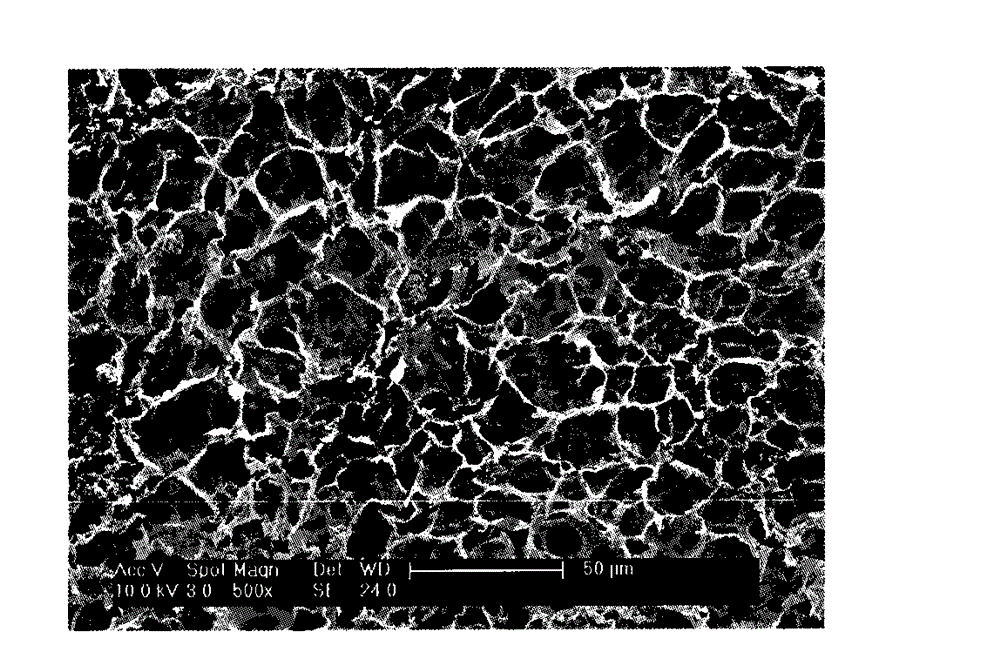

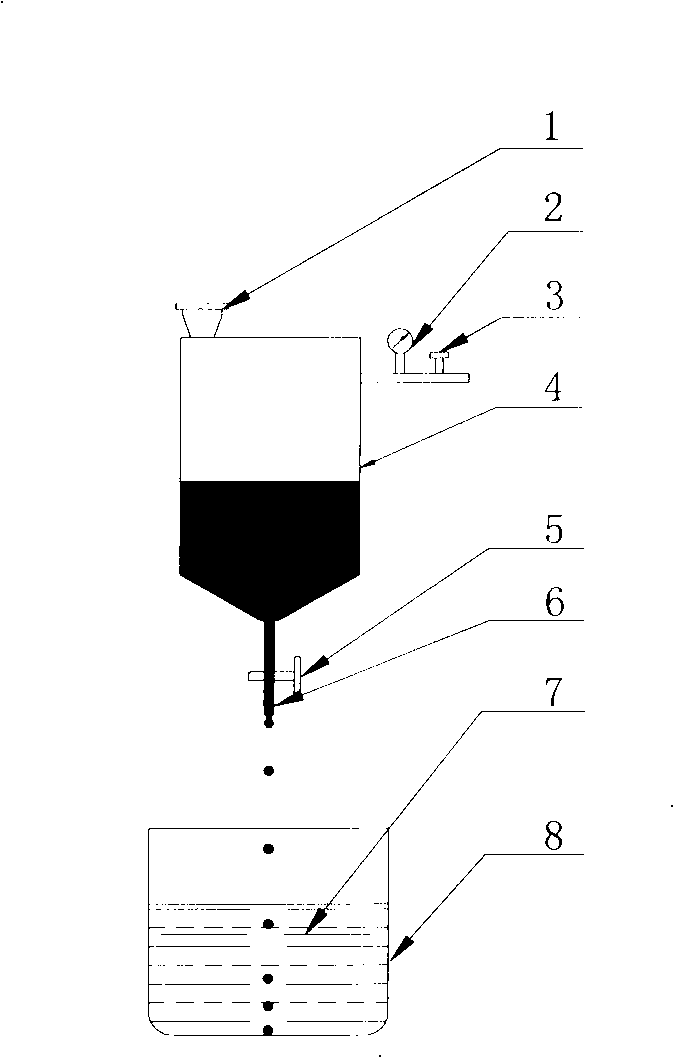

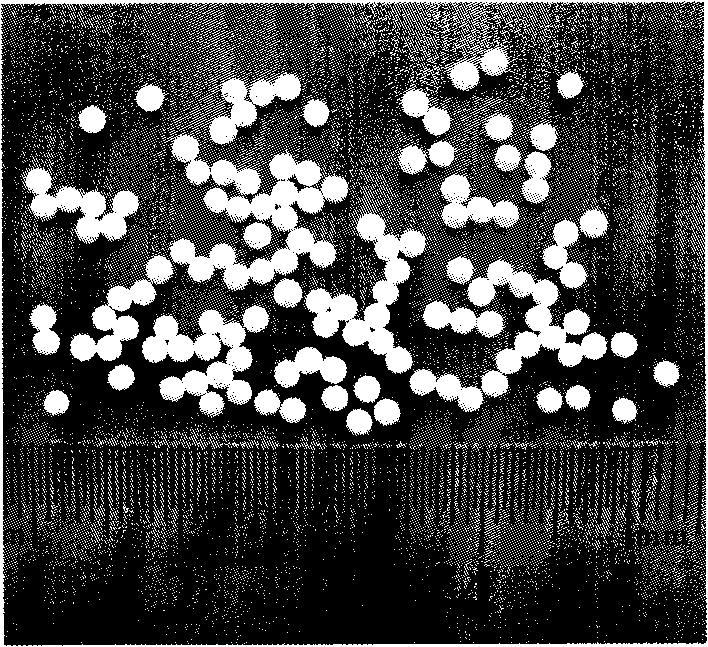

Chitosan spherical honeycombed grain material, producing method and apparatus thereof

InactiveCN101401956AGood particle size uniformityConducive to flowImpression capsDentistry preparationsThermal insulationChemistry

The invention relates to a chitosan spherical porous particle material, and a method and a device for preparing the same. The method comprises the following steps: step one, preparing a chitosan acetic acid solution by using an acetic acid solution, wherein the mass concentration of the acetic acid solution is between 1 and 5 percent, and the mass of the chitosan is between 5 and 25 percent of the total mass of the chitosan acetic acid solution; step two, adding the solution into a material storage tank from a feed opening, and controlling the pressure in the material storage tank between 0.08 and 0.5 Mpa through a pressure meter and a pressure control valve, wherein the chitosan acetic acid solution uniformly flows out of the material storage tank at a speed of between 10 and 60 drops per minute, and then is dripped into a condensate with a temperature between 10 and 20 DEG C below zero in a thermal insulation container to be condensed, so that a collagen spherical porous particle material with good sphericity and uniform particle diameter is formed; and step three, separating, freezing, drying, crosslinking and cleaning the collagen spherical porous particle material to obtain the chitosan spherical porous particle material. The spherical particle material has homogeneous particle diameter distribution, contains a large number of micropores communicated with one another therein, has higher specific surface area, and can be applied to tissue repair and medicament slow release.

Owner:JIANGSU HAIJIAN +1

Drug-loaded egg protein microspheres and preparation method thereof

ActiveCN104083770AHigh strengthEasy to packGranular deliveryMacromolecular non-active ingredientsEgg proteinMicrosphere

The invention relates to drug-loaded egg protein microspheres and a preparation method thereof, belonging to the field of drug controlled release. The invention aims at solving the technical problem of providing the drug-loaded egg protein microspheres and the preparation method thereof. A vector of the drug-loaded egg protein microspheres is egg protein. The preparation method comprises the following steps: mixing a surfactant with an oily component to obtain an oil phase; adding a mixed liquor of the egg protein and drugs to the oil phase to stir and emulsify, and then directly heating and solidifying or adding an aldehyde curing agent to carry out crosslinking solidification; demulsifying by using a petroleum ether after solidification is ended; and cleaning and centrifuging by using isopropyl alcohol, and carrying out freeze-drying, so as to obtain the drug-loaded egg protein microspheres. The microspheres disclosed by the invention have good biocompatibility and biological activity; the particle sizes are 0.2-20mu m, and can be adjusted according to different solidification methods; and the microspheres are good in controlled release effect, are applied to a plurality of drug-delivery ways, such as injection, oral administration and the like, and are wide in material source, low in price, simple and feasible in preparation process and low in production cost.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

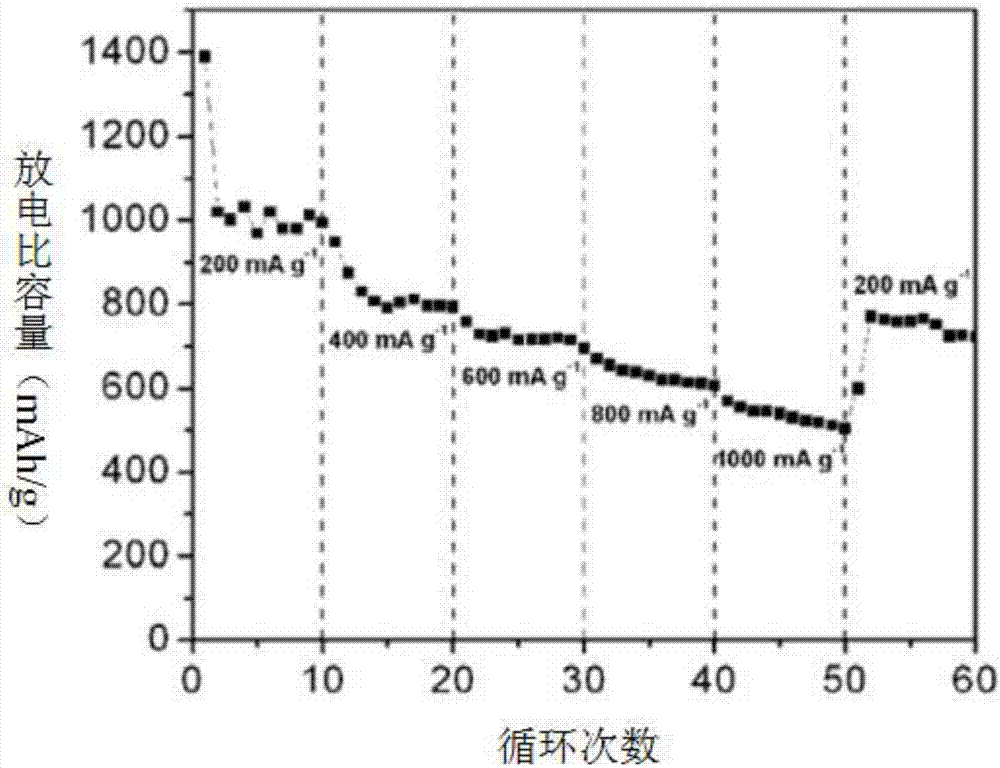

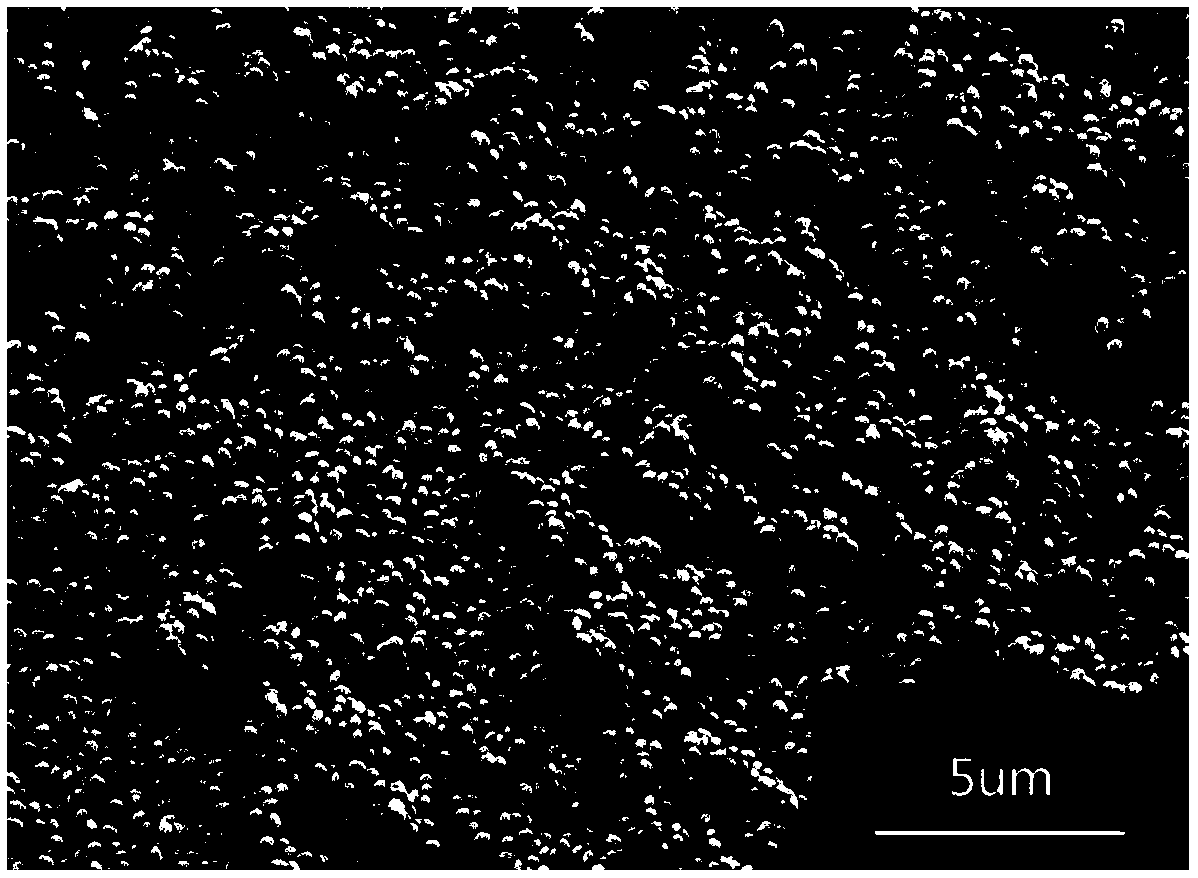

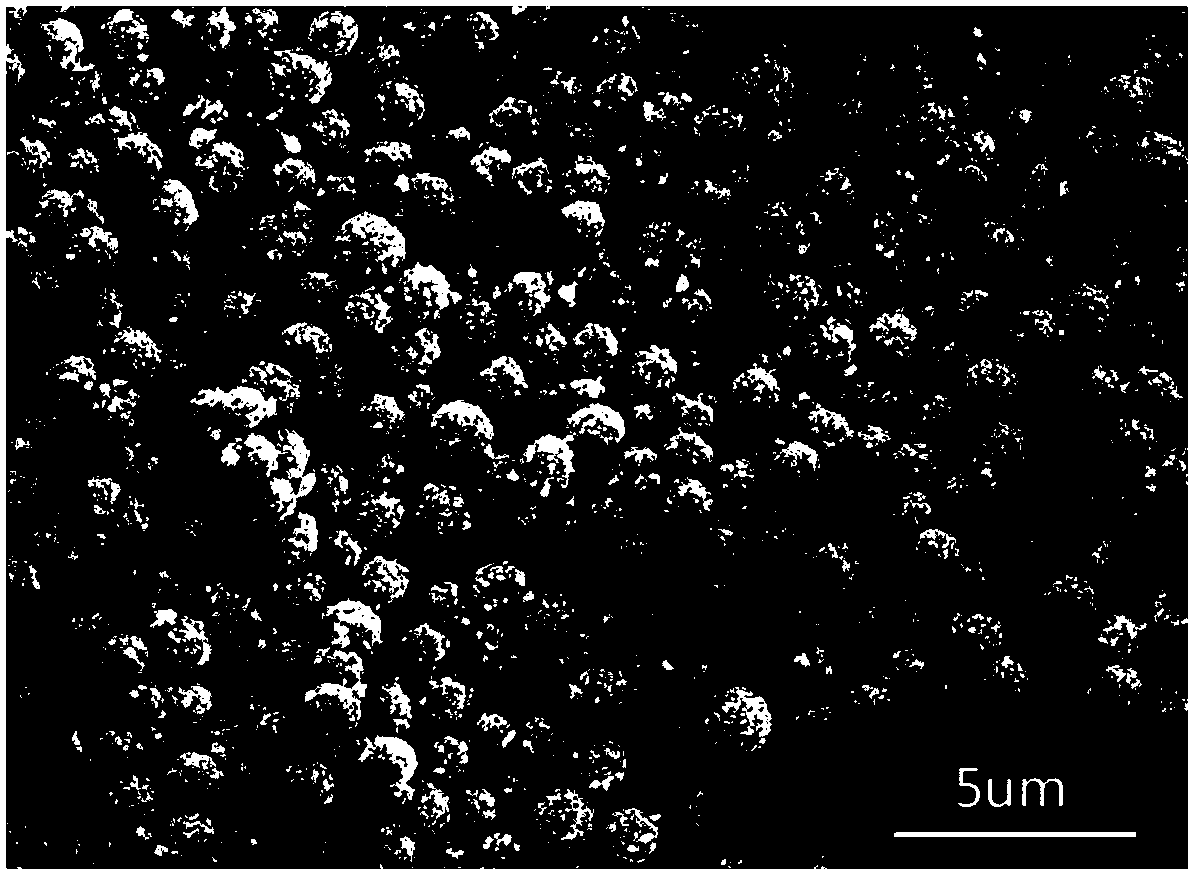

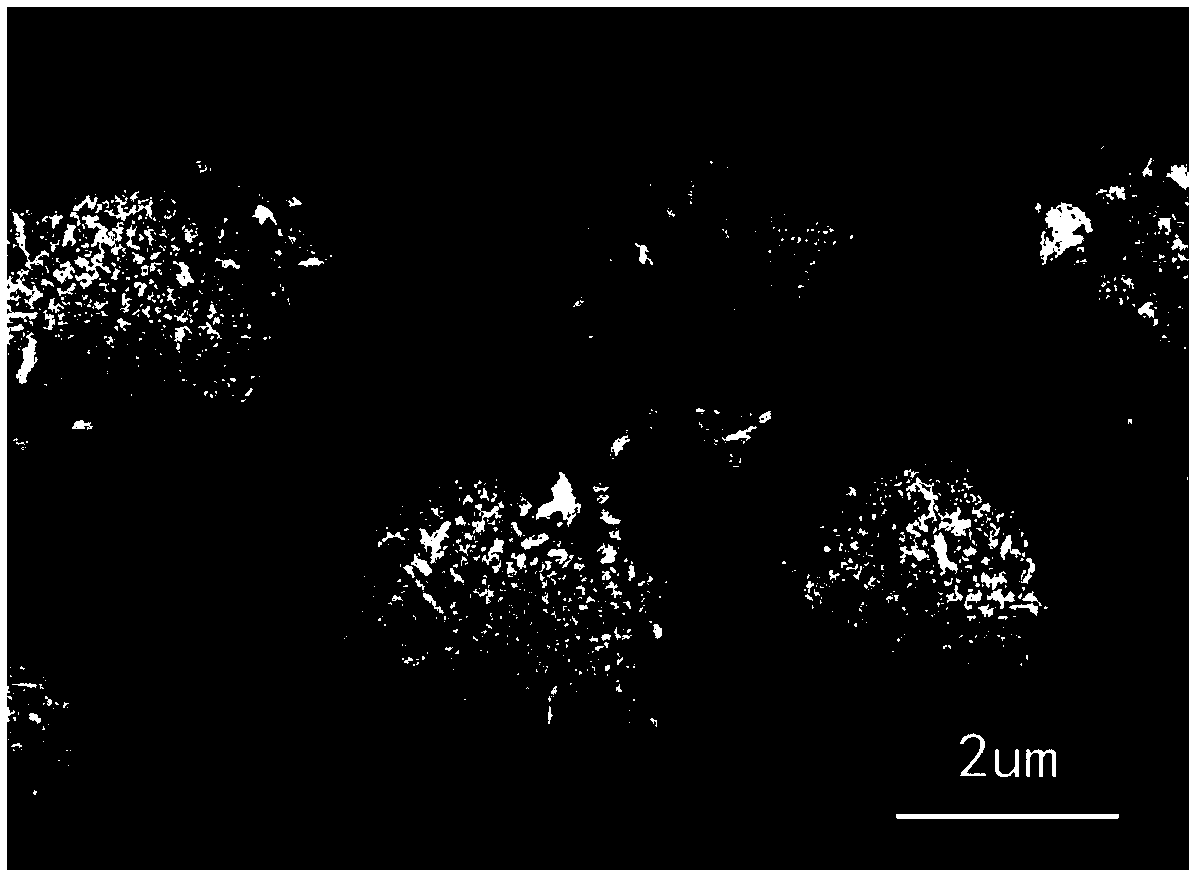

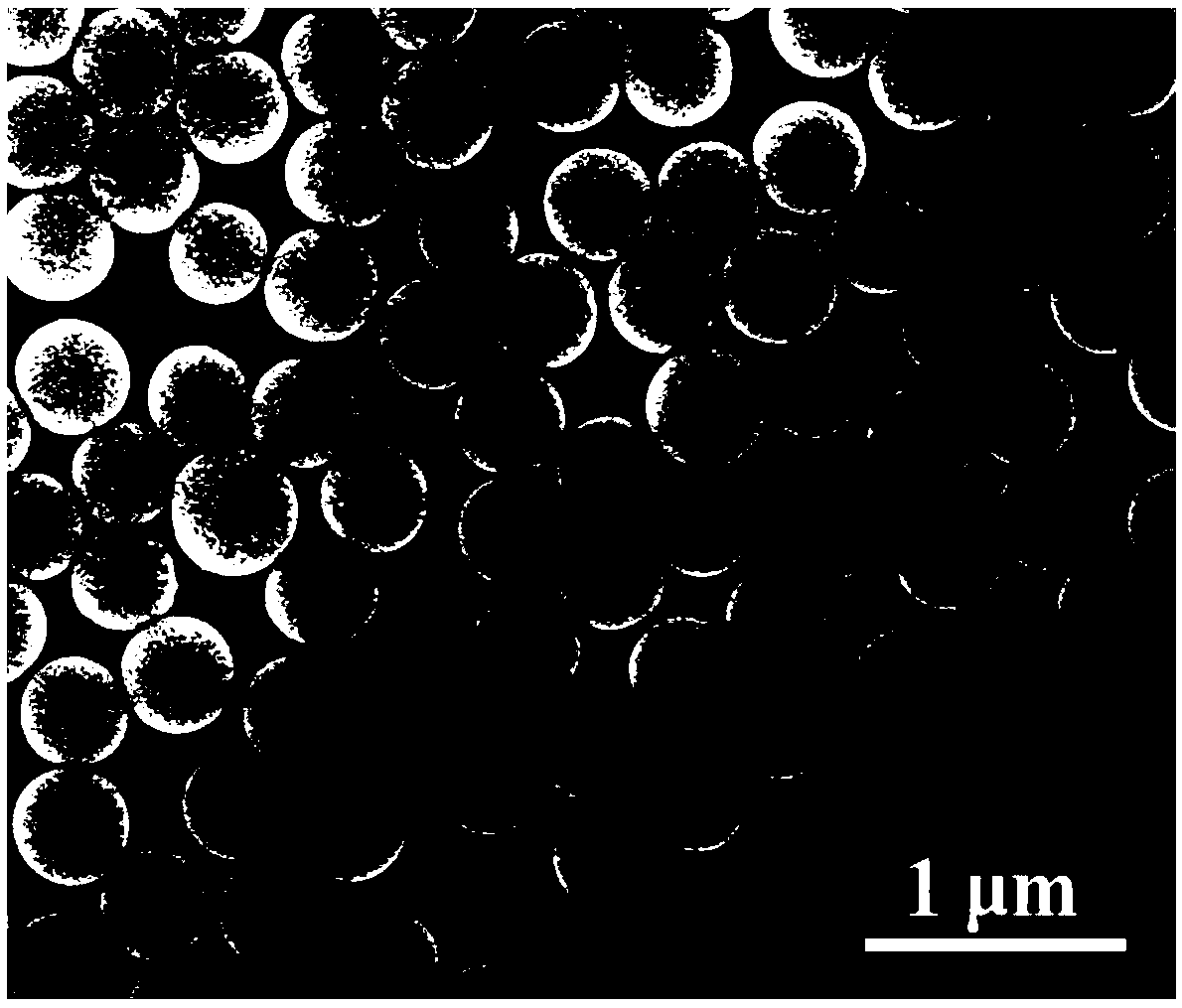

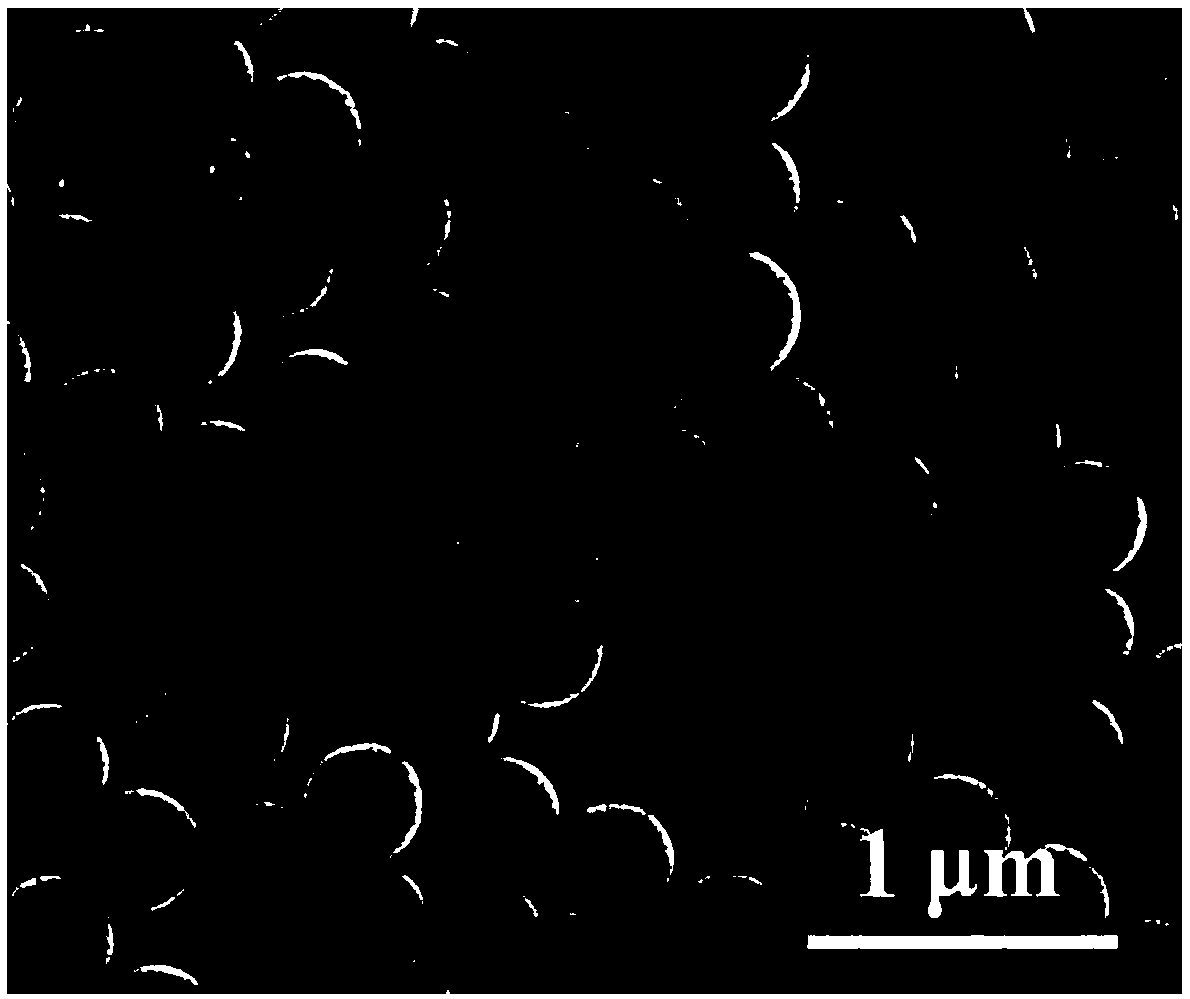

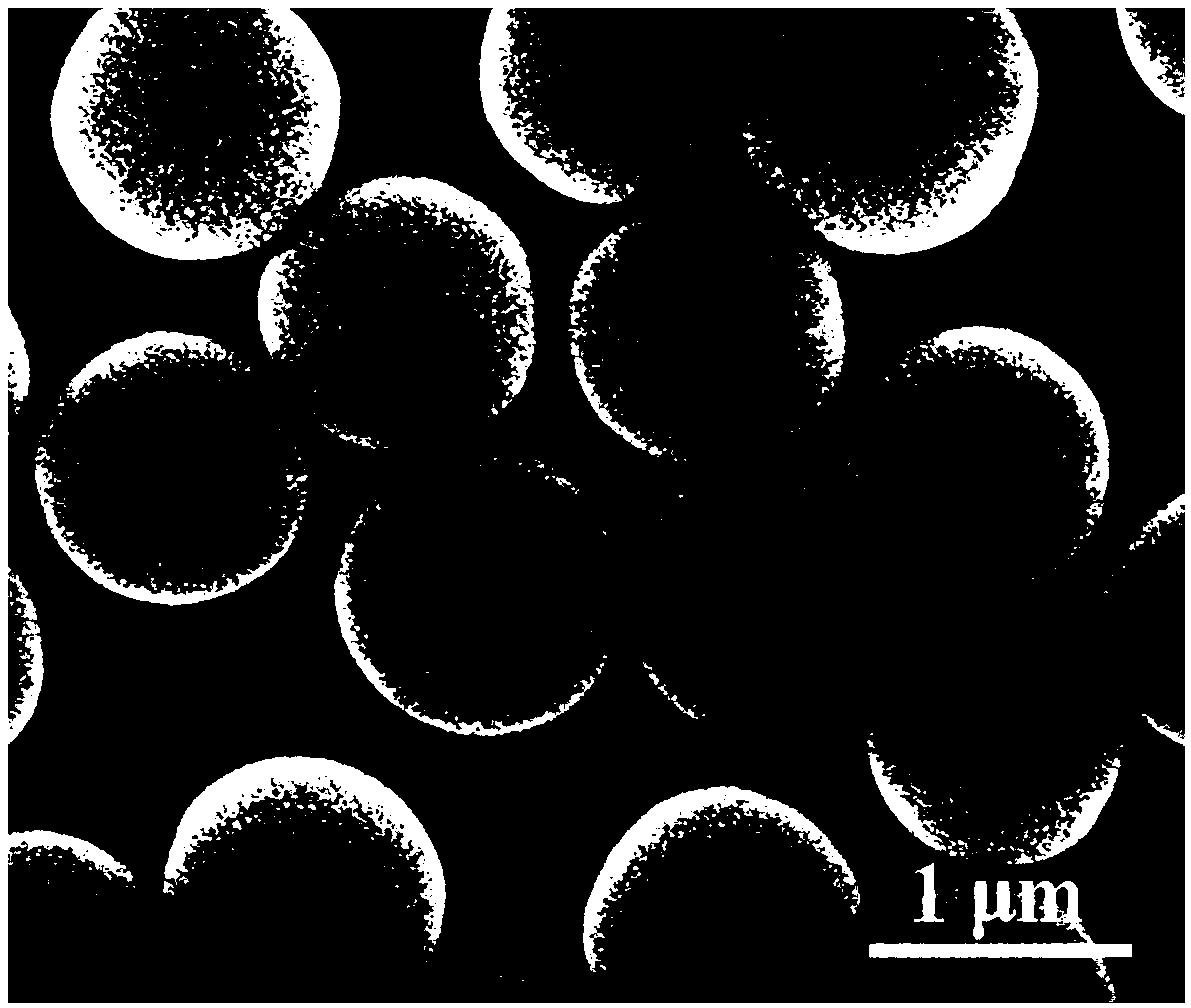

Preparation method of hollow ferric oxide cathode material in porous structure

InactiveCN107572595AEnsure consistencyRestrict growthCell electrodesSecondary cellsDispersityIron salts

The invention discloses a preparation method of a hollow iron oxide cathode material in a porous structure. The preparation method comprises the steps of weighing an organic ligand compound and iron salt at a mole ratio of 1:(1-10), adding a solvent, performing uniform stirring and dispersion, allowing a mass ratio of a solute to the solvent to be 1:(100-800), preparing a high polymer coordinationpolymer by a hydrothermal / solvothermal method under conditions of a pH (potential of hydrogen) value of 3-11, the temperature of 100-200 DEG C and reaction time of 10-72h, roasting the prepared polymer at a 200-800 DEG C oxygen-containing atmosphere, and obtaining the hollow iron oxide cathode material in a multilevel structure. A hollow ferric oxide particle in the porous structure is obtained by a hydrothermal / solvothermal - high-temperature burning two-step method; the method has the advantages that ferric ions are arrayed orderly in a long range in a lattice; an organic framework supporting the ferric ion can limit growth of the ferric oxide particle in a three-dimensional direction via aerobic burning; the obtained ferric oxide particle is good in particle size uniformity and dispersity; and the increase and improvement of a multiplying factor and cycle performance of a material are facilitated.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

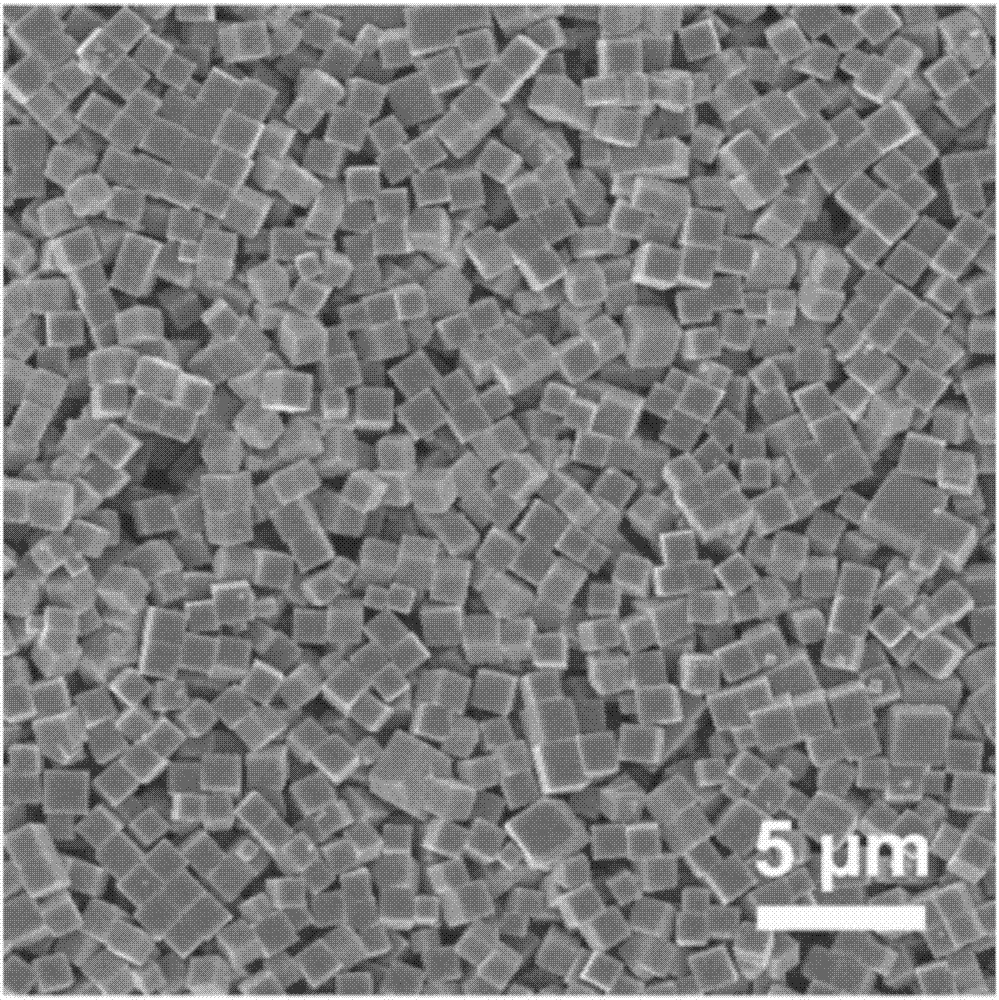

Micron-sized barium sulfate micro-sphere synthesis method

ActiveCN108529659APromote hydrolysisGood particle size uniformityCalcium/strontium/barium sulfatesChemical synthesisMicrometer

The invention discloses a micron-sized barium sulfate micro-sphere synthesis method, and belongs to the technical field of chemical synthesis. A micron-sized barium sulfate micro-sphere is synthesizedby a reaction system comprising S2O8<2-> soluble salt, Ba<2+> soluble salt and complexing agents, and the shape of the barium sulfate micro-sphere is regulated by changing the mole ratio of the Ba<2+> soluble salt and the complexing agents, complexing temperature and the addition amount of the S2O8<2-> soluble salt. The synthesis method is simple, efficient, environmentally friendly and free frompollution, the yield of the prepared micron-sized barium sulfate micro-sphere reaches 90% or more, the particle size of the prepared micron-sized barium sulfate micro-sphere is 0.8-3 micrometers, andgranularity uniformity is good.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Chitosan spherical honeycombed grain material, producing method and apparatus thereof

InactiveCN101401956BLarge specific surface areaEasy to moveImpression capsDentistry preparationsPolymer scienceTissue repair

The invention relates to a chitosan spherical porous particle material, and a method and a device for preparing the same. The method comprises the following steps: step one, preparing a chitosan acetic acid solution by using an acetic acid solution, wherein the mass concentration of the acetic acid solution is between 1 and 5 percent, and the mass of the chitosan is between 5 and 25 percent of the total mass of the chitosan acetic acid solution; step two, adding the solution into a material storage tank from a feed opening, and controlling the pressure in the material storage tank between 0.08 and 0.5 Mpa through a pressure meter and a pressure control valve, wherein the chitosan acetic acid solution uniformly flows out of the material storage tank at a speed of between 10 and 60 drops per minute, and then is dripped into a condensate with a temperature between 10 and 20 DEG C below zero in a thermal insulation container to be condensed, so that a collagen spherical porous particle material with good sphericity and uniform particle diameter is formed; and step three, separating, freezing, drying, crosslinking and cleaning the collagen spherical porous particle material to obtain the chitosan spherical porous particle material. The spherical particle material has homogeneous particle diameter distribution, contains a large number of micropores communicated with one another therein, has higher specific surface area, and can be applied to tissue repair and medicament slow release.

Owner:JIANGSU HAIJIAN +1

Tumor recovery type aquatic collagen peptide food

InactiveCN105982336AIntervention division cycleFacilitate the induction of apoptosisHydrolysed protein ingredientsVitamin food ingredientsAbnormal tissue growthLymphatic Spread

The invention relates to the field of medical food and discloses a tumor recovery type aquatic collagen peptide food. Every 100g of tumor recovery type aquatic collagen peptide food contains various nutritional ingredients, including 12.4-14.4g of tuna skin collagen peptide powder, 7-8g of shark skin collagen peptide powder, 3.5-4.5g of whey protein powder, 10-12g of MCT fat, 9-11g of LCT fat, 41-42g of carbohydrate, 2.4-2.6g of ganoderan, 2.4-2.6g of agaricus blazei murill polysaccharide, other vitamins and microelements. The tumor recovery type aquatic collagen peptide food is fit for tumor radiotherapy and chemotherapy patient, can intervene cell division cycle, is beneficial to inducing tumor cell apoptosis, can relieve the burden of visceral organ and enhance immunity of the organism, is fit for malnourished cancer patients including patients suffering from malignant diseases, anorexia, chewing dysphagia, and the like, can effectively relieve the side reaction appearing in the process of radiotherapy and chemotherapy and can effectively relieve the emesis symptom and reduce the tumor metastasis.

Owner:ZHEJIANG MARINE DEV RES INST

Grinding device for cement production

The invention discloses a grinding device for cement production. The grinding device comprises a smashing machine body; an abrasive disk is arranged at the bottom end in the smashing machine body, an upward opening is formed in the abrasive disk, and the abrasive disk is connected with a speed reducer which is arranged outside the smashing machine body; the speed reducer is connected with a motor, and a feeder is arranged on one side of the smashing machine body; a dryer for receiving materials in the feeder is arranged under the feeder, and the dryer stretches into the smashing machine body, is located above the abrasive disk, and is used for sending the materials into the abrasive disk; an intelligent powder choosing machine is arranged at the top end in the smashing machine body and right above the abrasive disk, and a fine powder outlet is formed in the intelligent power choosing machine. The grinding machine can enable larger particles in powder to continuously fall back into the abrasive disk to be smashed continuously, so that the final discharged cement powder has excellent fineness and is very good in particle uniformity. Thus, a cement using effect is remarkably improved, and the project quality of building engineering is guaranteed.

Owner:无锡得戟重工有限公司

Collagen spherical honeycombed grain material, producing method and apparatus thereof

InactiveCN101401971AGood particle size uniformityEasy to moveImpression capsDentistry preparationsFreeze drySolution flow

The invention relates to a collagen spherical porous granular material, a method and a device for preparing the same. The preparation method comprises the following steps: step one, collagen acetum solution is prepared by 1-5 mass percent acetum, wherein the mass of the collagen accounts for 3 to 15 percent of the total mass of the collagen acetum solution; step two, the solution is added to a storage tank from a charging hole, and uniformly flows out at a speed of 10-60 drops / minute under the condition that the pressure is controlled to between 0.08 and 0.5MPa, and the collagen acetum solution flowing out from a catheter is dripped into a condensed fluid for condensation so as to form the collagen spherical porous granular material with good sphericity and homogeneous grain diameter; and step three, the spherical grains are separated, undergo freeze drying and then cross-linking treatment for 3 to 24 hours, and then are washed by absolute ethyl alcohol, so as to obtain the collagen spherical porous granular material. The spherical granular material has the homogeneous particle size distribution, contains a large number of mutually communicated micropores, has high specific surface, and can be applied to tissue restoration and drug release.

Owner:JIANGSU HAIJIAN +1

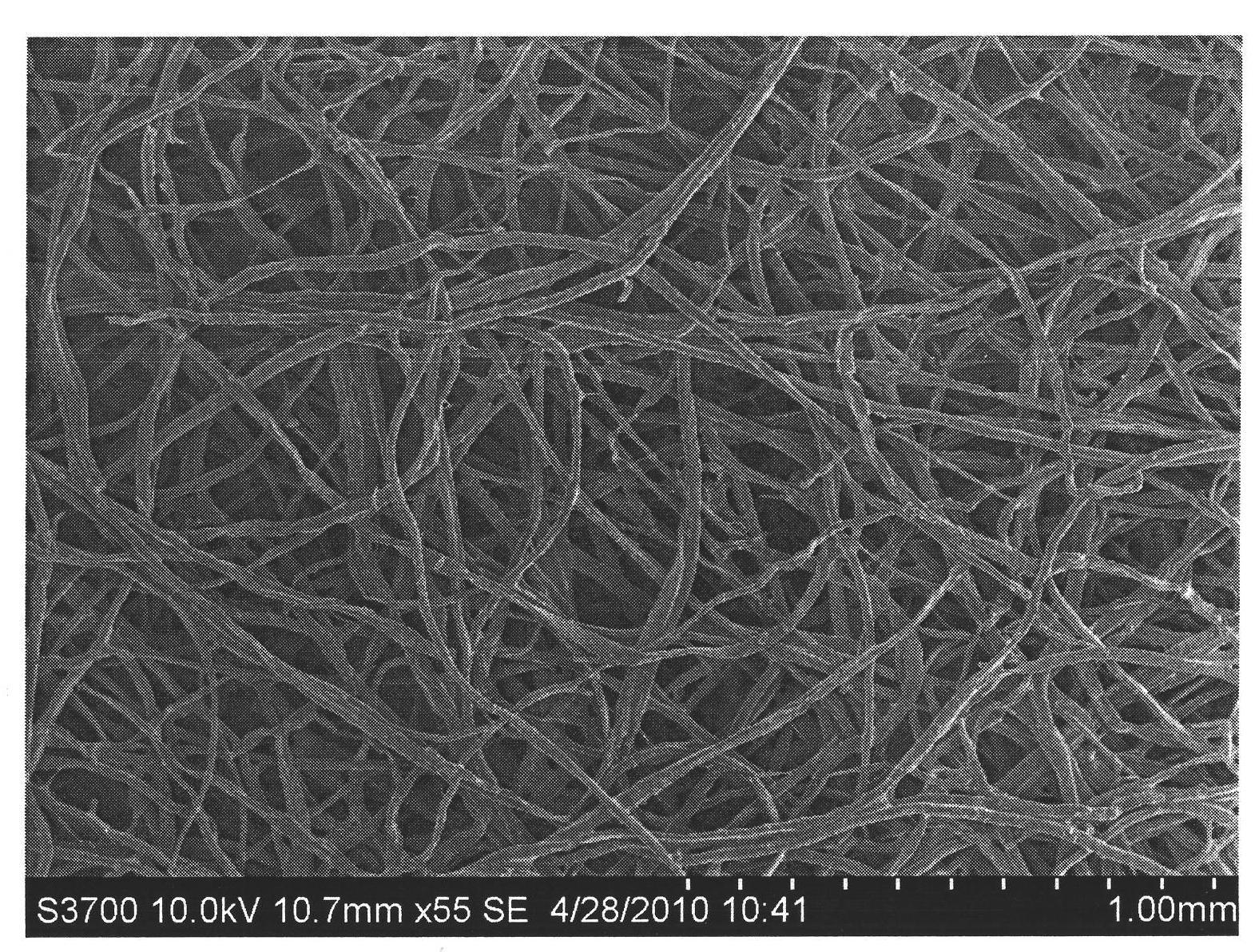

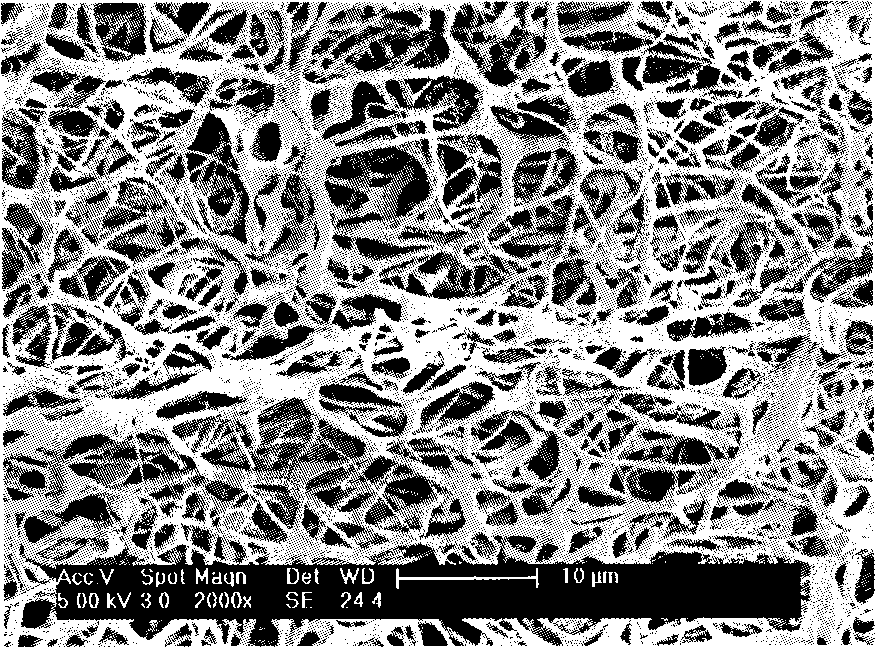

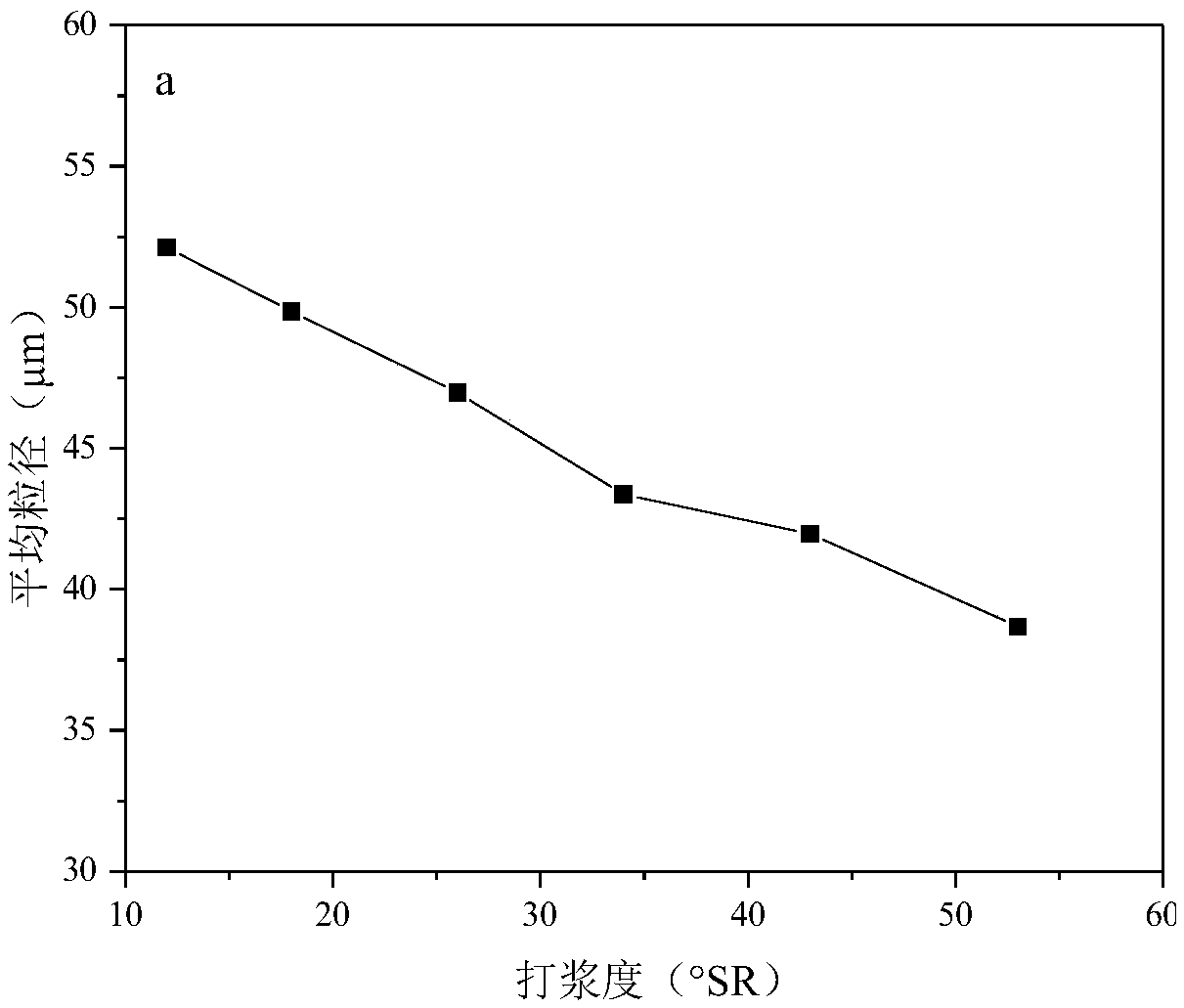

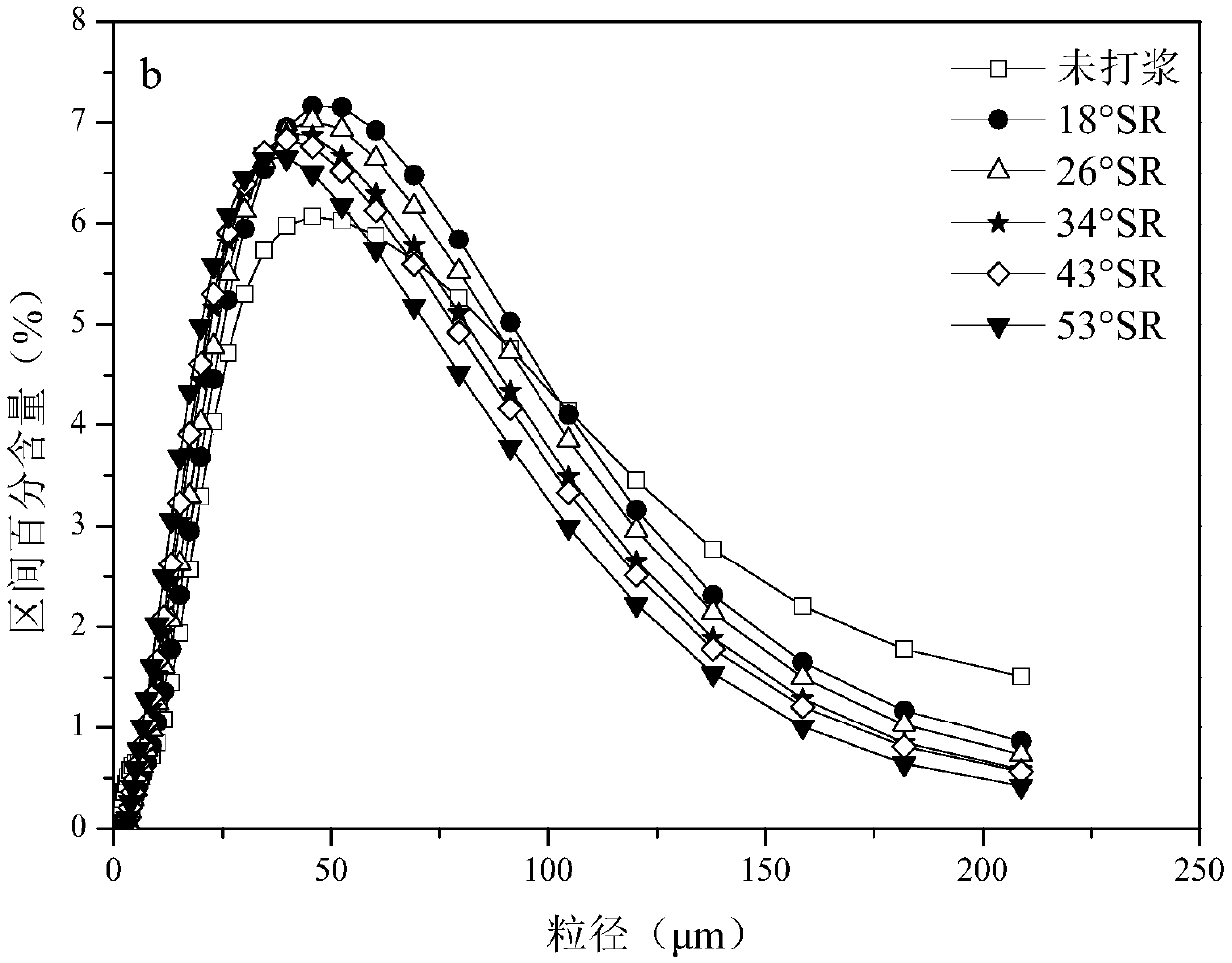

Method for preparing microcrystalline celluloses by acid hydrolysis after pretreatment through high shear machinery

The invention discloses a method for preparing microcrystalline celluloses by acid hydrolysis after pretreatment through high shear machinery. The method comprises the following steps: firstly, pulping and filtering wood dissolving pulp or refined cotton by high shear machinery to obtain pretreated pulp; mixing the pretreated slurry with acid liquor, and carrying out acid hydrolysis reaction to obtain an acid hydrolysis reaction product; finally, filtering the acid hydrolysis reaction product to obtain hydrolyzed celluloses; and washing the hydrolyzed celluloses to be neutral, and carrying outspray drying to obtain microcrystalline celluloses. According to the invention, the wood dissolving pulp or refined cotton is subjected to pulping pretreatment by the high shear machinery, the actingforce of the high shear machinery is used for cutting off fibers in the pretreatment process, so that the porosity and the specific surface area inside the fibers are increased, the accessibility ofacid liquor to the celluloses is improved, the penetration speed of the acid liquor into the celluloses is increased, the acid hydrolysis rate of the acid liquor to a cellulose amorphous region is increased, and the dosage of chemicals is reduced or the reaction time is shortened. The particle size of the microcrystalline cellulose product is regulated and controlled.

Owner:SHAANXI UNIV OF SCI & TECH

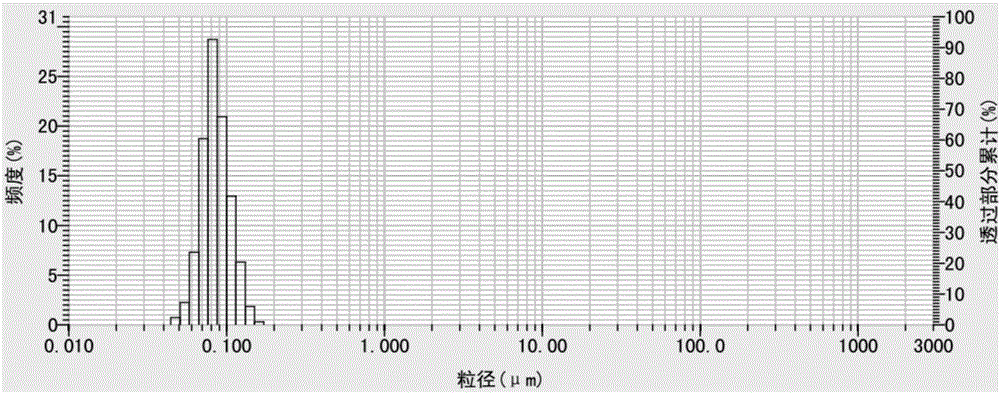

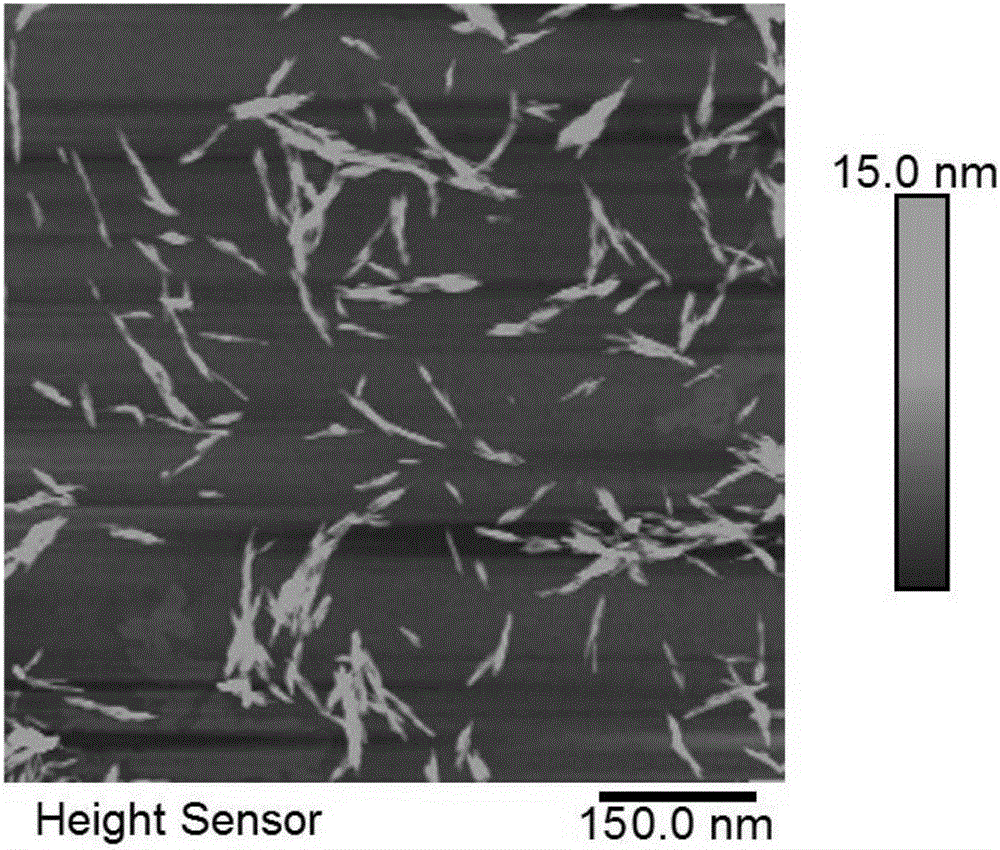

Preparation process of nanocrystal cellulose

The invention discloses a preparation process of nanocrystal cellulose and relates to the field of cellulose materials. The preparation process includes: adding mechanically-processed cellulose wood pulp into a hydrochloric acid solution to perform first-gradient hydrolysis reaction until polymerization degree is smaller than 350, filtering and cleaning, and draining; adding filter cakle into a sulfuric acid solution to perform second-gradient hydrolysis reaction until polymerization degree is smaller than 100, filtering and cleaning, and drying to obtain the nanocrystal cellulose. The preparation process has the advantages that the cellulose wood pulp is used as the raw material, the low-concentration hydrochloric acid solution is used to perform the first-gradient hydrolysis reaction before sulfuric acid hydrolysis, then the sulfuric acid solution is used to perform second-gradient hydrolysis reaction, the prepared nanocrystal cellulose is small in particle size and concentrated in particle size distribution, and the purity and yield of the nanocrystal cellulose are increased greatly.

Owner:SHENZHEN YOUPUHUI PHARM CO LTD

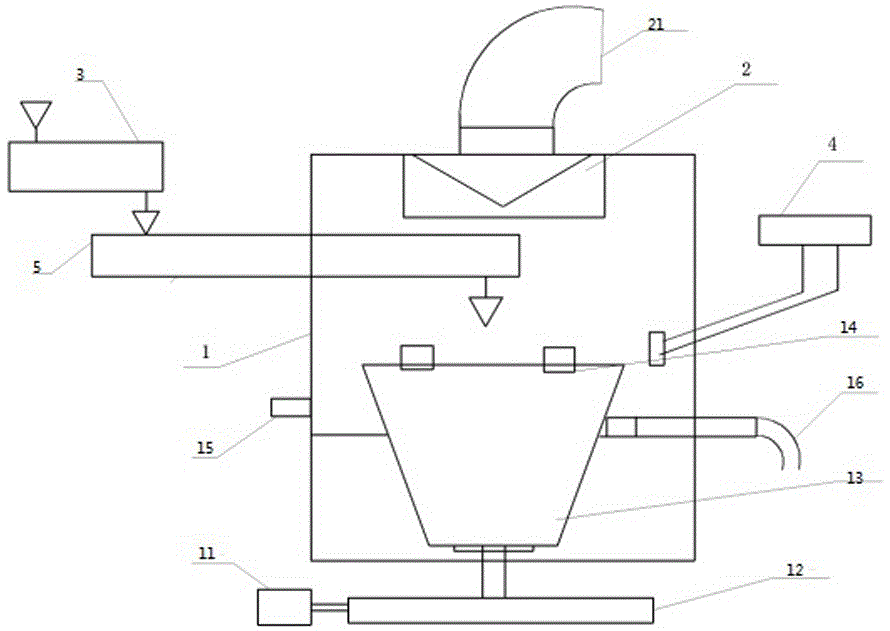

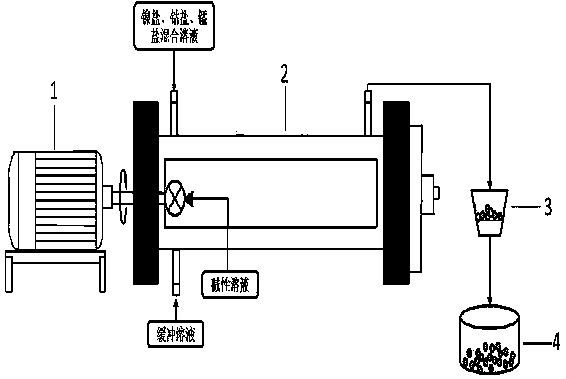

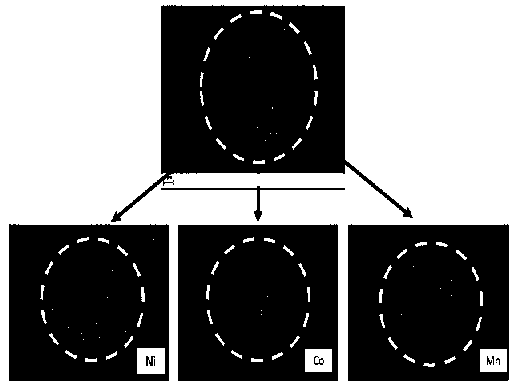

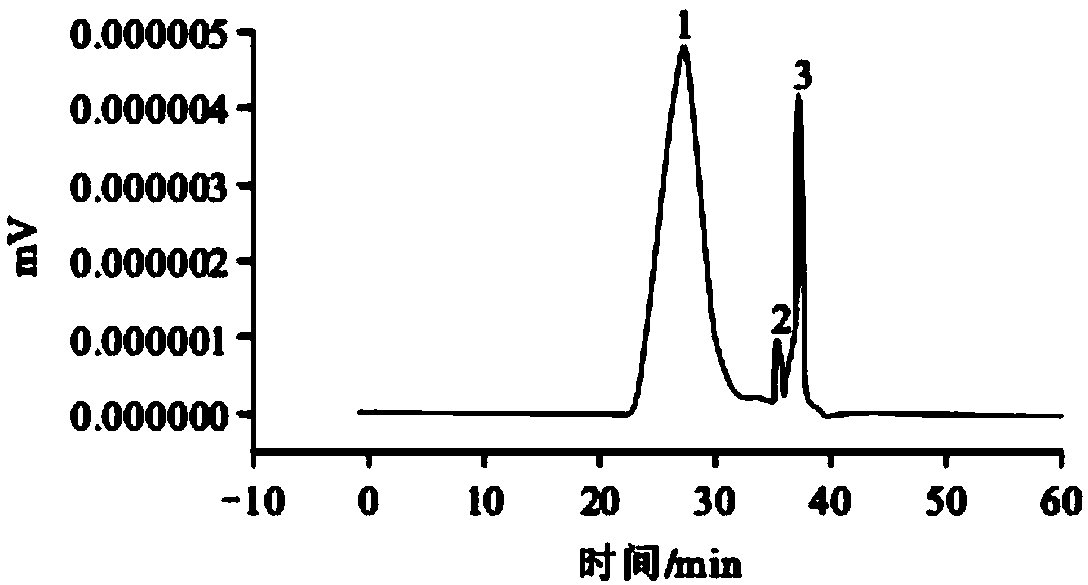

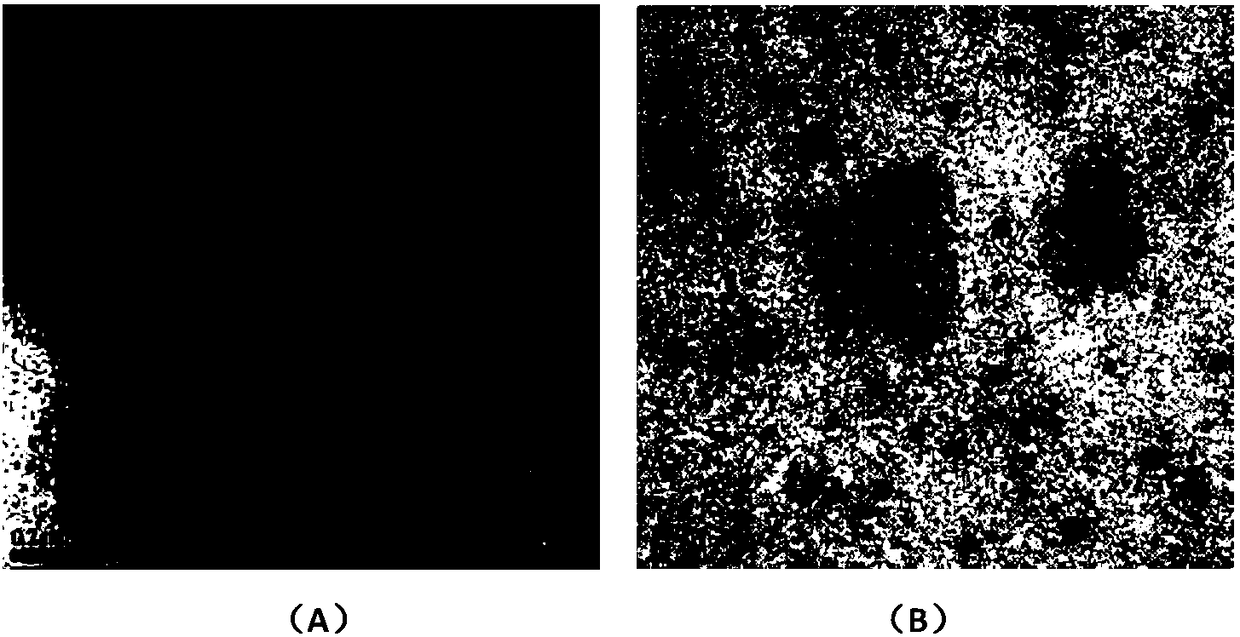

Method for continuously and quickly preparing high-nickel nickel-cobalt-manganese ternary material precursor

The invention belongs to the field of a positive electrode material of a lithium ion battery, and particularly relates to a method for continuously and quickly preparing a high-nickel nickel-cobalt-manganese ternary material precursor. According to the method for continuously and quickly preparing the high-nickel nickel-cobalt-manganese ternary material precursor, the ternary material precursor is(Ni<x>Co<y>Mn<z>)O<2>, wherein x+y+z is equal to 1; x is greater than or equal to 0.5; y is less than or equal to 0.4; and z is less than or equal to 0.4. According to the method, based on a Taylor vortex flow principle in the production method, the reactants are reacted fully to accelerate a crystallization reaction, thereby quickly preparing the spherical nickel-cobalt-manganese ternary material precursor; in addition, the precursor is controllable in granular size, high in granular size uniformity and high in product tap density; and the high-nickel ternary material can be continuously andquickly prepared by adopting a Taylor vortex crystallizer, so that the characteristics of simple preparation process, easy realization of industrialization and the like are achieved.

Owner:陈训财

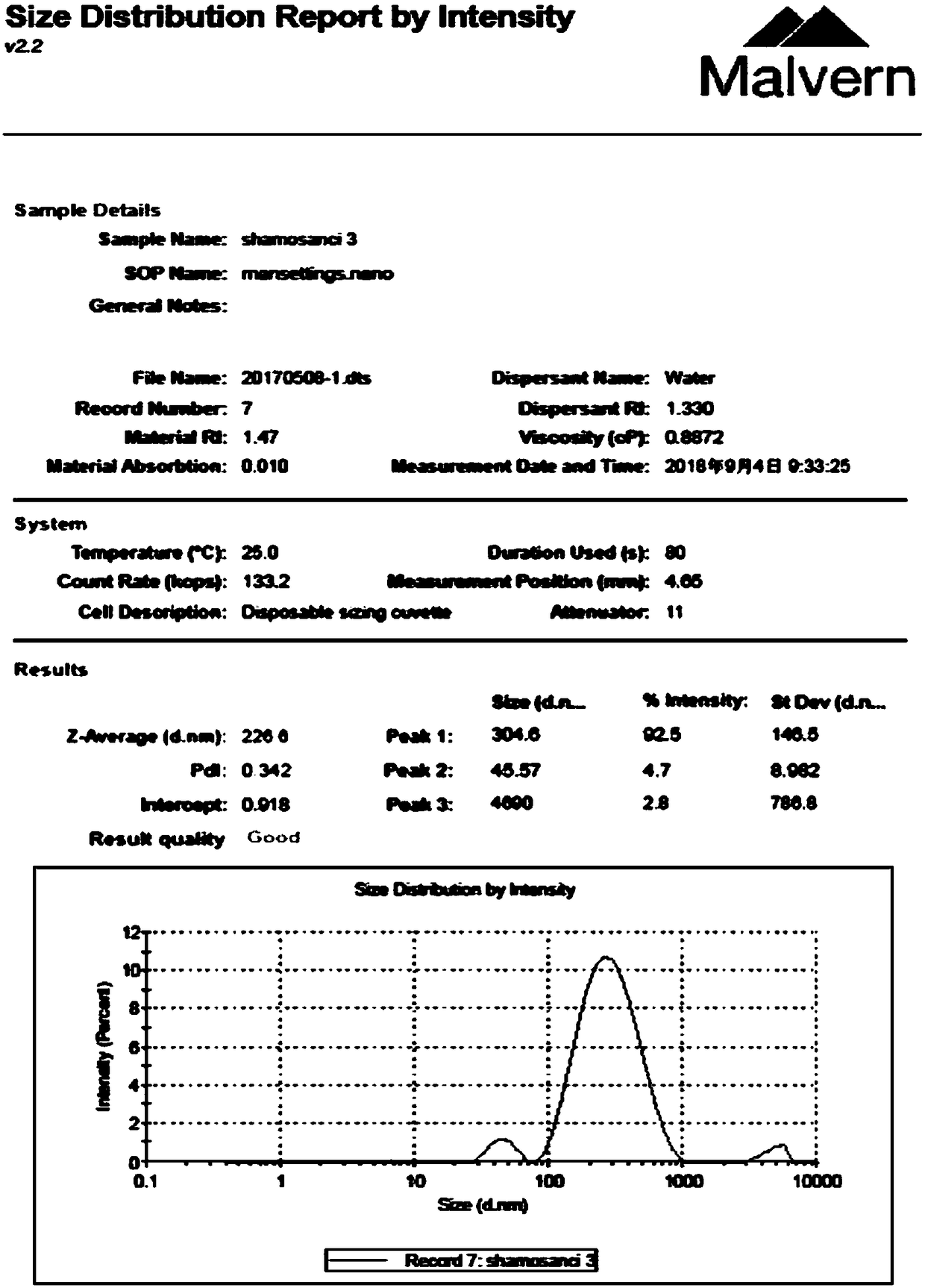

A compound immune adjuvant and its preparation method and application

ActiveCN106798920BDiureticHigh puritySsRNA viruses positive-senseViral antigen ingredientsMedicineGinkgo biloba

The invention discloses a complex immunity adjuvant. The adjuvant is prepared from the following components in percentage by weight: 1.5 to 3.5 percent of horttuyia cordala thunb polysaccharide, 0.2 to 0.55 percent of alanine, 0.8 to 2.2 percent of ginkgo leaf flavonoid, 5 to 8 percent of polyethylene castor oil, 5 to 8 percent of Span 80, 2.5 to 5 percent of polyethylene glycol, 6 to 10 percent of squalene, 30 to 35 percent of soybean oil for injection and 35 to 50 percent of water for injection, and the sum of the percentage by weight of the various components is 100 percent. The complex immunity adjuvant is safe and effective, can effectively enhance the immunostimulation capacity of PRRSV vaccines, and is suitable for immunoprophylaxis of porcine reproductive and respiratory syndrome (PRRS).

Owner:北京康宝利华生物科技有限公司

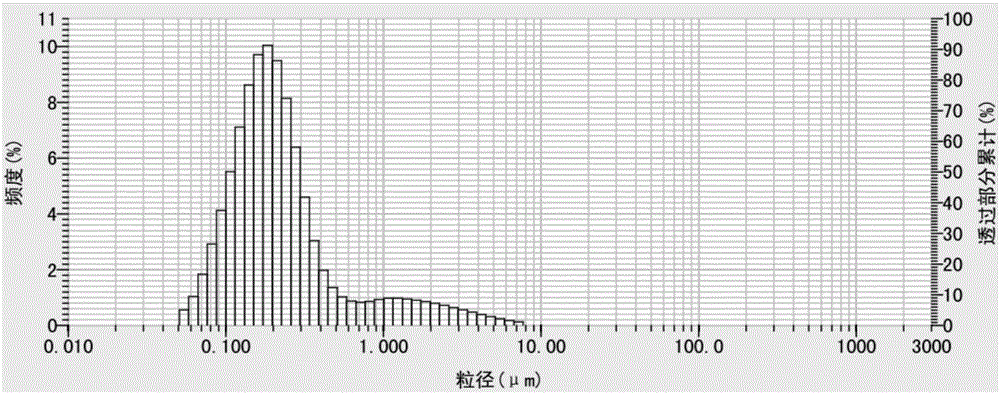

Preparation method and application of micro-nano cellulose

ActiveCN109208366AStrong oxidation abilityImprove dehydration abilityPaper material treatmentFiberCellulose

The invention discloses a preparation method and application of micro nano cellulose. The preparation method comprises the steps of: hydrolyzing plant fiber by a hydrolyzing agent to obtain the micronano cellulose; wherein the hydrolyzing agent is composed of (meth)sulfonic acid, sulfuric acid and water. The preparation method is thorough in reaction, and the prepared micro nano cellulose has good particle size uniformity, and the method can be applied in industrial production of the micro-nano cellulose.

Owner:刘永红 +2

Complex immunity adjuvant, and preparation method and application thereof

ActiveCN106798920ADiureticHigh puritySsRNA viruses positive-senseViral antigen ingredientsAdjuvantGinkgo biloba

The invention discloses a complex immunity adjuvant. The adjuvant is prepared from the following components in percentage by weight: 1.5 to 3.5 percent of horttuyia cordala thunb polysaccharide, 0.2 to 0.55 percent of alanine, 0.8 to 2.2 percent of ginkgo leaf flavonoid, 5 to 8 percent of polyethylene castor oil, 5 to 8 percent of Span 80, 2.5 to 5 percent of polyethylene glycol, 6 to 10 percent of squalene, 30 to 35 percent of soybean oil for injection and 35 to 50 percent of water for injection, and the sum of the percentage by weight of the various components is 100 percent. The complex immunity adjuvant is safe and effective, can effectively enhance the immunostimulation capacity of PRRSV vaccines, and is suitable for immunoprophylaxis of porcine reproductive and respiratory syndrome (PRRS).

Owner:北京康宝利华生物科技有限公司

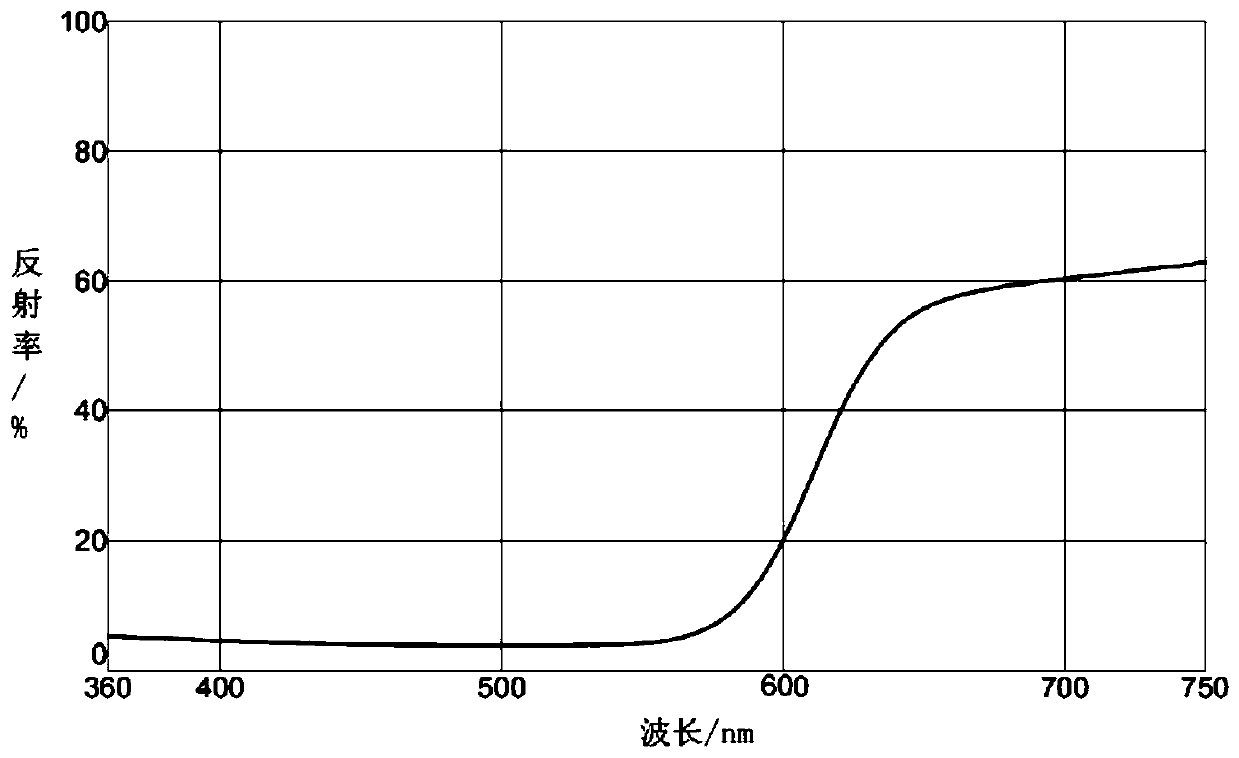

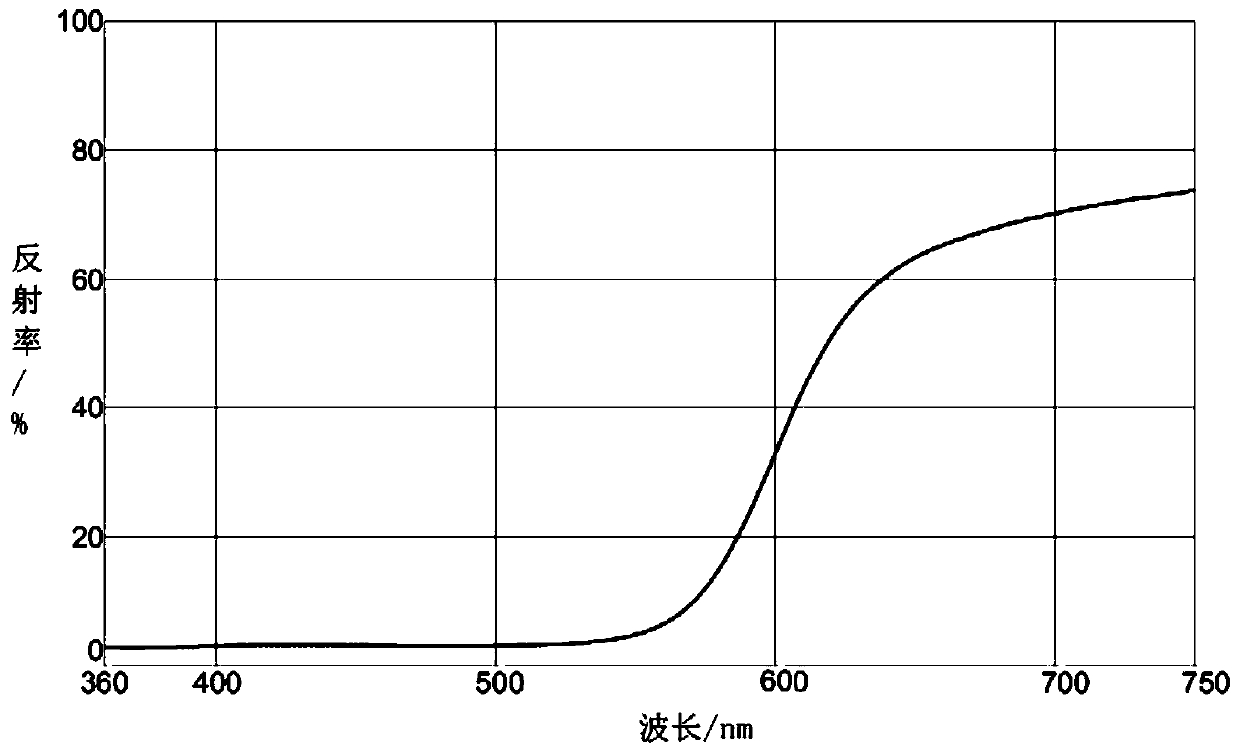

Rare earth sulfide and/or rare earth sulfur oxide colorant and preparation method thereof

InactiveCN110591414AImprove temperature resistanceGood weather resistanceInorganic pigment treatmentSolid carbonZinc compounds

The invention relates to a rare earth sulfide and / or rare earth sulfur oxide colorant and a preparation method thereof. A rare earth compound, sulfur, an alkali metal compound, solid carbon and an auxiliary agent are used as raw materials, an initial product of the rare earth sulfide and / or rare earth sulfur oxide colorant is obtained by roasting, water is added to the initial product, then an alkaline compound is added to adjust pH, a treated colorant solid is obtained, an alcohol-water mixed solution is added to the treated colorant solid, then ammonia, PVP, a zinc compound, ethyl orthosilicate and sodium silicate are added for treatment, and washing and drying are carried out to obtain the rare earth sulfide and / or rare earth sulfur oxide colorant. The preparation method has mild reaction conditions, simple operation, low cost, and high production efficiency. The rare earth sulfide and / or rare earth sulfur oxide colorant prepared by the method has stable product performance, high saturation, stable chromaticity, and good particle size uniformity.

Owner:包头中科世纪科技有限责任公司

Preparation method of silicon dioxide microspheres

The invention discloses a preparation method of silicon dioxide microspheres, which comprises the following steps: adding polymer seeds into an alcoholic solution containing a stabilizer and a catalyst to form a uniformly dispersed seed suspension; adding a silicon dioxide precursor into the alcoholic solution, and stirring the mixture to form a precursor solution; dispersing the precursor solution into the seed suspension in a liquid droplet manner through a nozzle; allowing the seeds to absorb the liquid droplets and grow and polymerize to obtain silicon dioxide composite microspheres; and further calcining the silicon dioxide composite microspheres to obtain the porous silicon dioxide microspheres. The porous silicon dioxide microsphere prepared by the method is uniform and controllablein particle size, and has potential application in the fields of biology and catalysts.

Owner:无锡迈科为生物科技有限公司

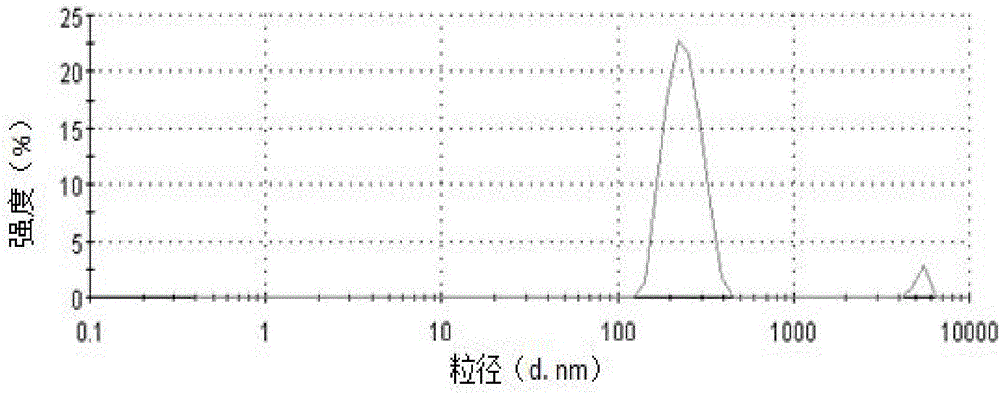

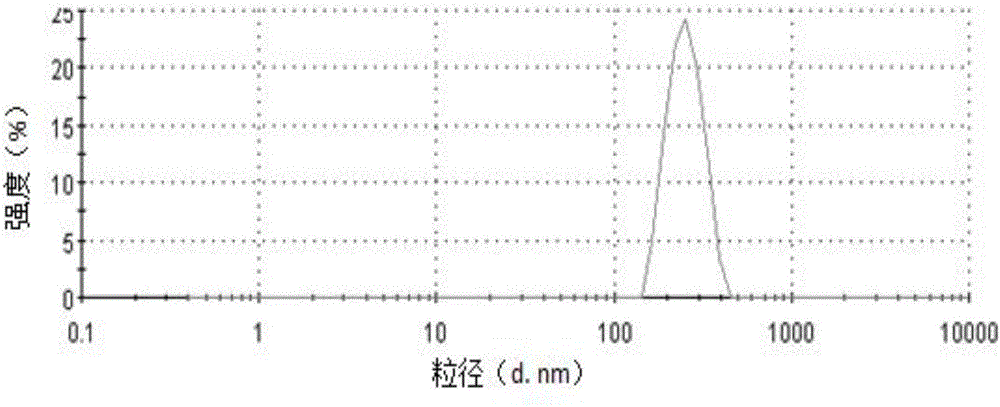

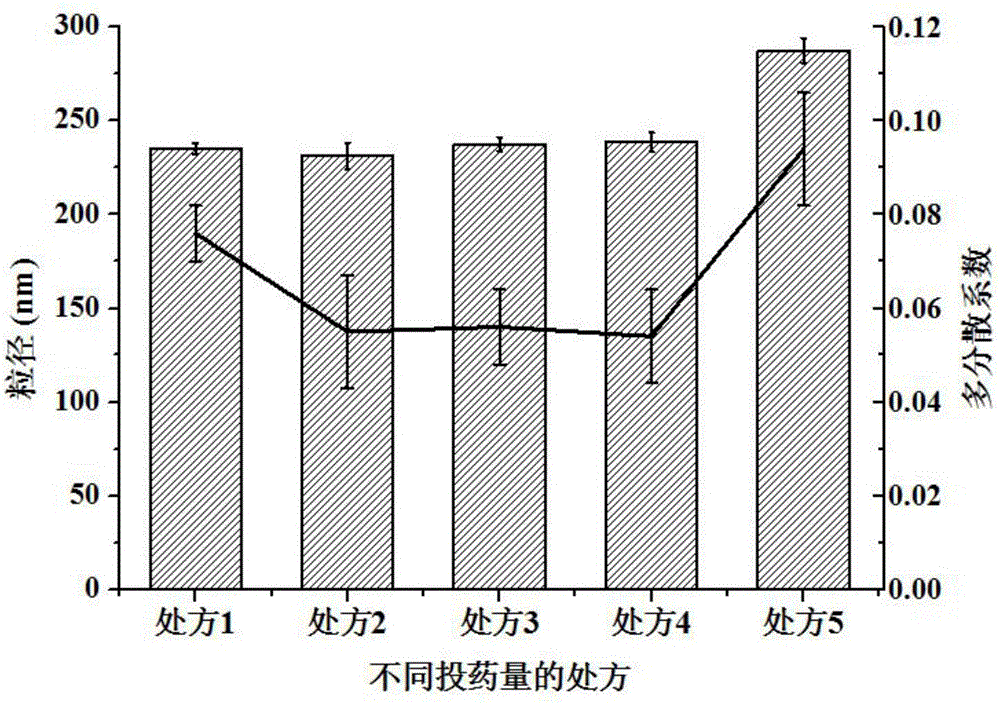

Ibuprofen cubic liquid crystal precursor solution, cubic liquid crystal nanoparticles and preparation method of cubic liquid crystal nanoparticles

InactiveCN106692057AOvercoming dissolution barriersImprove adhesionOrganic active ingredientsAntipyreticSolubilityFatty acid glycerol esters

The invention relates to an ibuprofen cubic liquid crystal precursor solution, cubic liquid crystal nanoparticles and a preparation method of the cubic liquid crystal nanoparticles. The ibuprofen cubic liquid crystal precursor solution is mainly prepared from ibuprofen, a liquid crystal material and a stabilizer, wherein a mass ratio of the ibuprofen to the liquid crystal material to the stabilizer is (0.01-2.5):(10):(0.5-2.5); the liquid crystal material is phytantriol; and the stabilizer is selected from at least one of fatty glyceride, polyol type nonionic surfactants, polyoxyethylene type nonionic surfactants, poloxamer and lecithin. The ibuprofen cubic liquid crystal precursor solution is prepared into ibuprofen cubic liquid crystal nanoparticles used for oral administration, and the defects such as low solubility and short half-life in vivo in the oral administration process of ibuprofen can be overcome, so that the bioavailability of oral administration of ibuprofen can be obviously improved.

Owner:GUANGZHOU ZHONGDA NANSHA TECH INNOVATION IND PARK +1

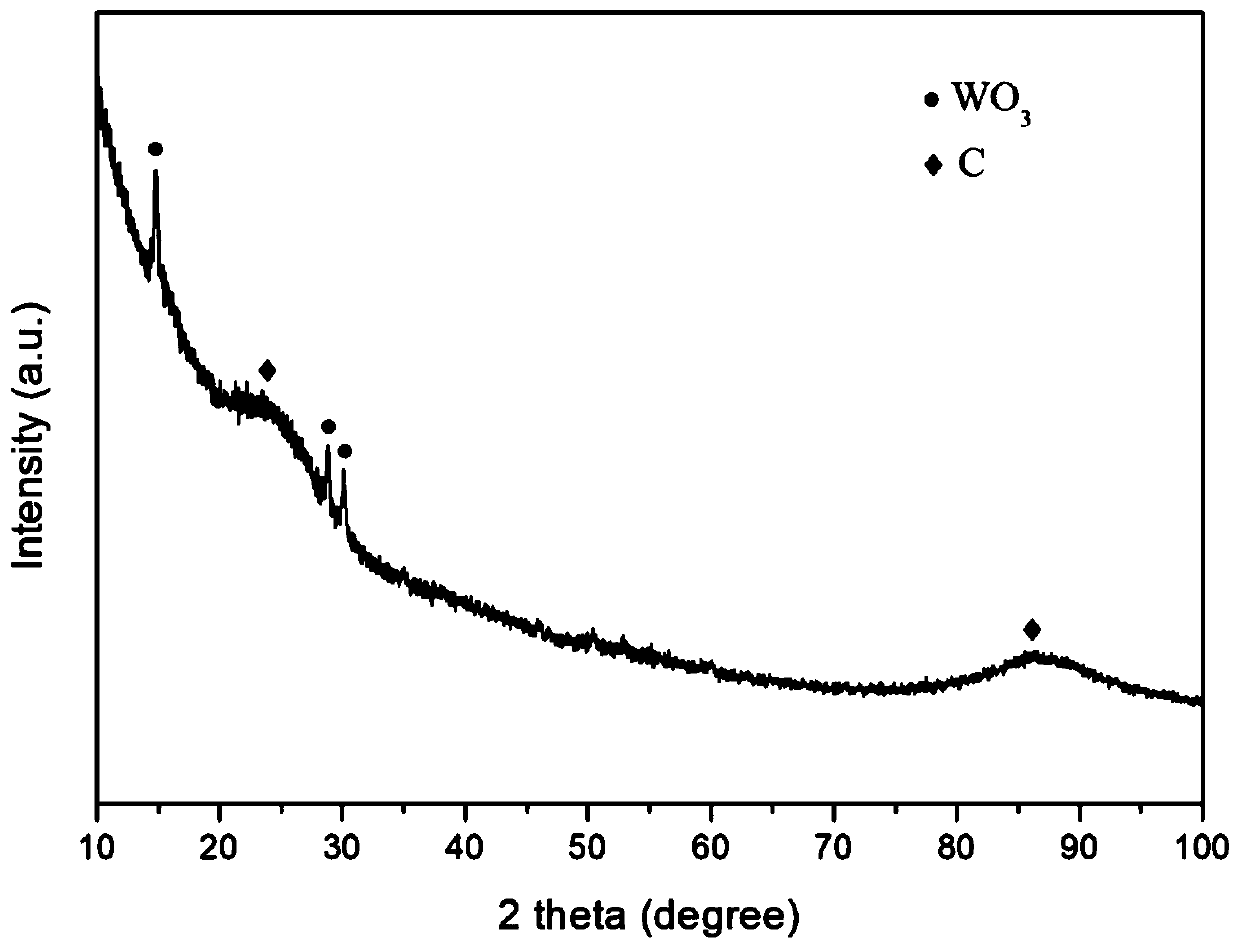

Method for preparing carbon-film-coated tungsten oxide nanospheres in one step by using hydrothermal process and application of carbon-film-coated tungsten oxide nanospheres

ActiveCN110563043ADetection application prospect is goodObvious Detection Application ProspectsTungsten oxides/hydroxidesCarbon preparation/purificationCarbon filmTungstate

The invention relates to a method for preparing carbon-film-coated tungsten oxide nanospheres in one step by using a hydrothermal process and application of the carbon-film-coated tungsten oxide nanospheres. The method comprises the following steps: respectively acquiring tungstate and a carbon source according to a mass ratio of 1: 0.5 to 1: 5, adding the tungstate and the carbon source into deionized water, and carrying out sufficient dissolving to obtain a mixed solution; putting the mixed solution into a reaction kettle, and performing natural cooling after a hydrothermal reaction to obtain a reacted turbid liquid; and cleaning and centrifuging the reacted turbid liquid with deionized water and ethanol, and performing vacuum drying to obtain the carbon-film-coated tungsten oxide nanospheres. The invention also provides a glucose detection sensor electrode prepared from the carbon-film-coated tungsten oxide nanospheres. Compared with the prior art, the preparation method disclosed by the invention has the advantages of simple process, safety, reliability and the like, and the formed detection electrode has the characteristics of high sensitivity, strong anti-interference performance, capability of monitoring blood glucose of a human body in a measurement range and the like.

Owner:SHANGHAI JIAO TONG UNIV

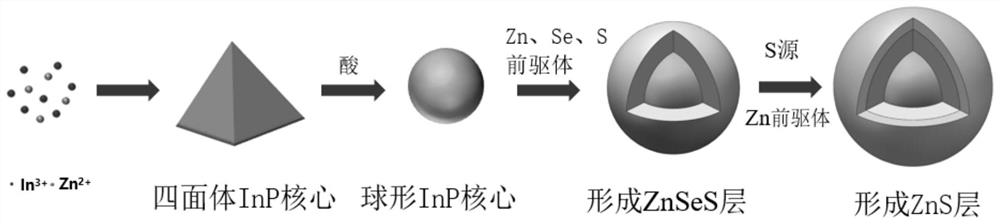

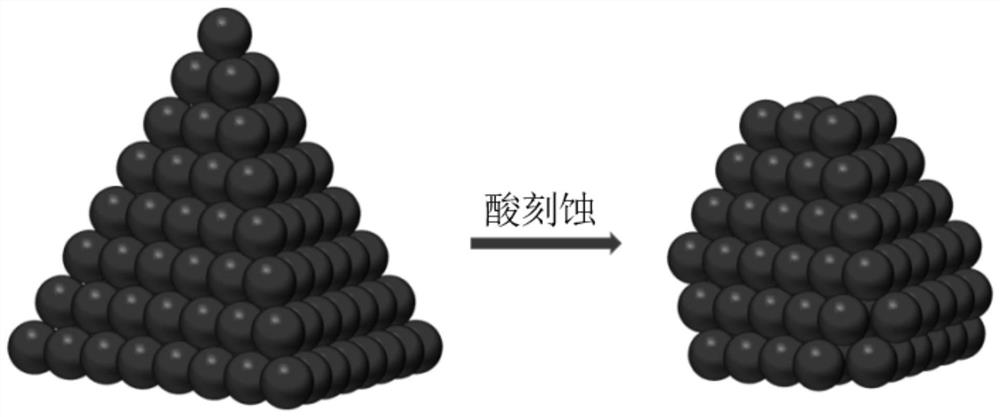

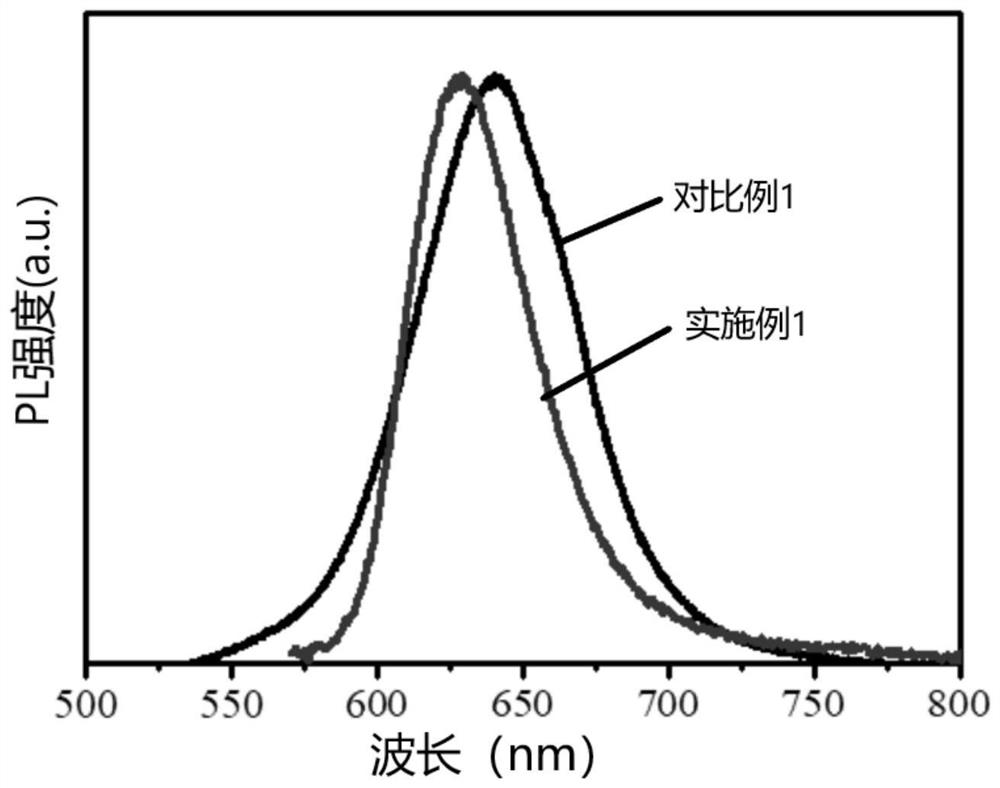

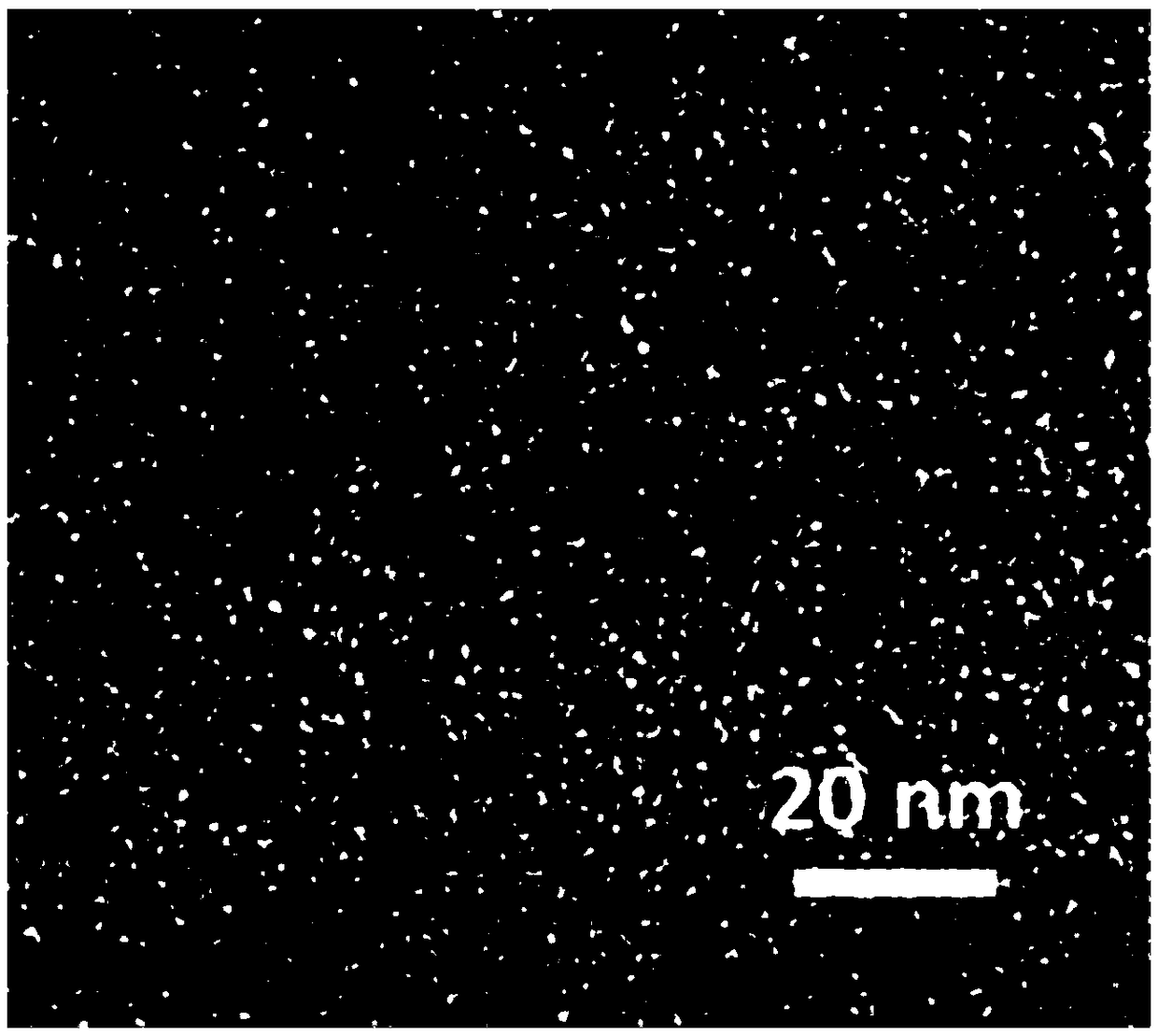

Quantum dot and preparation method and application thereof

PendingCN113105884AHigh particle size uniformityRemoval of oxide defectsLuminescent compositionsQuantum dotMaterials science

The invention provides a quantum dot and a preparation method and application thereof. The quantum dot comprises an InP quantum dot core, a ZnSeS layer coating the surface of the InP quantum dot core and a ZnS layer coating the surface of the ZnSeS layer, wherein the InP quantum dot core is obtained through acid etching. The quantum dot is obtained through acid etching, oxide defects on the surface of the quantum dot can be removed, the quantum dot can be etched into a sphere-like structure, the particle size uniformity of the quantum dot is improved, and the InP quantum dot high in quantum efficiency and narrow in half-peak width is obtained.

Owner:SHENZHEN PLANCK INNOVATION TECH CO LTD

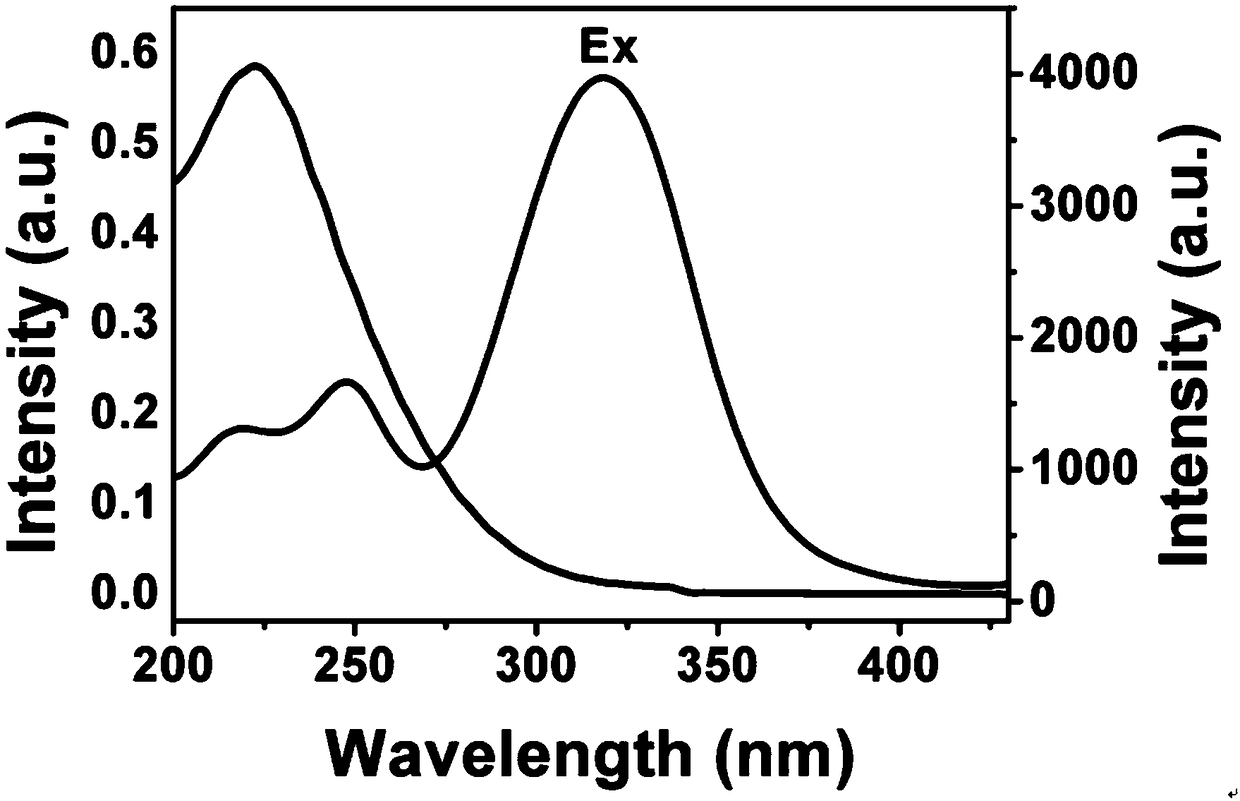

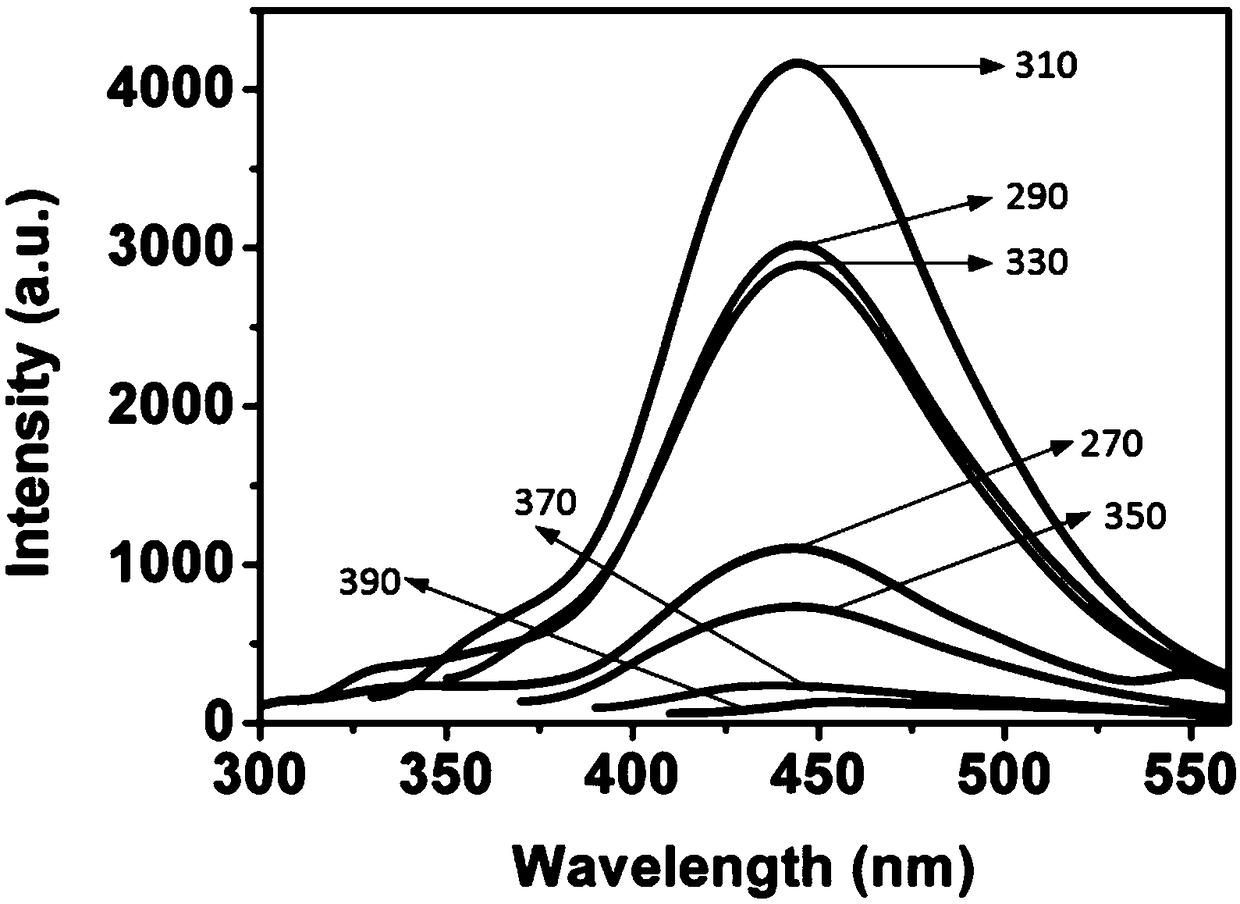

Fluorescent carbon quantum dot and preparation method and application thereof

ActiveCN108865132AExcellent optical propertiesHigh fluorescence quantum yieldMaterial nanotechnologyNanoopticsQuantum yieldIn vivo

The invention discloses a fluorescent carbon quantum dot. The fluorescent carbon quantum dot is a nitrogen and phosphor-doped carbon quantum dot; a carbon source of the fluorescent carbon quantum dotis naphthalenedicarboxylic acid; the fluorescent carbon quantum dot has high yield rate of fluorescent quantum, can enter the microorganism to specially mark after the microorganism is deactivated, and the death and living of the microorganism can be effectively distinguished. The invention also discloses a preparation method of the fluorescent carbon quantum dot. The preparation method has the advantages that the raw materials are easy to obtain, and the preparation method is suitable for preparing the fluorescent carbon quantum dot with high yield rate of quantum. The invention discloses application of the fluorescent carbon quantum dot in activity detection of microorganisms and biomedical imaging; the fluorescent carbon quantum dot is used for effectively distinguishing the death and living of the microorganisms, so as to detect the activity of the microorganism at high efficiency; the cell toxicity of the fluorescent carbon quantum dot is low, and the fluorescent carbon quantum dot is suitable for in-vitro or in-vivo biomedical imaging detection.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Method for preparing VO2 composite film with optical limiting performance

ActiveCN108950492AImprove laser protection performanceLow laser transmittanceVacuum evaporation coatingSputtering coatingOptical limitingSurface plasmon polariton

The invention belongs to the technical field of functional films, and particularly relates to a method for preparing a VO2 composite film applying to the laser protection technology. A uniform-particle-size size-adjustable Au / SiO2 or Ag / SiO2 nanostructure layer is prepared on the surface of the VO2 film based on a surface plasmon resonance technique, and therefore the laser protection performanceof the film is effectively improved. Compared with a conventional pure VO2 laser protection film, the VO2 composite film is lower in laser transmittance and higher in laser damage threshold. The process can effectively improve the responsiveness of the film to lasers and the laser radiation resistance of the film. The preparation process of the film is simple and controllable, and expensive equipment is not required. Meanwhile, special requirements for the size and shape of the VO2 film are not available. A novel technology with high efficiency, short cycle and industrial implementation is provided for the VO2-based laser protection film.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for preparing quaternary ammonium salt surface-modified monodisperse polystyrene microsphere emulsion

The invention relates to a method for preparing a quaternary ammonium salt surface-modified monodisperse polystyrene microsphere emulsion. The quaternary ammonium salt surface-modified monodisperse polystyrene microsphere emulsion is prepared by introducing a hydrophilic functional monomer and changing the feeding ratio of styrene to water, so as to achieve effective control on the monodisperse polystyrene microsphere. The method comprises the following steps: by taking styrene as a main monomer, dimethyl diallyl ammonium chloride as a functional monomer, methyl methacrylate as a third monomer, potassium peroxodisulfate or ammonium persulfate as an initiator and water as a reaction medium, preparing the polystyrene microsphere with quaternary ammonium salt gathered on the surface by adopting a soap-free emulsion polymerization method in a semi-continuous manner. No surfactant, organic solvent or inorganic salt is added in the preparation process; the method is simple in preparation technology and low in cost; the particle size of the obtained quaternary ammonium salt surface-modified monodisperse polystyrene microsphere can be flexibly controlled between 150nm and 600nm by regulating the dosage ratio of the initiator to the three monomers.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com