Method for preparing polymer fluorescent microsphere

A fluorescent microsphere and polymer technology, applied in the field of polymer fluorescent microsphere preparation, can solve the problems of difficult to obtain microspheres with highly uniform particle size and difficult to control the particle size of fluorescent microspheres, and achieve stable microsphere structure and use of raw materials The effect of small amount and high uniformity of particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the accompanying drawings and examples. However, the invention is not limited to the examples given.

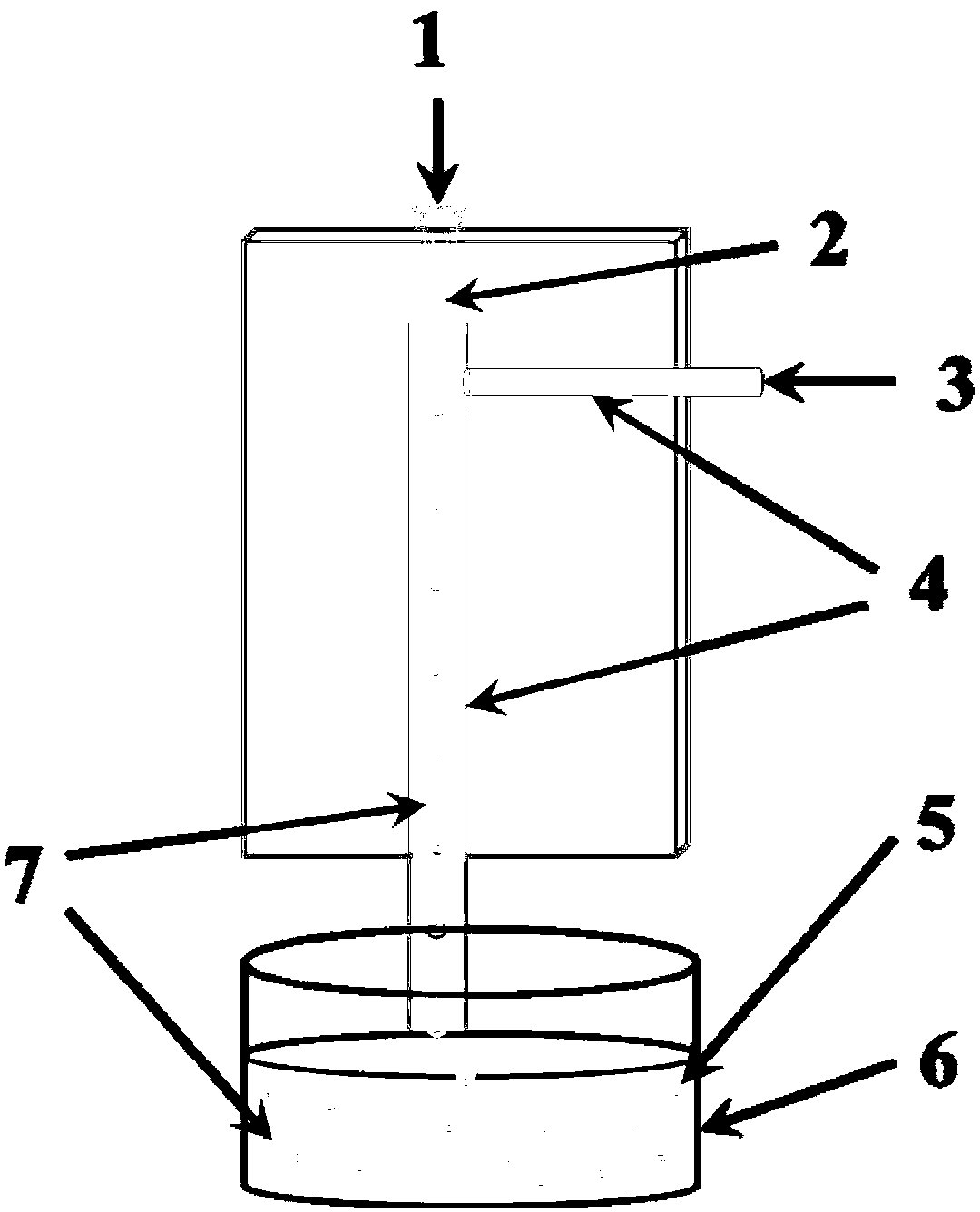

[0029] This embodiment uses a T-tube microfluidic device: insert one end of a polytetrafluoroethylene capillary tube with a length of 5 cm and an inner diameter of 1 mm into one end of a polydimethylsiloxane pipe with an inner diameter of 2 mm and a length of 10 cm to form a T-shaped channel . The other end of the polytetrafluoroethylene capillary was used as the inlet of the continuous phase, one end of the polydimethylsiloxane tube was inserted into a 27G needle as the inlet of the discontinuous phase, and the other end was used as the outlet of the polymer fluorescent microspheres. Use a watch glass filled with the continuous phase solution as a receiving device for fluorescent microspheres, and place it below the outlet end of the polydimethylsiloxane pipeline (such as figure 1 show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com