Chitosan nano-microspheres product and preparation method thereof

A chitosan and nano-micro technology, applied in the direction of making medicines into special physical or ingestible devices, pharmaceutical formulas, medical preparations of non-active ingredients, etc., can solve the problem of uneven and uncontrollable nutrient and cell density , high emulsification pressure, etc., to achieve good drug activity retention, high drug embedding rate, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

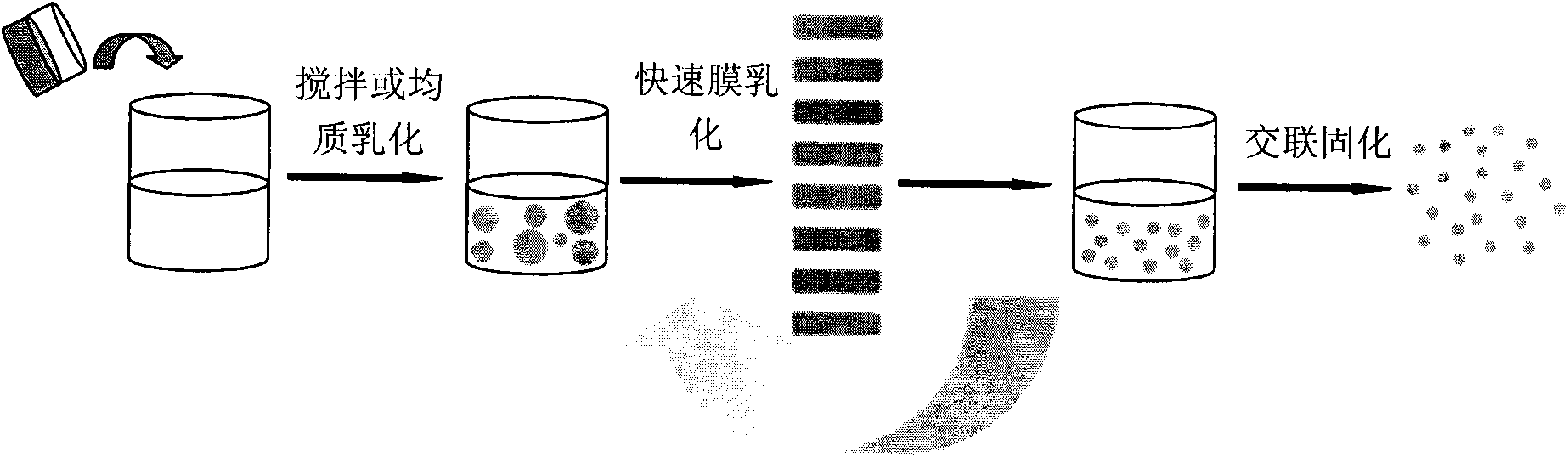

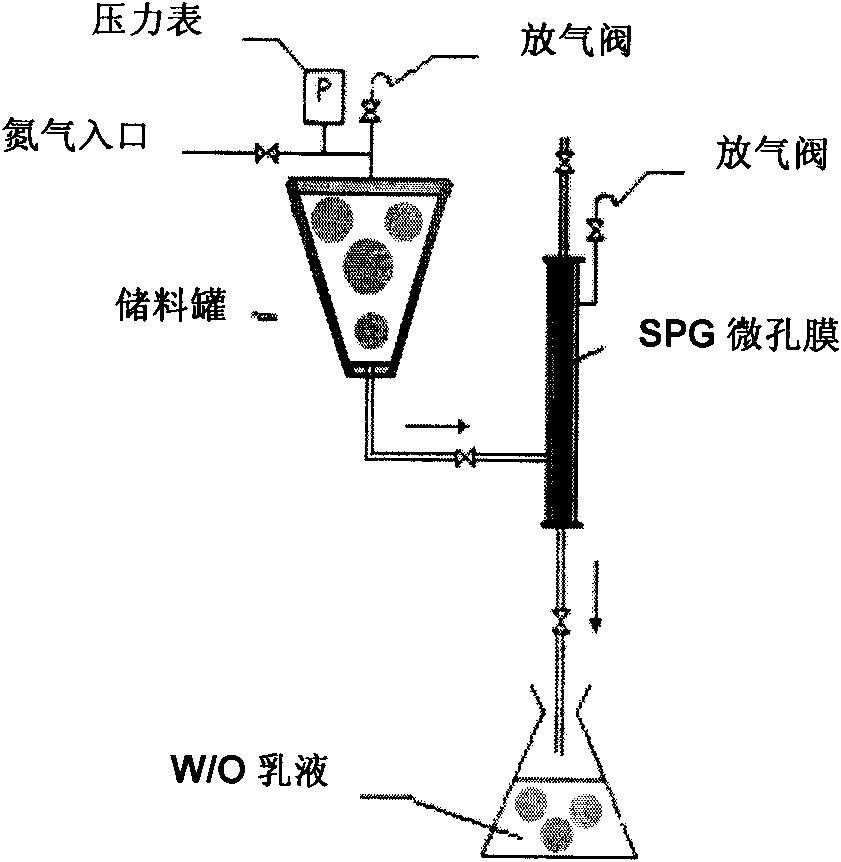

[0070] In some embodiments, the preparation method of the present invention includes the following steps: dissolving a certain amount of chitosan in 1% aqueous acetic acid solution, and the resulting solution is used as the water phase; taking a certain amount of oil-soluble emulsifier and dissolving The compatible organic phase is used as the oil phase; after the water phase and the oil phase are mixed rapidly, the W / O type pre-emulsion is prepared by homogeneous emulsification or mechanical stirring; the pre-emulsion is quickly pressed through the passed or untreated The W / O emulsion with uniform particle size can be obtained from the hydrophobically treated glass microporous membrane; in order to make the particle size more uniform, the emulsion obtained each time can be used as a pre-emulsion, which is repeatedly pressed out through the membrane pores under higher pressure; A certain amount of cross-linking agent or precipitating agent is added to the emulsion, or the emuls...

Embodiment 1

[0093] Soak the hydrophilic SPG glass membrane with a pore size of 1.4 microns in a mixed oil phase of liquid paraffin and petroleum ether at a volume ratio of 5:7 overnight or ultrasonically for half an hour to fully wet the membrane pores. Accurately take a certain amount of chitosan and dissolve it in 1% acetic acid aqueous solution, make it fully dissolve under magnetic stirring to obtain chitosan acetic acid aqueous solution, its concentration is 0.5wt%, this solution is centrifugally removed insoluble impurity under 2000rpm, retains The supernatant was used as the aqueous phase for later use. Add the oil-soluble emulsifier PO-500 into 60 ml of a mixture of liquid paraffin and petroleum ether (5:7 by volume) at a concentration of 4 wt%, and stir until completely dissolved as an oil phase. The above-mentioned chitosan acetic acid aqueous solution of 2ml is mixed with oil phase and is emulsified for 1 minute under third gear (6000rpm) with homogeneous emulsifier, forms pre-...

Embodiment 2

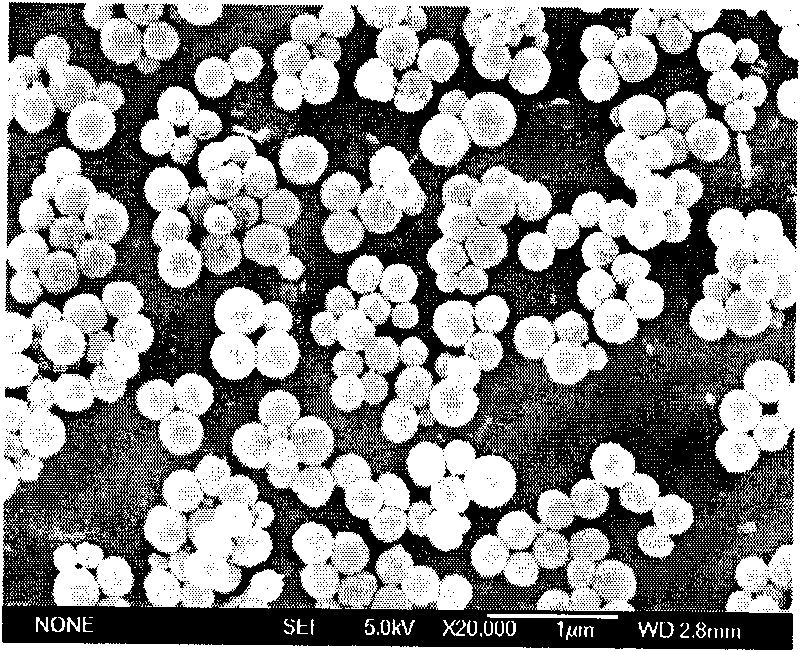

[0102] Chitosan nano-microspheres are prepared using the same device and method as in Example 1, wherein the difference is that the SPG membrane with a pore size of 1.4 microns is treated through hydrophobic treatment, and the cross-linking and curing reaction of emulsion droplets is carried out under heating conditions. Be 45 ℃, the average particle diameter of gained chitosan nano-microsphere is 350.0 nanometers, and C.V. is 14.18%, and the scanning electron micrograph of gained microsphere is as follows Figure 8 As shown, the results showed that the prepared chitosan microspheres were relatively uniform in particle size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com