Preparation method of silicon dioxide microspheres

A technology of silica and microspheres, which is applied in the direction of silica and silicon oxide, can solve the problems of difficult control of particle size and wide particle size distribution of microspheres, and achieve uniformity of particle size and controllability of particle size High, easily absorbed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention provides a method for preparing silica microspheres. The method for preparing silica composite microspheres includes:

[0033] Adding polymer seeds to an alcoholic solution containing stabilizers and catalysts to form a homogeneously dispersed seed suspension;

[0034] Adding the silicon dioxide precursor to the alcohol solution and stirring to form a precursor solution;

[0035] The precursor solution is dispersed into the seed suspension in the form of droplets through the nozzle;

[0036] Heating and reacting to obtain silica composite microspheres after separation.

[0037] Further, the silica composite microspheres are calcined at a preset temperature to form porous silica microspheres. The preset temperature is 500-800°C. After the polymer seeds in the silica composite microspheres are decomposed, porous silica microspheres can be produced.

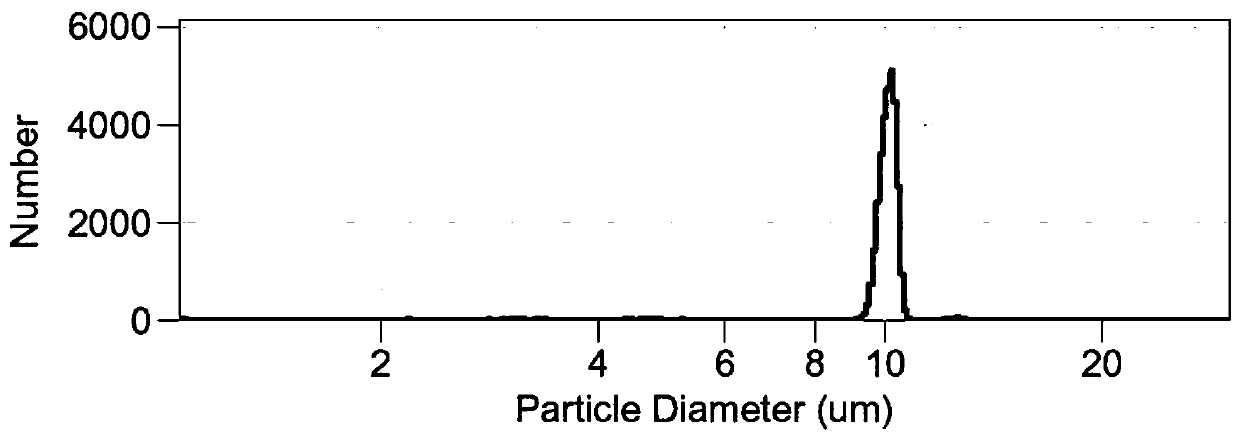

[0038] The porous silica microspheres obtained in the embodiment of the present...

Embodiment 1

[0057] Prepare the seed suspension in the first container: 62 g of styrene-divinylbenzene seeds (its particle size is 2 μm, CV=3%) prepared by emulsion polymerization are added to a tank containing 1.5 g of hydroxymethylcellulose and 300 g of ammonia In the ethanol solution, the ethanol solution is an aqueous ethanol solution with a volume fraction of 75%, and the content of the ethanol solution is 150 g, and a uniformly dispersed seed suspension is formed after uniform stirring.

[0058] The precursor solution was prepared in the second container, wherein a nozzle was installed on the second container, and the hole diameter of the nozzle was 20 μm. Specifically, 165 g of ethyl orthosilicate was added to 200 g of ethanol solution, and stirred evenly to form a precursor solution.

[0059] Apply a preset pressure of 0.35MPa to the second container, maintain a temperature environment of 35°C, disperse the precursor solution into the seed suspension within 10 minutes in the form o...

Embodiment 2

[0063] Preparation of seed suspension in a first container: 620 g of styrene-divinylbenzene seeds (4.6 microns in particle size, CV=3%) prepared by emulsion polymerization were added to a container containing 9.5 g of hydroxymethylcellulose and 3000 g of ammonia In the ethanol solution, the ethanol solution is an aqueous ethanol solution with a volume fraction of 75%, and the content of the ethanol solution is 1450 g, and a uniformly dispersed seed suspension is formed after uniform stirring.

[0064] The precursor solution was prepared in the second container, wherein a nozzle was installed on the second container, and the hole diameter of the nozzle was 50 μm. Specifically, 1590 g of ethyl orthosilicate was added into 1100 g of ethanol solution, and stirred evenly to form a precursor solution.

[0065] Apply a preset pressure of 1.35MPa to the second container, maintain a temperature environment of 45°C, disperse the precursor solution into the seed suspension within 15 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com