Nanoparticles used for biological detection with fluoride lutecium as main component

A nanoparticle and biological detection technology, applied in material excitation analysis, fluorescence/phosphorescence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

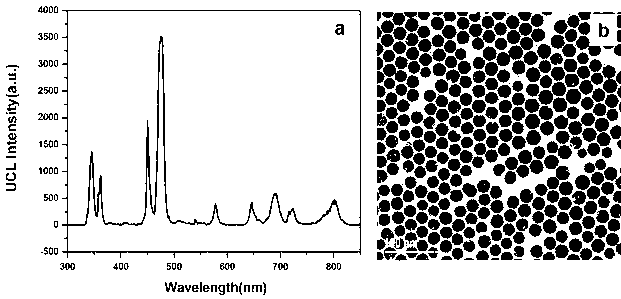

[0069] Example 1: NaXF 4 (X=79mol%Lu, 20mol%Yb, 1mol%Tm) Preparation of mixed nanoparticles

[0070] Salt mixed in proportion (CF 3 COO) 3X (X=79mol%Lu, 20mol%Yb, 1mol%Tm) totals 2 mmol, add 4 mmol of sodium trifluoroacetate, disperse in 20ml oleylamine, heat up to 110°C to remove water for 1 hour, then heat up to 340°C, Keep the temperature for 2 hours, then cool to room temperature, add 30 ml of cyclohexane, disperse with KQ-500DB ultrasonic generator at 80% power for 5 minutes, then centrifuge at 14000r / min for 10 minutes, discard the liquid part, and wash the precipitated solid with cyclohexane Wash 3 times (10 ml each time). The washed solid was vacuum dried at room temperature for 12 hours to obtain NaXF 4 (X=79mol%Lu, 20mol%Yb, 1mol%Tm) mixed nanoparticles. identified, such as figure 1 As shown in b, the particle size of the nanoparticle is about 20nm, and the particle size is basically uniform, indicating that practical nanoscale particles have been prepar...

Embodiment 2

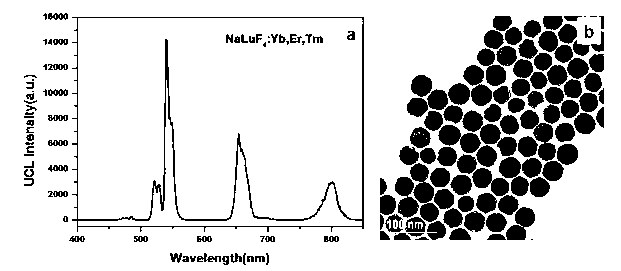

[0073] Example 2: LiXF 4 (X=88mol%Lu, 10mol%Yb, 1.6mol%Er, 0.4mol%Tm) Preparation of mixed nanoparticles

[0074] Rare earth chloride salt XCl mixed in proportion 3 (X=88mol%Lu, 10mol%Yb, 1.6mol%Er, 0.4mol%Tm) total 1mmol, dispersed in the mixed solution of 10mL oleic acid and 10mL octadecene, heated to 160°C to form a uniform solution, cooled to room temperature, add 10 mL of NH containing 2 mmol LiOH and 4 mmol 4 The methanol solution of F was stirred for 30 min, heated to 100 °C to remove methanol for 1 h, then heated to 300 °C under the protection of Ar gas for 1 h, cooled to room temperature, added 25 ml of toluene, centrifuged at 12000 rpm for 8 min, discarded the liquid part, and used Disperse and wash with toluene and centrifuge 3 times (suspend the precipitate with 10 ml of toluene each time, then centrifuge at 12000 rpm for 5 min, discard the liquid part), and dry the precipitated solid in vacuum at room temperature for 24 hours to obtain LiXF 4 (X = 88mol...

Embodiment 3

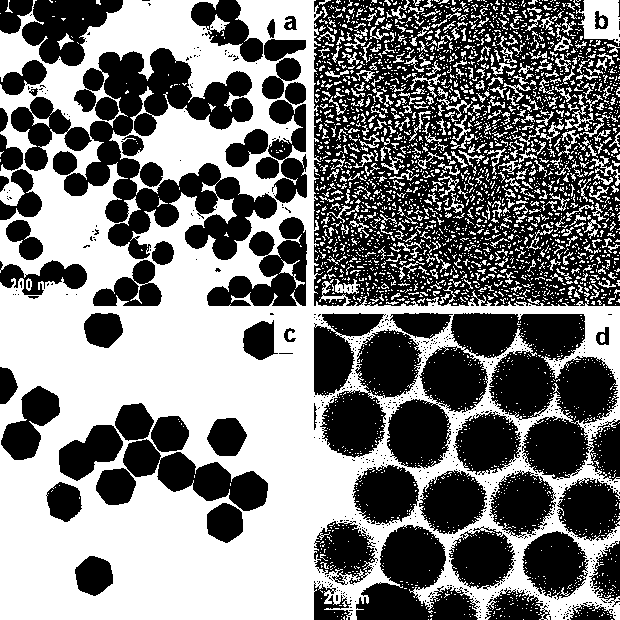

[0077] Example 3: KXF 4 (X=65mol%Lu, 30mol%Yb, 5%molDy) Preparation of mixed nanoparticles

[0078] Mix 1.2g KOH, 9ml water, 10ml ethanol and 20ml oleic acid together, stir to obtain a homogeneous solution, add 1.2ml total 0.5mol / L rare earth chloride XCl mixed in proportion to this solution 3 (X=65mol%Lu, 30mol%Yb, 5mol%Dy) aqueous solution, stirred for 5min, then added 4ml NaF (1.0M) aqueous solution, stirred for 10min. The mixed solution was transferred to a 50ml hydrothermal kettle, and hydrothermally treated at 160°C for 16h. After natural cooling, add 20 ml of n-hexane to dissolve the precipitate, add 20 ml of ethanol to precipitate the precipitate and collect it by centrifugation, wash the precipitate with n-hexane 3 times (10 ml each time), and dry the precipitate in vacuum at -30°C for 10 hours to obtain KXF 4 (X = 65mol% Lu, 30mol% Yb, 5% mol Dy) mixed nanoparticles. identified, such as image 3 As shown in a, the particle size of the nanoparticle is abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com