Rare earth sulfide and/or rare earth sulfur oxide colorant and preparation method thereof

A technology of rare earth sulfur oxides and rare earth sulfides, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of many impurities, unstable color of cerium sulfide, and uneven particle size, and achieve The effect of good particle size uniformity, stable color and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

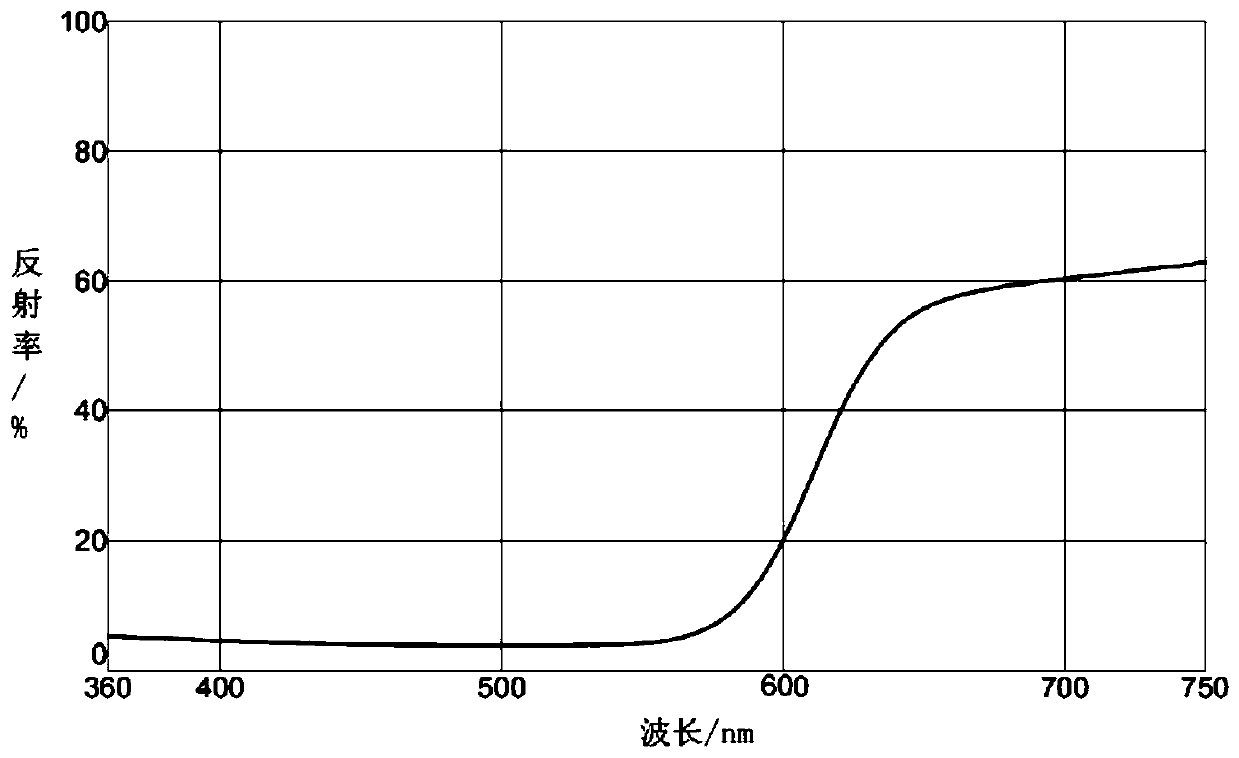

[0053] The present embodiment provides a kind of method of producing red cerium sulfide coloring agent, comprises the steps:

[0054] (1) Take 0.05mol of cerium carbonate, 0.25mol of sulfur, 0.004mol of sodium carbonate, 0.5mol of solid carbon (activated carbon) and 0.01mol of alumina respectively, fully mix them uniformly, and carry out roasting reaction at 800° C. for 20 hours to obtain cerium sulfide colorant. primary product;

[0055] (2) Add 5 times the quality of water to the initial product of the cerium sulfide colorant, then add sodium hydroxide to adjust the pH value to 8, and fully stir for 0.5h before solid-liquid separation to obtain the treated colorant solid;

[0056] (3) Add ethanol and water to the coloring agent solid after described treatment according to the mixed solution of mass ratio 20:1 composition, then add ammoniacal liquor, pvp, zinc chloride, tetraethyl orthosilicate and sodium silicate successively, so The add-on of ammonia water accounts for 5% ...

Embodiment 2

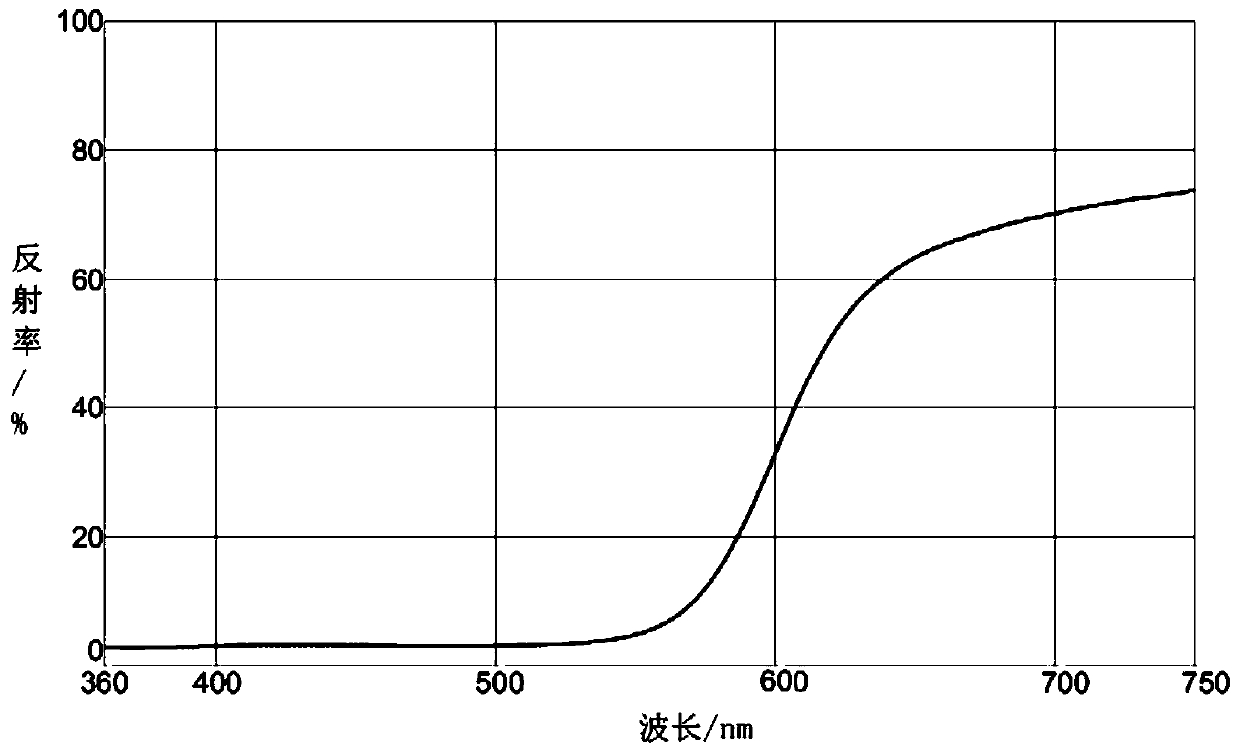

[0065] The present embodiment provides a kind of method of producing yellow samarium sulfide and samarium oxysulfide mixed coloring agent, comprises the steps:

[0066] (1) Take 0.05mol of samarium carbonate, 0.07mol of sulfur, 0.0035mol of sodium carbonate, 0.3mol of solid carbon and 0.00025mol of sodium borate, mix well, and roast at 1300°C for 1 hour to obtain mixed coloring of samarium sulfide and samarium oxysulfide The initial product of the agent;

[0067] (2) Add 20 times the quality of water to the initial product of the samarium sulfide and samarium oxysulfide coloring agent, then add potassium hydroxide to adjust the pH value to 12, fully stir for 6 hours, and then separate the solid from the liquid to obtain the treated colorant solid ;

[0068] (3) Add ethanol and water to the coloring agent solid after described treatment according to the mixed solution of mass ratio 1:1 composition, add ammoniacal liquor, pvp, zinc nitrate, tetraethyl orthosilicate and sodium s...

Embodiment 3

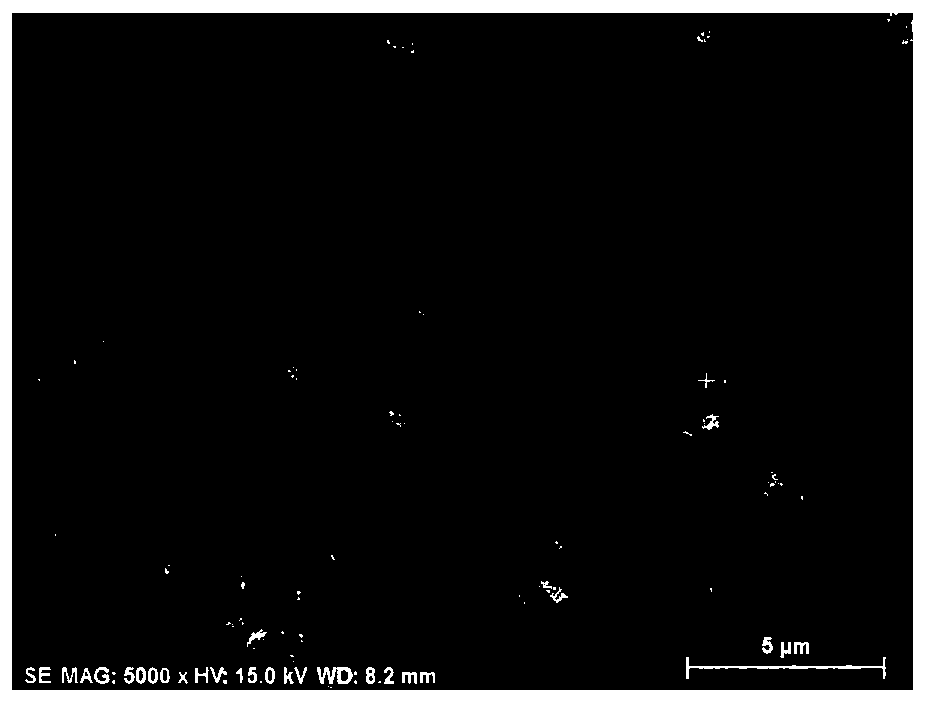

[0077] Present embodiment provides a kind of method of producing light-colored lanthanum cerium sulfide coloring agent, comprises the steps:

[0078] (1) Take 0.04mol of lanthanum carbonate, 0.8mol of sulfur, 0.01mol of cerium oxide, 0.01mol of lithium carbonate, 5mol of solid carbon and 0.005mol of aluminum chloride, mix well, and roast at 1050°C for 15 hours to obtain lanthanum cerium sulfide Primary products of colorants;

[0079] (2) Add 12 times the quality of water to the initial product of the lanthanum cerium sulfide colorant, then add potassium hydroxide to adjust the pH value to 10, and fully stir for 3.2 hours for solid-liquid separation to obtain the treated colorant solid;

[0080] (3) Add ethanol and water to the coloring agent solid after described treatment according to the mixed solution of mass ratio 10:1 composition, add ammoniacal liquor, pvp, zinc sulfate, tetraethyl orthosilicate and sodium silicate afterwards, described ammoniacal liquor The adding amou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com