Preparation process of nanocrystal cellulose

A nanocrystal and preparation technology, applied in the field of cellulose materials, can solve the problems of low purity, wide particle size distribution, and low yield of nanocrystalline cellulose, and achieve good particle size uniformity, simple preparation process, and high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

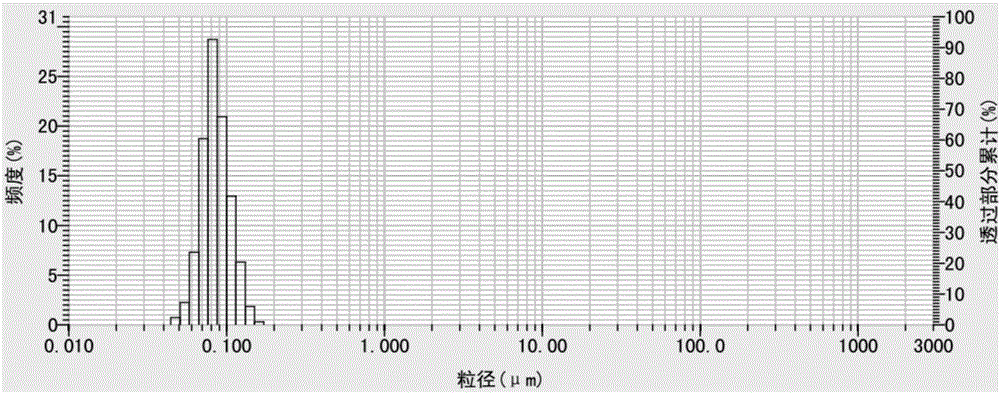

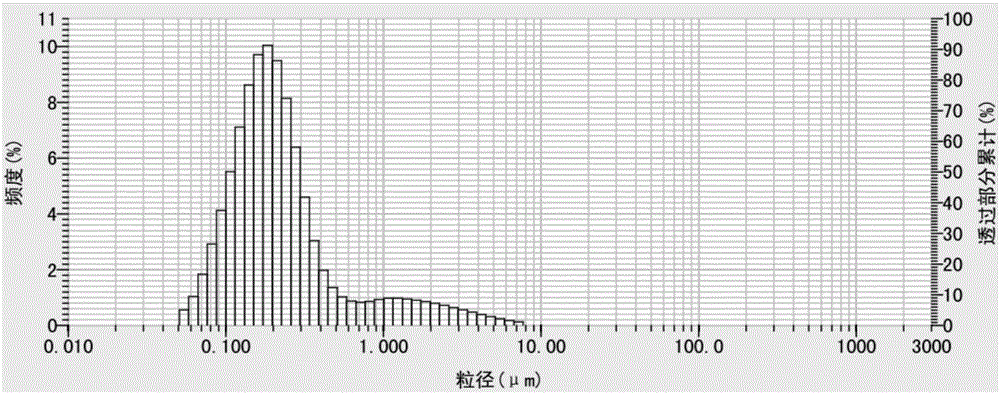

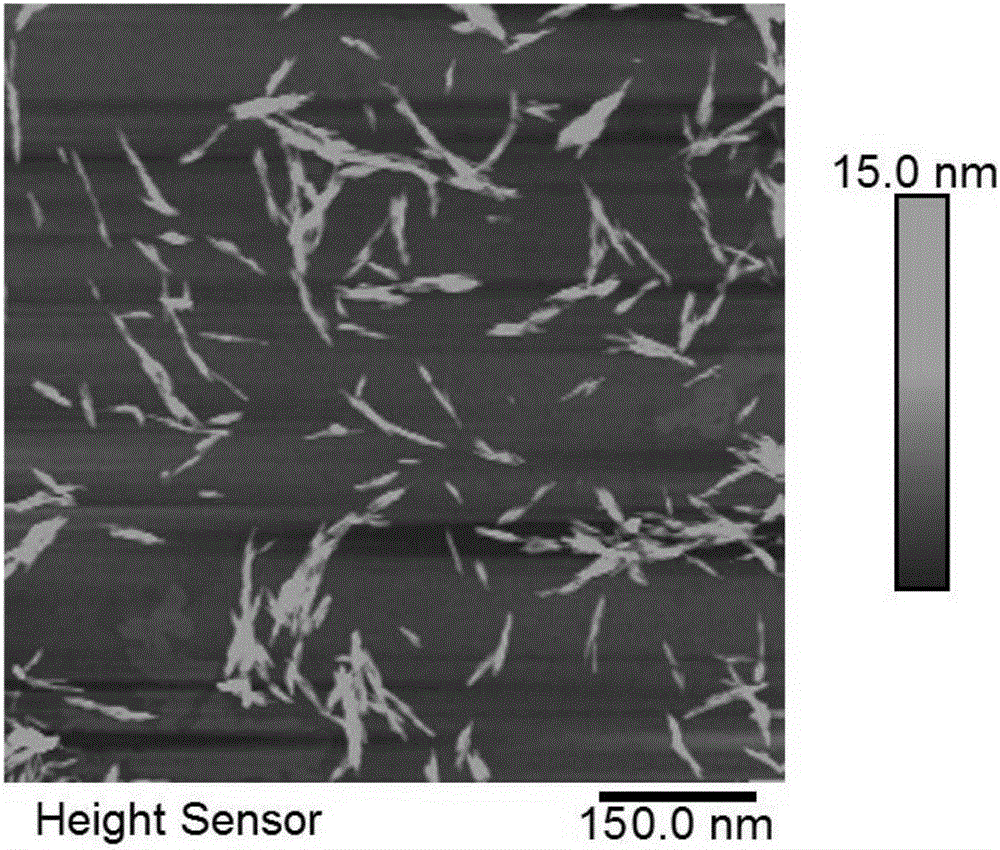

[0034] Commercially available pulp (α-cellulose-rich pulp made of cellulose) was added to a slicer and cut into 2 cm x 2 cm squares. Add 100g of cellulose slurry to 900ml of 1.0mol / L hydrochloric acid solution, carry out the first gradient hydrolysis reaction at 100°C, stir with an overhead stirrer at 300 rpm for 20 minutes, filter and wash with water, and obtain a solid content of 40wt%. Cellulose filter cake, the degree of polymerization is 320; add 1000ml of 45wt% sulfuric acid solution to the filter cake, carry out the second gradient hydrolysis reaction at 50°C, the reaction time is 30 minutes, filter and wash with water, and spray dry to obtain nanocrystalline cellulose. The physical characterization parameters are shown in Table 1, figure 1 , image 3 shown.

Embodiment 2

[0036] Commercially available pulp (α-cellulose-rich pulp made of cellulose) was added to a slicer and cut into 2 cm x 2 cm squares. Add 100g of cellulose slurry to 800ml of 3.0mol / L hydrochloric acid solution, carry out the first gradient hydrolysis reaction at 100°C, stir with an overhead stirrer at 300 rpm for 20 minutes, filter and wash with water, and obtain a solid content of 40wt%. Cellulose filter cake, the degree of polymerization is 300; add 1000ml of 30wt% sulfuric acid solution to the filter cake, carry out the second gradient hydrolysis reaction at 80°C, the reaction time is 30 minutes, filter and wash with water, and spray dry to obtain nanocrystalline cellulose. The physical characterization parameters are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com