Process control for acetic acid manufacture

A technology of process control and acetic acid, applied in chemical/physical/physicochemical processes, chemical/physical processes, control/regulation processes, etc. of applied energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

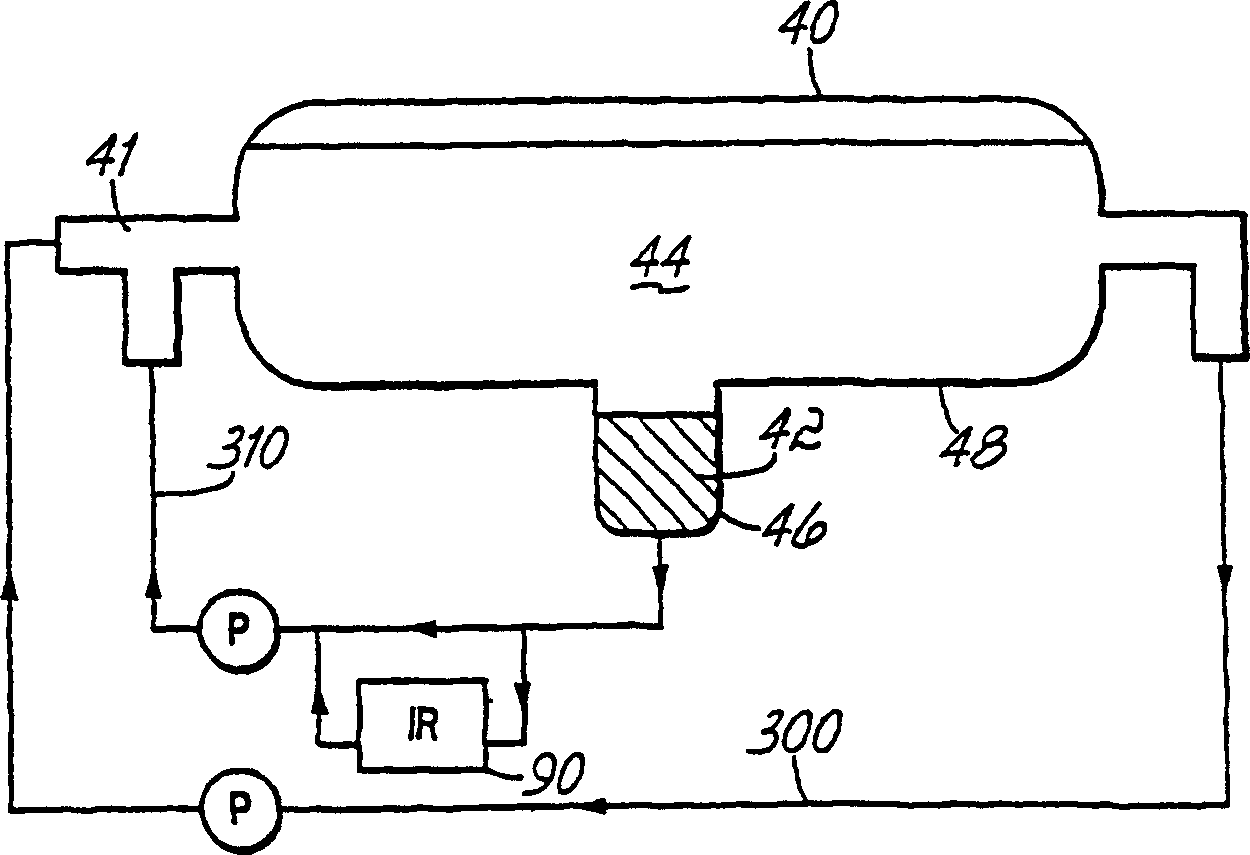

[0109] In this embodiment, the return line 310 of the heavy liquid phase solution in the decanter is connected to a 0.5 mm transmission cell equipped with selenite window holes, that is, the heavy liquid phase 42 is continuously monitored by extended mid-infrared zone analysis. The transmission cell is placed in the cell chamber of an FTIR (Fourier Transform Infrared Spectroscopy) spectrometer equipped with a DTGS detector. Circulate the decanter solution with the composition shown in the first column of Table 7 for about 18 minutes, and at the same time Figure 6 The online data points shown are recorded approximately every 35 seconds. The trend line in 18 minutes shows that the accuracy of the measurement for all components is better than + / -0.06 moles. Add MeOAc to the decanter at this point. Figure 6 The trend line shows the effect of adding MeOAc on the composition of the heavy liquid phase as measured by infrared. Sure enough, MeOAc showed a considerable increase in concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com