Method for atomization smoke curing of meat products by liquid smoke

A technology of meat products and smoked liquid, which is applied in the field of food processing, can solve the problems of meat product quality decline, achieve the effect of improving quality, good texture quality, and eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The specific operation steps of smoked liquid atomized smoked meat products are as follows:

[0036] 1) Hang the bacon products in the oven

[0037] 3kg of sausages were suspended on the hanging rod of the oven, and the distance between adjacent sausages was 6cm. Enema is a meat product processed from livestock and poultry meat with auxiliary materials, ground meat, stirred, pickled, enema and baked.

[0038] 2) Add 300g of smoked liquid obtained from processing hickory nut shells into the ultrasonic atomizer. The amount of smoked liquid added is 1% of the mass of the meat product to be smoked, and the fog outlet pipe of the atomizer is connected to the air inlet of the oven;

[0039] 3) First smoking

[0040] Adjust the temperature of the oven to 80°C, preheat the enema for 20 minutes; adjust the temperature of the oven to 80°C, turn on the ultrasonic atomizer, adjust the frequency to 2.4MHZ, close the exhaust outlet of the oven, and smoke for 1.0h; then adjust the t...

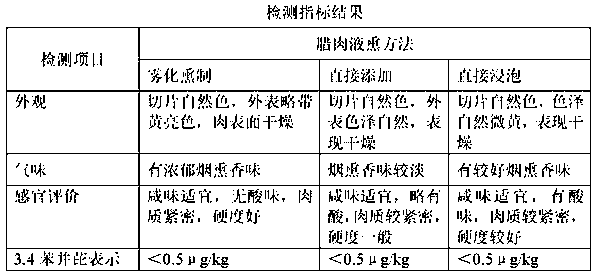

Embodiment 2

[0057] The specific operation steps of smoked liquid atomized smoked meat products are as follows:

[0058] 1) Hang the bacon products in the oven

[0059] Hang 3kg of ham slices on the hanging rod of the oven, keeping the distance between the divided ham slices at 3-10cm; the thickness of the ham slices is 5cm. Sliced ham is a meat product processed from pig hind leg meat after trimming, salt water injection, pickling, drying, slicing, and packaging.

[0060] 2) Add 600g of No. 1 smoke liquid to the ultrasonic atomizer, the amount of smoke liquid added is 2% of the mass of the meat product to be smoked, and connect the fog outlet pipe of the atomizer to the air inlet of the oven.

[0061] 3) First smoking

[0062] Adjust the oven temperature to 90°C, preheat for 15 minutes; adjust the oven temperature to 75°C, turn on the ultrasonic atomizer, adjust the frequency to 2.4MHZ, close the oven exhaust port, atomize and smoke for 0.5h; then adjust the oven temperature to 60 ℃,...

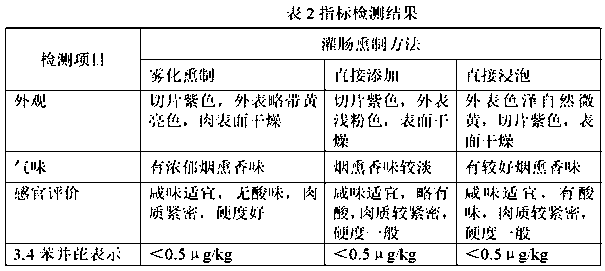

Embodiment 3

[0069] The specific operation steps of smoked liquid atomized smoked meat products are as follows:

[0070] 1) Hang the bacon products in the oven

[0071] Hang 3kg of bacon on the hanging rod of the oven, keeping the distance between the divided ham slices at 3-5cm; the thickness of the bacon is 2cm. Bacon is made from livestock meat or poultry meat, which is processed into meat products through deboning, brine injection, curing, rolling, molding, drying and grilling.

[0072] 2) Add 900g of No. 2 smoke liquid to the ultrasonic atomizer. The amount of smoke liquid added is 3% of the mass of the meat product to be smoked. Connect the fog outlet pipe of the atomizer to the air inlet of the oven.

[0073] 3) First smoking

[0074] Adjust the oven temperature to 88°C, preheat for 10 minutes; adjust the oven temperature to 70°C, turn on the ultrasonic atomizer, adjust the frequency to 2.4MHZ, close the oven exhaust outlet, atomize and smoke for 1.5h; then adjust the oven tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com