Method for preparing monodisperse polystyrene microsphere with controllable grain diameter

A technology of polystyrene microspheres and monodispersity, applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbons, etc., can solve problems such as uneven particle size distribution, and the method is simple and easy, The effect of low purity and simple reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

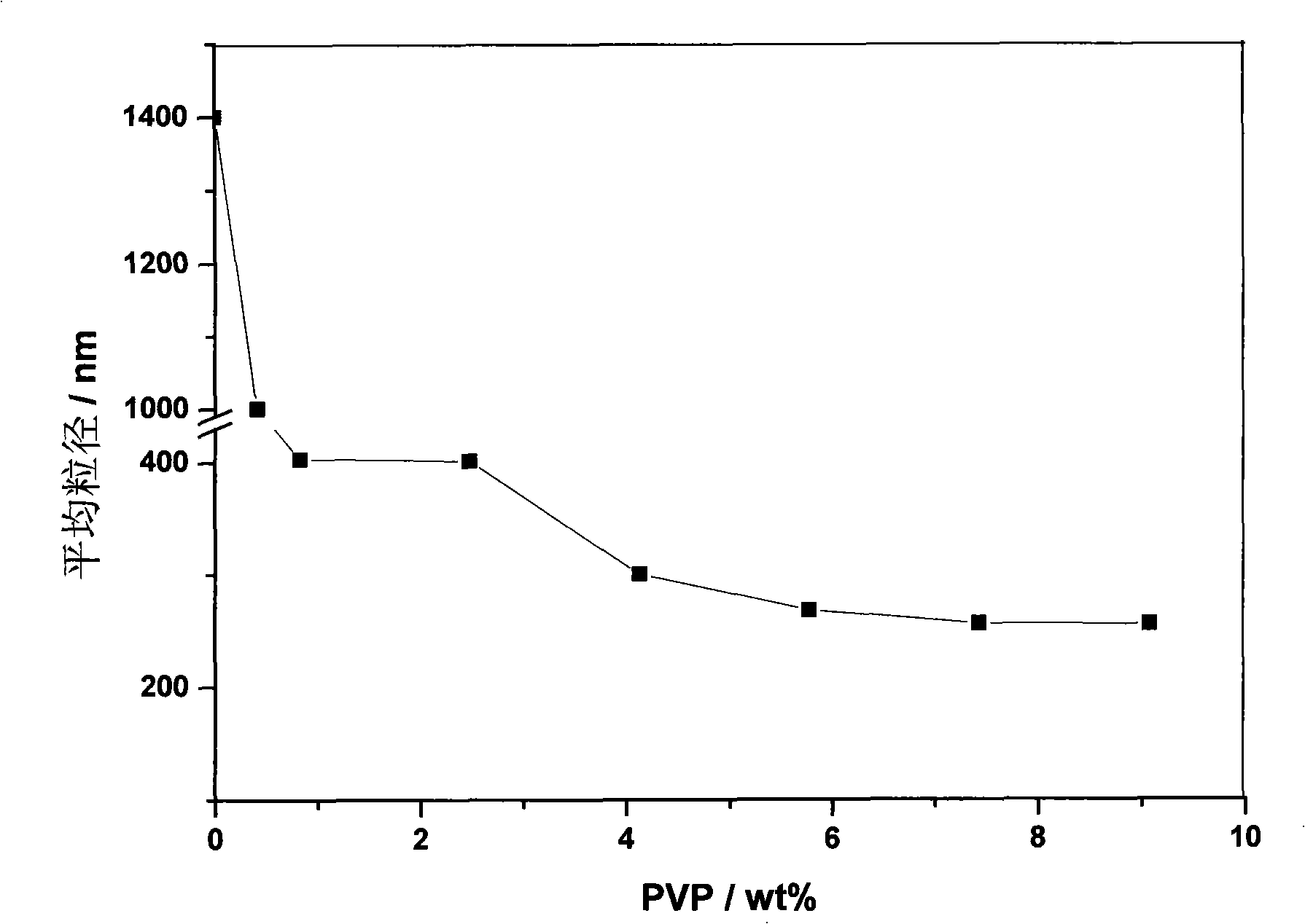

[0035] Commercially available styrene (analytically pure, Beijing Chemical Reagent Company) was washed 3 times with 5wt% sodium hydroxide (analytical pure, Beijing Chemical Reagent Company) aqueous solution to remove the polymerization inhibitor in the raw material styrene, and then washed with pure water Wash several times until the solution is neutral, dry with a small amount of anhydrous calcium chloride, and store at low temperature until use. Put 100 milliliters of deionized water into a single-necked round-bottomed flask (placed in a water bath), this single-necked round-bottomed flask is placed in a water-bathed pot, and magnetically stirred (about 300rpm / min), take the above-mentioned rough-treated polystyrene 13 milliliters, put into above-mentioned one-necked flask, get a certain amount of stabilizing agent polyvinylpyrrolidone (PVP) as table 1, also put into above-mentioned one-necked flask, stir to make it mix evenly, about 10 minutes. Put 0.3 g of potassium persul...

Embodiment 2

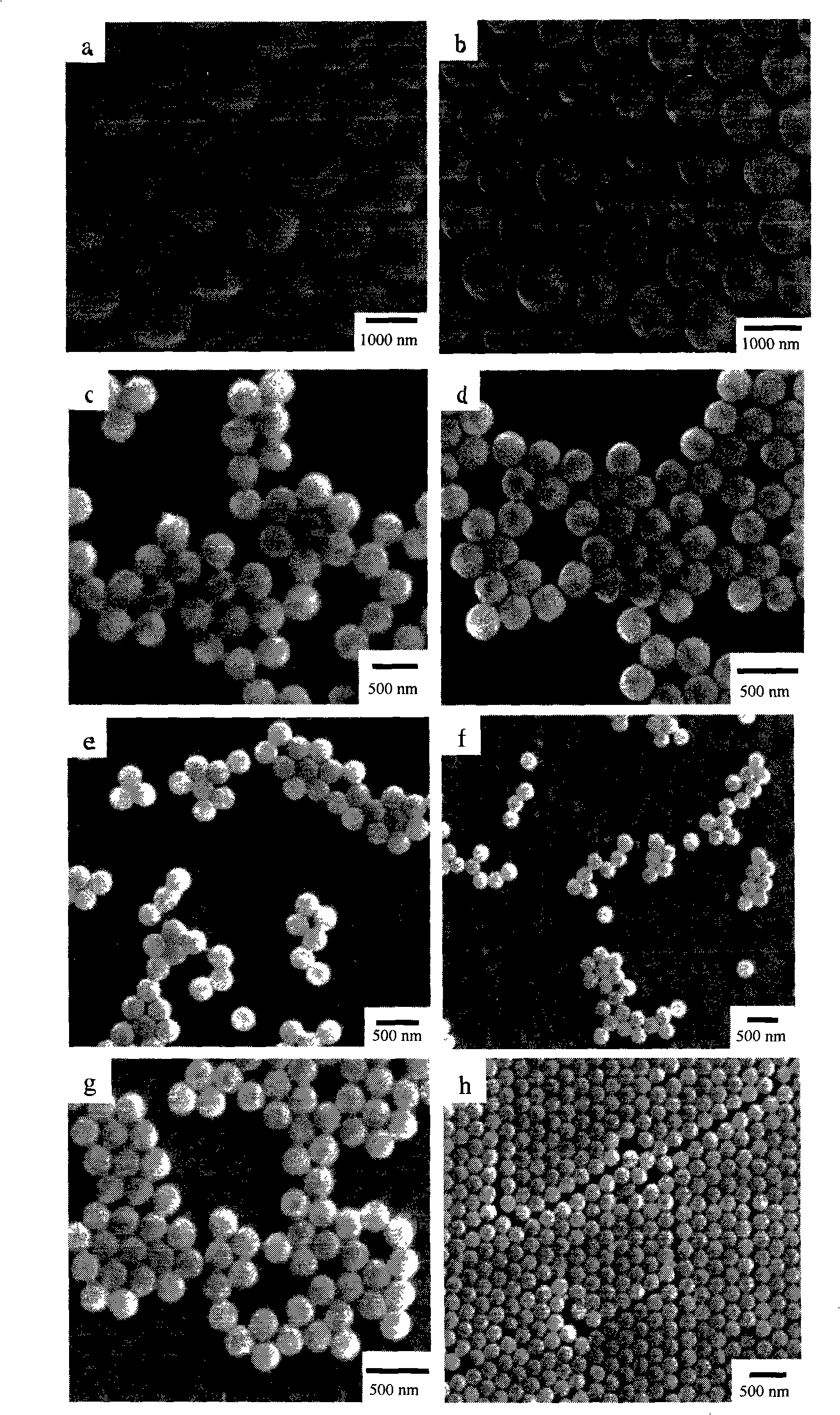

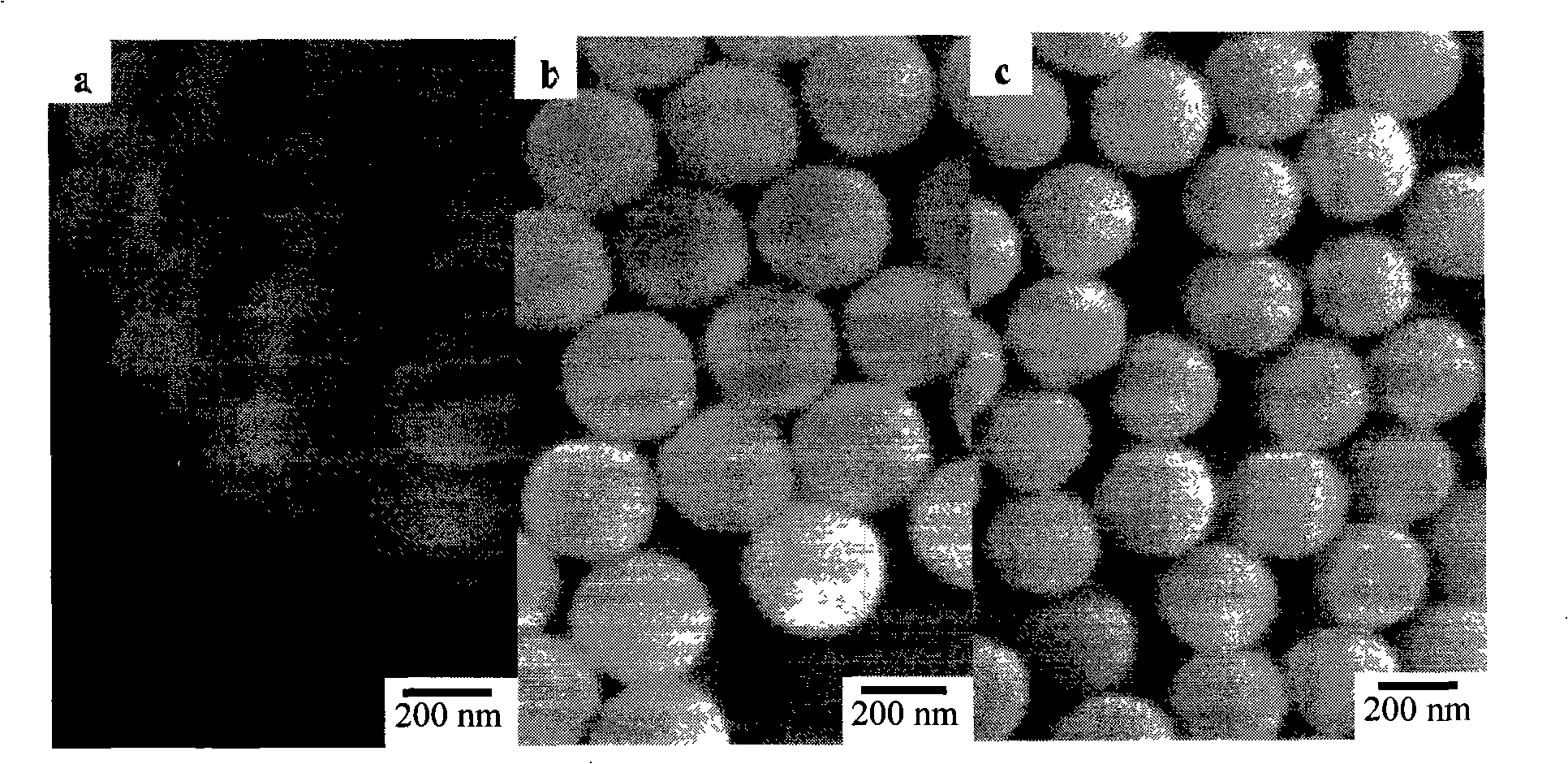

[0040] Effect of the amount of styrene monomer on the particle size of polystyrene microspheres. As shown in Table 2, in experiments No. 1 to No. 4, under the condition of keeping other experimental conditions the same as in Example 1, polyvinylpyrrolidone was selected as 0.5 g, and the amount of styrene monomer was gradually increased from 10 mL to 19 mL. The particle size of the microspheres does not change very much, the maximum difference is 60nm, and the change trend is not obvious. The morphology of the prepared polystyrene microspheres is as follows: image 3 As shown in the scanning electron microscope pictures (a) to (c) in , the monodispersity is relatively not very good.

[0041] Table 2 The effect of monomer styrene content on the particle size of polystyrene microspheres

[0042]

[0043] *Mass percentage wt% is the mass ratio of styrene mass to water

Embodiment 3

[0045] Effect of the amount of initiator potassium persulfate on the particle size of polystyrene microspheres. As shown in table 3, in No. 1 to No. 4 tests, under the same situation of keeping other test conditions and embodiment 1, keep the consumption of each experiment stabilizer polyvinylpyrrolidone to be 0.5g, the consumption of initiator potassium persulfate Gradually increasing from 0.2g to 0.5g, although the particle size of polystyrene microspheres does not change very much, it gradually becomes smaller, showing obvious regularity as Figure 4 As shown, the maximum gap is 26nm, and the morphology of the prepared polystyrene microspheres is as follows Figure 5 As shown in the scanning electron microscope pictures (a) to (c) in , it has good monodispersity.

[0046] The impact of table 3 KPS initiator dosage on polystyrene microsphere particle size

[0047]

[0048] *Mass percentage wt% is the mass ratio of potassium persulfate to styrene

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com