Packaging and fresh-keeping method for foodstuff

A food packaging and food technology, which can be applied to the field of packaging and modified atmosphere preservation of baked food, can solve the problems of unstable voltage, lack of environmental protection, and inhibit the characteristics of various shapes of pastry food, and achieves average heating and pressure. Economic benefits, the effect of saving packaging materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

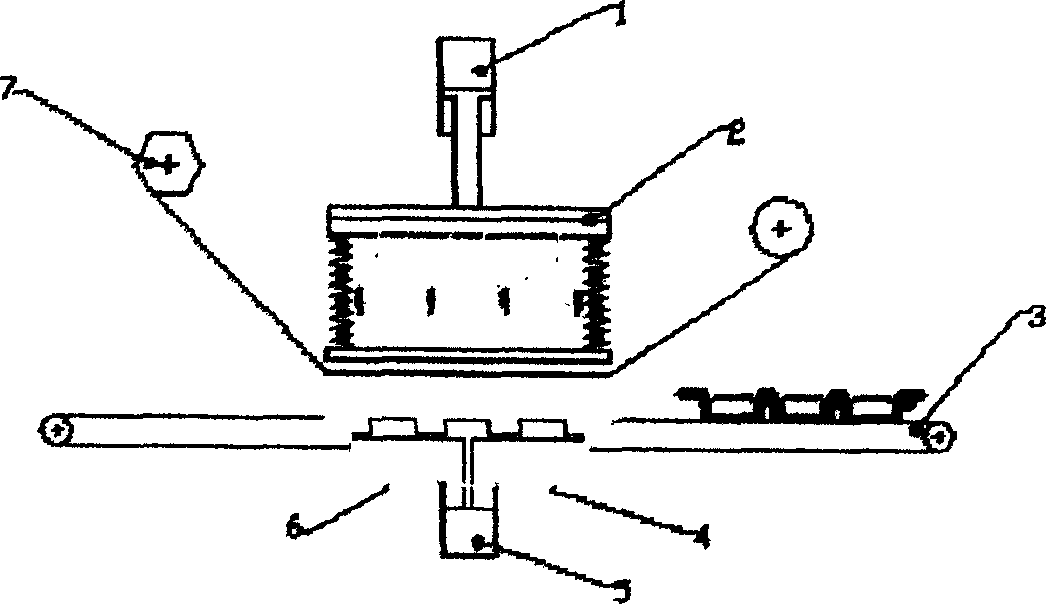

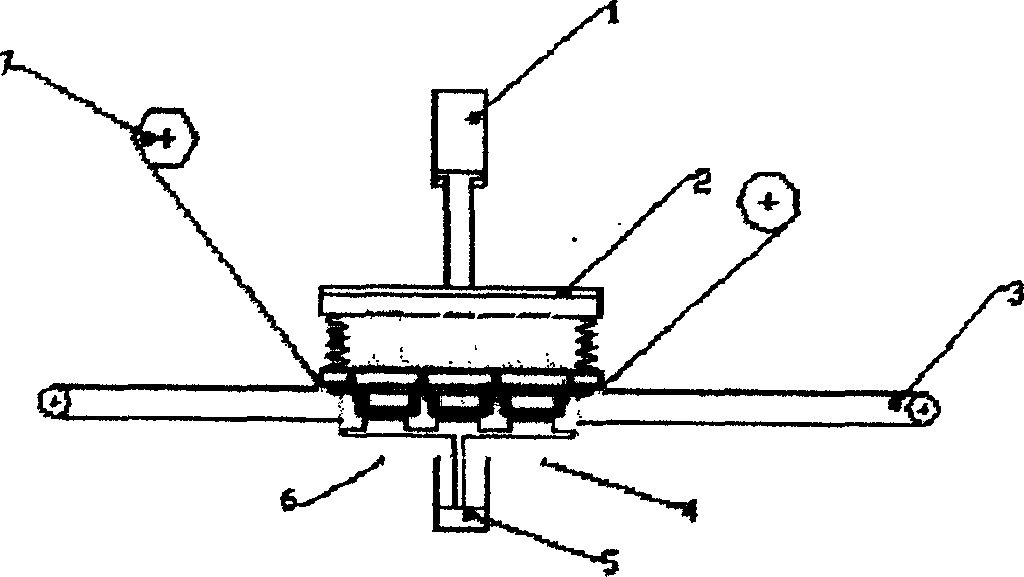

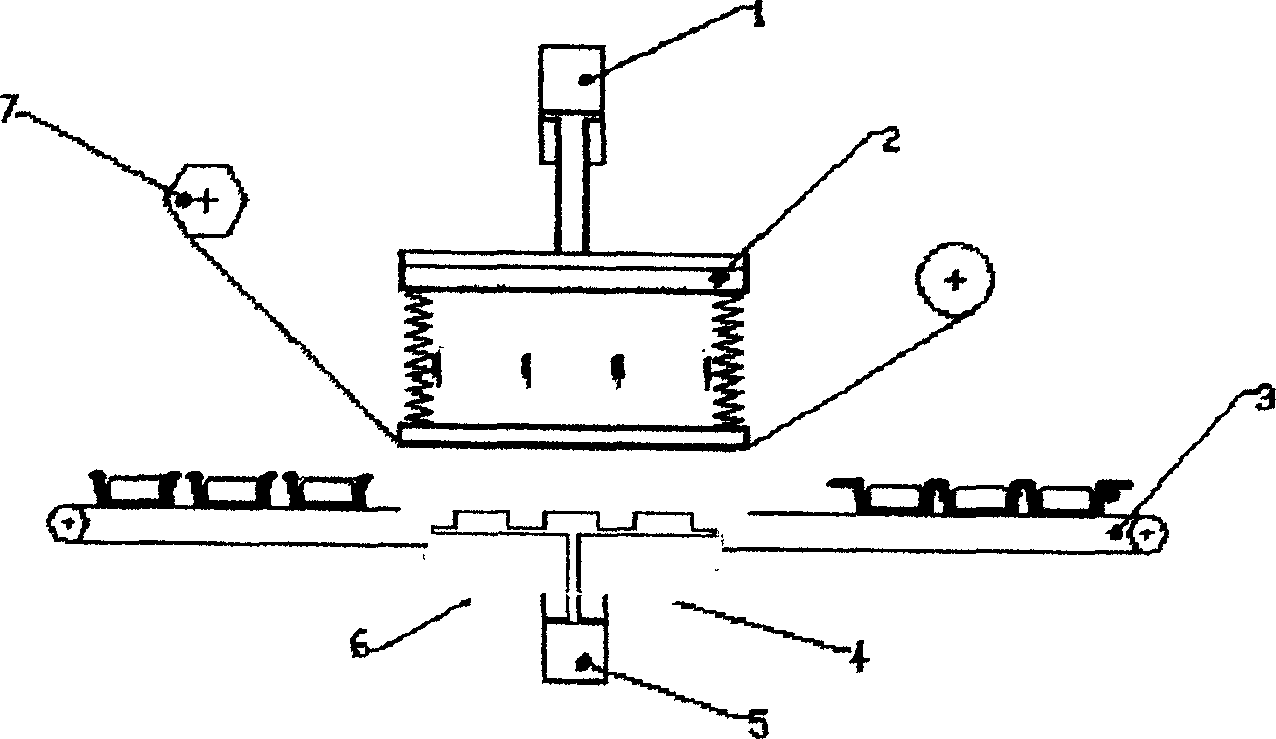

[0067] Present embodiment is the process of continuous packaging production:

[0068] 1) Through the conveying device (3) of the packaging machine, the conjoined packaging bottom box to be packaged is accurately conveyed to the supporting device (5) in the inflation, sealing and cutting station of the packaging machine. Taking the packaged food with a diameter of 50-100mm as an example, it can deliver one conjoined bottom box consisting of 1-20 independent packaging boxes of different sizes each time. When the conveying device (3) feeds the material, the film rolling device (7) moves synchronously thereupon.

[0069] 2) The bottom box of the package descends to the set position along with the supporting device (5) and then stops.

[0070] 3) Pushed by the variable pressure device (1), the sealing and cutting device (2) is pressed down. The film pressing frame of the hexagram cutting device (2) first presses the film, so that the film and the supporting device (5) surround th...

Embodiment 2

[0076] This embodiment is the process of discontinuous packaging production

[0077] 1) Place the conjoined packaging bottom box to be packaged on the supporting device (5) in the inflation and sealing station of the packaging machine by manual or other means.

[0078] 2) The combined package bottom box stops after falling to the set position with the support device (5).

[0079] 3) Pushed by the variable pressure device (1), the sealing and cutting device (2) is pressed down. The film pressing frame of the sealing and cutting device (2) first presses the film, so that the film and the supporting device (5) surround the food to be packaged, thereby forming a sealed cavity. Then, the air pumping device (4) vacuumizes; after the vacuum pumping action is completed, the gas filling device (6) is filled with protective gases such as nitrogen, carbon dioxide or mixed gas. If there is a higher requirement on the effect of preservation, the protective gas can be pumped and charged m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com