Patents

Literature

117results about How to "Reduce packaging process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

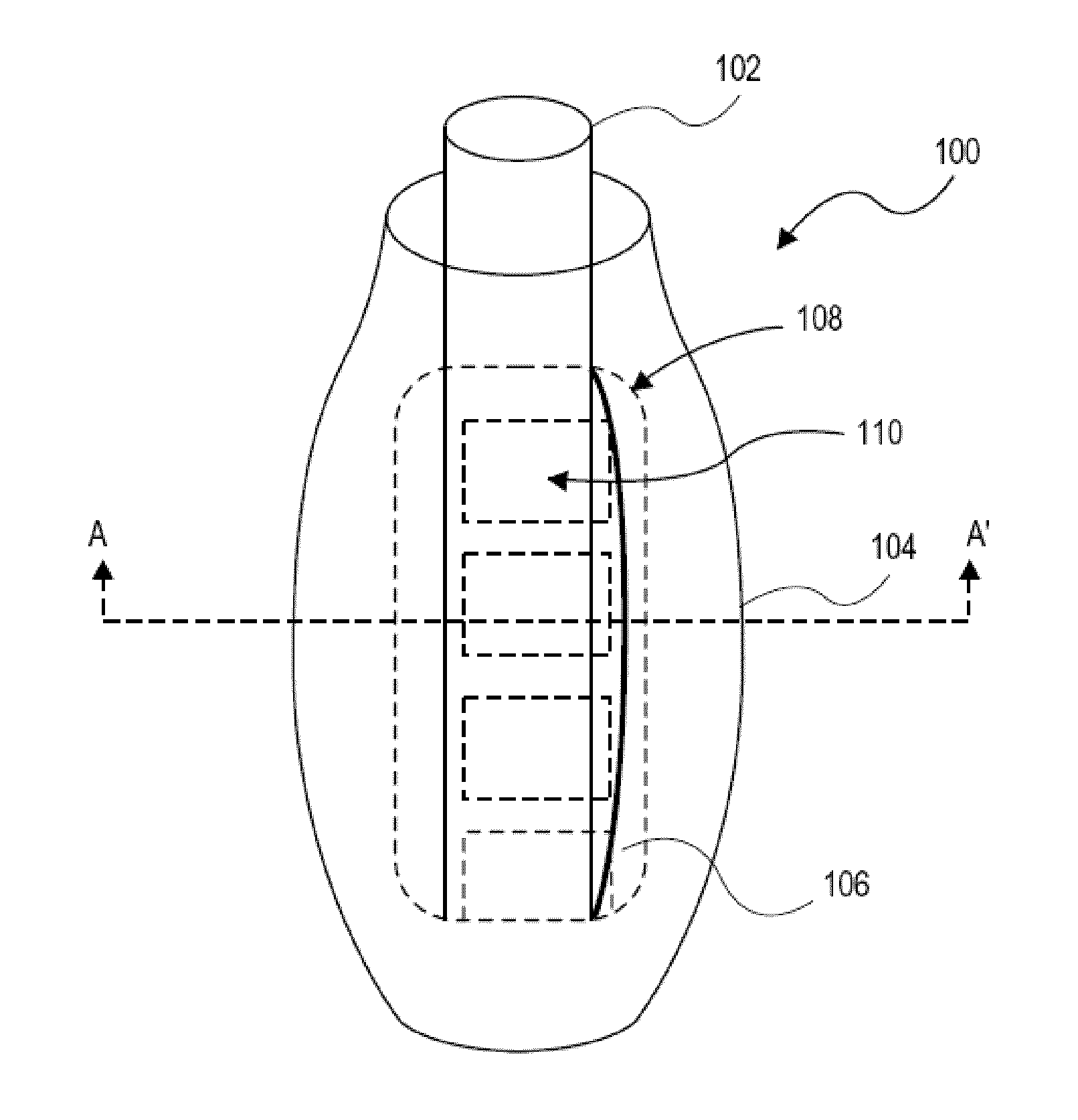

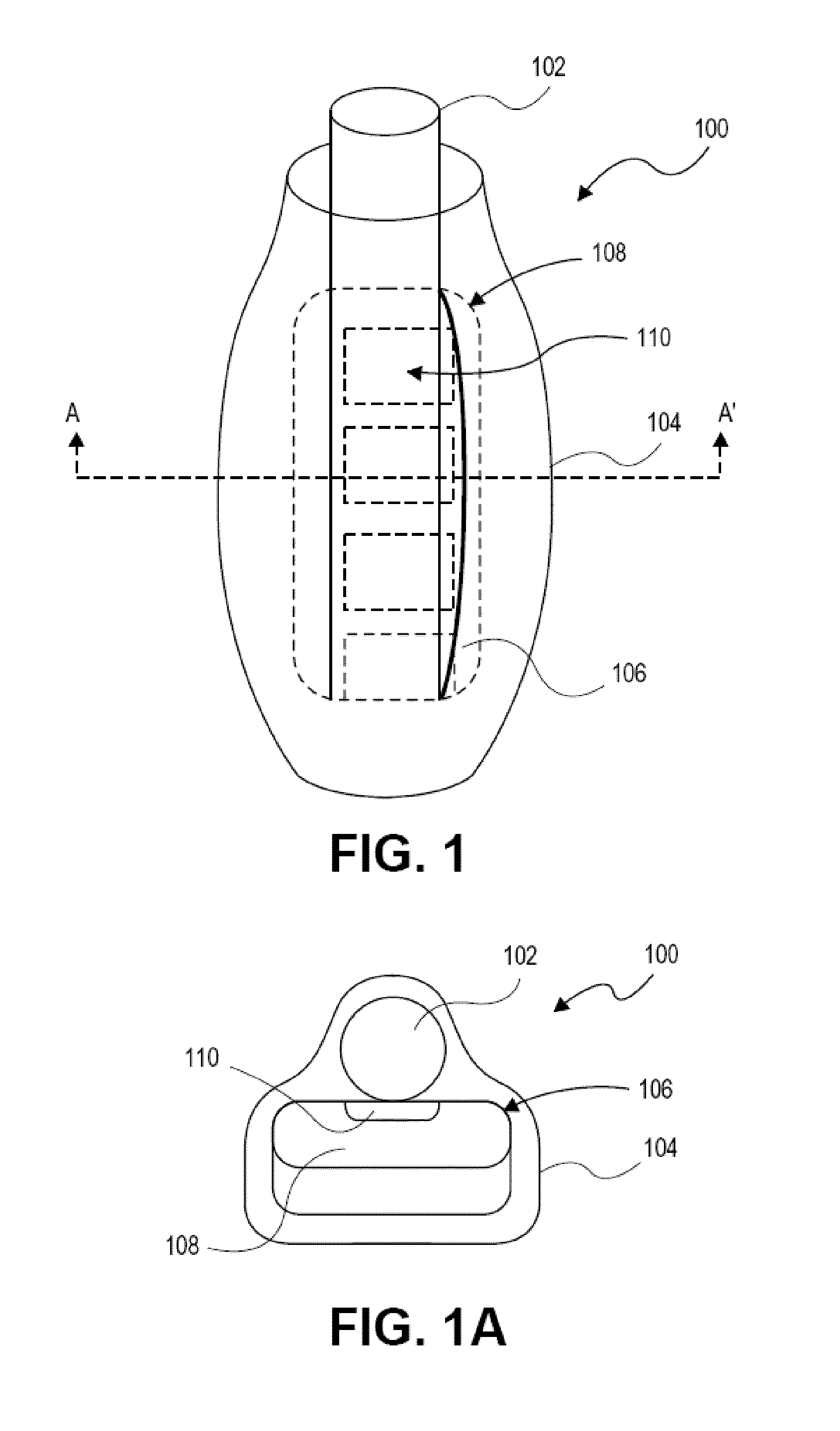

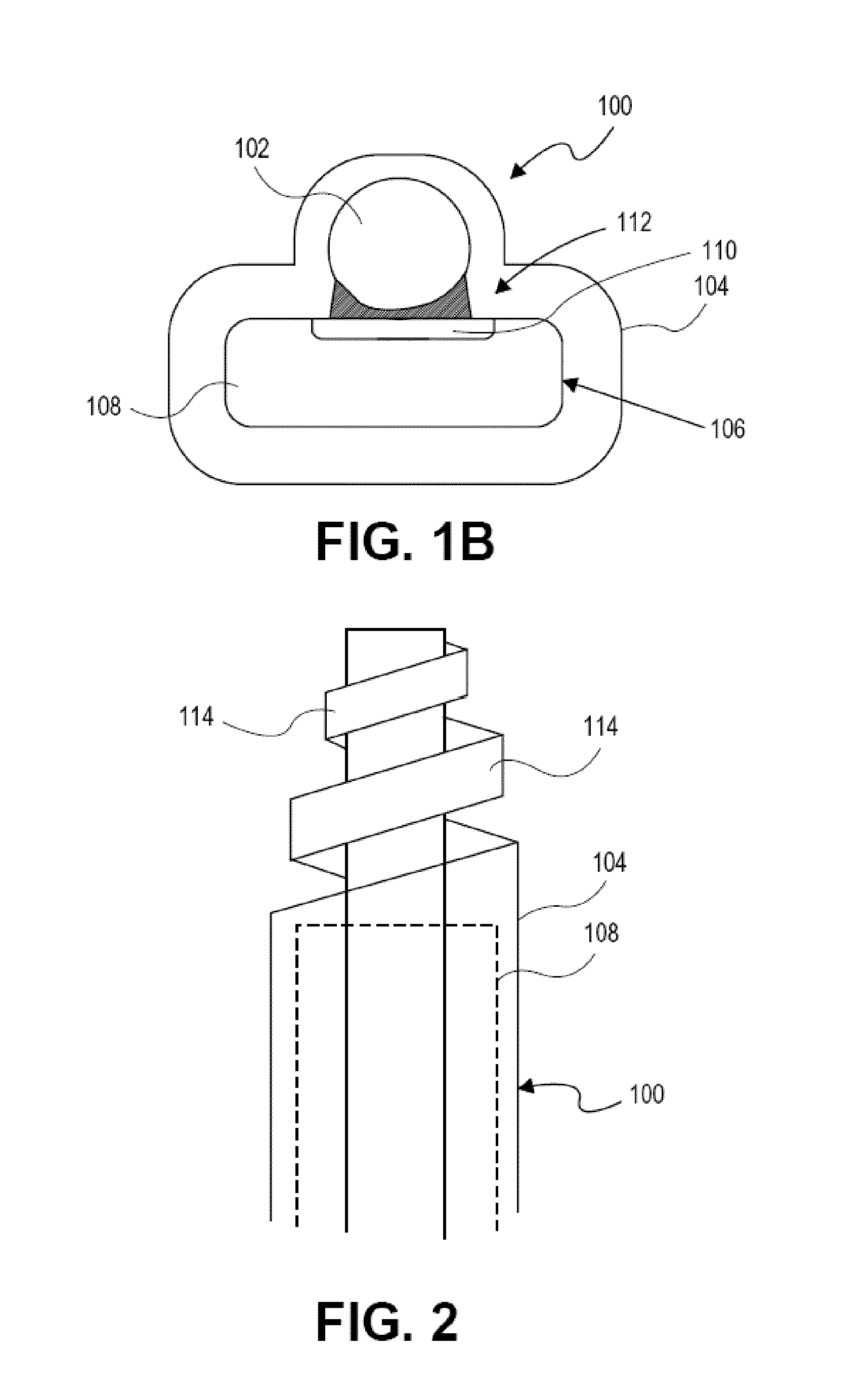

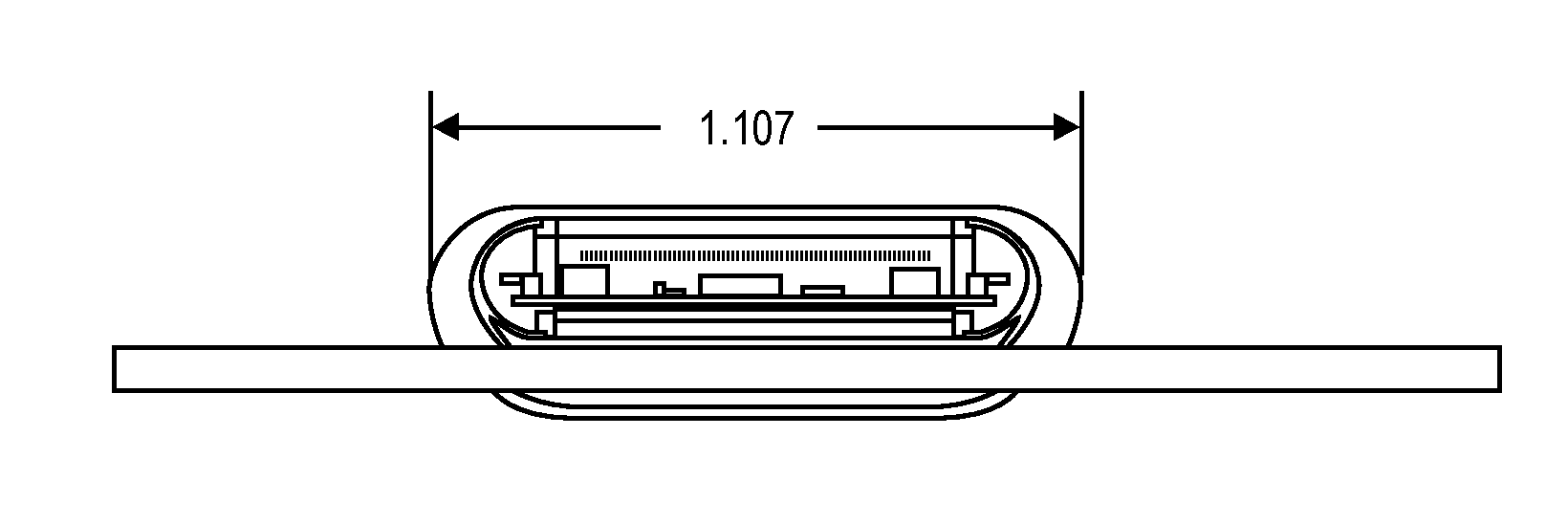

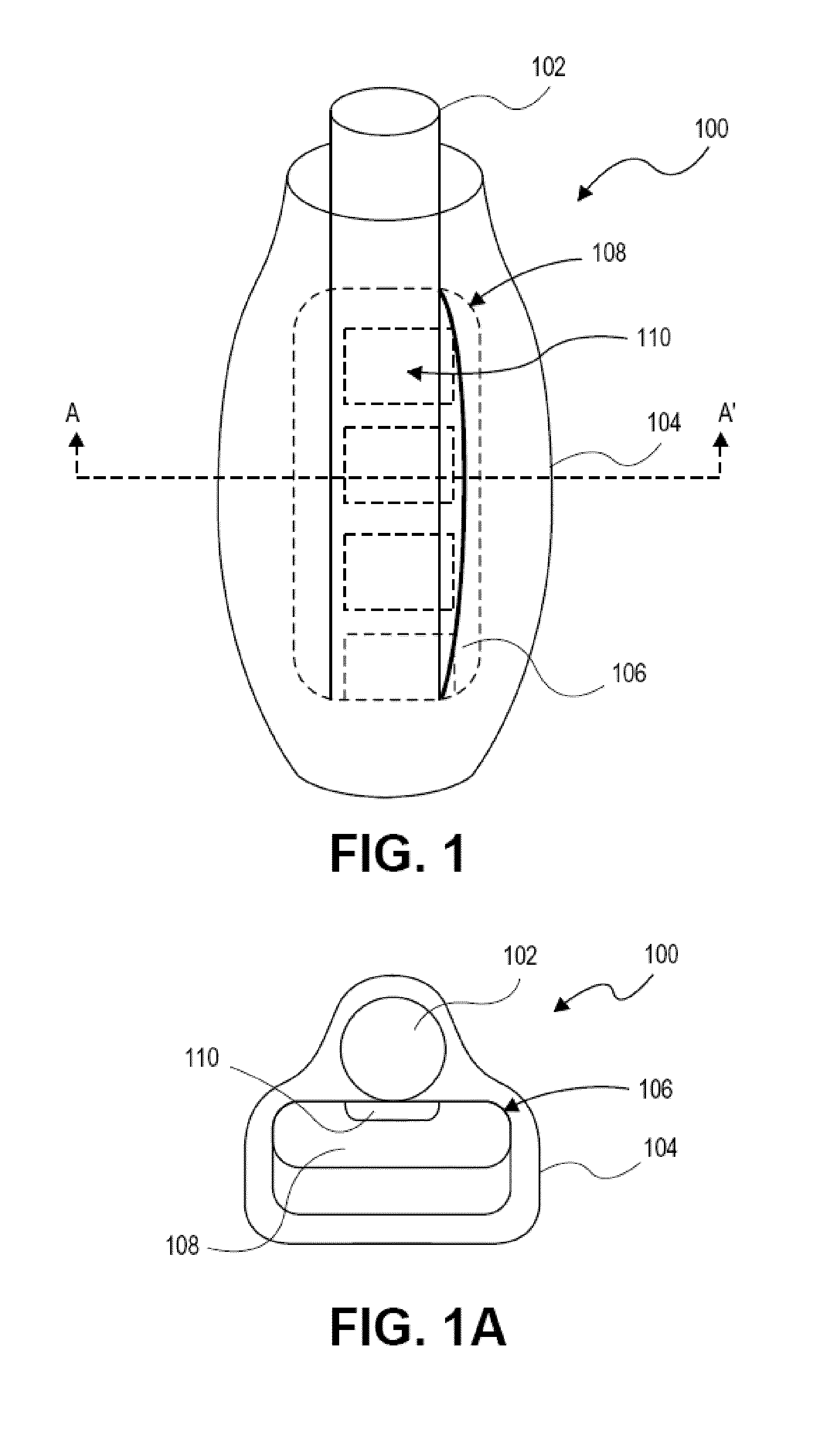

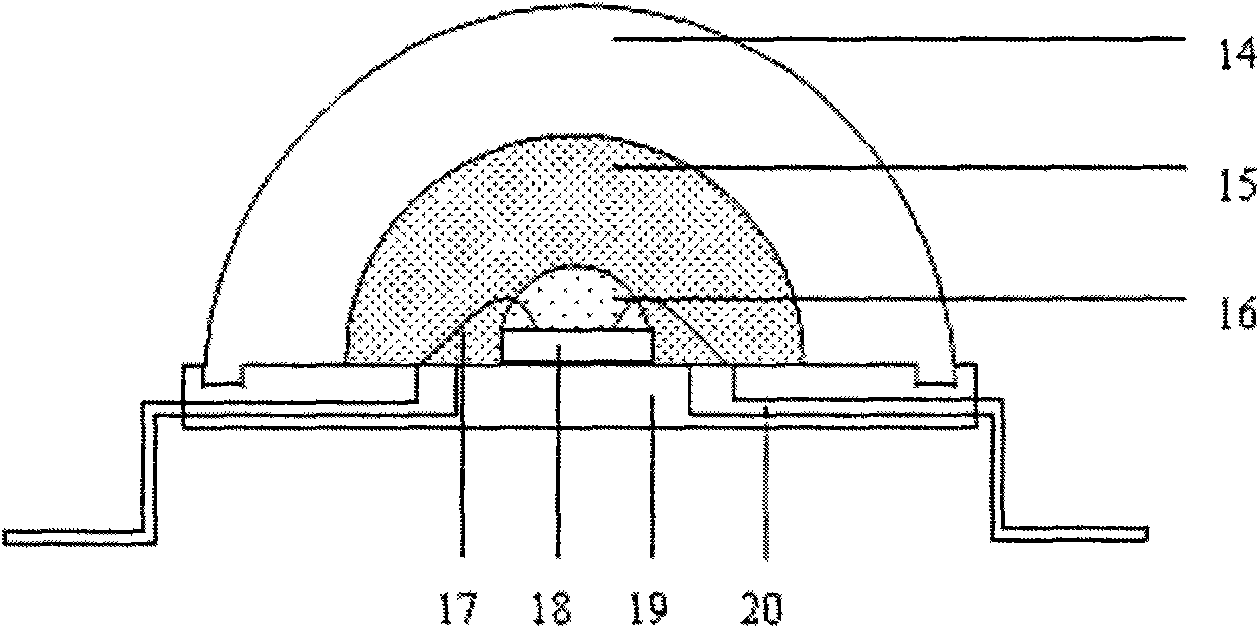

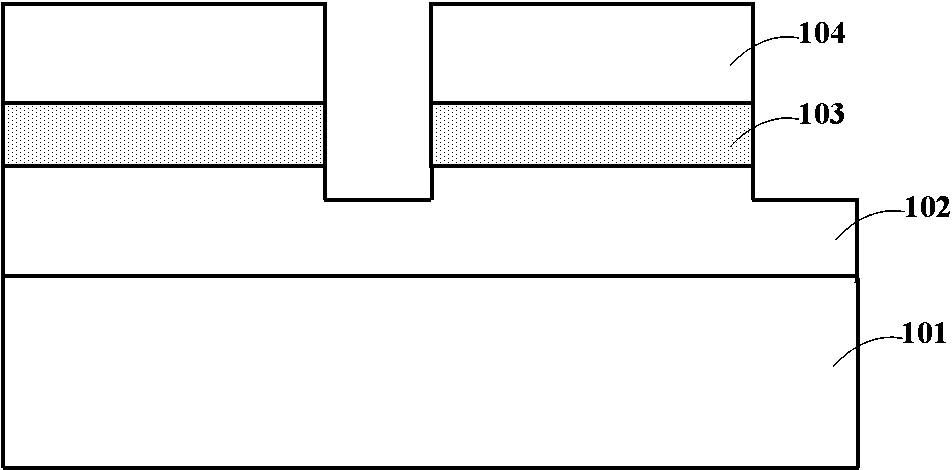

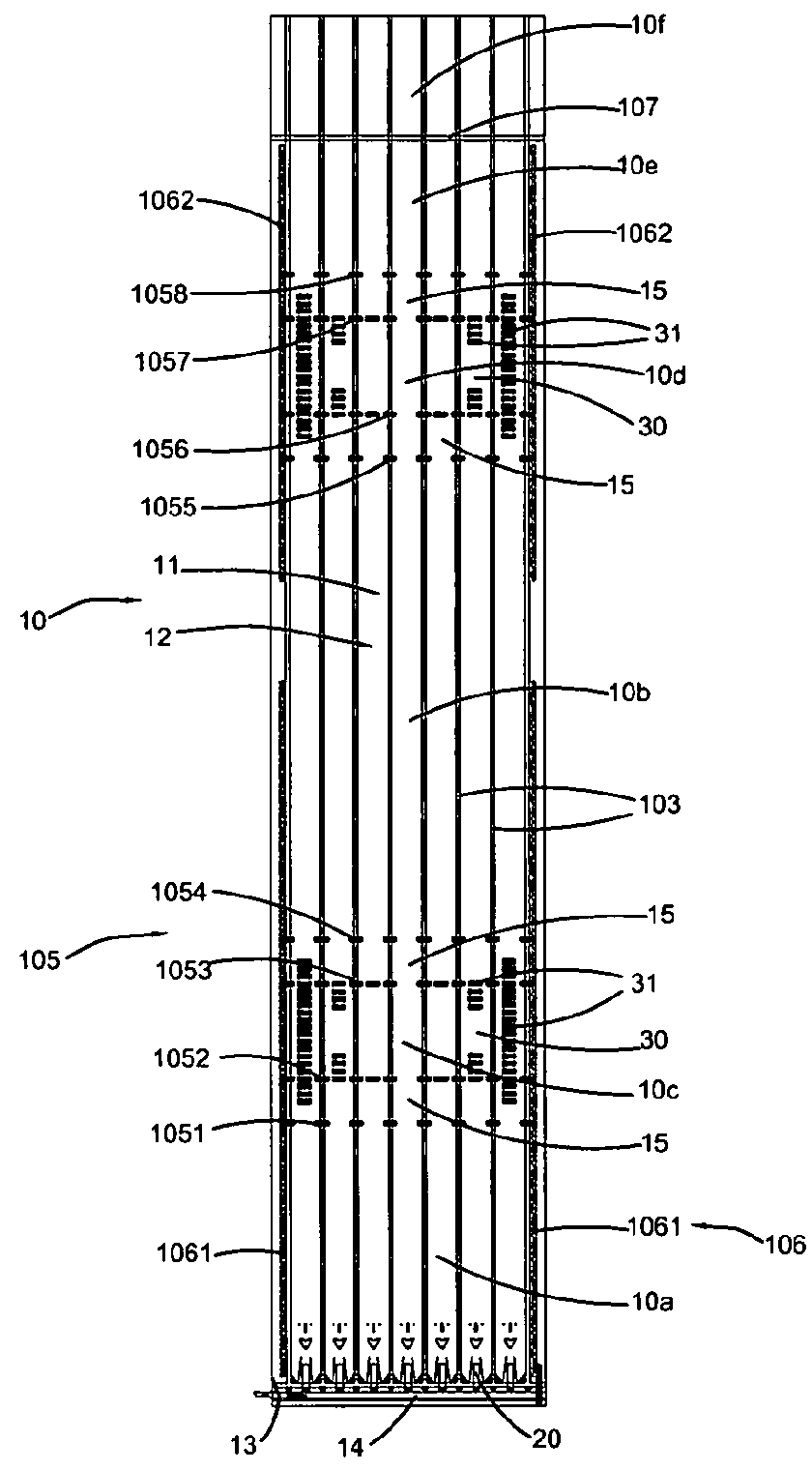

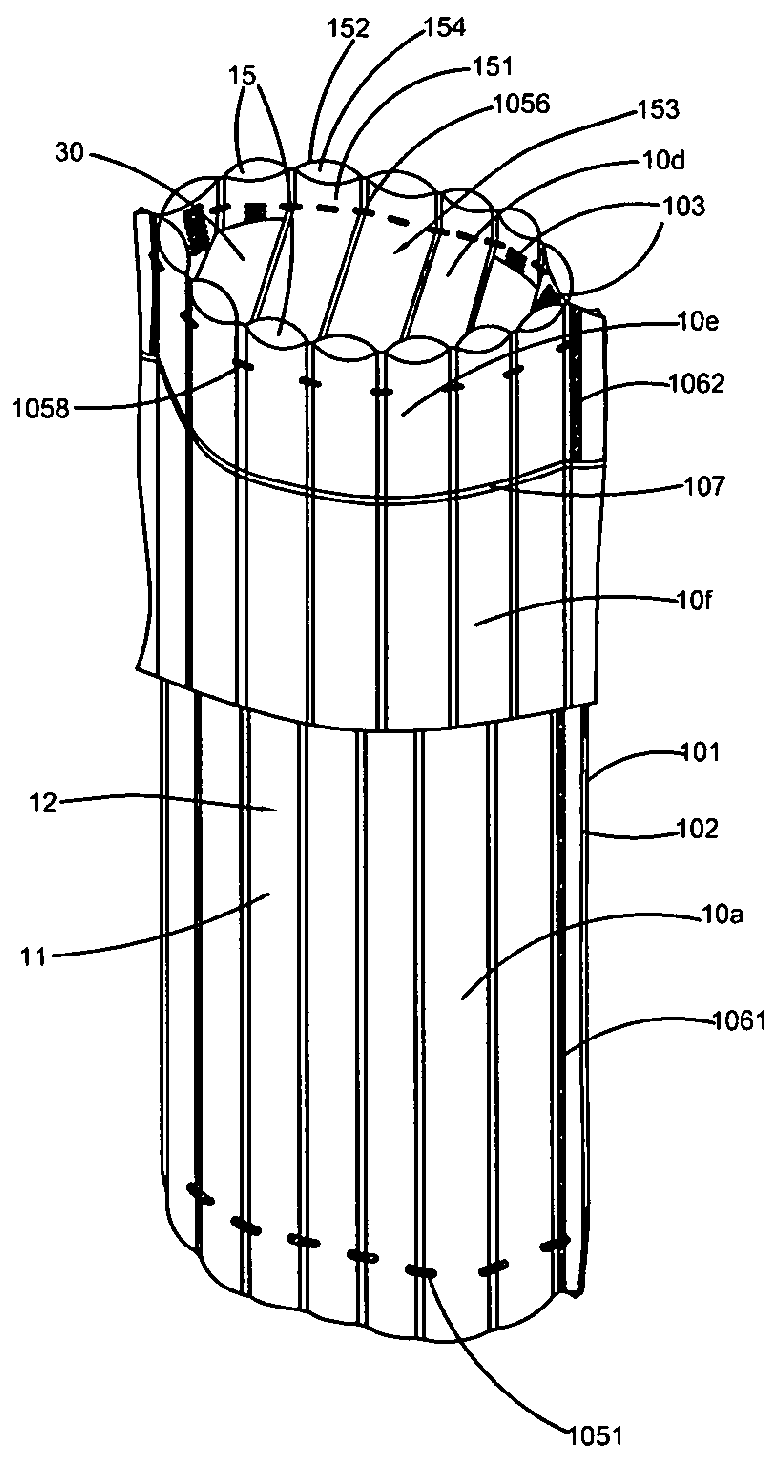

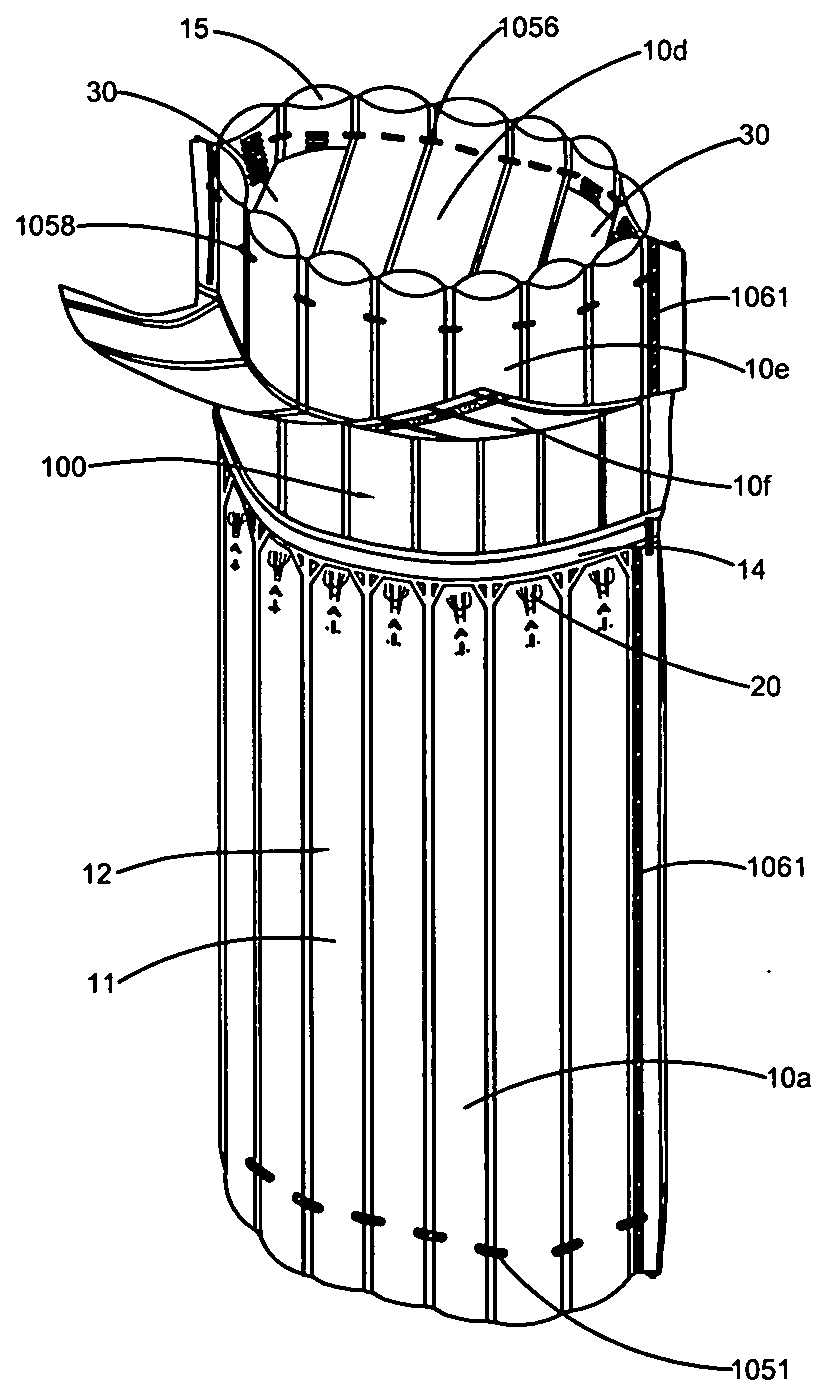

Nerve cuff with pocket for leadless stimulator

ActiveUS8886339B2Reduce packaging processLess “tugging”Spinal electrodesExternal electrodesNerve cuffImplanted device

An extravascular nerve cuff that is configured to hold a leadless, integral, implantable microstimulator. The nerve cuff may include a cuff body having a pocket or pouch for removably receiving the implantable device within. The nerve cuff can be secured around the nerve such that the electrodes of the device are stably positioned relative to the nerve. Furthermore, the nerve cuff drives the majority of the current from the stimulation device into the nerve, while shielding surrounding tissues from unwanted stimulation.

Owner:SETPOINT MEDICAL CORP

Nerve cuff with pocket for leadless stimulator

ActiveUS20100312320A1Avoid pinchingReduce packaging processSpinal electrodesExternal electrodesNerve cuffImplanted device

An extravascular nerve cuff that is configured to hold a leadless, integral, implantable microstimulator. The nerve cuff may include a cuff body having a pocket or pouch for removably receiving the implantable device within. The nerve cuff can be secured around the nerve such that the electrodes of the device are stably positioned relative to the nerve. Furthermore, the nerve cuff drives the majority of the current from the stimulation device into the nerve, while shielding surrounding tissues from unwanted stimulation.

Owner:SETPOINT MEDICAL CORP

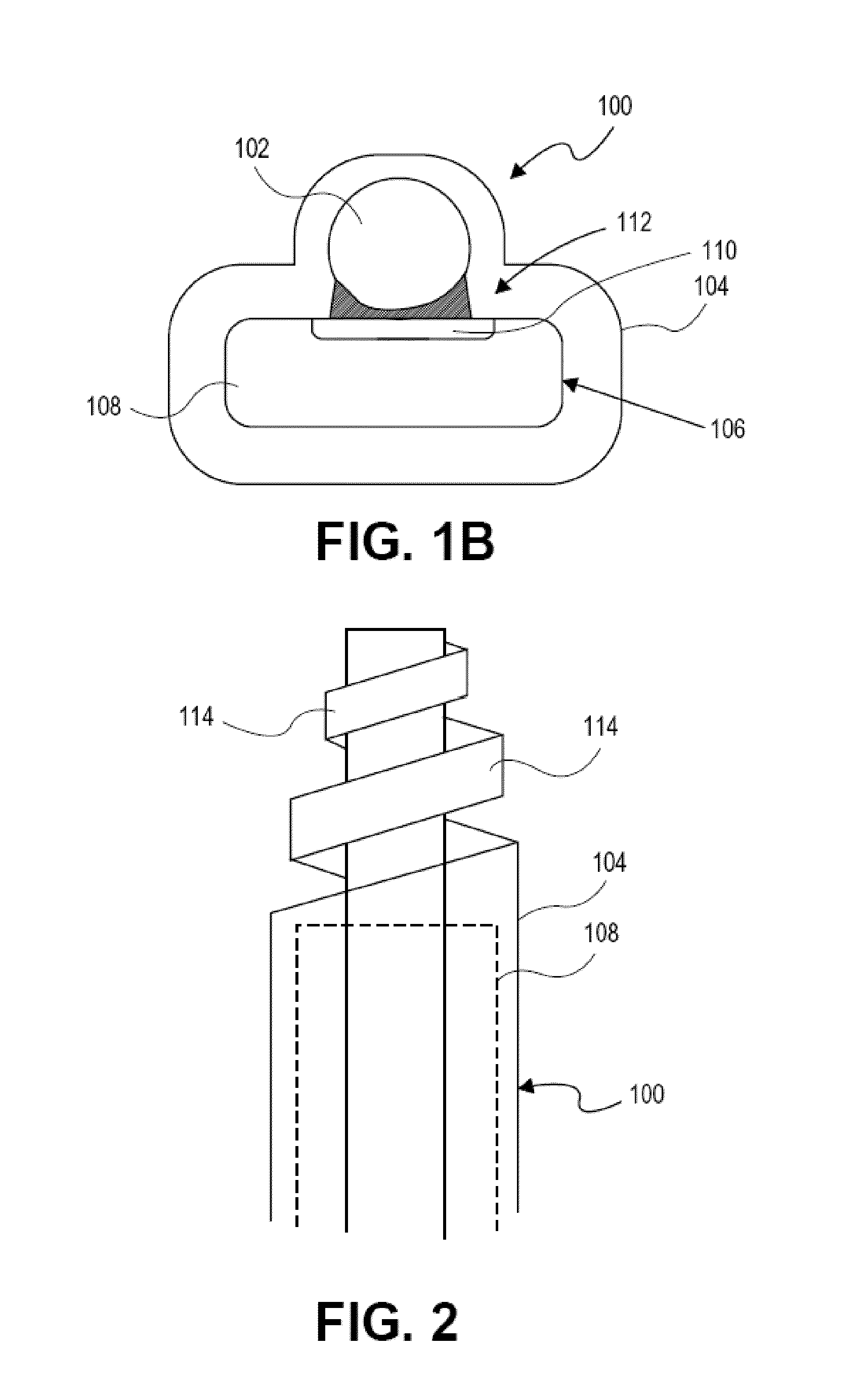

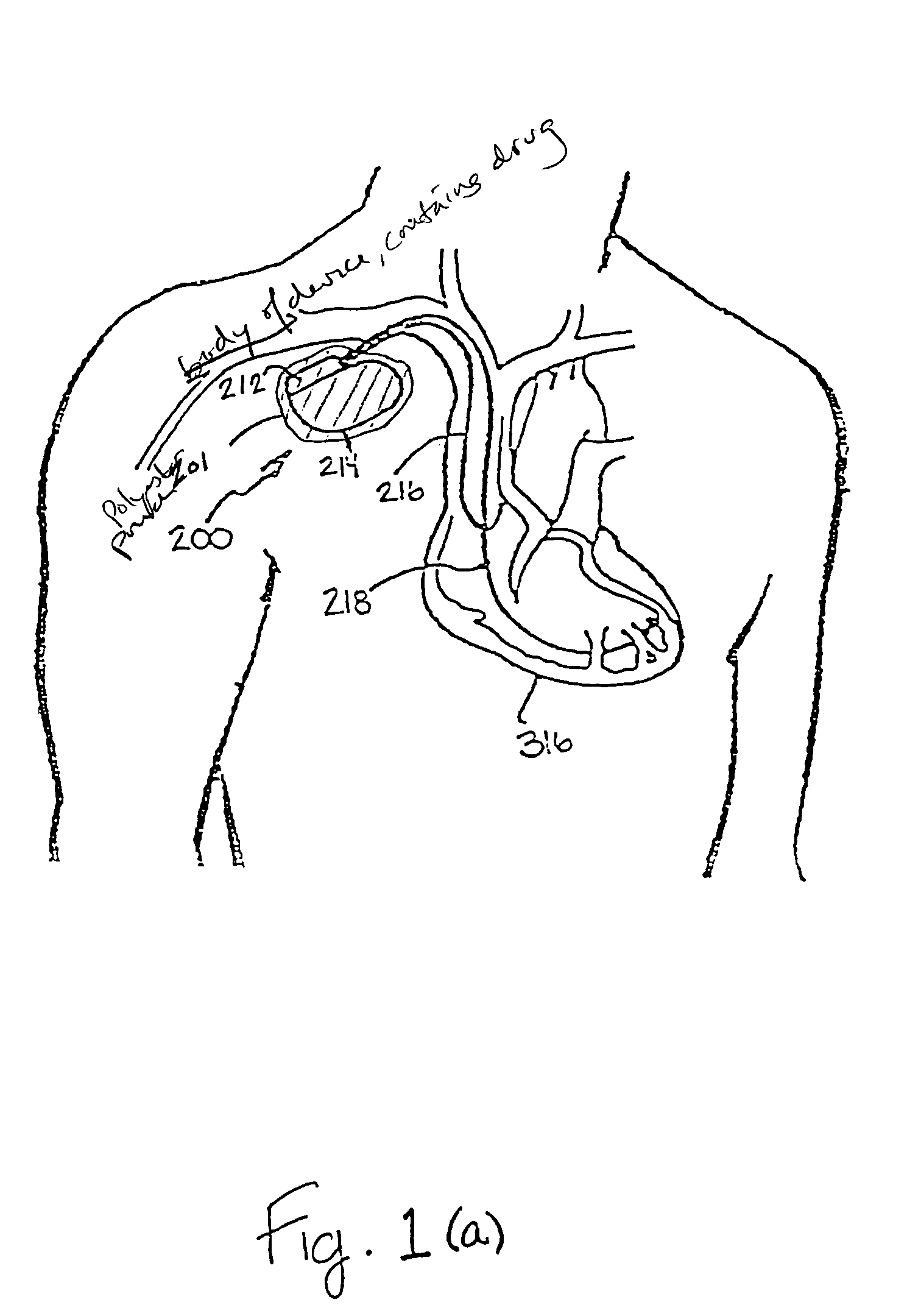

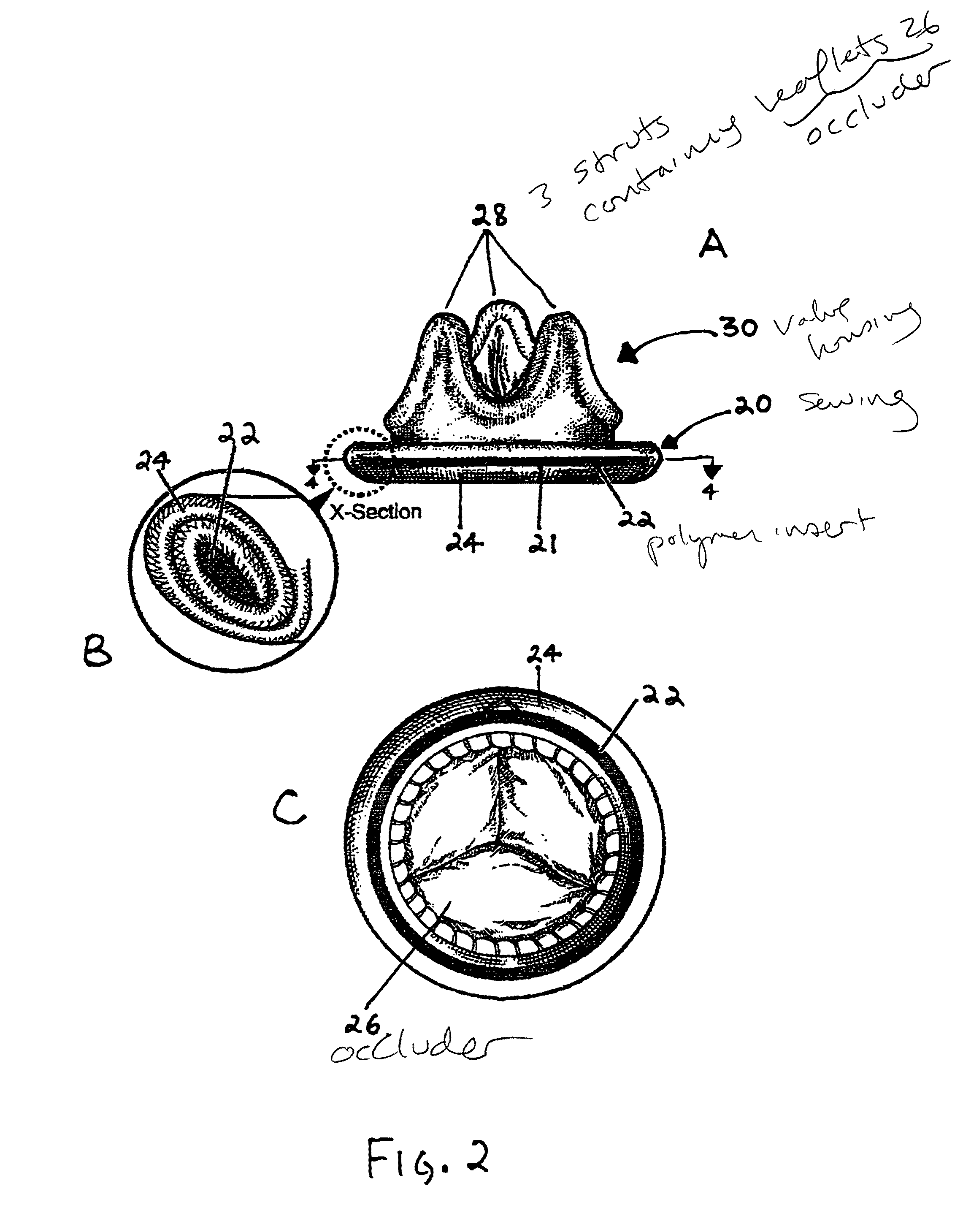

Implantable medical device with enhanced biocompatibility and biostability

InactiveUS7658727B1Good biocompatibilityMitigating fibrous tissue formationAnnuloplasty ringsSurgeryBiocompatibility TestingProsthetic heart

An implantable medical device comprising a drug-loaded polymer overlaid with a fabric that promotes tissue ingrowth is useful in a wide variety of tissue engineering applications. The invention includes, for example, prosthetic heart valves, annuloplasty rings, and grafts, having enhanced biocompatibility and biostability. Methods of making and using the implantable medical devices of the invention are also included.

Owner:MEDTRONIC INC

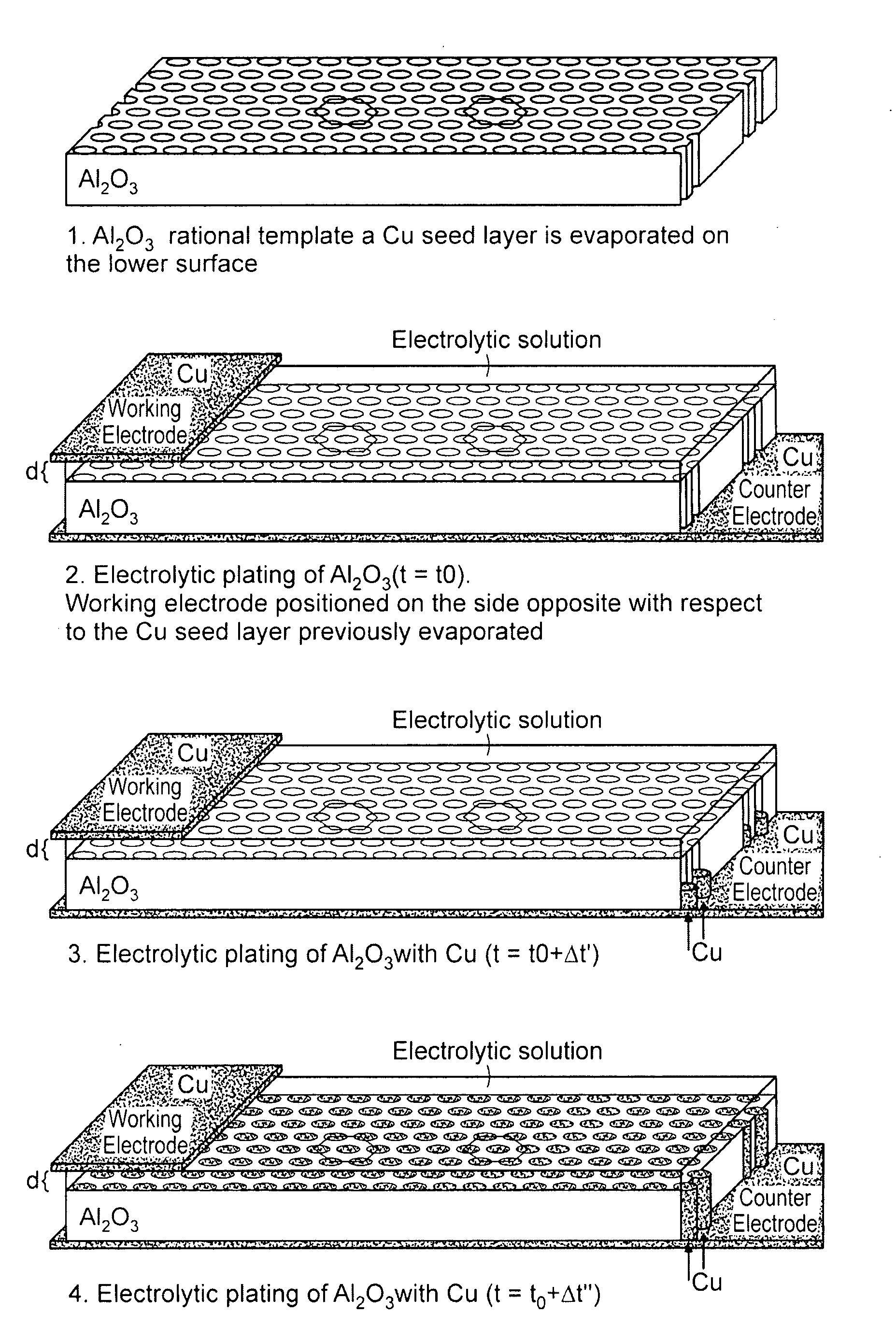

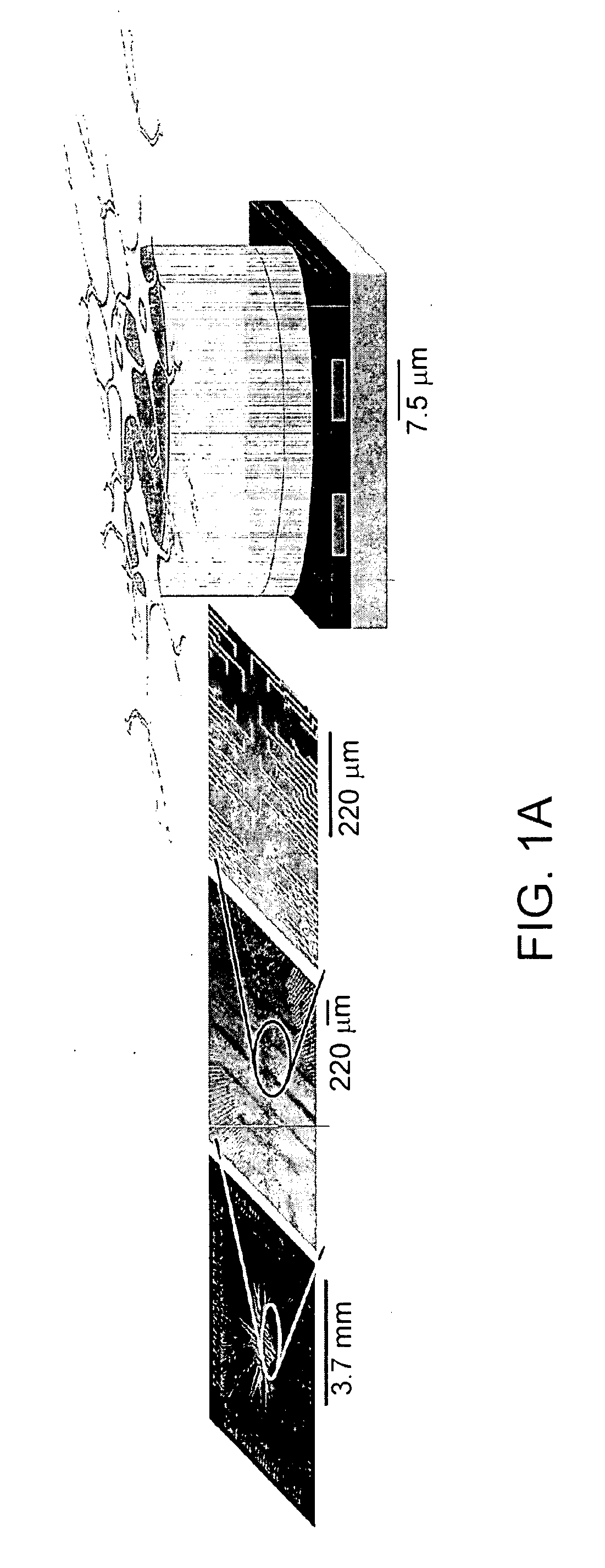

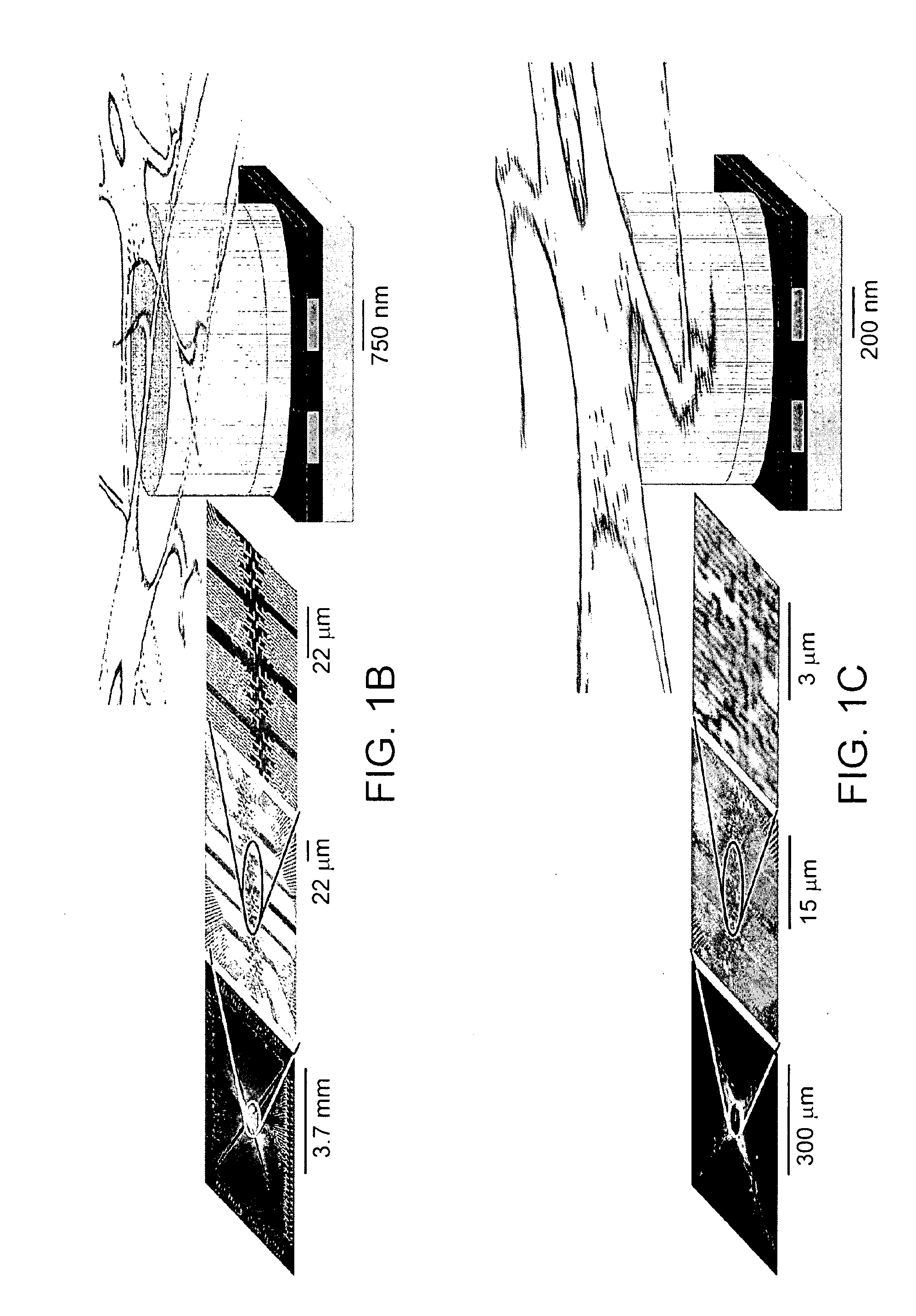

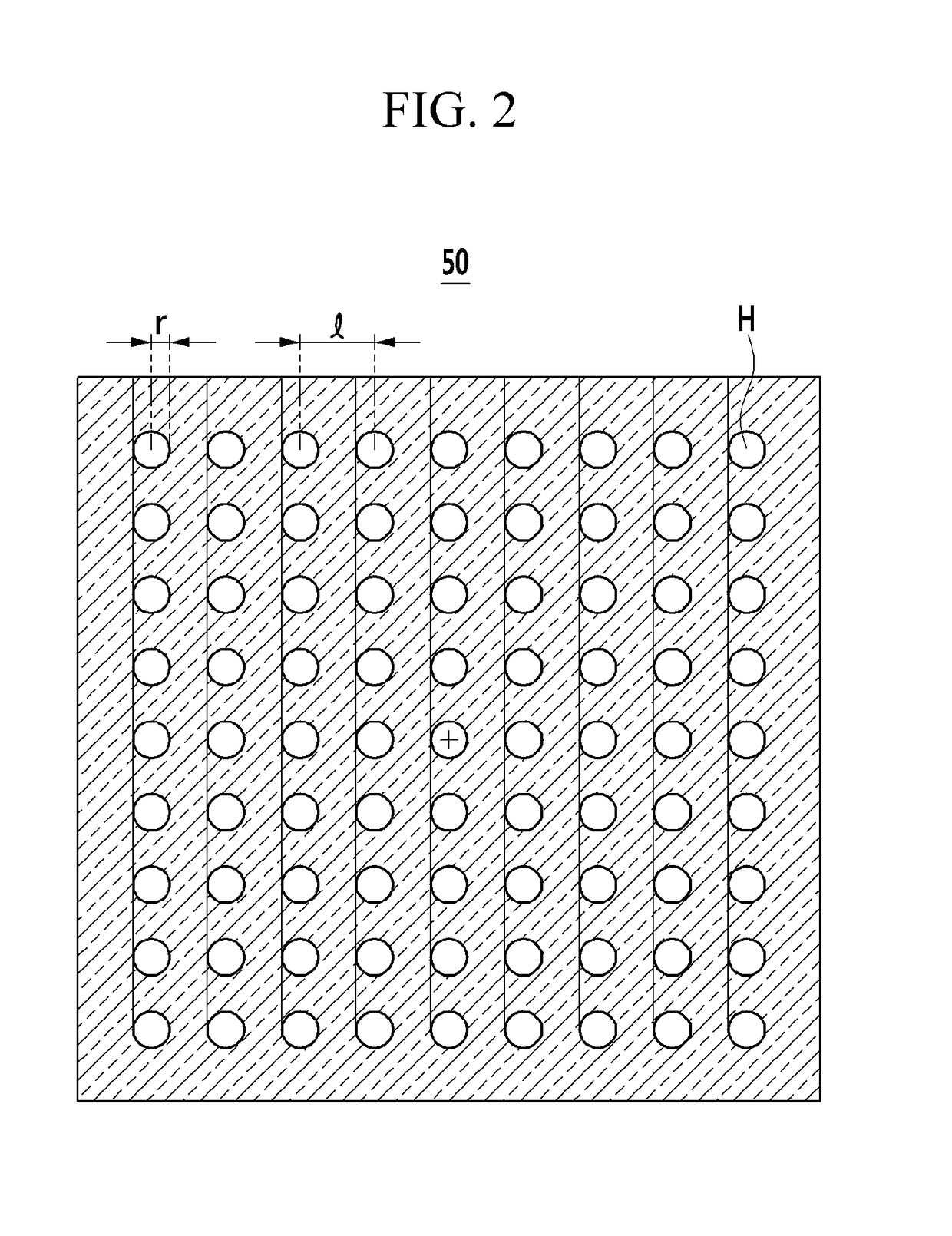

Nanoscale probes for electrophysiological applications

InactiveUS20070187840A1Improve spatial resolutionMaximize signal to noise ratioMaterial nanotechnologySemiconductor/solid-state device detailsDevice formEngineering

A device comprising a planar integrated circuit that includes an array of electrodes and at least one nanostructure, having a major axis, in electrical contact with at least one electrode. The device forms an interface between an integrated circuit platform and electro-physiologically active cells and is used in manipulate the same.

Owner:RENESSELAER POLYTECHNIC INST

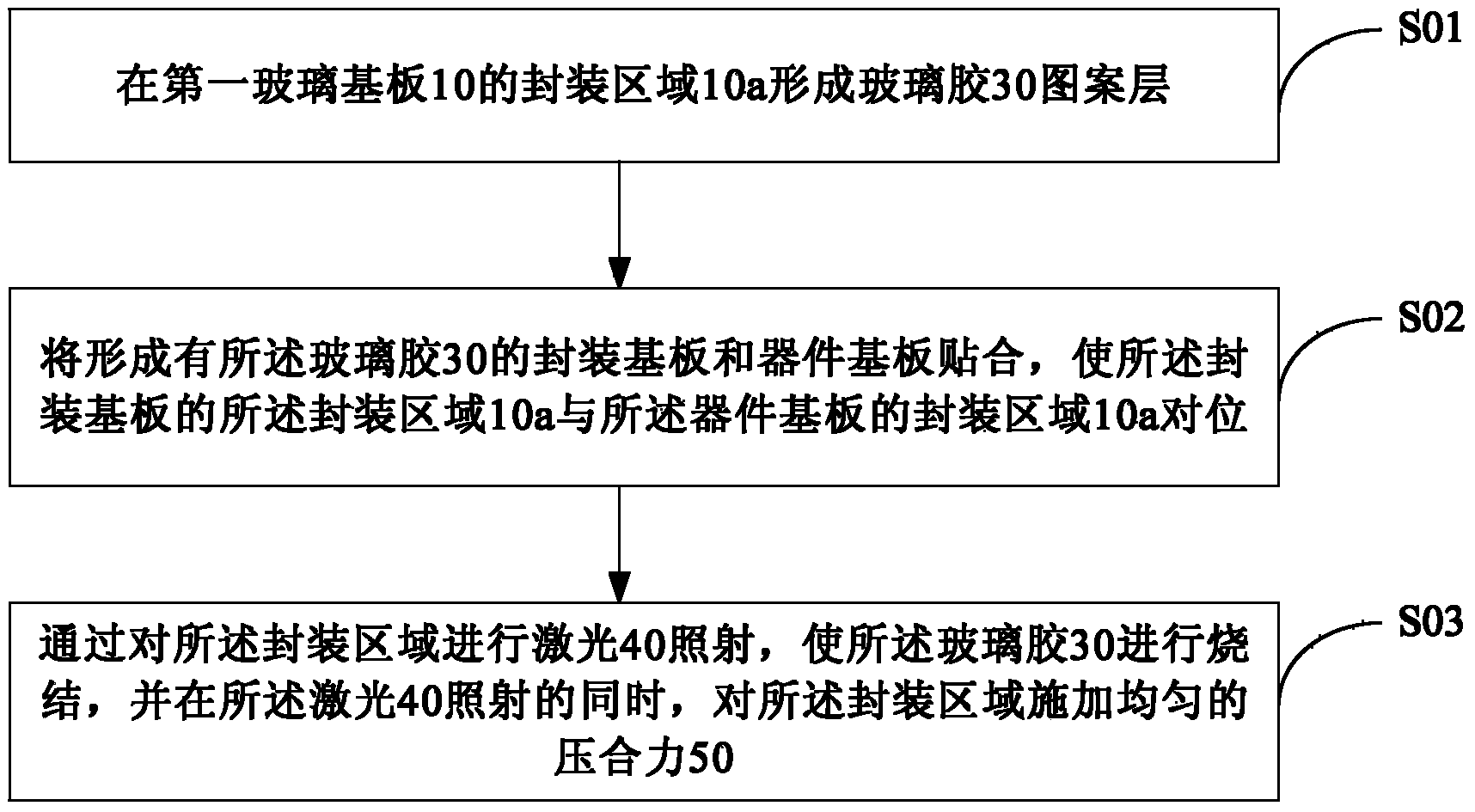

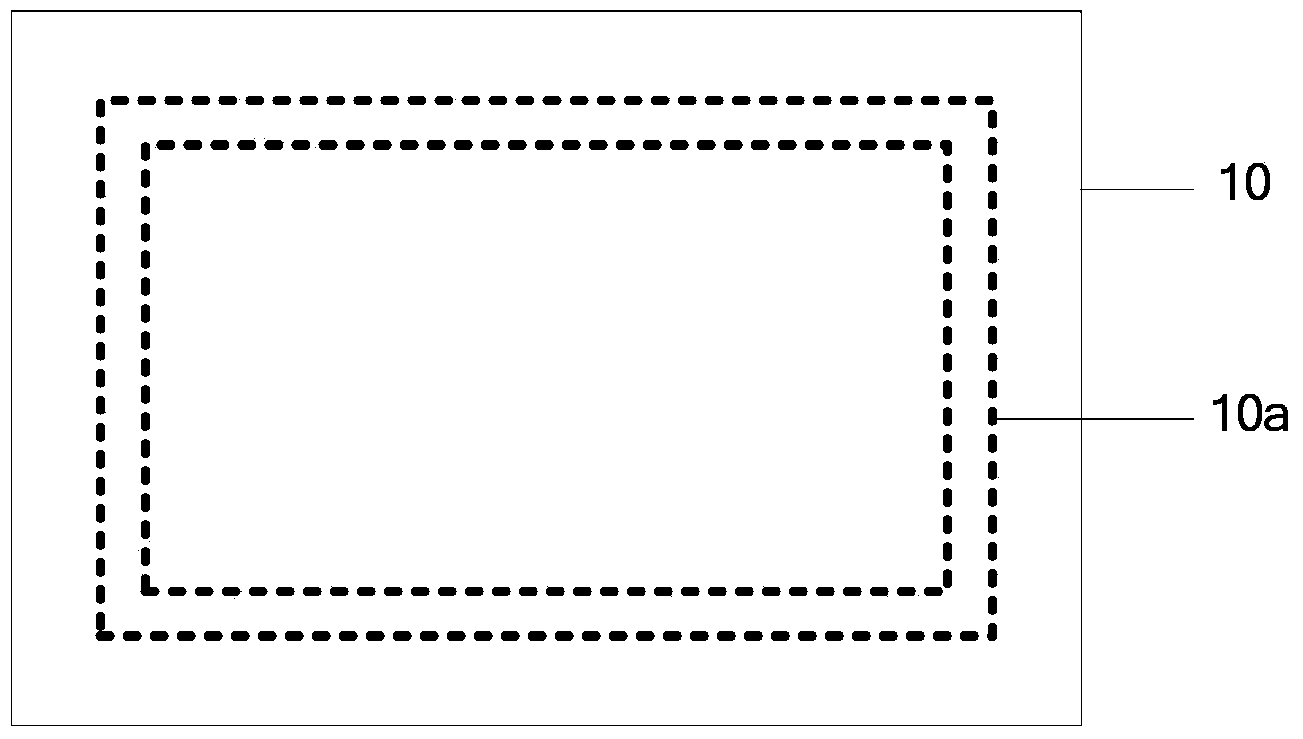

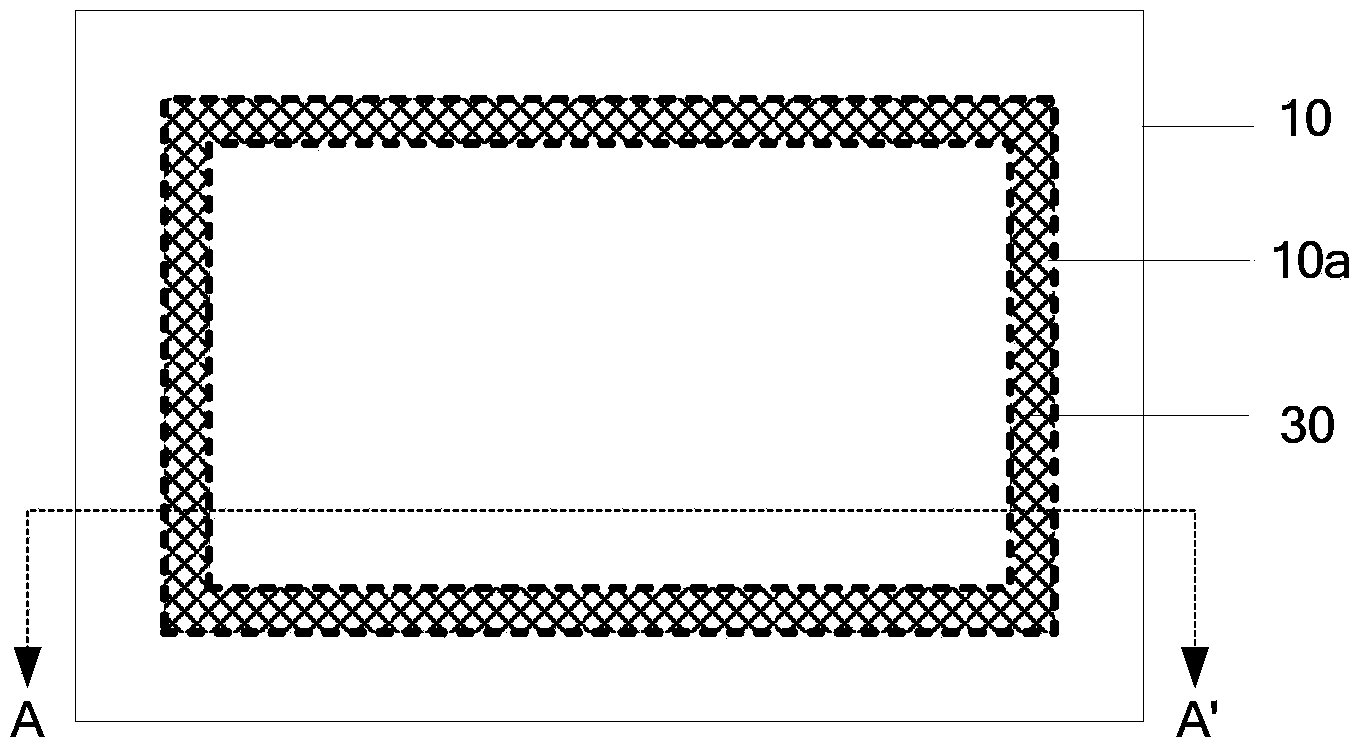

Packaging method and display device

InactiveCN103715371AUniform pressing forceFit tightlySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceIrradiation

The embodiment of the invention provides a packaging method and a display device and relates to the field of display device packaging preparation. The process of the packaging method can be simplified, and the occurrence of the phenomenon that stress is generated inside glass glue when laser beams are irradiated on the glass glue so as to cause poor packaging such as packaging glass cracking or peeling-off can be reduced. The packaging method comprises the following steps: forming a glass glue pattern layer in a packaging area of a first glass substrate; fitting the packaging substrate on which the glass glue is formed onto a device substrate to enable the packaging area of the packaging substrate to be aligned with a packaging area of the device substrate; and irradiating laser on the packaging areas, sintering the glass glue and applying uniform pressing force to the packaging areas during laser irradiation. The packaging method is used in packaging preparation of a display device needing to be isolated from the surrounding environment during packaging.

Owner:BOE TECH GRP CO LTD

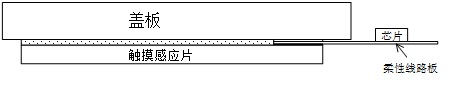

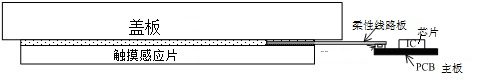

Capacitive touch screen and manufacture method thereof

ActiveCN102629177AReduce the requirements of the process technologyReduce packaging processInput/output processes for data processingManufacturing technologyEngineering

The invention relates to a capacitive touch screen and a manufacture method thereof. A touch control chip is not required to undergo a packaging test, and a chip wafer is only required, so that compared with a touch control chip adopted by a traditional touch screen module, the capacitive touch screen is reduced in costs of chip packaging and package test. Simultaneously as the area of the chip is small, compared with the traditional touch control chip with a package shape, the capacitive touch screen occupies small space. The overall material cost of the capacitive touch screen can be effectively reduced, simultaneously the capacitive touch screen is easy to produce, the requirement on the manufacture technology of the capacitive touch screen is reduced, and the product yield is improved.

Owner:FOCALTECH SYST LTD

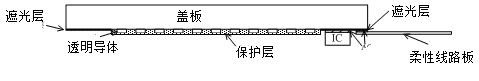

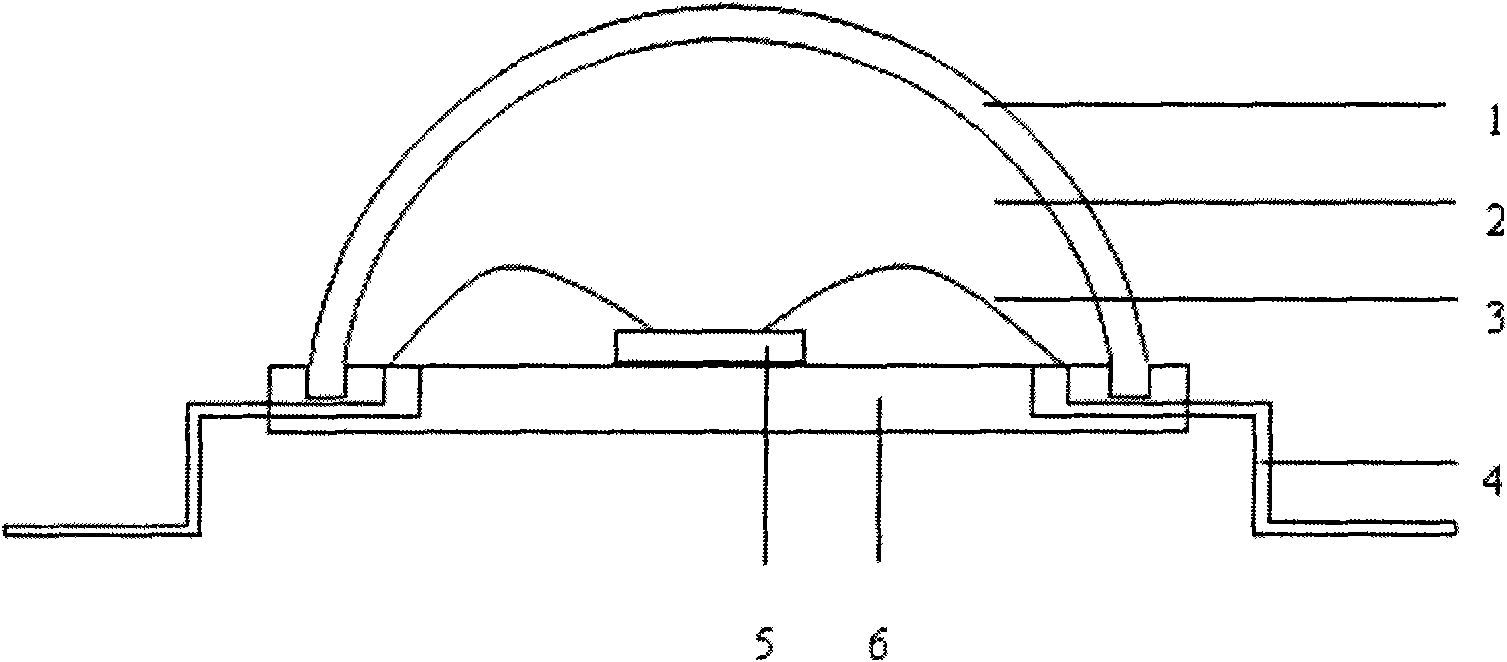

Method for actively encapsulating LED chip and encapsulation structure thereof

InactiveCN101582477AImprove light extraction efficiencyGood process repeatabilitySemiconductor devicesUltraviolet lightsWork in process

The invention discloses an active encapsulation method which utilizes the spontaneous light of a chip to initiate photosensitive resin polymerization for the in-situ preparation of a lens with an LED single layer and multilayer structure. The method includes the following steps: photosensitive resin liquid wave band light which is sensitive to specific wave band light is prepared; an LED semi-finished product which is processed by electrode connection and die bond is presoaked in photosensitive resin for die bond; the LED semi-finished product is inverted to be soaked in the photosensitive resin liquid, low working current is led into and enables the LED chip to be luminous, photosensitive resin is triggered to generate preliminary polymerization, and a photosensitive resin core is formed on the luminous surface of the LED chip; the LED semi-finished product is separated from the surface of the photosensitive resin liquid, and the drops of the photosensitive resin liquid need to be attached to the photosensitive resin core and a chip base; the intermediate working current is led into and enables the LED chip to be luminous, and the drops of the photosensitive resin liquid are stimulated to be solidified; after the solidification of the drops of the photosensitive resin liquid, high working current is led into a sample so as to enable the LED chip to be luminous, and then the steps of solidification and decoloration are carried out, or the sample is irradiated by sunlight, purple light or ultraviolet light to be decolourized; and finally the sample processed by solidification and decoloration is cleaned.

Owner:SUN YAT SEN UNIV

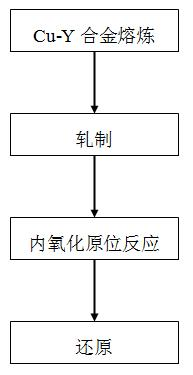

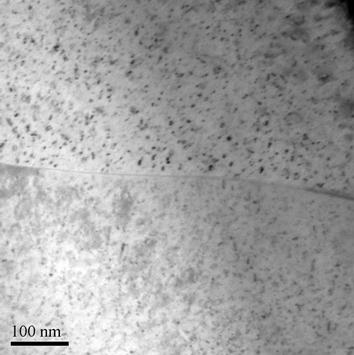

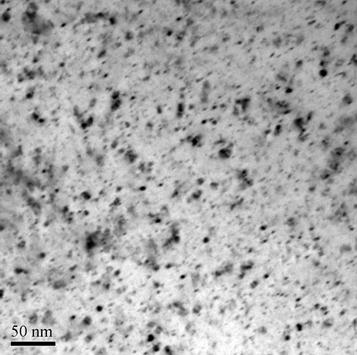

Dispersion strengthening copper-based composite material and preparation method thereof

The invention relates to a dispersion strengthening copper-based composite material and a preparation method thereof. The dispersion strengthening copper-based composite material and the preparation method thereof are characterized in that A dispersion strengthening phase is yttrium oxide, and the content of yttrium oxide in copper is 1-2.5 percent by weight, and the preparation method comprises the processes of alloy smelting, rolling, internal oxidation, reduction and the like. The preparation method has the advantages of short process and low production cost. The tensile strength of the product is greater than 550 MPa, the conductivity exceeds 90 percent IACS (international annealed copper standard), and the softening temperature is higher than 900 DEG C. The dispersion strengthening copper-based composite material has higher mechanical property, excellent electrical conductivity and high-temperature softening resistance. The Y2O3 granulate dispersion strengthening copper-based composite material prepared in the invention can be applied to computer integrated circuit lead frames, resistance welding electrodes for automobile industry, linings of crystallizers of continuous casting machines for metallurgical industry, equipment and carrier rockets, electric car and electric power train aerial conductor and the like, and the character of service and the service life can be obviously improved.

Owner:NANCHANG UNIV

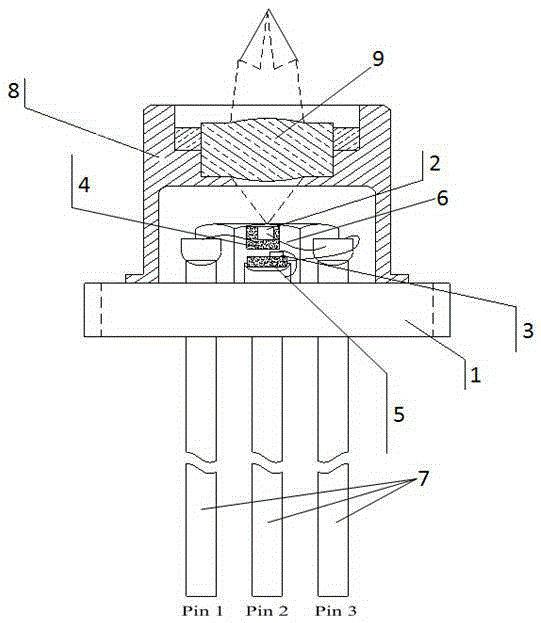

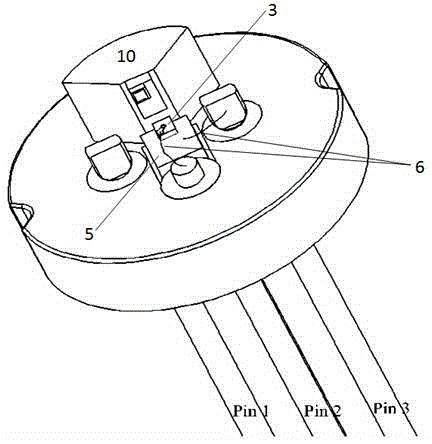

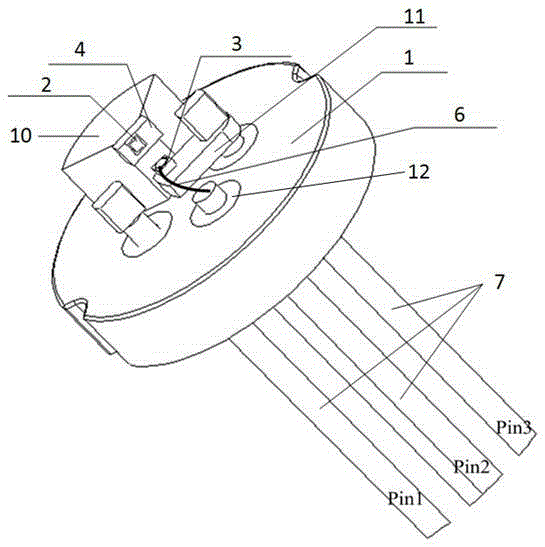

Transistor outline (TO)-CAN packaged semiconductor laser and fabrication method thereof

InactiveCN105261929ALow costAvoid the risk of easy sheddingLaser detailsSemiconductor lasersSemiconductor packageSemiconductor chip

The invention proposes a transistor outline (TO)-CAN packaged semiconductor laser and a fabrication method thereof. The TO-CAN packaged semiconductor laser comprises a TO tube base, a semiconductor laser chip, a backlight detector chip, a gold bonding wire, pins and a heat sink block, wherein the heat sink block is arranged on the upper surface of the TO tube base, the pins are fixed on the TO tube base in an insulation way, the upper end of at least one pin protrudes out of the upper surface of the TO tube base, the semiconductor laser chip is fixed on the surface of the heat sink block, the upper part of the pin protruding out of the upper surface of the TO tube base is connected with a support table, and the backlight detector chip is arranged on the support table and below the semiconductor laser chip. In the TO-CAN packaged semiconductor laser, the backlight detector chip is arranged on the support table integrated and connected with the pins, thus, an independent cushion block is omitted, and the material cost of the cushion block is saved; and moreover, the gold wire bonding process between the backlight detector chip and the cushion block in one time is omitted, the gold wire bonding process is simplified, the gold wire bonding cost is saved, and the stability of a laser product is improved.

Owner:武汉海赛姆光电技术有限公司

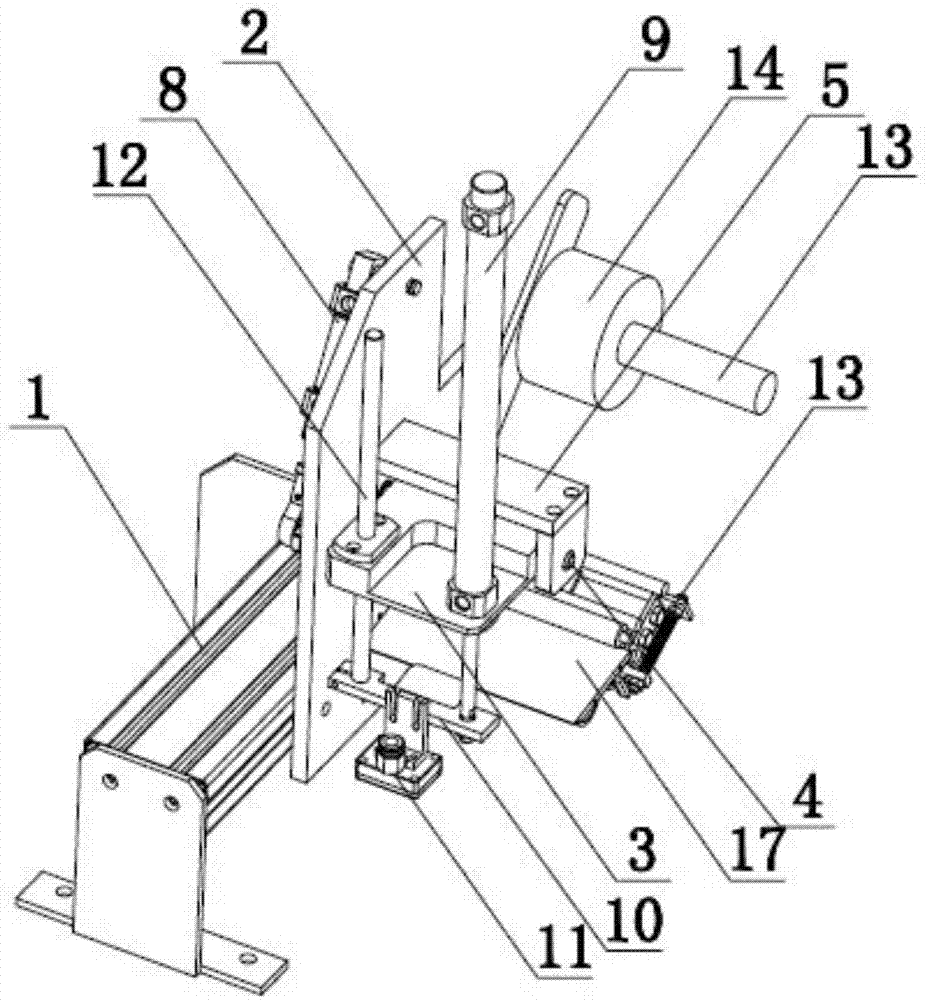

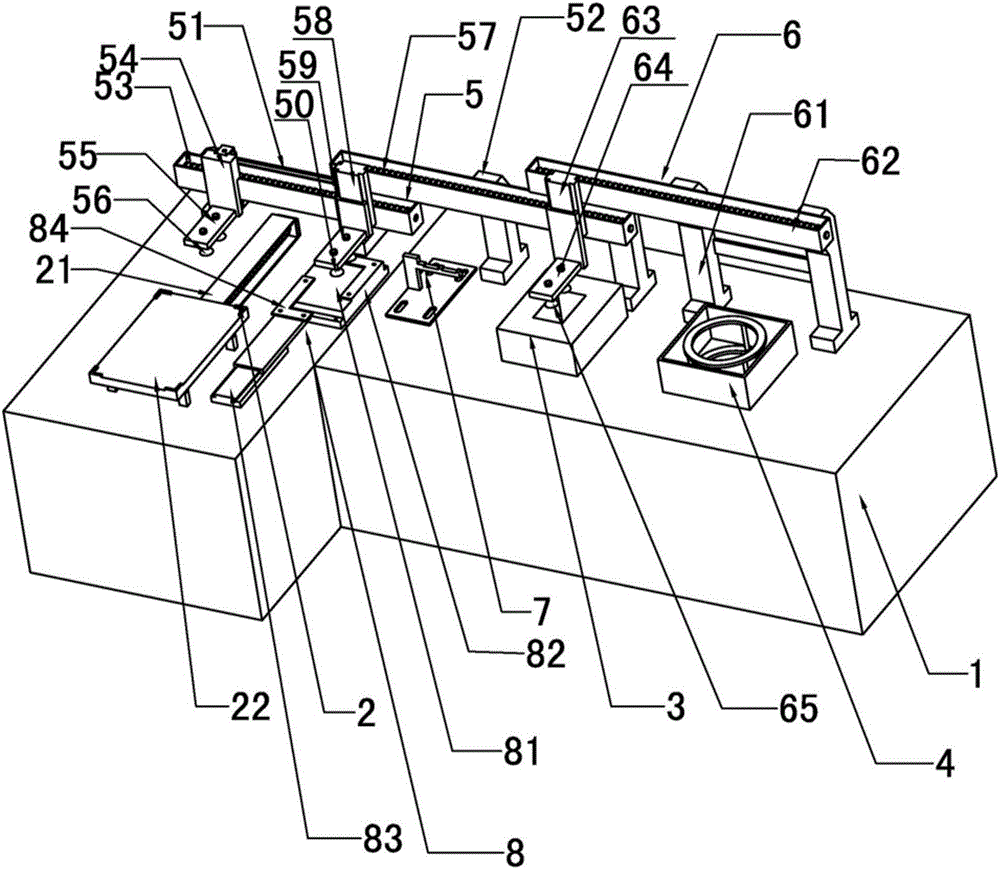

Label adsorption and attachment device and implementation method thereof

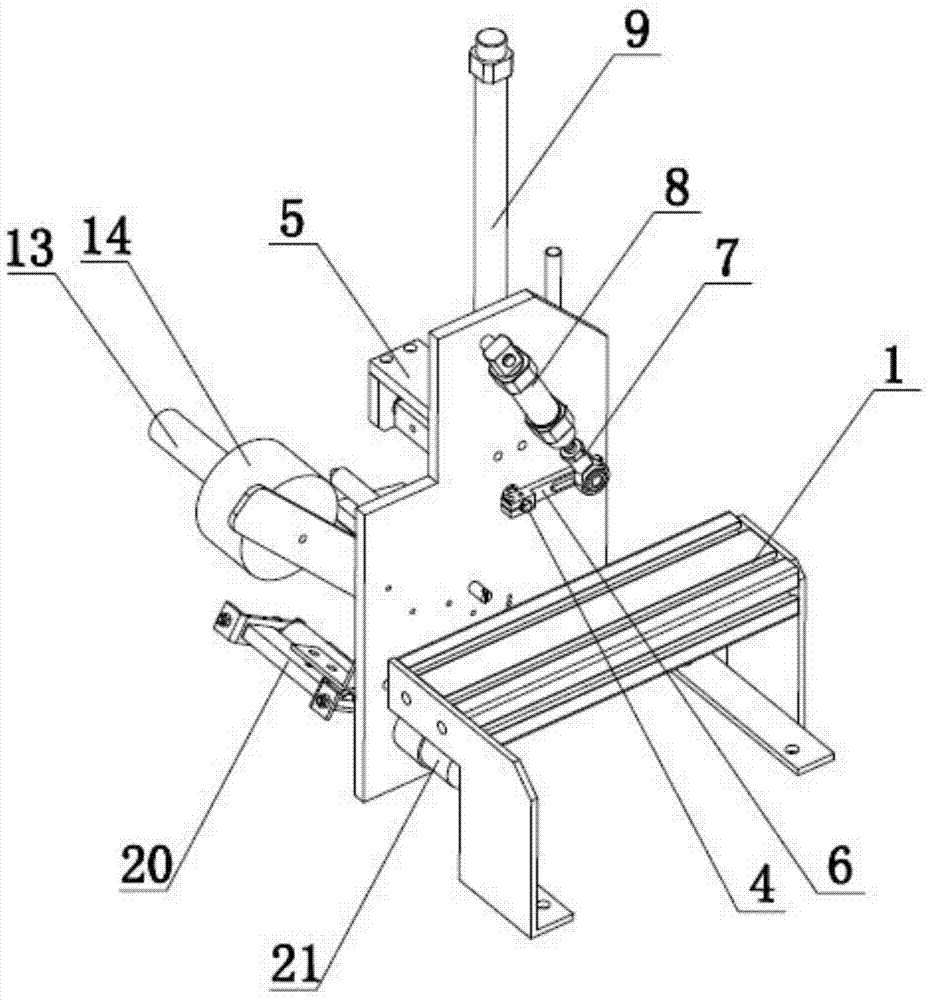

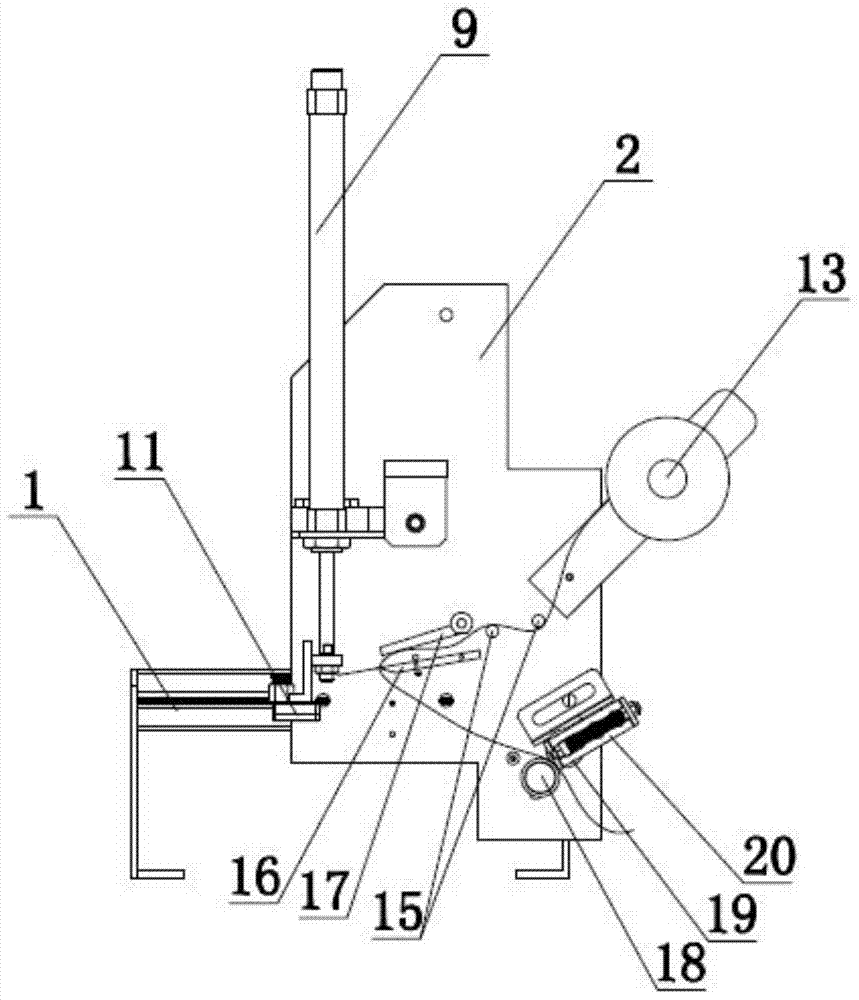

ActiveCN104276317AImprove work efficiencyReduce packaging processLabelling machinesPaper tapeEngineering

The invention discloses a label adsorption and attachment device and an implementation method thereof. The label adsorption and attachment device comprises a stander, wherein a wall plate is vertically arranged on the stander; a material supply polish rod, a flat material guide plate and a pair of tension rollers are arranged on the side surface of the wall plate according to three vertexes of three angles, respectively; a paper-tape coil with labels is arranged on the material supply polish rod in a sleeving manner; the free head of the paper-tape coil runs along the flat material guide plate, passes through a bent position and then is clamped between the two tension rollers; a vacuum cavity type adsorption head is arranged at the bent position in a clutching manner and is arranged on a rotating and lifting power mechanism which is used for driving the vacuum cavity type adsorption head to do reciprocating rotation along an arc trace and can rise and fall along the longitudinal direction. The label adsorption and attachment device can simulate operation of an operator of bending and upwarping an adhesive edge of a label and manually stripping off the label, namely when the paper-tape coil runs to the bent position, the label at the paper-tape coil is upwarped by bending, and furthermore, the vacuum cavity type adsorption head strips off the label by using negative pressure gas; the label is safely, reliably, successfully and efficiently taken in the whole process.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

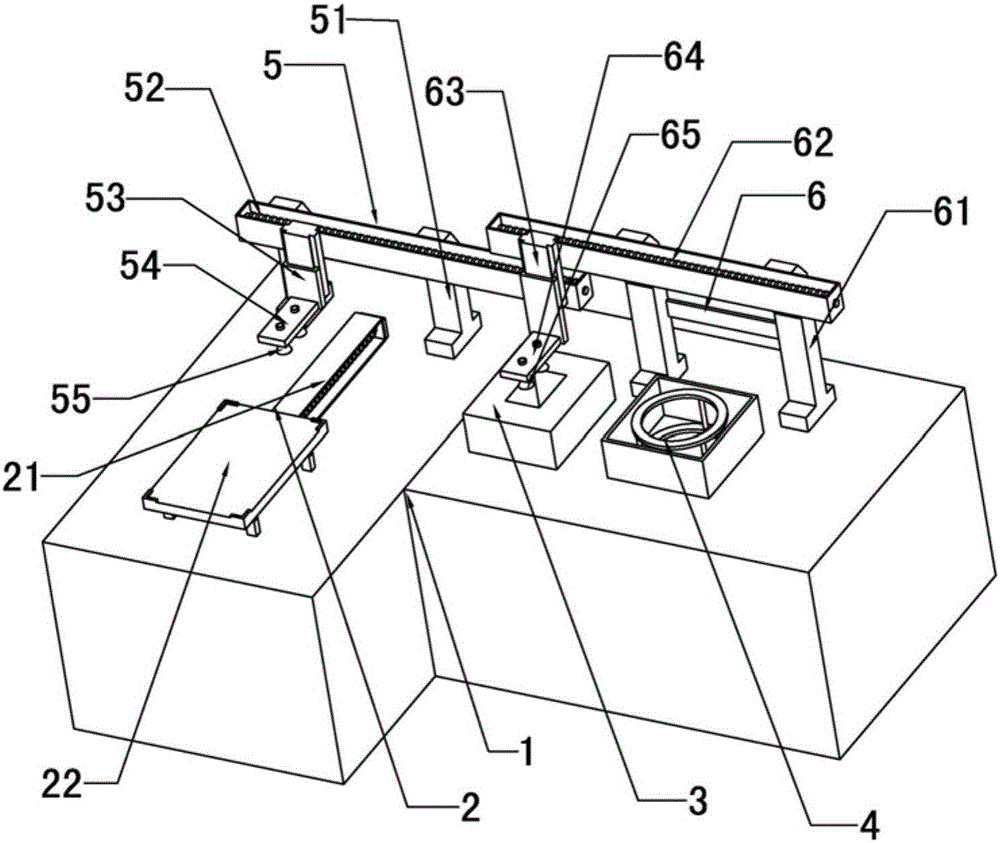

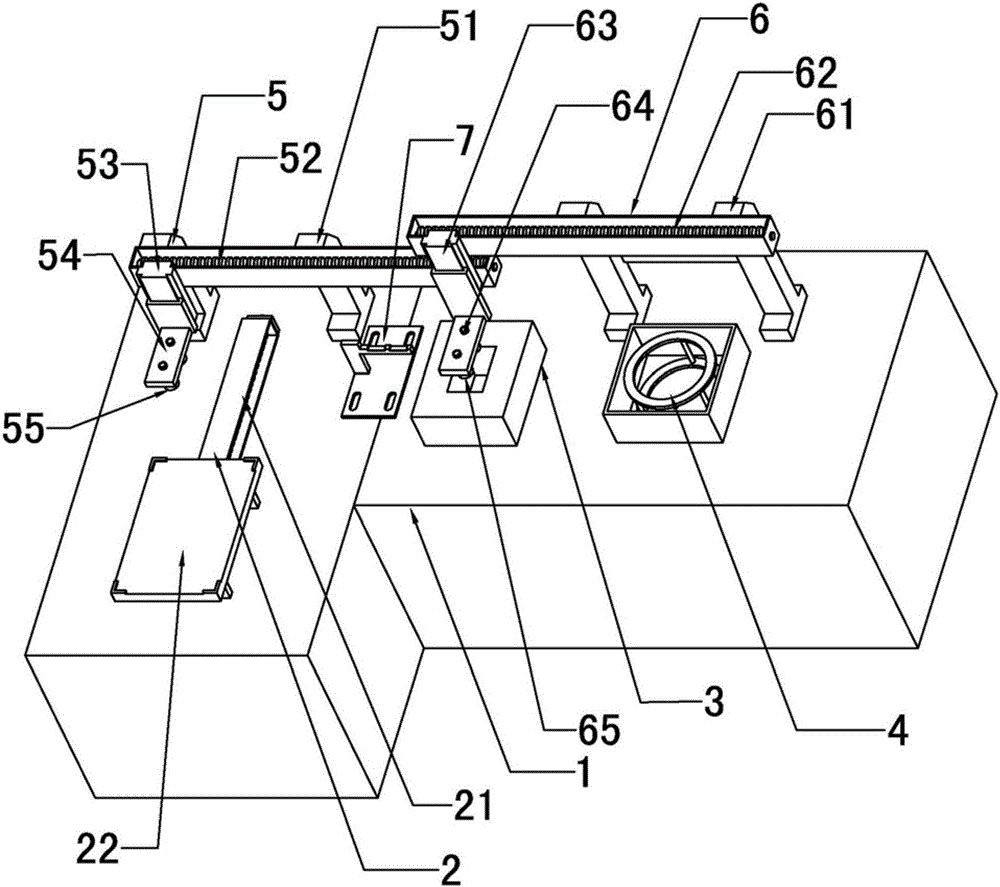

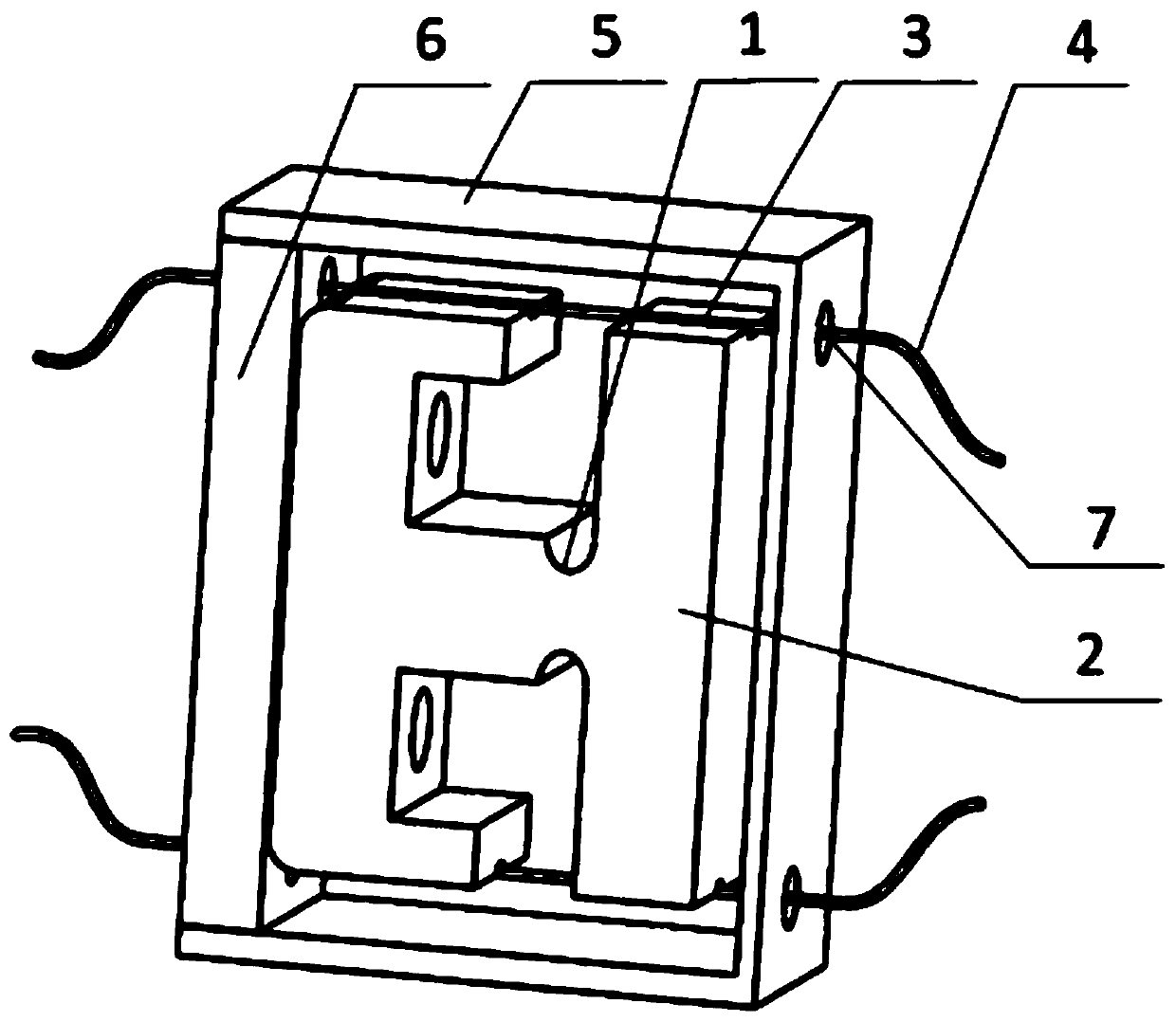

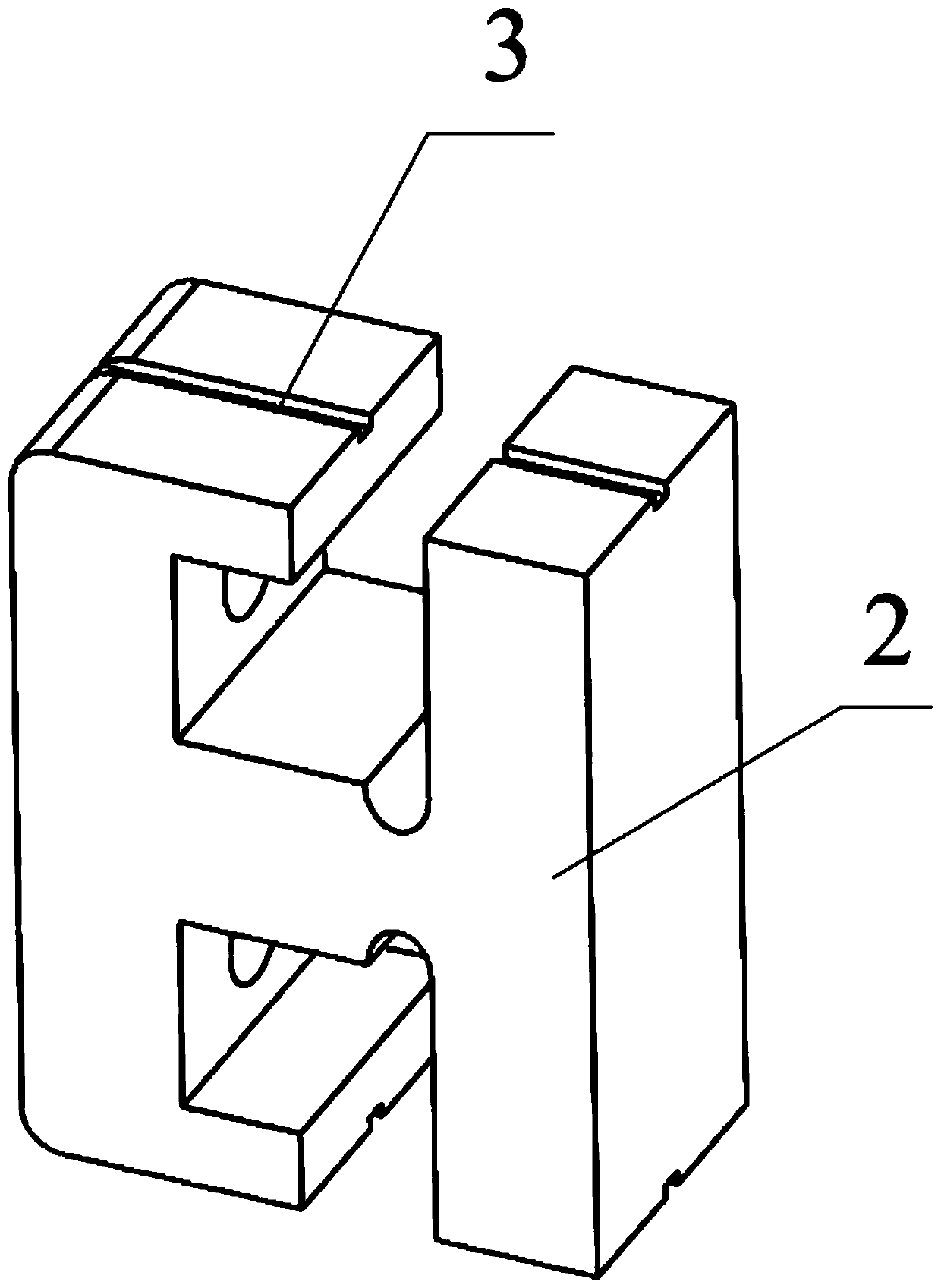

Magnetic steel magnetization and magnetic flux detection integrated equipment

InactiveCN106144579ARealize integrated operationOmit the transfer processMagnetic bodiesMagnitude/direction of magnetic fieldsIntegrated operationsMagnetization

The invention discloses magnetic steel magnetization and magnetic flux detection integrated equipment. The integrated equipment comprises a worktable; a feeding station, a magnetizing station and a magnetic flux detecting station are arranged on the worktable in sequence; a feeding device is arranged in the feeding station; a magnetizing coil connected with a magnetizing machine is arranged in the magnetizing station; a magnetic flux measurer is arranged in the magnetic flux detecting station; a first conveying device for conveying magnetic steel from the feeding station to the magnetizing station is arranged between the feeding station and the magnetizing station; and a second conveying device for conveying the magnetized magnetic steel to the magnetic flux detecting station is arranged between the magnetizing station and the magnetic flux detecting station. The equipment has the advantages of realizing integrated operation of magnetization and magnetic flux detection, saving both manpower and material resources, reducing the production cost and improving the production efficiency.

Owner:江苏晨朗电子集团有限公司

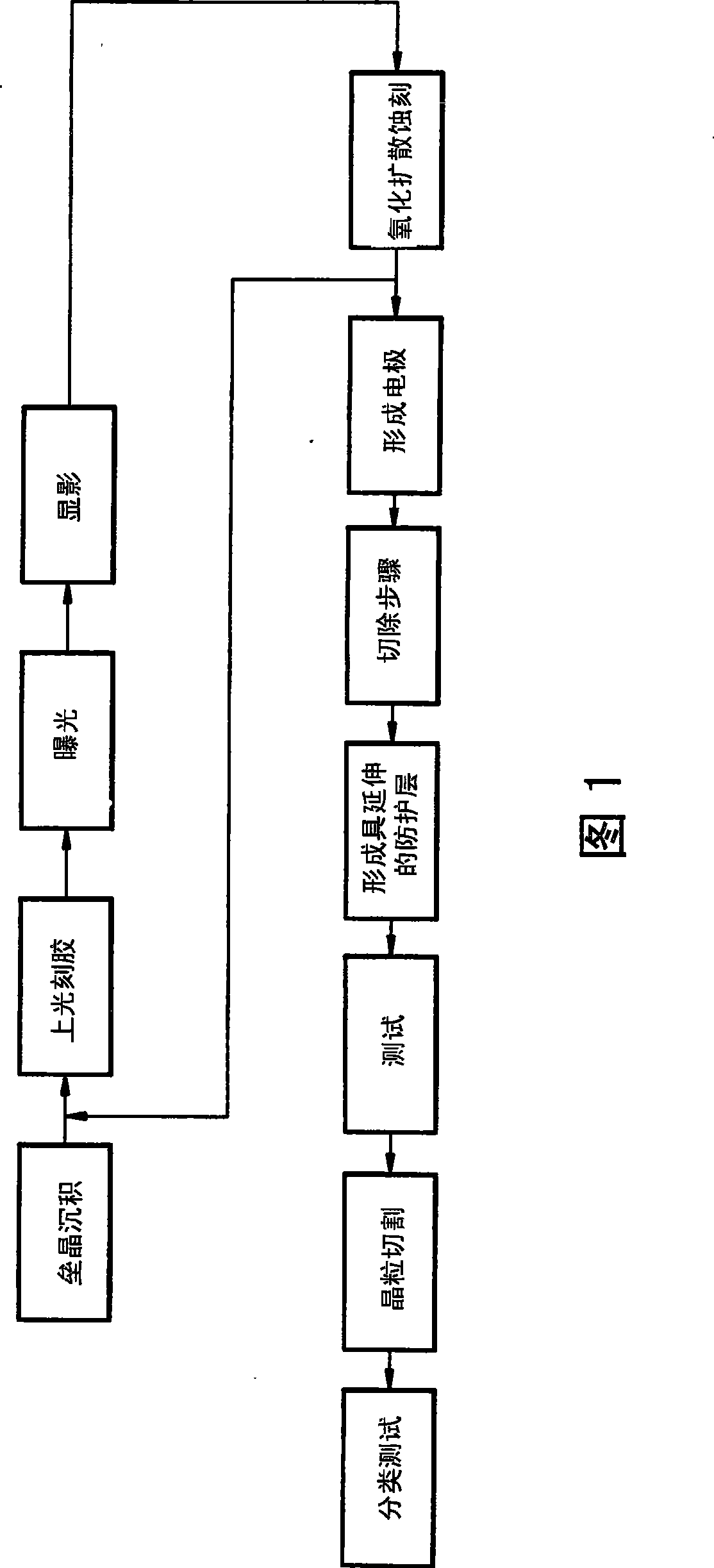

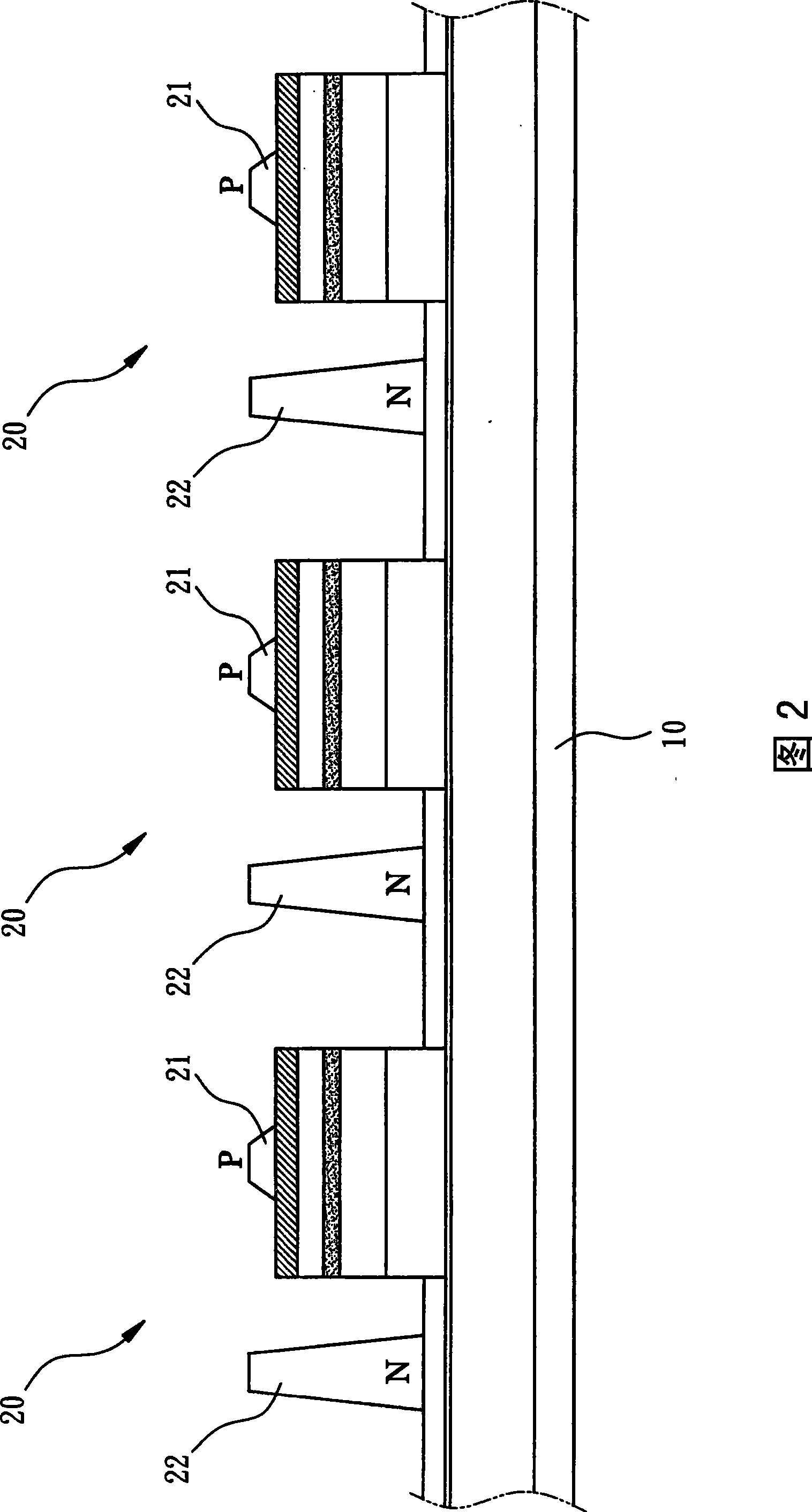

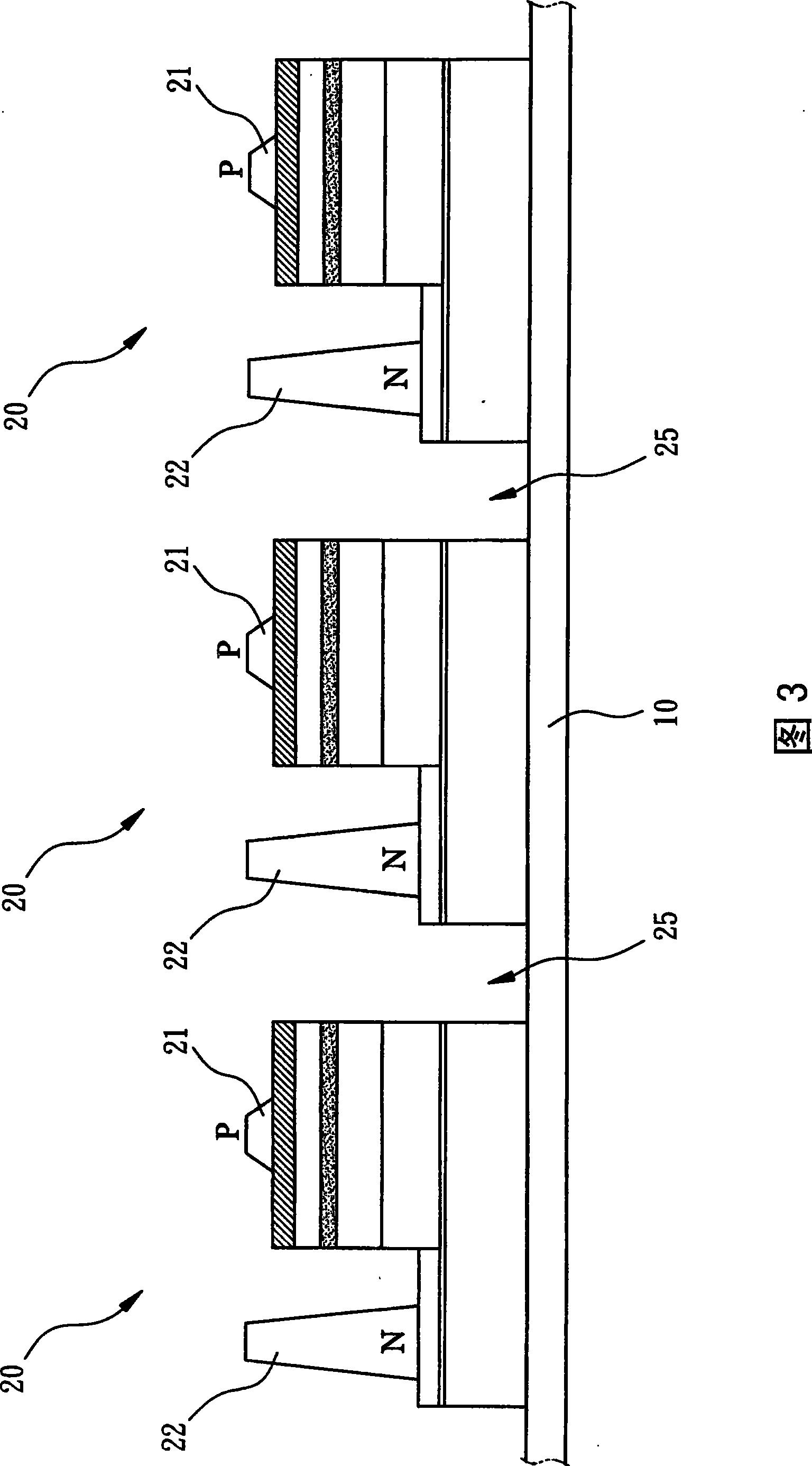

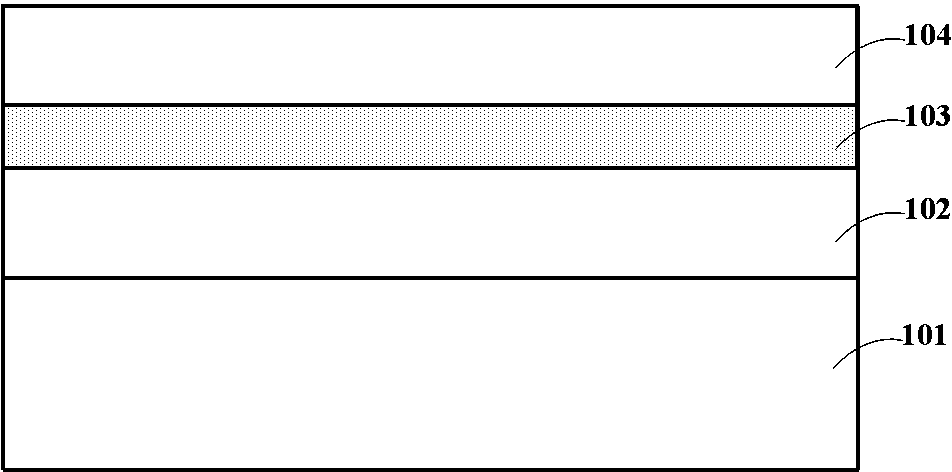

Wafer stage encapsulation LED chip and manufacturing method thereof

InactiveCN101452975AReduce assembly lineReduce packaging processSemiconductor/solid-state device detailsSolid-state devicesManufacturing cost reductionEconomic benefits

The invention provides a wafer-level packaged LED chip, and a manufacture method thereof. The method is characterized in that an LED is formed on a wafer substrate by utilizing the steps of smearing photoresist, exposing, developing, etching and the like in a semiconductor process; the top surface of the LED is provided with a positive electrode and a negative electrode; before the wafer substrate is cut into a single LED chip, an extension layer connected with the adjacent LED is removed through a cutoff step; through a step of forming protective layers with extensions, a protective layer with an extension is formed on the periphery of the LED except the top surfaces of the positive and negative electrodes, so as to ensure that the LED chip can utilize the protective layer to generate self-protection functions of resisting moisture, preventing oxidation, preventing short circuit and the like; therefore, subsequent assembly routing, packaging, package test and other actions can be reduced; and the method can greatly shorten production flow and time, reduce production cost, raise product yield, and then increases economic benefit.

Owner:杨秋忠

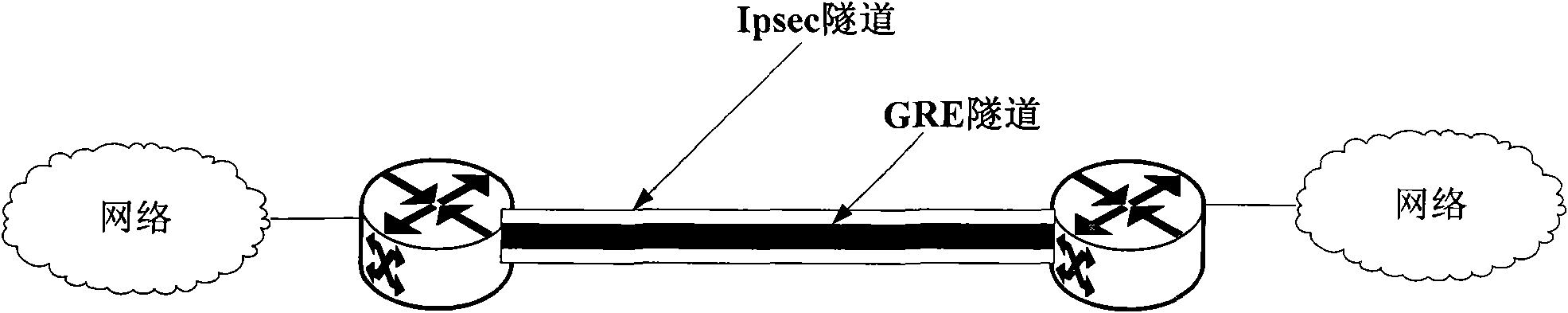

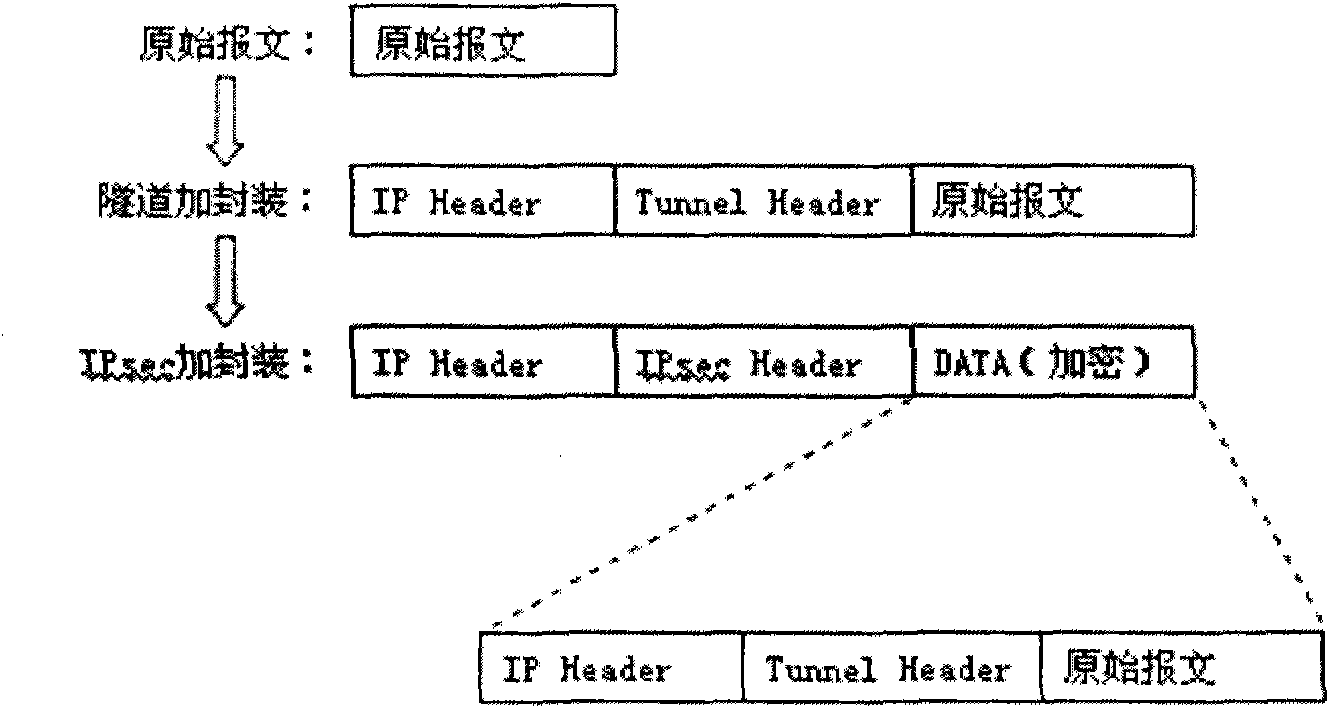

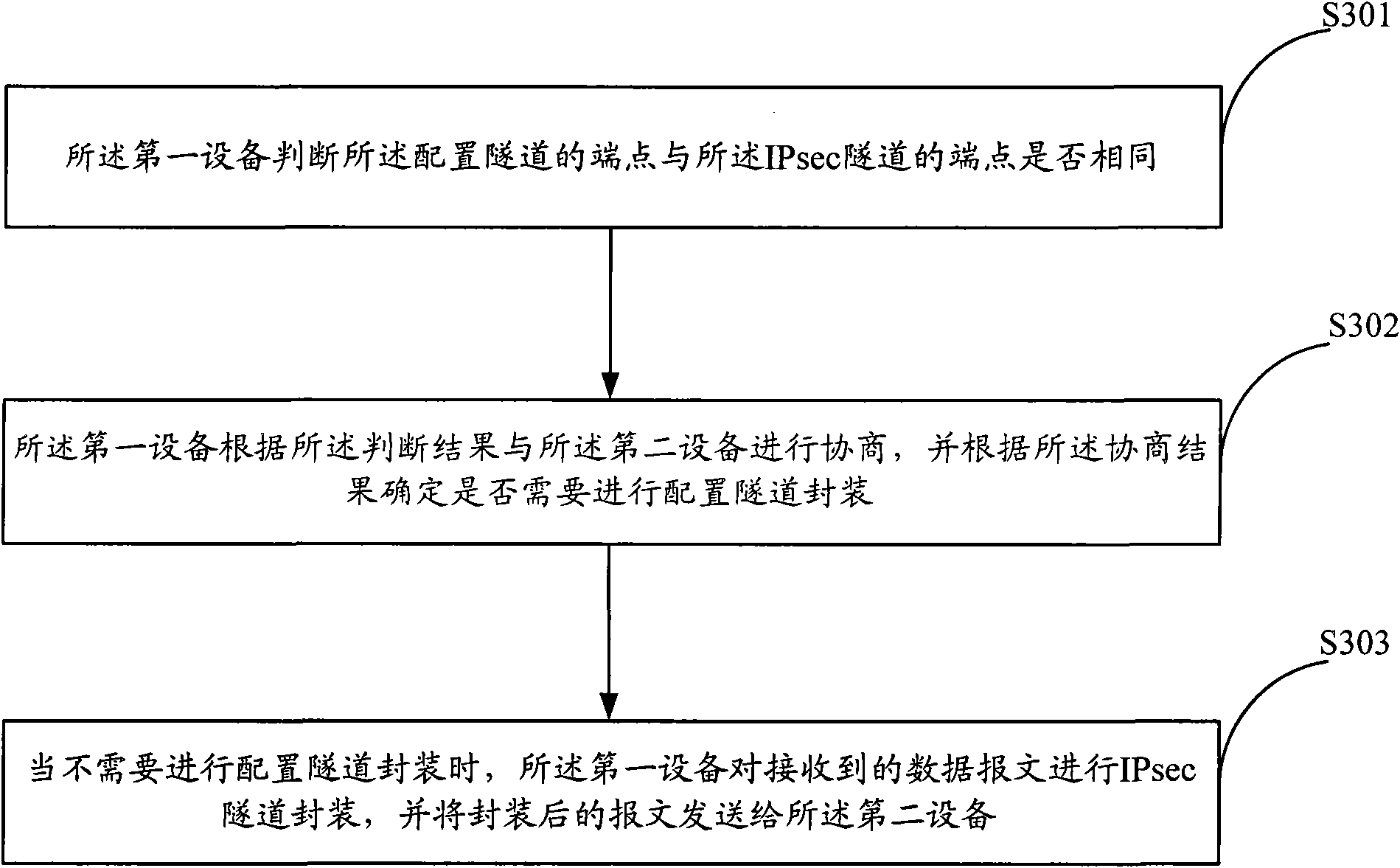

Data encapsulation method and equipment thereof

The invention discloses a data encapsulation method. The method comprises the following steps: first equipment judges whether an endpoint of a configured tunnel is the same as that of an IPsec tunnel; the first equipment negotiates with second equipment according to a judgment result, and determines whether encapsulation of the configured tunnel is required according to a negotiation result; and the first equipment performs IPsec tunnel encapsulation on the received data message and sends an encapsulated message to the second equipment when encapsulation of the configured tunnel is not required. In the invention, IPsec tunnel encapsulation is required only once, thus decreasing the encapsulation process of the configured tunnel. The invention also provides equipment corresponding to the data encapsulation method.

Owner:NEW H3C TECH CO LTD

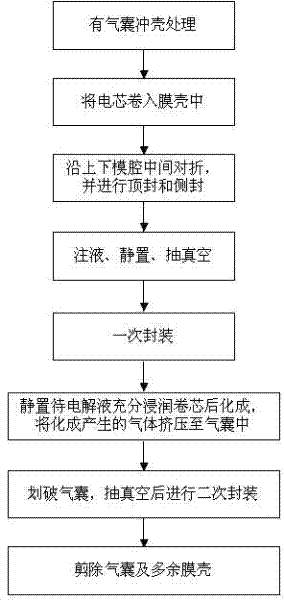

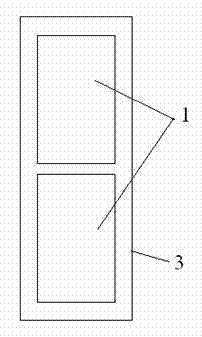

Flexible package lithium ion battery and processing method thereof

InactiveCN102403530ALow raw material costSave work stations and a certain amount of man-hoursFinal product manufactureSecondary cellsElectrical batteryEngineering

The invention provides a flexible package lithium ion battery and a processing method thereof. The flexible package lithium ion battery comprises a membrane housing, a lug, and an electric core and an electrolyte which are arranged in the membrane housing, wherein the membrane housing is provided with a sheet one-way valve, one end of the sheet one-way valve is inserted into the electric core and the other end of the sheet one-way valve is exposed outside the electric core, and the sheet one-way valve is used for exhausting gas inside the flexible package lithium ion battery. The processing method of the flexible package lithium ion battery comprises the following steps of: A, punching the housing without an air bag; B, coiling the electric core into the membrane housing; C, doubling over along an upper die cavity and a lower die cavity, carrying out tip seal and side seal, packaging the sheet one-way valve on the membrane housing; D, injecting electrolyte, standing until the electrolyte is absorbed completely and vacuumized; E, packaging the electrolyte-injecting side; and F, degassing. Through arranging the sheet one-way valve on the top, gas generated during the degassing can be immediately exhausted, the air bag and the air bag and the right side part of the air bag can be removed during punching the housing, thus raw materials and processing procedures are saved, and packaging effect and safety of the battery are improved.

Owner:SHENZHEN EPT BATTERY

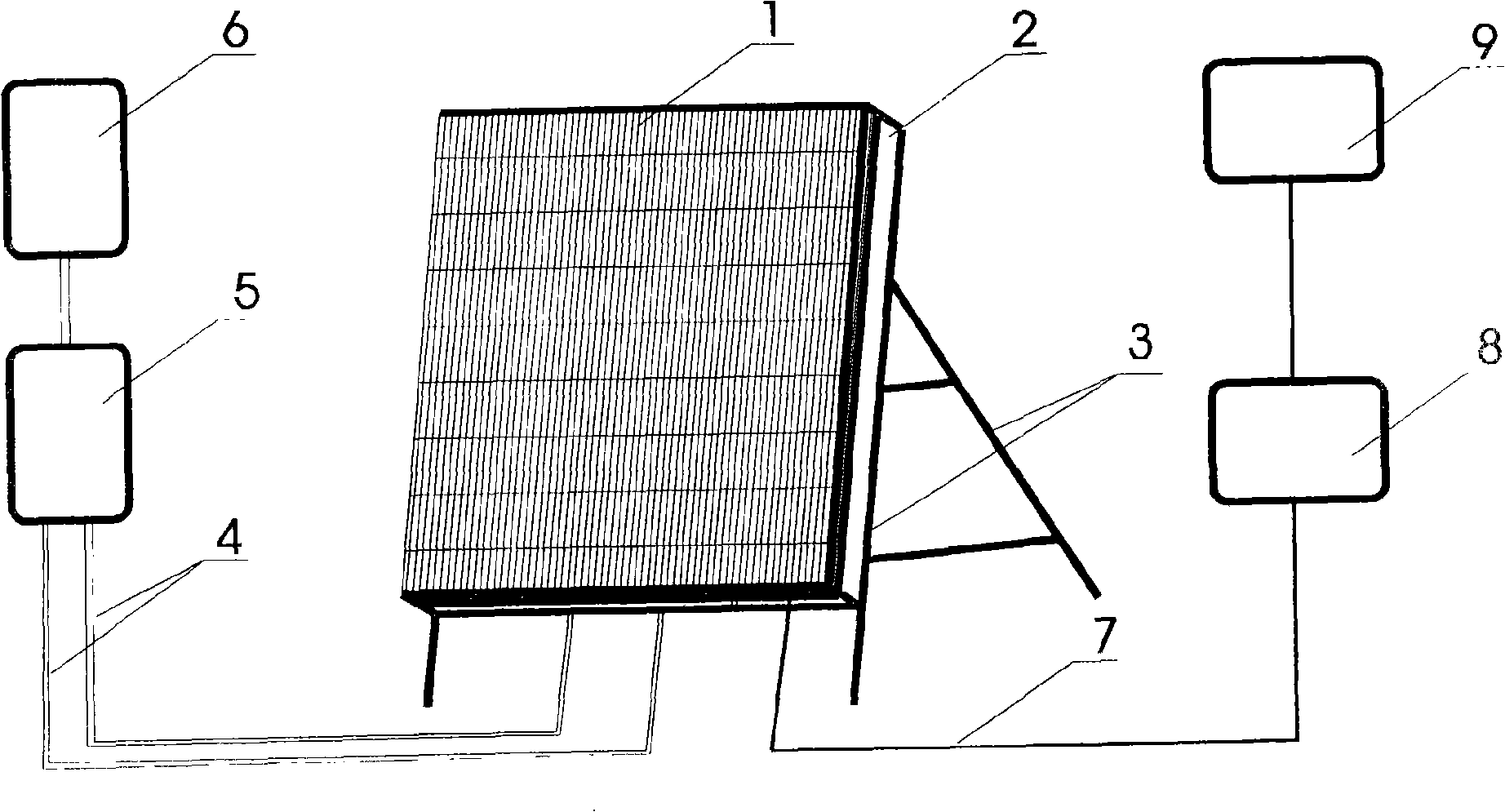

Cogeneration solar boiler

InactiveCN101359885AHigh energy conversion rateReduce manufacturing costBatteries circuit arrangementsSolar heat devicesThermal energyCogeneration

Disclosed is a cogeneration solar boiler, which belongs to the technique field of high-efficient solar energy utilization. The solar boiler optimizes and matches a photovoltaic generation solar panel with a heat abstractor of a solar thermal utilization product which are connected and combined into the cogeneration solar boiler. The boiler can fully utilize the light and heat of sunshine, and utilize the heat of the rest parts while converting the part that can be directly converted into electric energy in the radiation energy into electric energy. The solar boiler thereby can substantially increase the energy conversion rate of solar energy utilization products, greatly reduce manufacturing costs, and provide a new technical proposal for high-efficient solar energy development and utilization.

Owner:雷加良

Manufacturing method for LED chip

ActiveCN103904174AImprove light extraction efficiencyFlat surfaceSemiconductor devicesEtchingEngineering

The invention provides a manufacturing method for an LED chip by utilizing the laser scribing technology, the etching technology and the reflective layer back-plating technology. Two times of laser light are adopted for deflecting back scribing, so that scribing width and scribing depth are increased, and a U-shaped gap is formed; due to etching, scraps caused by laser scribing can be removed, and the surface of the U-shaped gap is more flat; a locally tilted side face is formed on a sapphire substrate through the U-shaped gap, after the side face and the obverse side of the substrate form a high-reflectance layer, rays emitted from a light-emitting layer can be reflected upward to a greater degree, and therefore the light-emitting efficiency of the LED chip is enhanced.

Owner:ANHUI SANAN OPTOELECTRONICS CO LTD

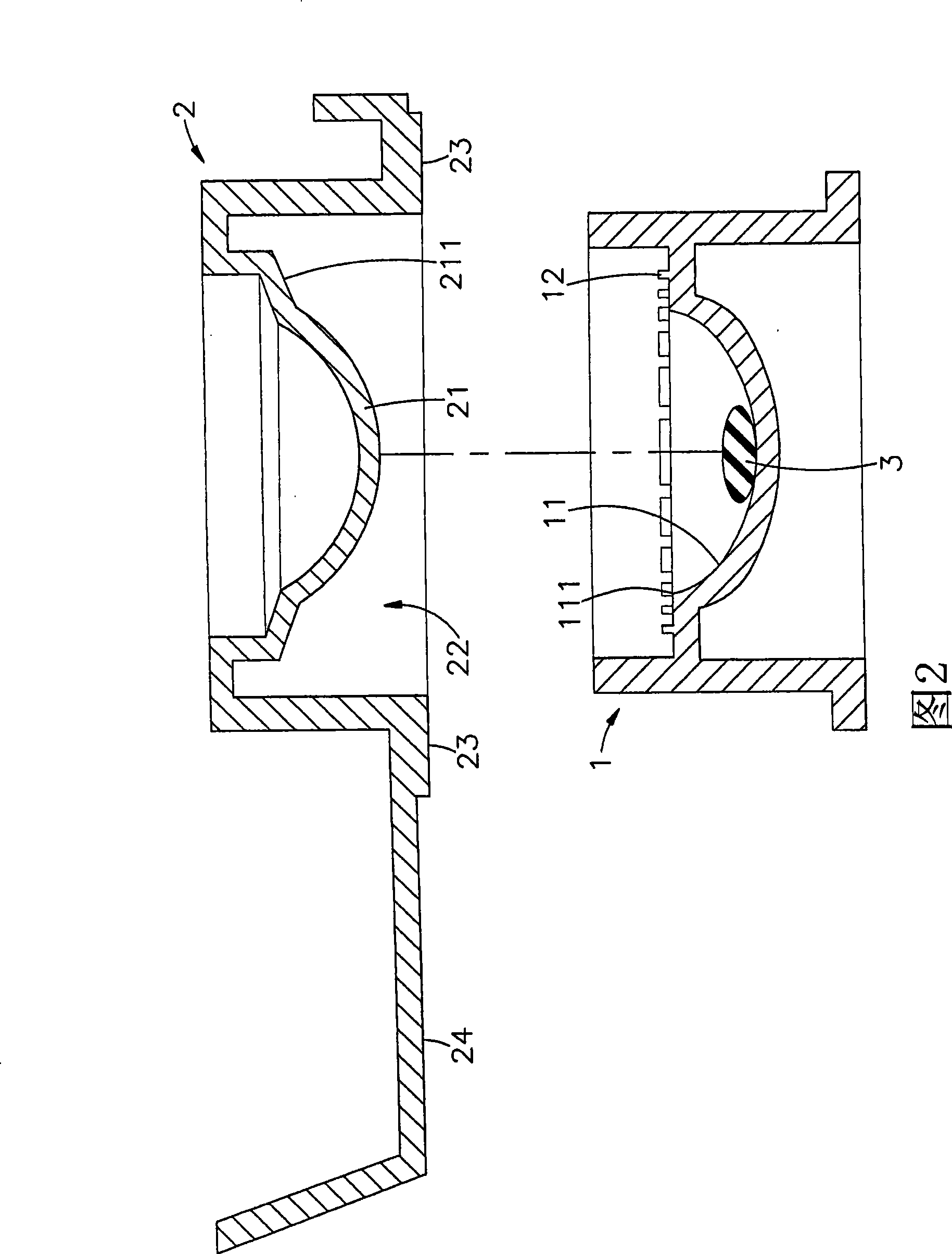

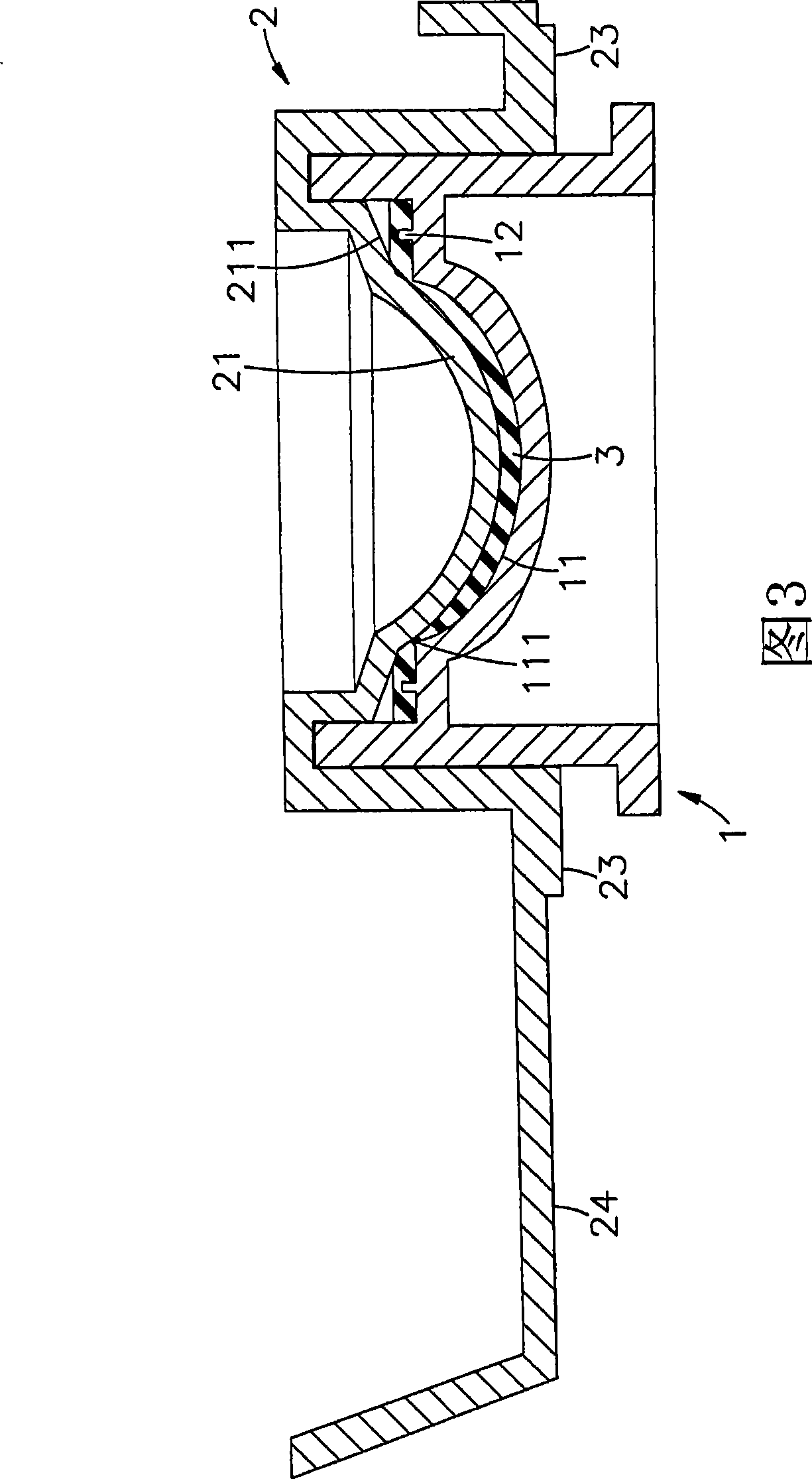

Contact lens molding method and mould

InactiveCN101428477ASimple processShort processOptical articlesUsing protective liquidsManufacturing cost reductionLens plate

The invention relates to a method for shaping contact lenses and a mould, particularly a method which can use simple moulds for forming the contact lenses. The method comprises the following steps: placing the contact lens material in a die cavity of a mould; then, using the mould of an auxiliary appliance to press the lens material in the die cavity; causing the lens material to spread and extend along an arc surface of a die cavity and a mould; pushing excessive materials and overflowing out of the corner cut edge; proving the retained surface at the outer part of the mould for jointing the corner cut edge; removing the excessive materials; solidifying and treating the lens material in the mould; jointing the lens material on the surface of the mould of the auxiliary appliance; shaping glasses of the contact lenses after testing; packaging after injecting buffer solution in the appliance space of the outer part of the mould of an auxiliary appliance; and manufacturing products for selling. The contact lens has the advantages that the manufacturing procedure is simple and fast; and the purposes for saving labor and time, reducing the manufacturing cost, and keeping with the economic effect can be achieved.

Owner:UNICON OPTICAL

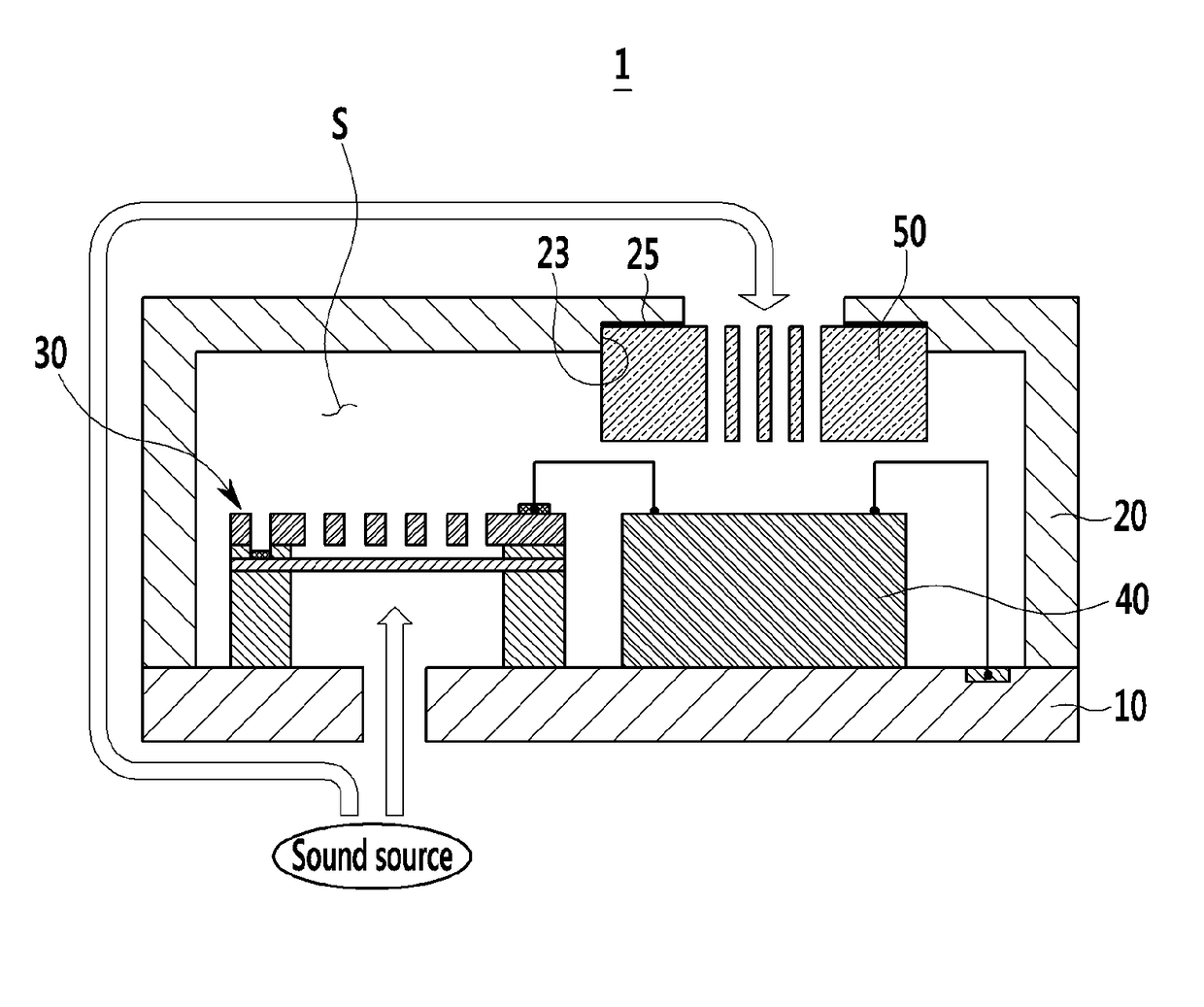

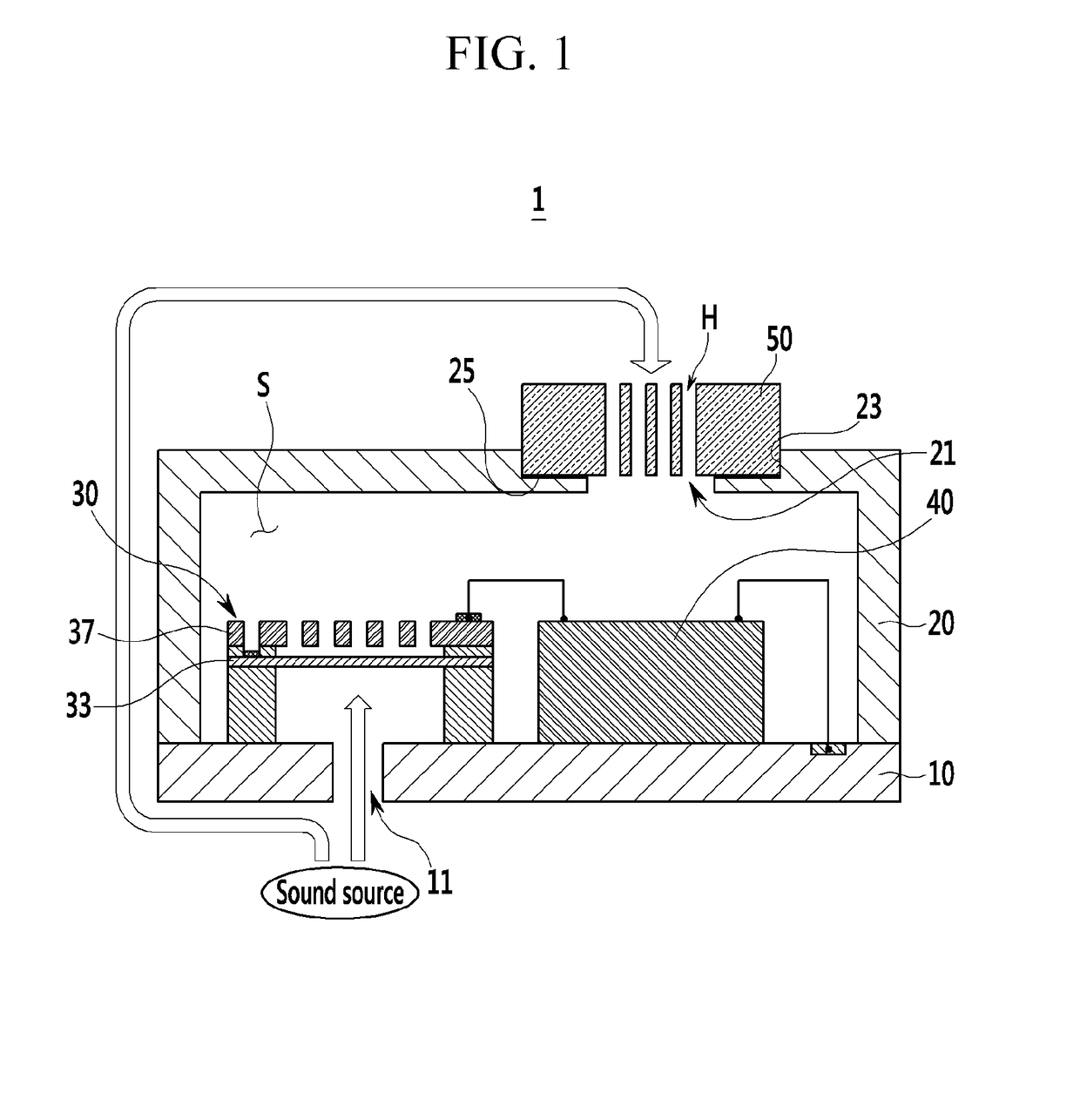

Microphone and manufacturing method thereof

InactiveUS20170094405A1Reduce packaging processLow costMicrophonesLoudspeakersSemiconductor chipEngineering

A microphone and a method for manufacturing the same are disclosed. The microphone includes: a main substrate in which a first sound hole is formed; a sound sensing module formed in the main substrate corresponding to the first sound hole; a semiconductor chip electrically connected with the sound sensing module and formed on the main substrate; a cover mounted to the main substrate, and in which a second sound hole is formed; and a sound delay filter mounted corresponding to the second sound hole, and in which a plurality of filter holes are formed.

Owner:HYUNDAI MOTOR CO LTD

Standing-Type Air-Filled Packaging Apparatus and Manufacturing Method Therefor

ActiveUS20180093809A1Avoid damageEnsure safetyPaper/cardboard articlesDispensing apparatusEngineeringAir chamber

A standing-type air-filled packaging apparatus and a manufacturing method therefor are provided. The apparatus includes an inflatable body and an inflation valve. The inflatable body includes multiple inflatable units that are formed by stacking together at least two layers of air chamber films and are connected with each other. The inflatable units are heat-sealed and bent to form an air-filled packaging apparatus provided with at least one accommodating chamber used for accommodating an item to be packaged. The inflation valve is mounted on the inflatable body to inflate the inflatable body. At least one distal side of the solid air-filled packaging apparatus forms an annular support part. When the air-filled packaging apparatus is inflated, the annular support part is suitable for standing on a surrounding surface, thus allowing the packaging apparatus to be in a firm standing state.

Owner:SHANGHAI AIR PAQ COMPOSITE MATERIAL

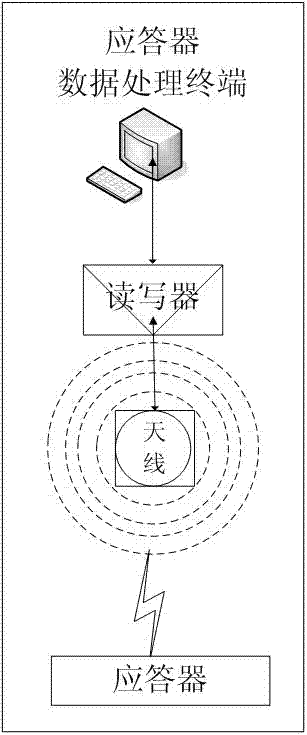

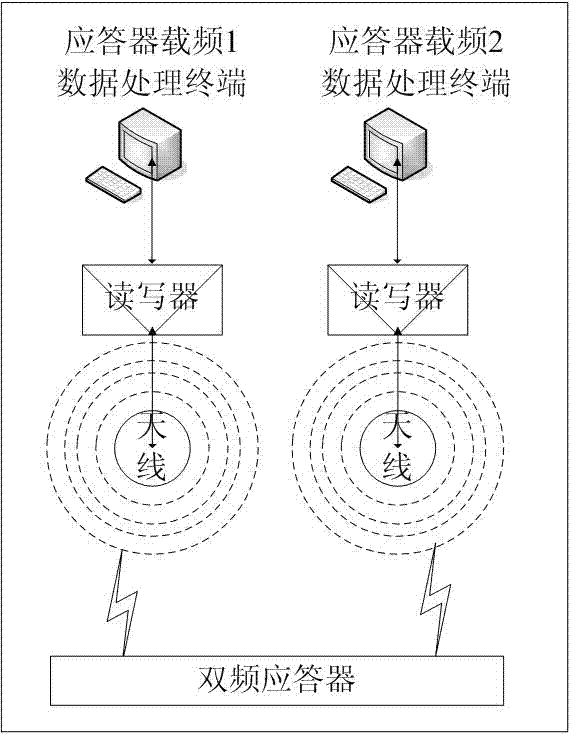

Dual-frequency responder technology

InactiveCN102780507AOvercoming the problem of not having redundancyReduce packaging processVehicle route interaction devicesTransmissionDual frequencyComputer science

The invention provides a dual-frequency responder system which comprises a ground dual-frequency responder, a vehicle-mounted dual-frequency responder reader, a vehicle-mounted antenna and affiliated equipment thereof, and a vehicle-mounted power supply. By using the dual-frequency responder system, the problem of backup redundancy of the responder can be solved.

Owner:骆燕胜

Packaging and fresh-keeping method for foodstuff

InactiveCN1631735ASave on packaging materialsLow costPackaging bakeryEnvironmental resistanceShielding gas

the invention disclose a food preserve and pack method including the following steps: 1) deliver the conjoined package box with the food inside to the packing, sealing and cutting area; 2) the sealing and cutting device (2) presses on the film coating so that the film and the support device will surround the foods and forms a seal cavity; (3) the air pumper evacuates; then pumper aerates into the cavity with protective gases. 4) the sealing and cutting device (2) pressure heat seals the cavity after the aerating; 5)the fluctuating pressure device(1) cuts the package box from the film coating; 6) the deliver mechanism delivers out the sealed package box. Above process including deliver in, locate, film coating press, evacuate, aerate, heat seal, cutand deliver out all finish continuously on a single machine. Each process is controlled by control logic made up of relays or PLC. The invention not only saves the package material, lowers the cost, enhance the efficiency but greatly varies the package patterns, and the preservation is effective and environmental,

Owner:苏明智

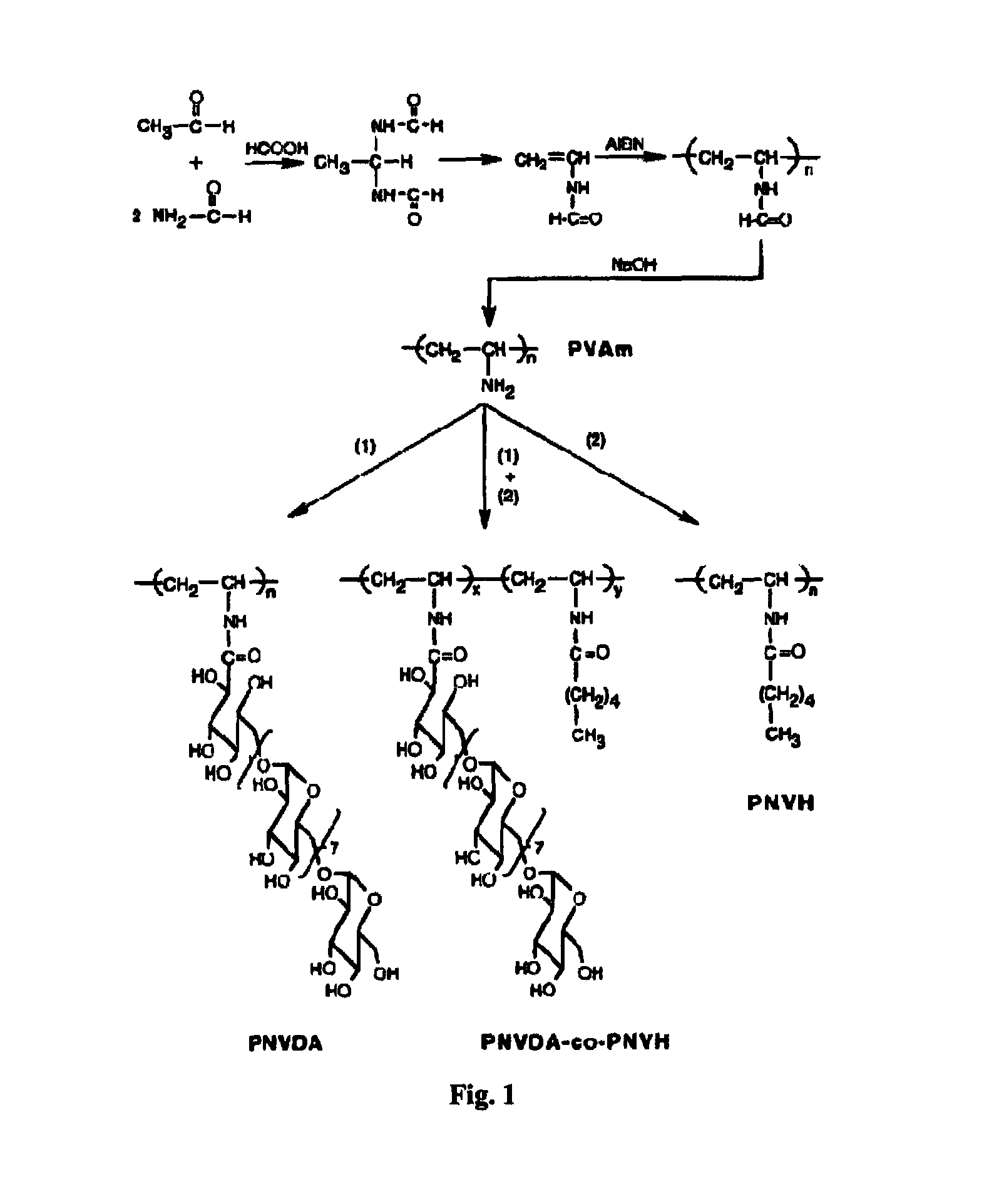

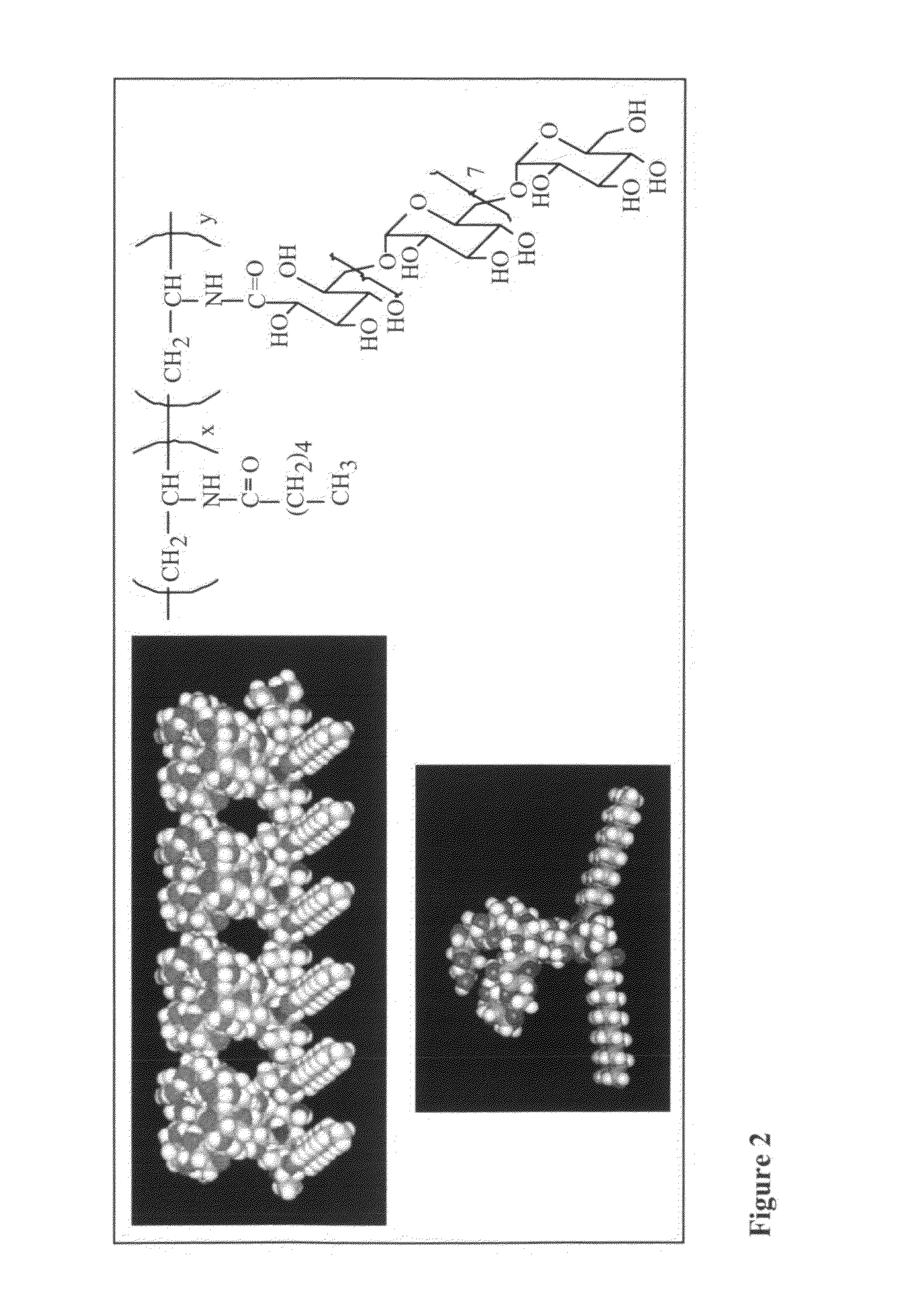

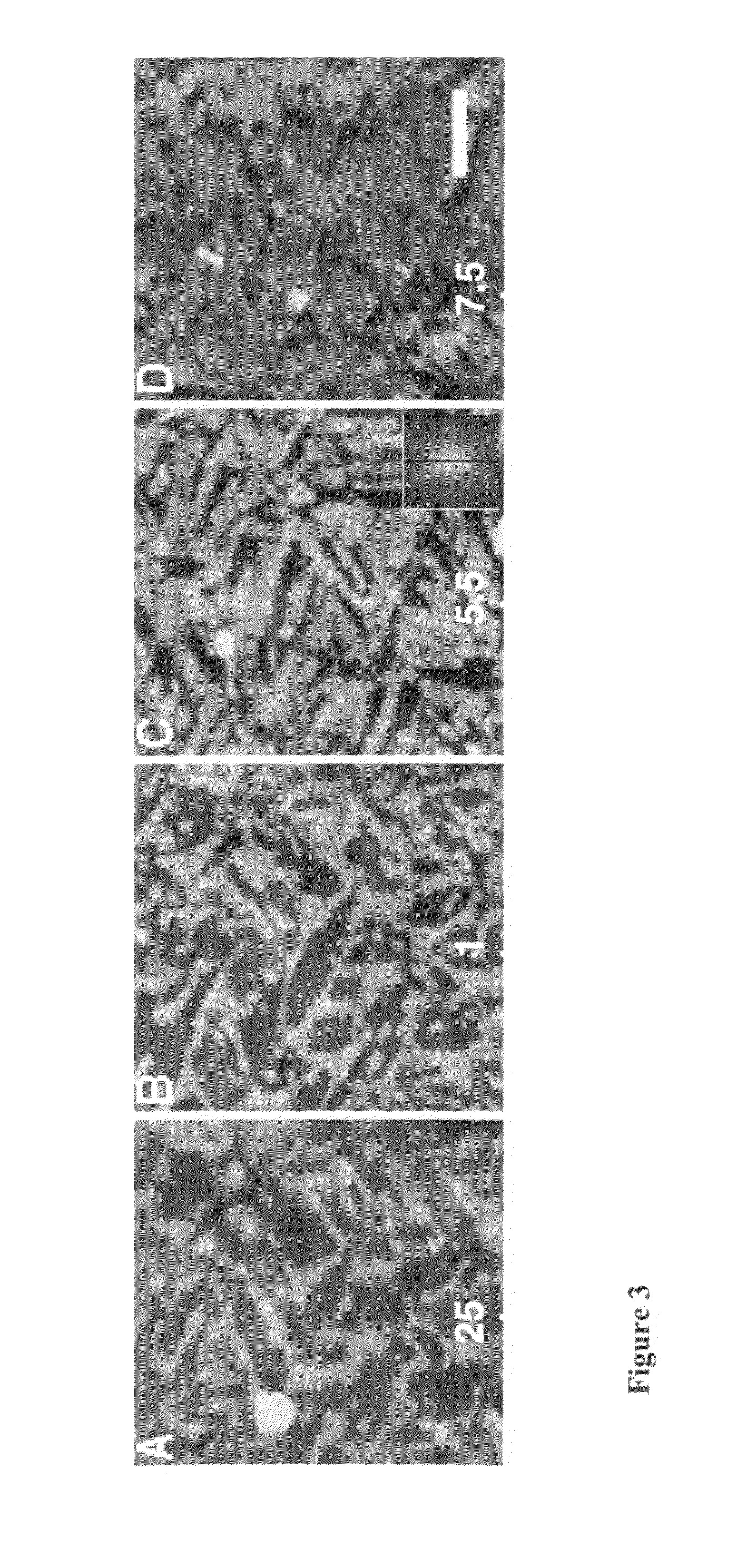

Methods of making and using surfactant polymers

InactiveUS8163302B2Reduce packaging processReduce colonizationPeptide/protein ingredientsLigamentsPolymer scienceActive agent

Comblike, surfactant polymers for changing the surface properties of biomaterials are provided. Such surfactant polymers comprise a polymeric backbone of repeating monomeric units having functional groups for coupling with side chains, a plurality of hydrophobic side chains linked to the backbone via the functional groups, and a plurality of hydrophilic side chains linked to said backbone via the functional groups. Medical devices coated with the surfactant polymers are also provided. The surfactant polymers may be used to decrease the thrombogenic properties, encapsulation, and bacterial colonization of medical devices.

Owner:NANOMIMETICS

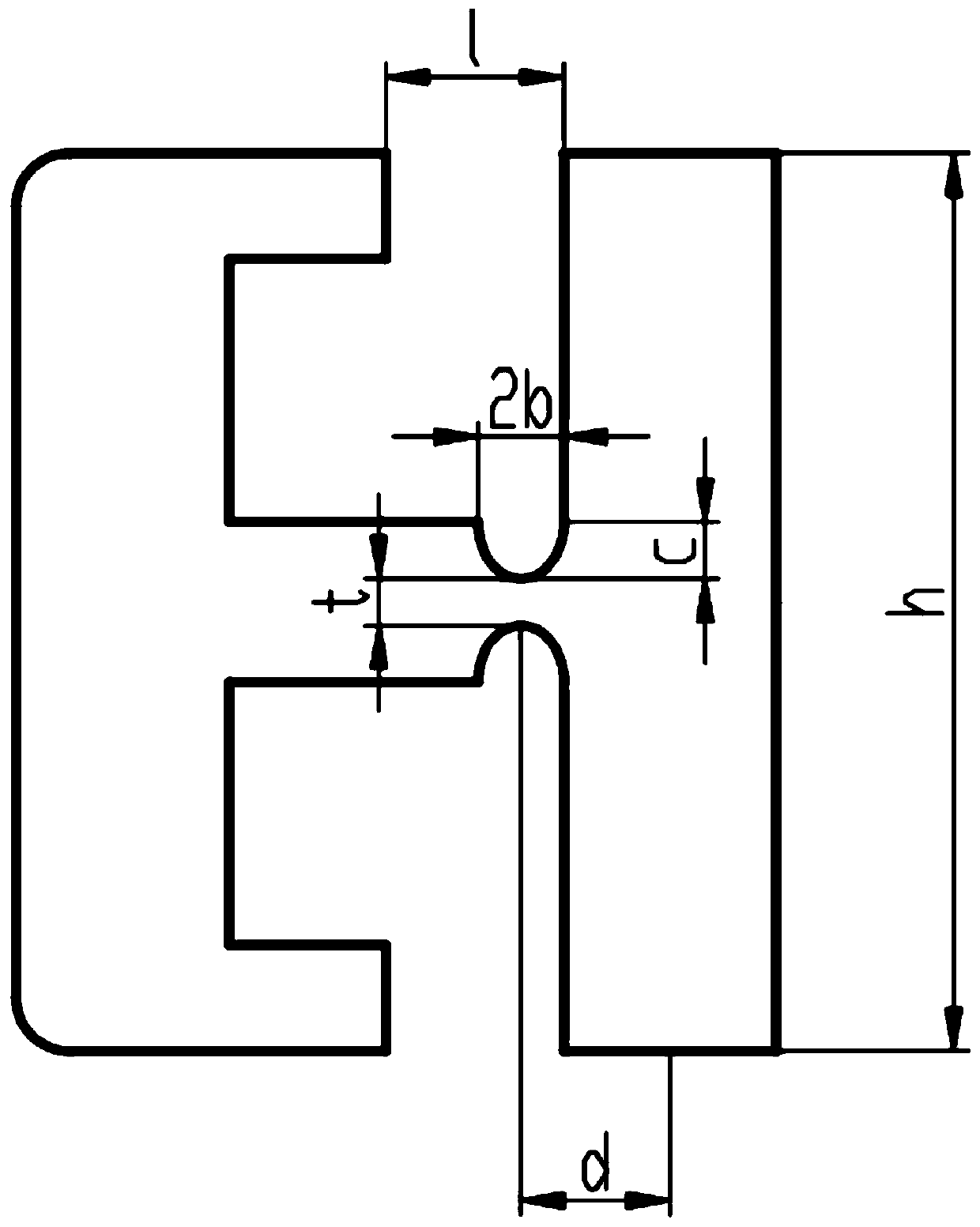

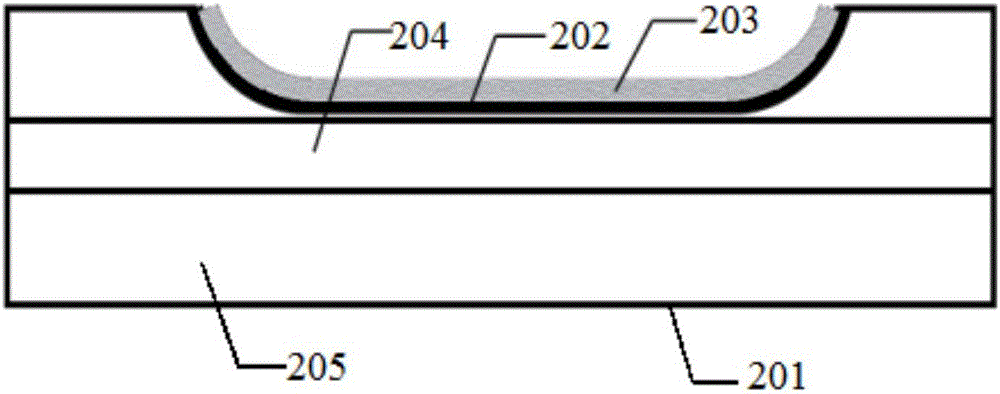

Temperature-insensitive elliptical hinge fiber Bragg grating acceleration sensor

InactiveCN111505337AReduce packaging processHigh sensitivityAcceleration measurement using interia forcesUsing optical meansCore (optical fiber)Engineering

The invention discloses a temperature-insensitive elliptical hinge fiber Bragg grating acceleration sensor. The fiber Bragg grating sensor comprises a sensor shell, a core body and two fiber Bragg gratings, the core body is composed of an inertia mass block, an oval flexible hinge and a base, the inertia mass block is symmetrical about the flexible hinge and is higher than the other side connectedwith the flexible hinge, and optical fiber grooves are formed in the inertia mass block and the upper and lower tops of the base opposite to the inertia mass block. The optical fibers penetrate through the optical fiber grooves and come out of the holes of the shells at the two sides, the optical fibers are engraved with gratings between the inertia mass block and the base, the flexible hinge isan oval flexible hinge, and the inertia mass block generates the relative displacement around the flexible hinge, so that the fiber gratings generate the relative displacement. The temperature-insensitive elliptical hinge fiber Bragg grating acceleration sensor is small in size and higher in frequency measurement range, is easy to package, and is insensitive to temperature.

Owner:中山市精量光电子科技有限公司 +1

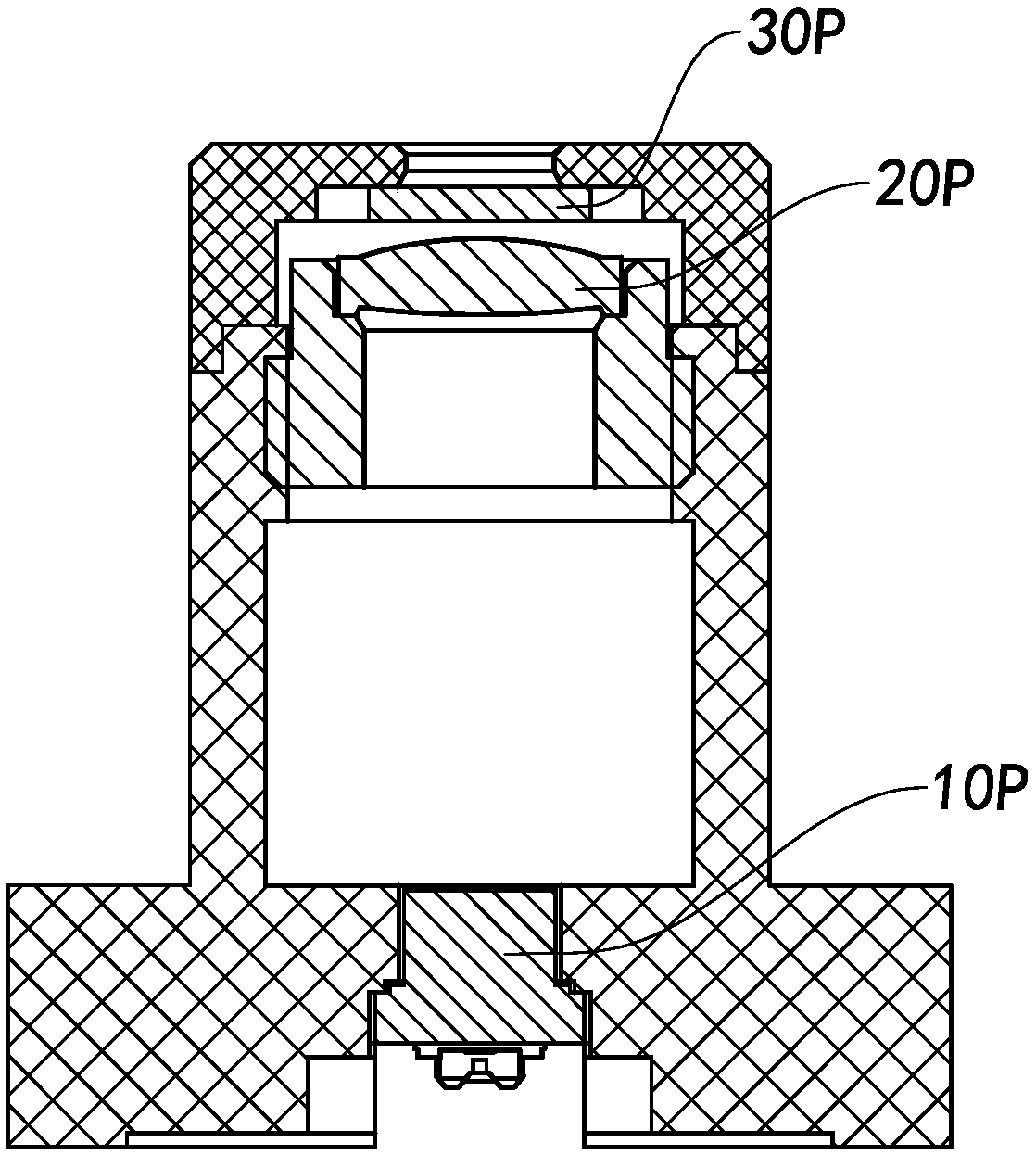

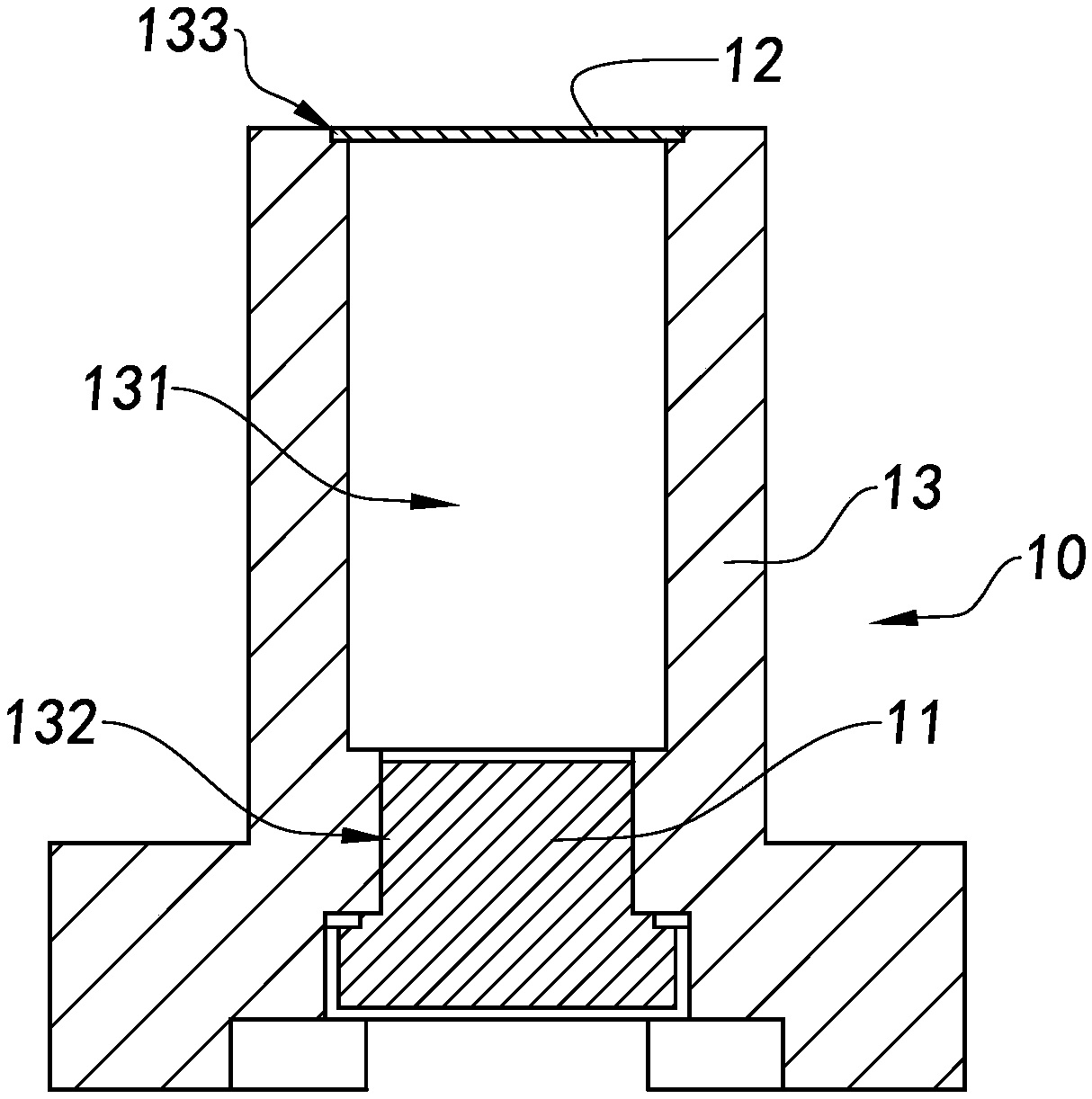

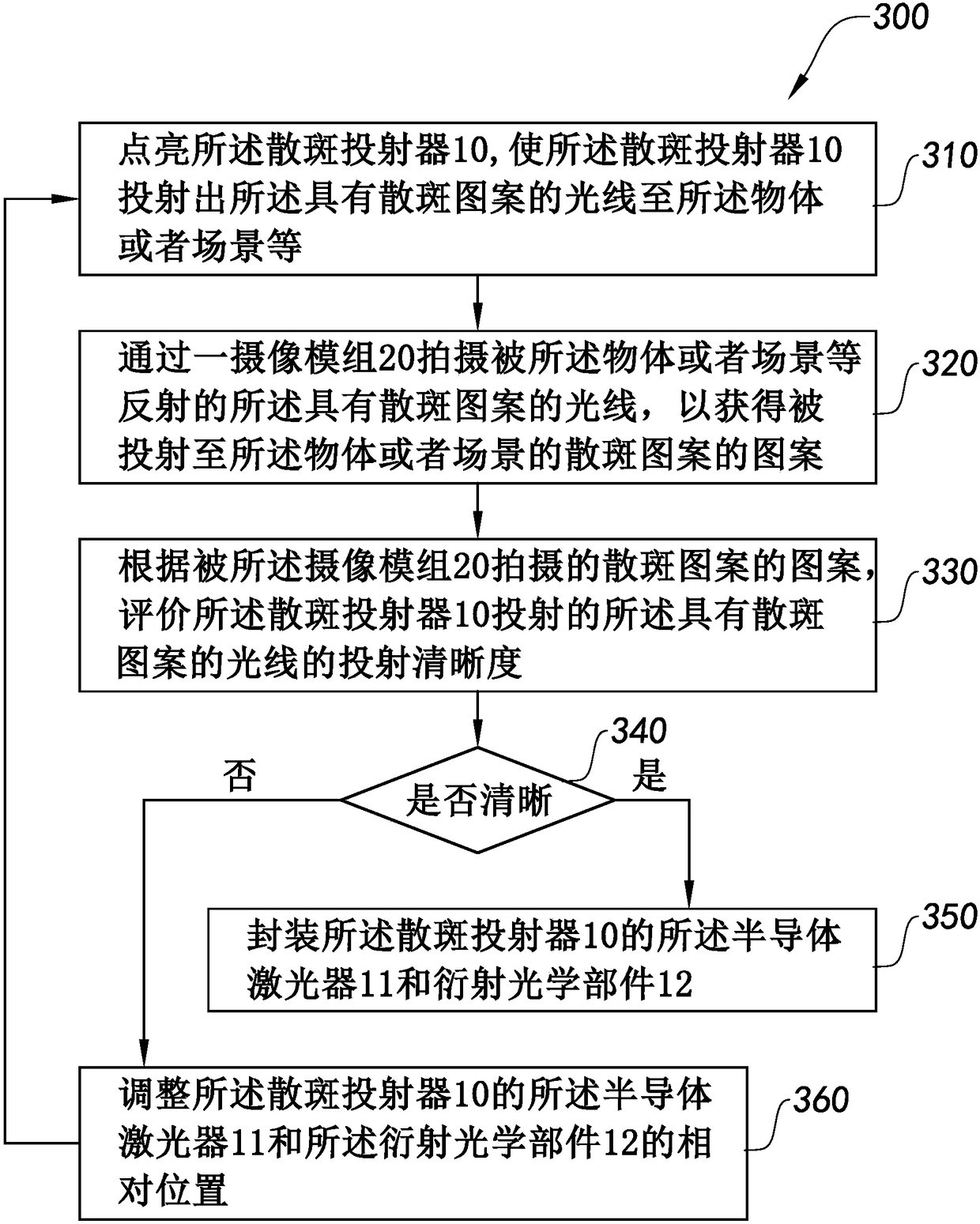

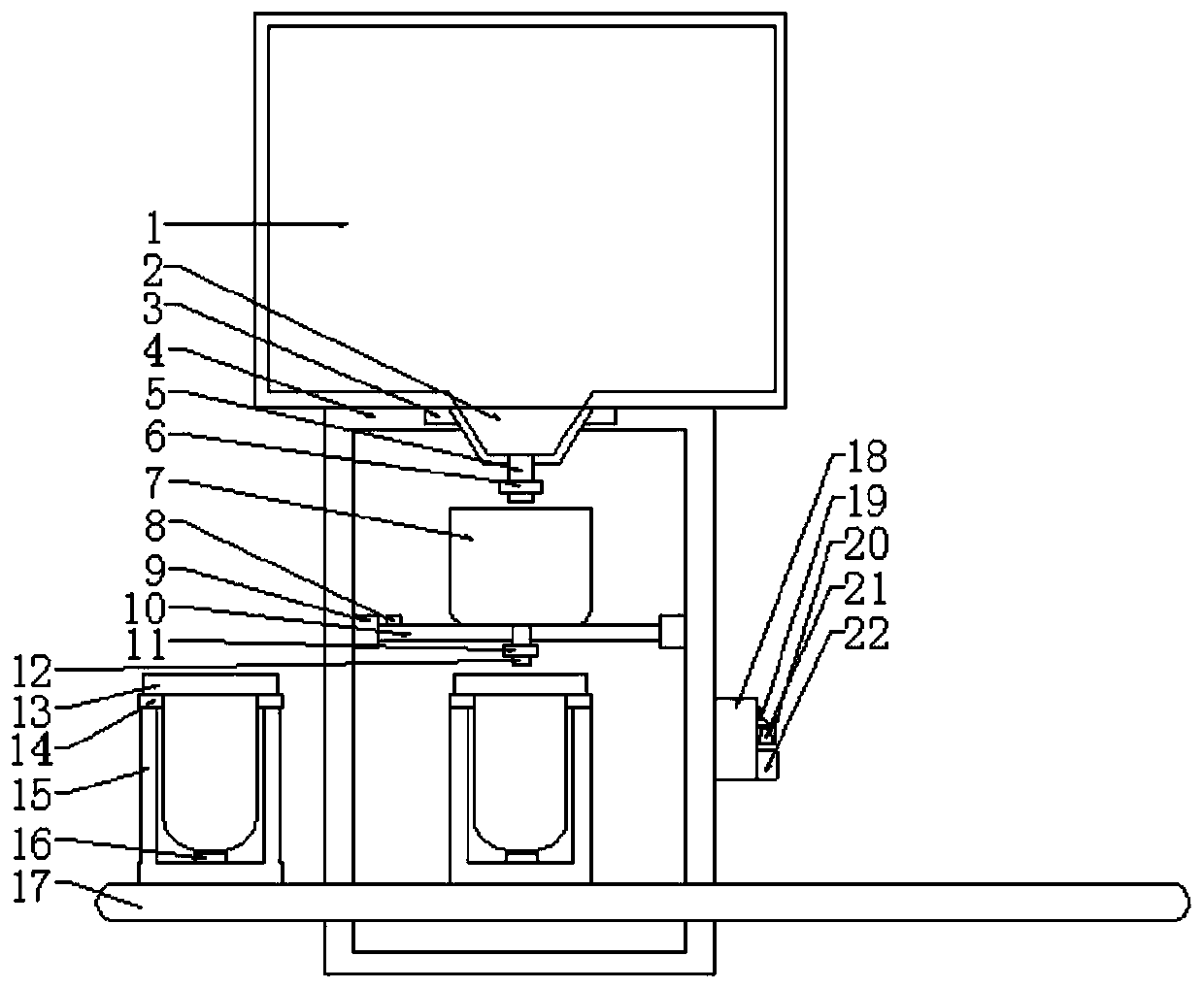

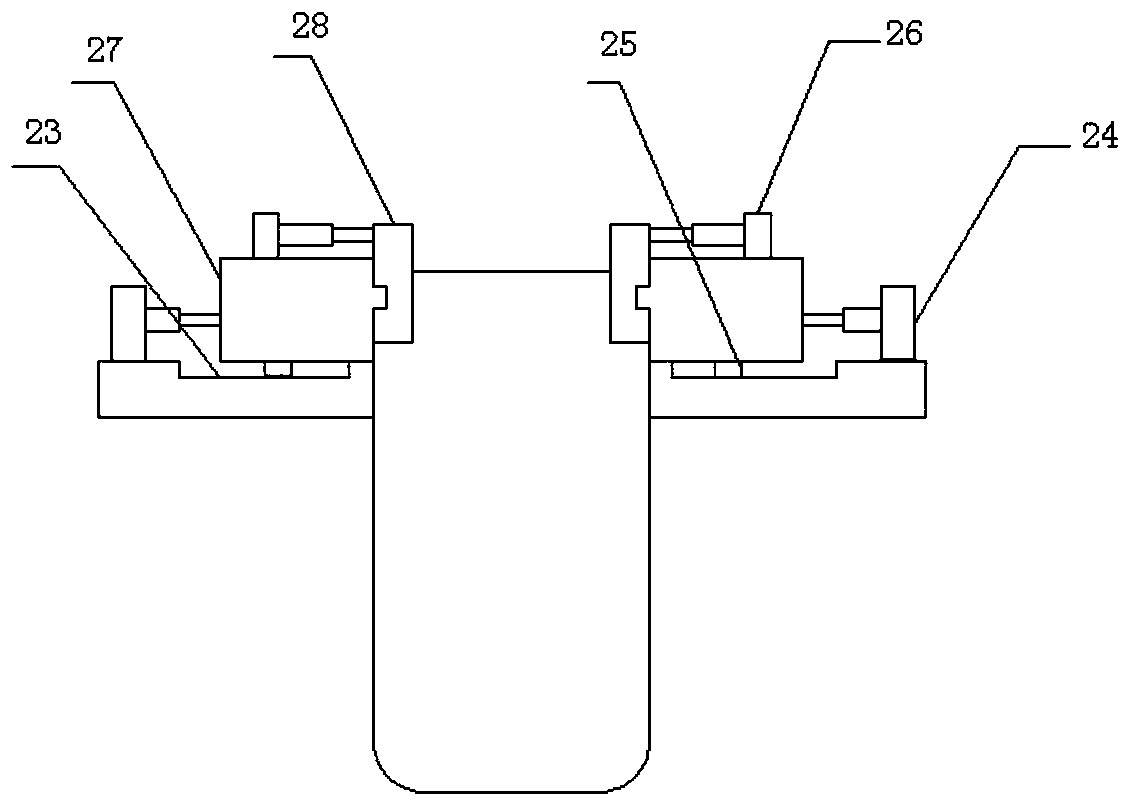

Light diffusion type speckle projector, focusing method thereof and three-dimensional reconstruction system

PendingCN108227232AReduce manufacturing costReduce packaging process3D-image renderingOptical elementsElectrical conductorMiniaturization

The invention provides a light diffusion type speckle projector, focusing method thereof and three-dimensional reconstruction system. The speckle projector includes at least one semiconductor laser and at least one diffraction optical component arranged in a light path of the semiconductor laser for forming a light beam having a speckle pattern after laser emitted by the semiconductor laser penetrates through the diffraction optical component. The speckle projector does not need a collimator arranged between the semiconductor laser and the diffraction optical component. Therefore, quality of the light beam having the speckle pattern projected by the speckle projector can be improved and the minimization of the speckle projector is facilitated, especially, the height dimension of the speckle projector can be reduced.

Owner:ZHEJIANG SUNNY INTELLIGENT OPTICAL TECH CO LTD

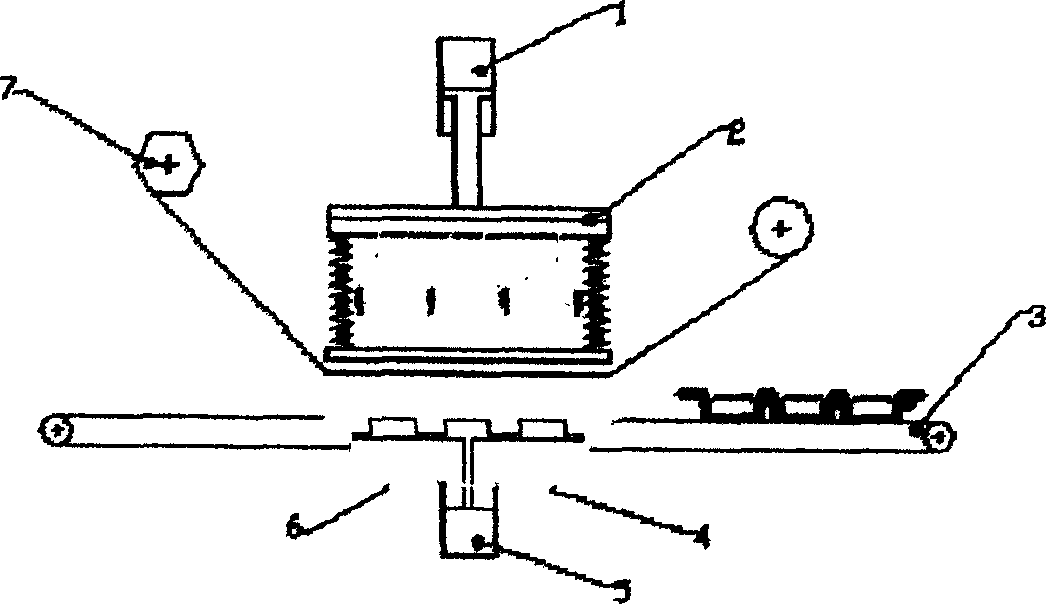

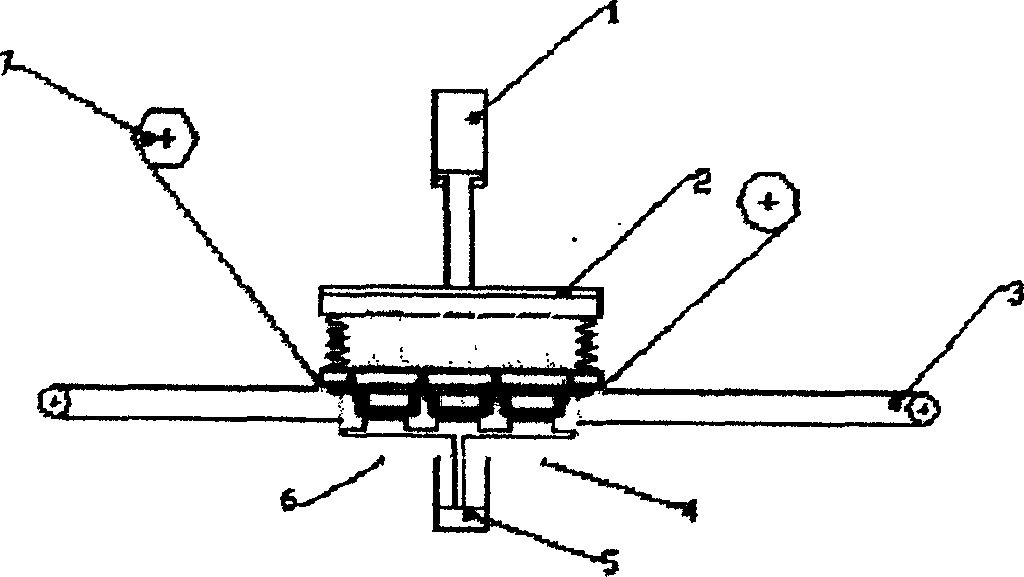

Weighing-type rice packaging machine

InactiveCN110182391AMutual gap reductionReduce packaging processWrapper twisting/gatheringSolid materialEngineeringElectric control

The invention discloses a weighing-type rice packaging machine. The weighing-type rice packaging machine comprises a storage box, a support, a weighing device, a funnel, a conveying device and a sealing device, wherein the storage box is arranged at the upper end of the support; two sides of the upper end of the funnel are provided with fixed sheets; a discharge port is arranged at the bottom endof the storage box through the fixed sheets; the discharge port at the lower end of the funnel is connected with a discharge pipe; a flow control valve is arranged on the discharge pipe; a weighing device is arranged at the lower end of the discharge pipe; the weighing device comprises a weighing box, a weighting plate, and a weighting sensor; the weighting box is of a cover-free frame structure,and the open end of the weighing box is directly opposite to the lower portion of the discharge pipe; the weighing box is mounted on the weighing plate; the two sides of the weighing plate are fixed with the support through fixing frames; the weighing sensor is arranged on one side of the weighing plate; a discharge opening is arranged at the bottom end of the weighing box; the discharge opening is connected with a discharge pipeline; an electric control valve is arranged on the discharge pipeline; and a conveying device is arranged at the lower portion of the discharge pipeline.

Owner:南京钢诺智能装备有限公司

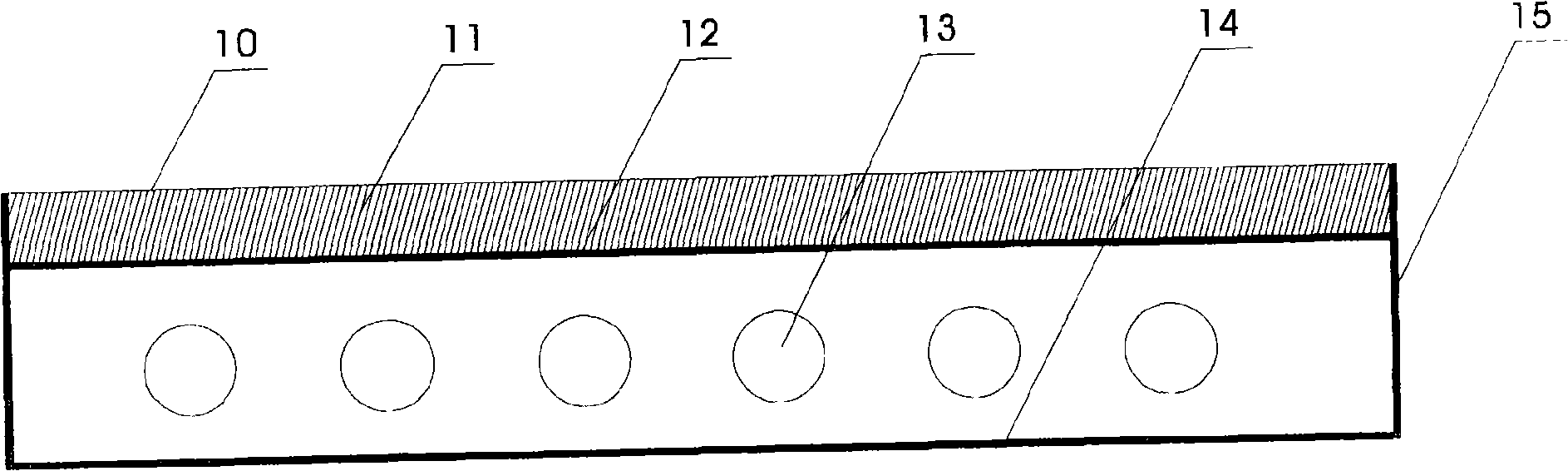

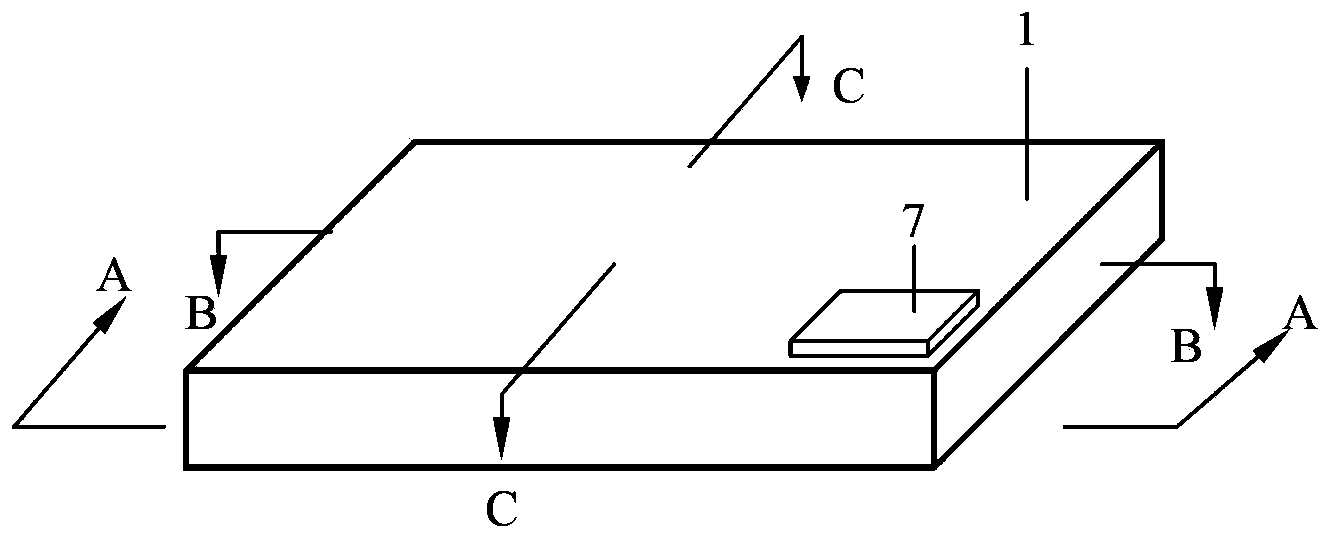

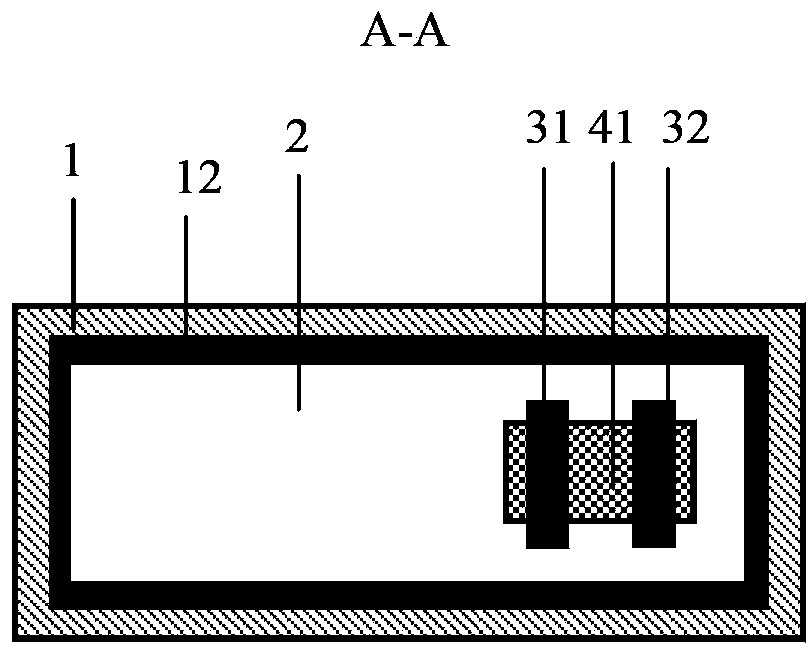

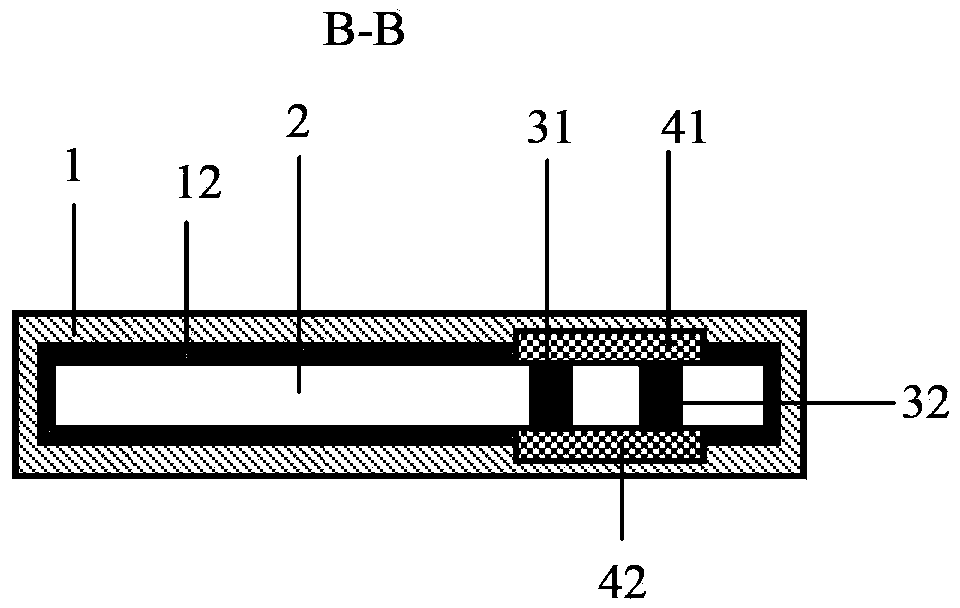

Integrated cavity type conductive fluid heat spreader

ActiveCN104125753AEliminate tightnessPrevent leakageCooling/ventilation/heating modificationsMagnetic polesEngineering

The invention provides an integrated cavity type conductive fluid heat spreader which includes a cavity (1), the heat absorbing end, flow, liquid, fluid pool, driving pump and a heat radiating end together in one room, the internal cavity structure, and the inner surface is an insulating layer (12); runner type electrode for (31, 32), arranged on the cavity surface, which is used as a channel and the direction of fluid flow regulator; a magnet for (41, 42), in the cavity body and the direction of the magnetic poles and the electrode is arranged on the current direction is vertical range setting; conductive fluid (2), the filling in the cavity; power supply chip (7) which is arranged in the cavity, the outer surface of the electrodes used to provide the input current. According to the heat spreader is provided by the invention greatly reduces the production and packaging process, completely avoid the fluid leakage; the compact volume, heat transfer capacity significantly; the cavity electrode on the position can be set flexibly, significantly enhance the electromagnetic driving force, resulting in the enhancement of heat transfer and flow effect is strong; between different parts of the body temperature of the fluid cavity different mixing efficiency is high, the heat transport capability is strong.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

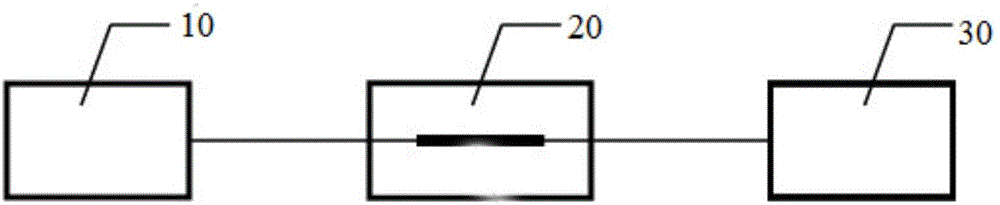

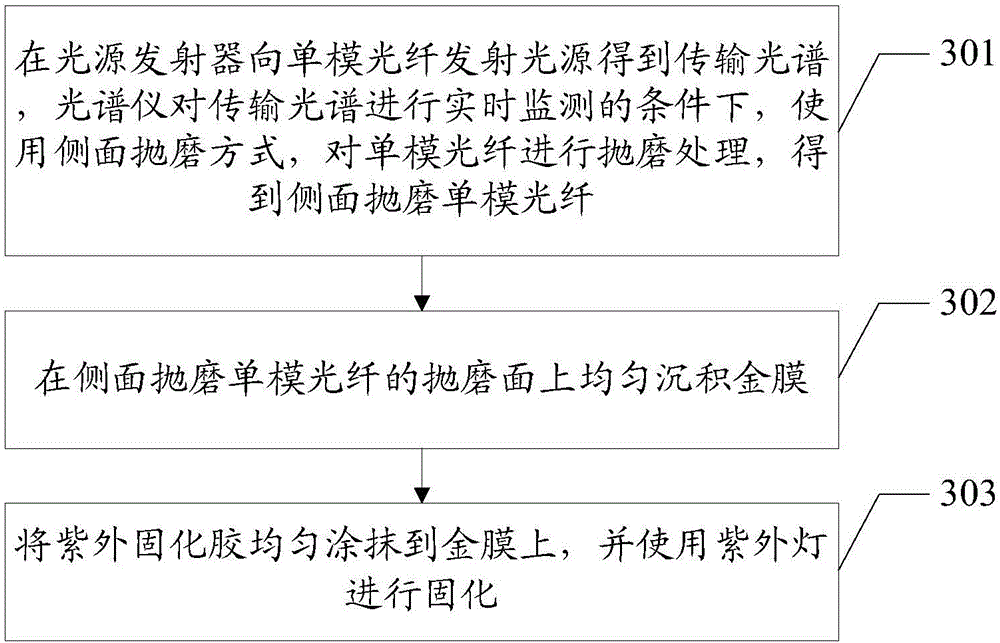

Temperature sensor based on surface plasma resonance and production method thereof

InactiveCN107525605AReduce packaging processImprove stabilityThermometers using physical/chemical changesSpectrographPlasma resonance

The invention discloses a temperature sensor based on surface plasma resonance and a production method thereof. The temperature sensor comprises a light source transmitter, a sensing device and a spectrograph, wherein the output end of the light source transmitter is connected with the input end of the sensing device, the output end of the sensing device is connected with the input end of the spectrograph, the sensing device comprises a side-polished single-mode optical fiber, a gold film and a temperature-sensitive thin film, the gold film is deposited on the polished side of the side-polished single-mode optical fiber, and the temperature-sensitive thin film is solidified on the gold film. The temperature sensor has the advantages the due to the fact that the solid temperature-sensitive thin film is solidified on the gold film and does not have flowability as a liquid material, the liquid encapsulation procedure in the prior art is omitted, and the production process is simplified; in addition, due to the fact that the solid temperature-sensitive thin film is not evident in thermal expansion effect, device structure stability is increased, and application of the temperature sensor in fields such as biochemistry is not limited.

Owner:SHENZHEN UNIV

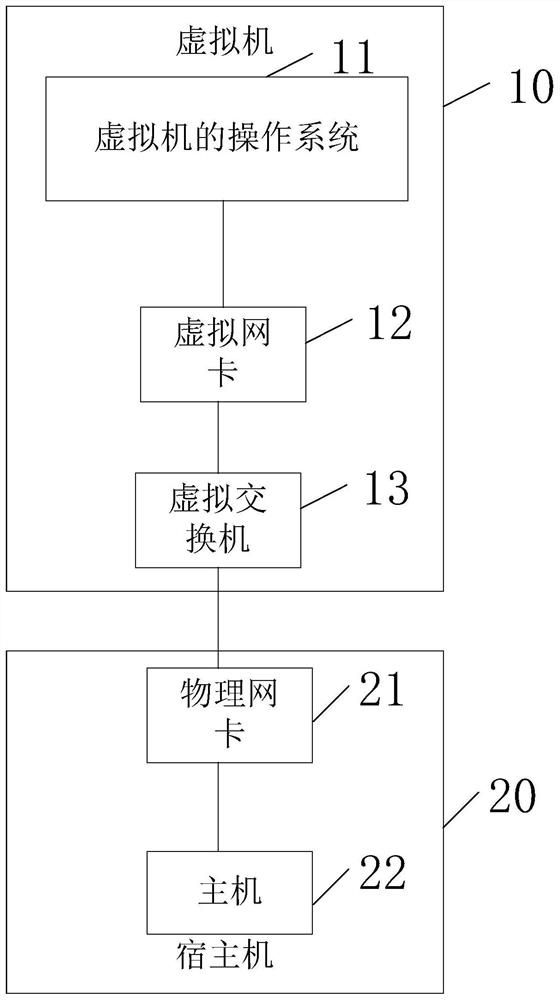

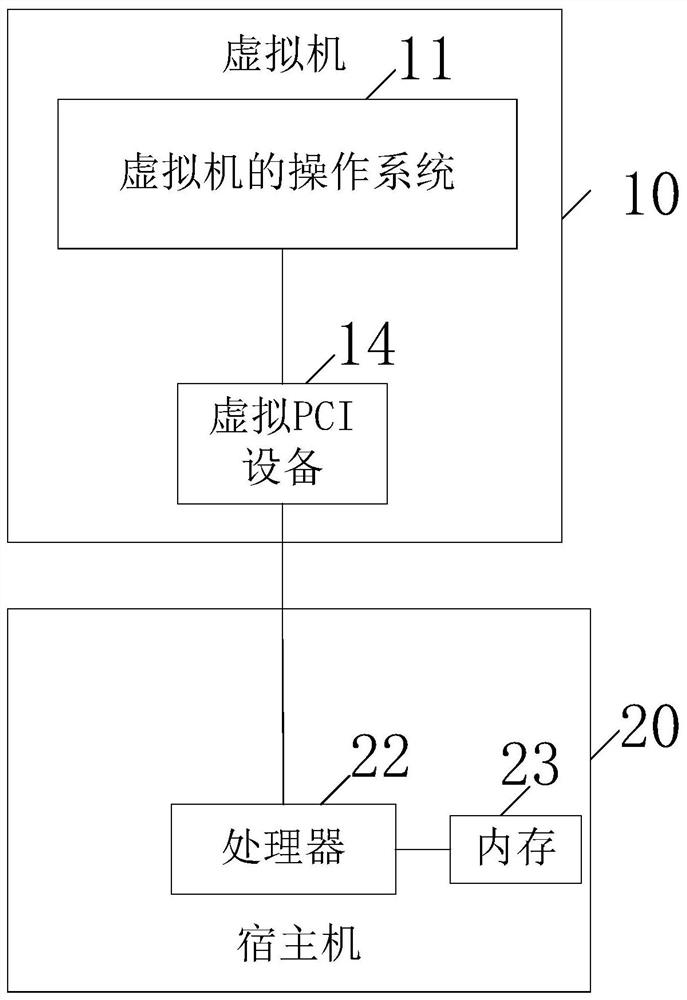

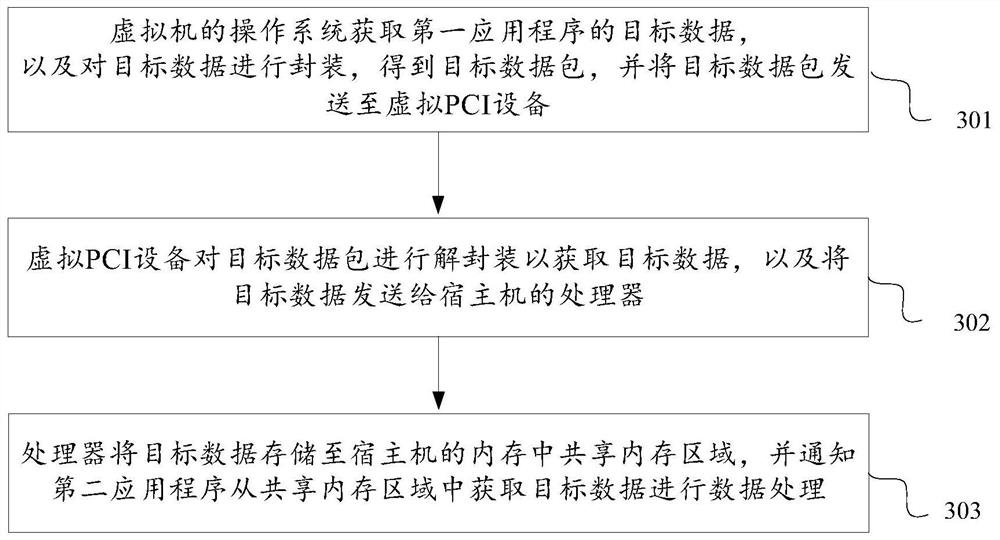

Data transmission method, device and system and storage medium

PendingCN113778611AReduce the number of data encapsulation and decapsulationShort data transmission pathInterprogram communicationSoftware simulation/interpretation/emulationData transmissionVisual appliances

The embodiment of the invention provides a data transmission method, device and system and a storage medium, and the method comprises the steps: obtaining target data of a first application program through an operation system of a virtual machine, packaging the target data, obtaining a target data package, and sending the target data package to virtual PCI equipment; by the virtual PCI equipment, de-encapsulating the target data packet to obtain target data, and sending the target data to a processor of the host machine; and by the processor, storing the target data to a shared memory area in the memory of the host machine, and notifying the second application program to obtain the target data from the shared memory area for data processing. According to the technical scheme provided by the embodiment of the invention, the data transmission efficiency between the virtual machine and the host machine can be improved.

Owner:锐捷网络(苏州)有限公司

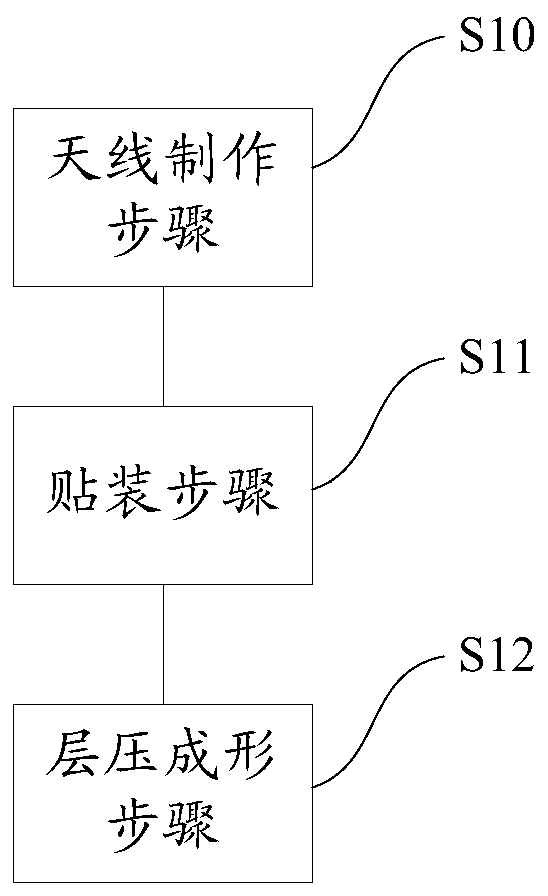

Ultrathin RFID intelligent card packaging method

PendingCN110689105AReduce thicknessHigh precisionRecord carriers used with machinesEngineeringSmart card

The method is suitable for the technical field of RFID card packaging. The invention discloses an ultra-thin RFID intelligent card packaging method which comprises the following steps: an antenna manufacturing step: winding an enameled wire on a first base material according to a set shape to form an antenna, and removing insulating layers on the surfaces of two leads on the antenna; a mounting step: respectively placing two welding spots on the RFID chip flip-chip bonding pad above the two leads of the antenna with the insulating layer removed; and a lamination forming step: covering a secondbase material on the bonding pad with the welding spots in the mounting step, and enabling the two welding spots on the bonding pad to respectively form close contact with the two leads of the antenna to form electric connection by laminating and melting the first base material and the second base material, i.e., one welding spot is electrically conducted with one antenna lead. Because the two leads of the antenna and the bonding pad do not need to be in hard connection through welding, on one hand, the packaging process can be reduced, and the packaging efficiency is improved; and on the other hand, the thickness of the RFID card can be reduced without welding. And the winding antenna is adopted, so that the precision is high.

Owner:湖北用芯物联科技有限公司

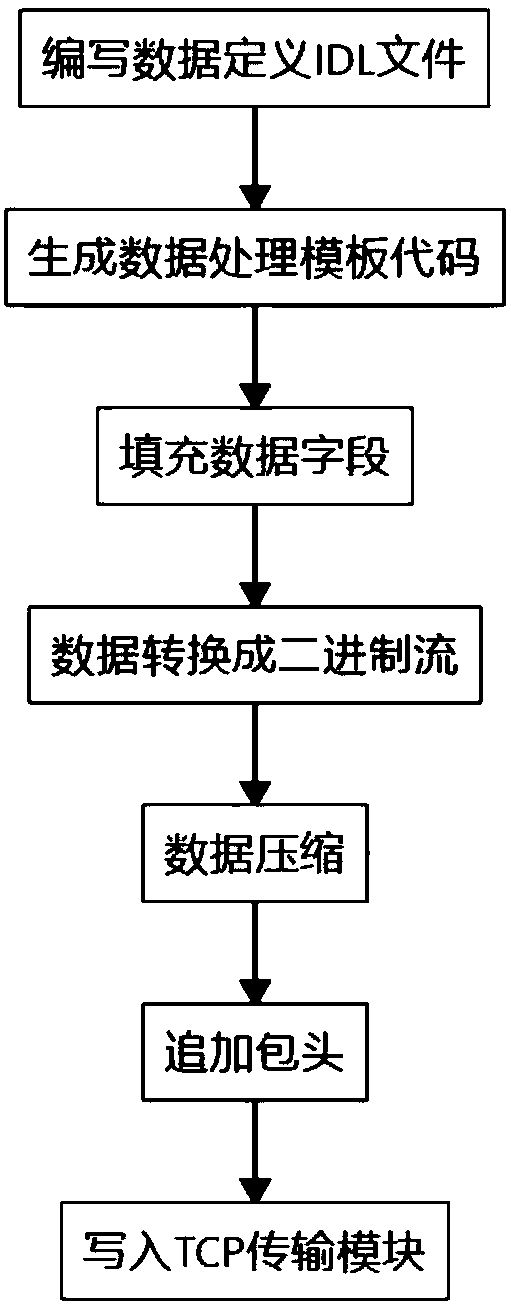

High-efficiency binary transmission protocol based on real-time streaming compression technology

PendingCN108683603AEasy to convertReduced packaging and design complexityData switching networksData transmissionThree level

The invention discloses a high-efficiency binary transmission protocol based on the real-time streaming compression technology, and the abstract design is performed according to an application layer data structure and binary bidirectional conversion, and a corresponding processing class can be generated according to an IDL (intermediate definition file), thereby simplifying the conversion of binary data stream and the application layer data structure, and reducing the packaging and design complexity of a conventional binary protocol. Moreover, a three-level design is employed for the protocol,and a packet header + message base mode is employed, wherein the message base is taken as an abstract layer and is embedded into a third-level business message structure. Because most of intermediatetransmission layers just need to recognize the first-level and second-level messages, and do not need to recognize a specific third-level message, a high-efficiency binary transmission protocol whichis easy to extend can be implemented through the above layered design. Meanwhile, the universal compression design of the second-level message is performed. Compared with a conventional method, the method employed in the invention reduces the data transmission flow by 50%-80%.

Owner:广州经传多赢投资咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com