Label adsorption and attachment device and implementation method thereof

A laminating device and labeling technology, applied in labeling, packaging, labeling machines, etc., can solve problems such as cutting off, labels that are prone to outage accidents, and imperfections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

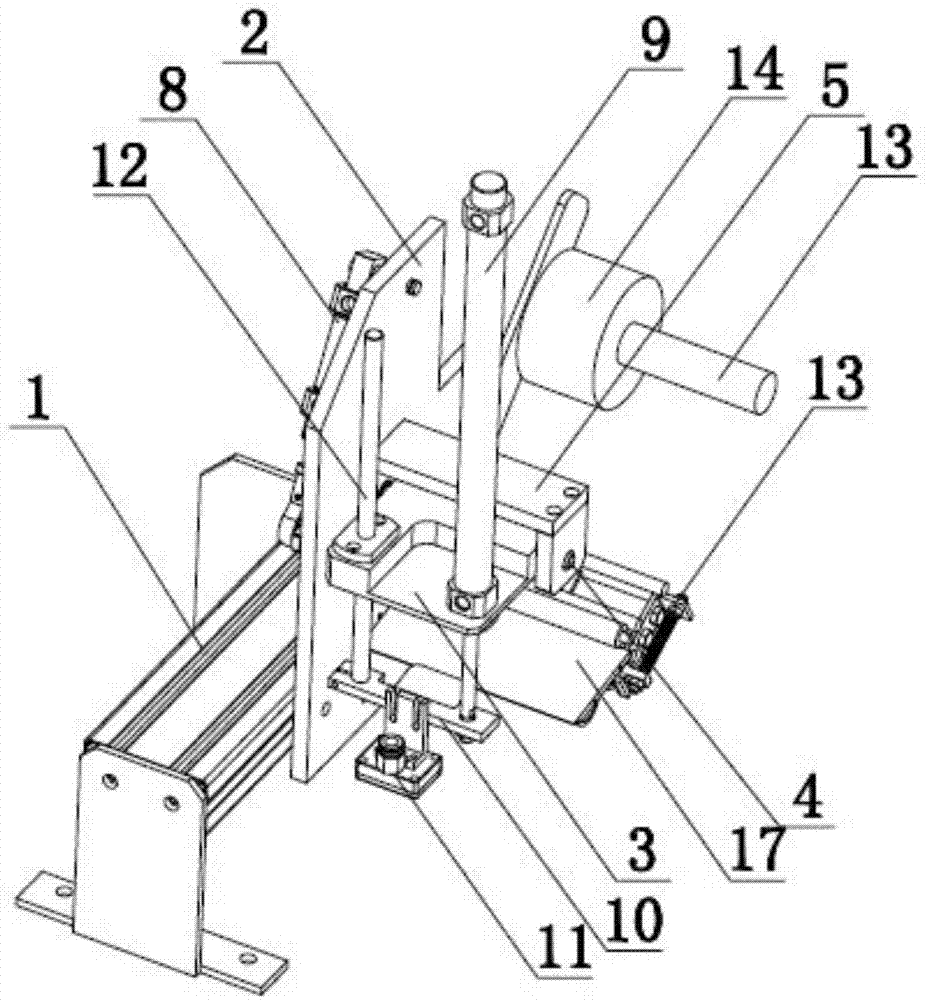

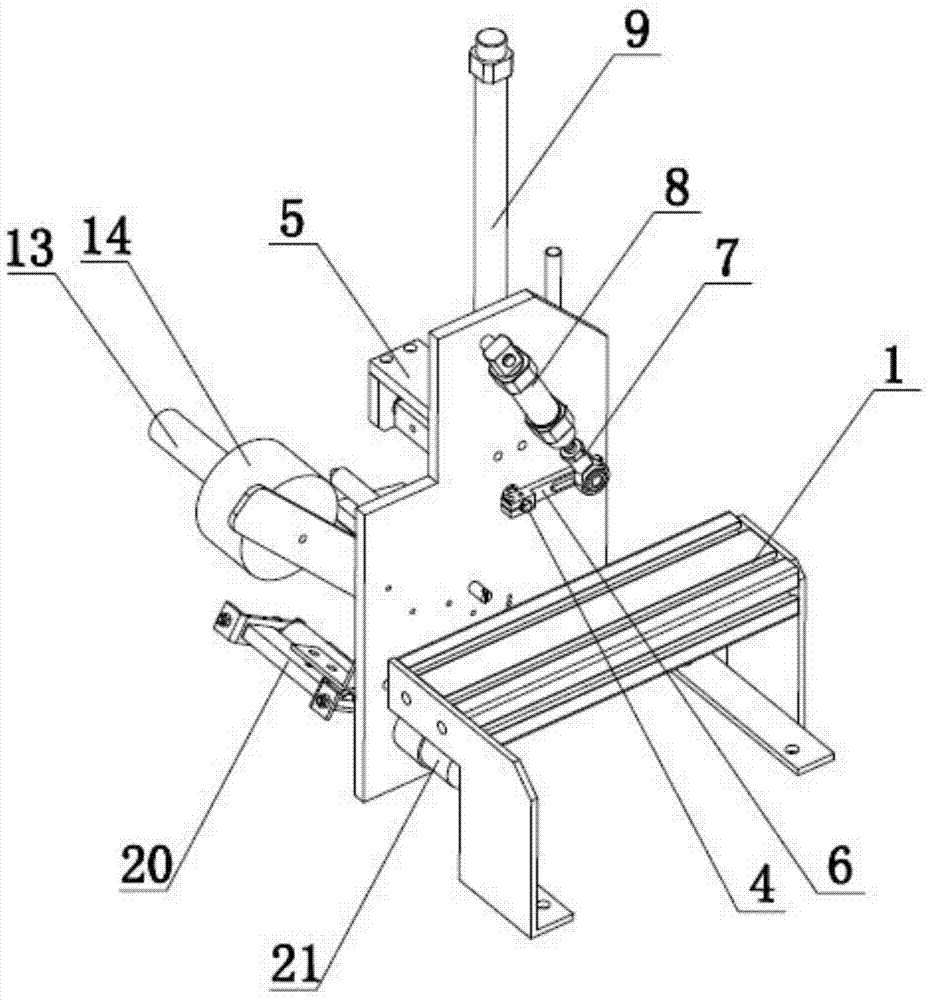

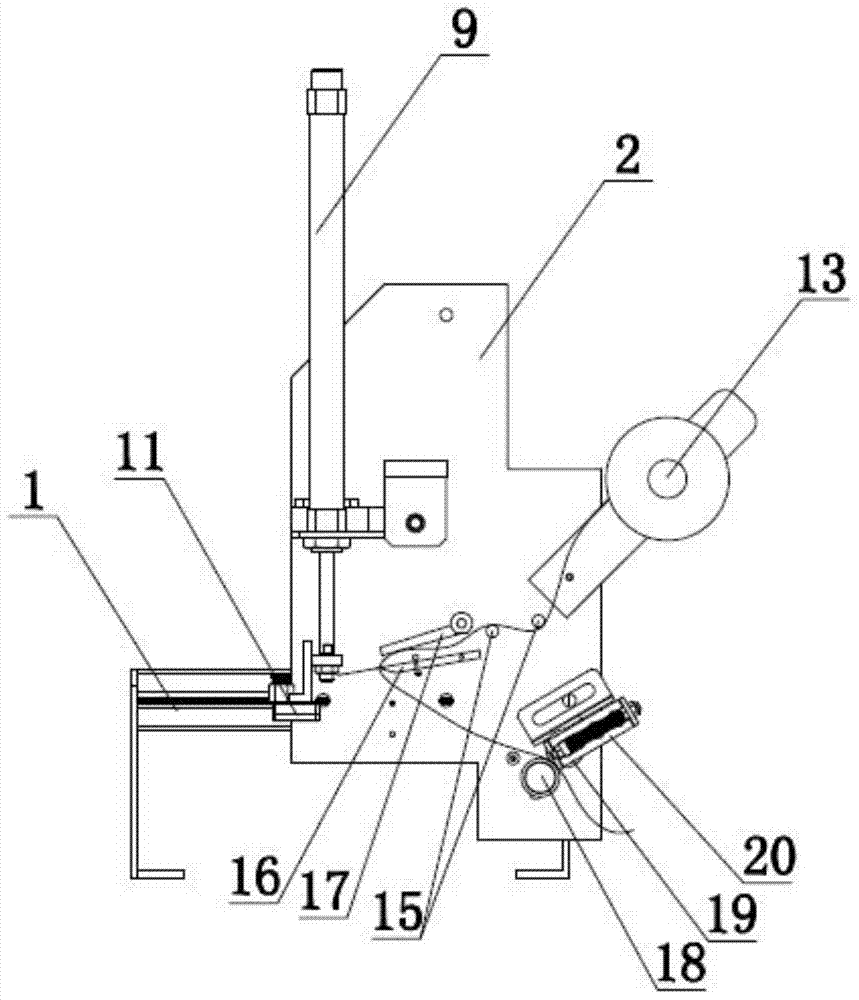

[0035] Example: such as figure 1 As shown, a label adsorption and bonding device includes a frame 1, which is actually composed of a pair of mounting bases and a beam. The present invention is mainly placed directly above a conveyor belt for transporting products, so that the present invention can be continuously Work. There is a wall panel 2 erected on the frame 1. On the side of the wall panel 2, according to the three vertices of the triangle, a feeding polished rod 13, a material guiding plate 16 and a pair of tension rollers are arranged respectively. The feeding polished rod 13 is sleeved with There is a paper tape roll 14 with a label, and the free head of the paper tape roll 14 is sandwiched between two tension rollers along the guide plate 16 and after passing through a bend. The plane of the paper tape roll 14 is formed by the path of the end edge of the material guide plate 16 without passing between the two tension rollers; a vacuum chamber type suction head 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com