Weighing-type rice packaging machine

A packaging machine and weighing device technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of inability to obtain stability and consistency of weight, long rice packaging process, waste of human resources, etc., to achieve the benefit of fixing The effect of separation and separation, shortening the packaging process, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

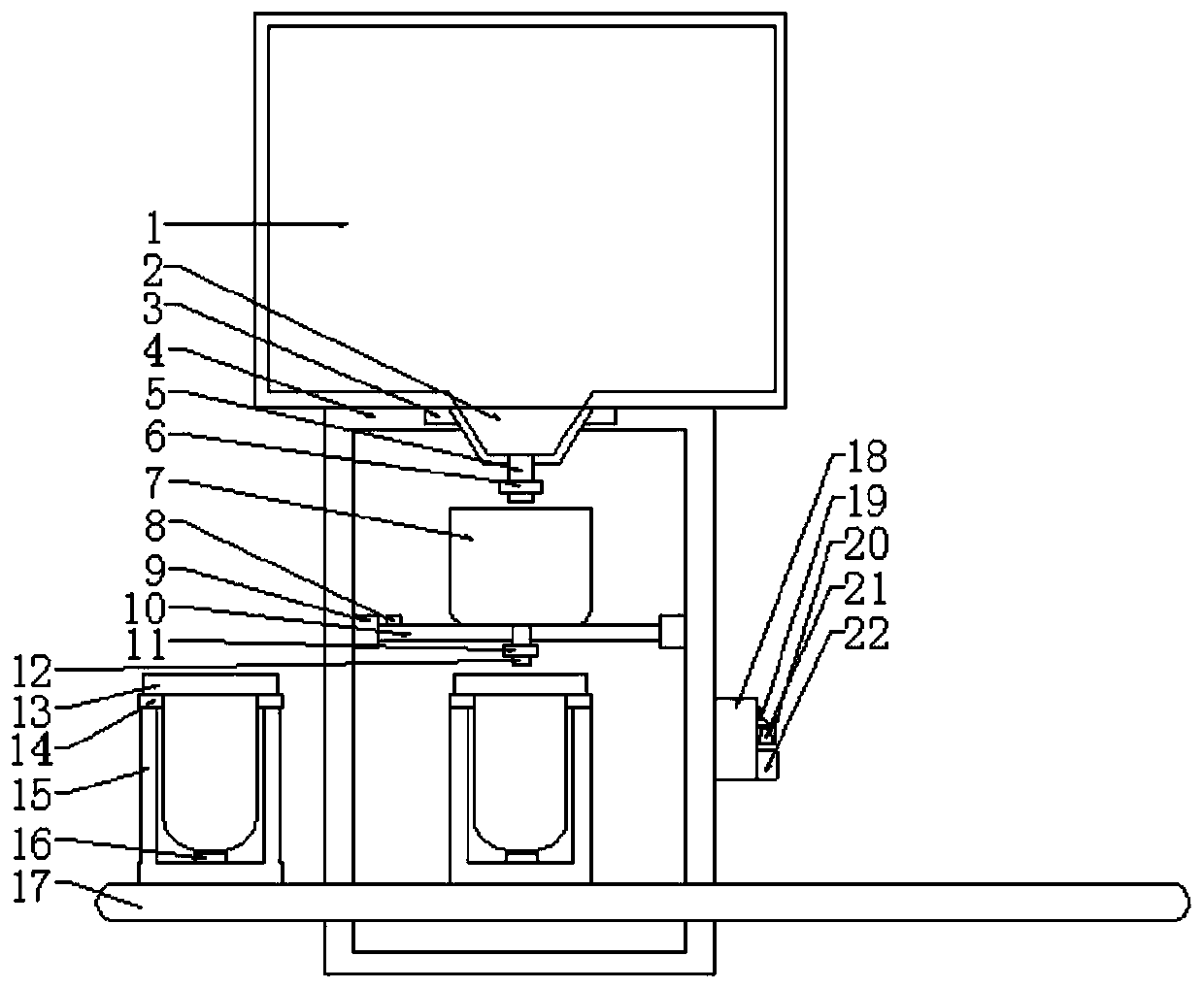

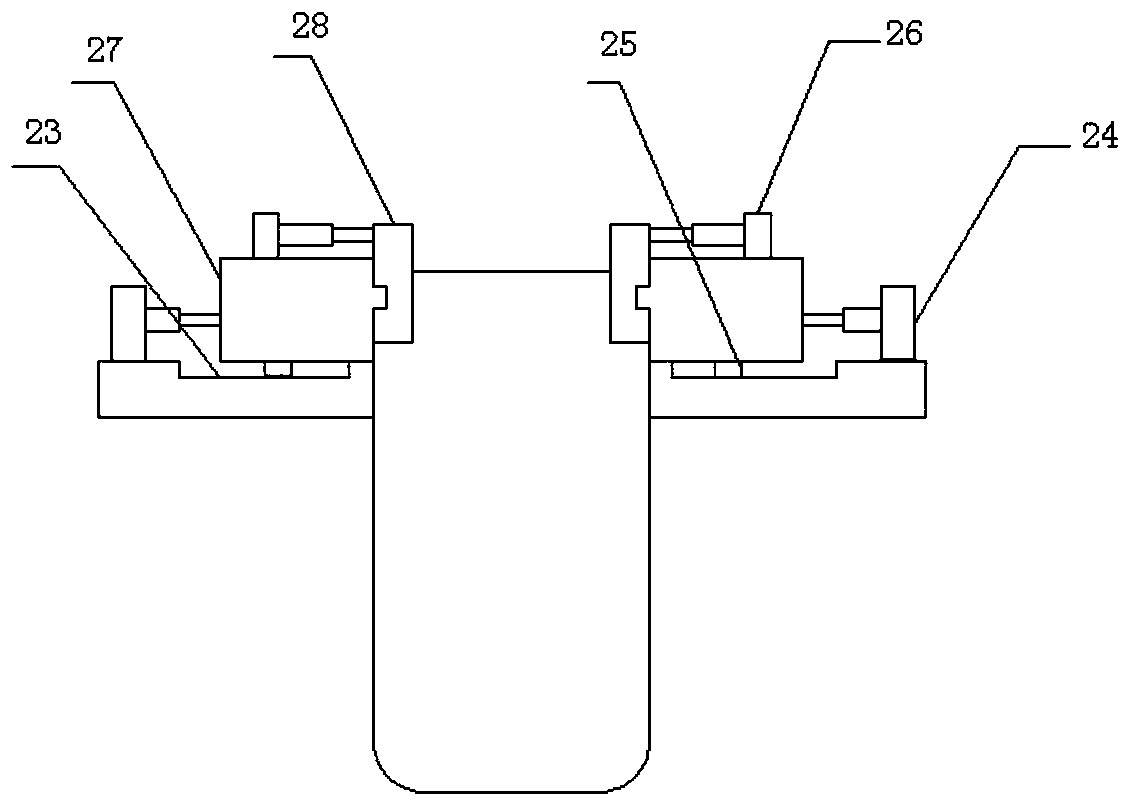

[0015] This implementation case provides a weighing rice packaging machine, its structure is as follows Figure 1-2 As shown, it includes a material storage box 1, a support 4, a weighing device, a funnel 2, a transfer device and a sealing device, the material storage box 1 is arranged on the upper end of the support 4, and the two sides of the upper end of the funnel 2 are provided with a fixed piece 3, and through the fixed piece 3 A discharge port is fixed at the bottom of the material storage box 1, and a discharge pipe 5 is connected to the discharge port at the lower end of the funnel 2. A flow control valve 6 is arranged on the discharge pipe 5, and a weighing valve is provided at the lower end of the discharge pipe 5. Weighing device, weighing device comprises weighing box 7, weighing plate 10 and load cell 8, and weighing box 7 is frame structure without cover, and its open end is facing the below of discharge pipe 5, and weighing box 7 Installed on the weighing plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com