Wafer stage encapsulation LED chip and manufacturing method thereof

A light-emitting diode, wafer-level packaging technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of poor heat dissipation, expensive equipment, and easy moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

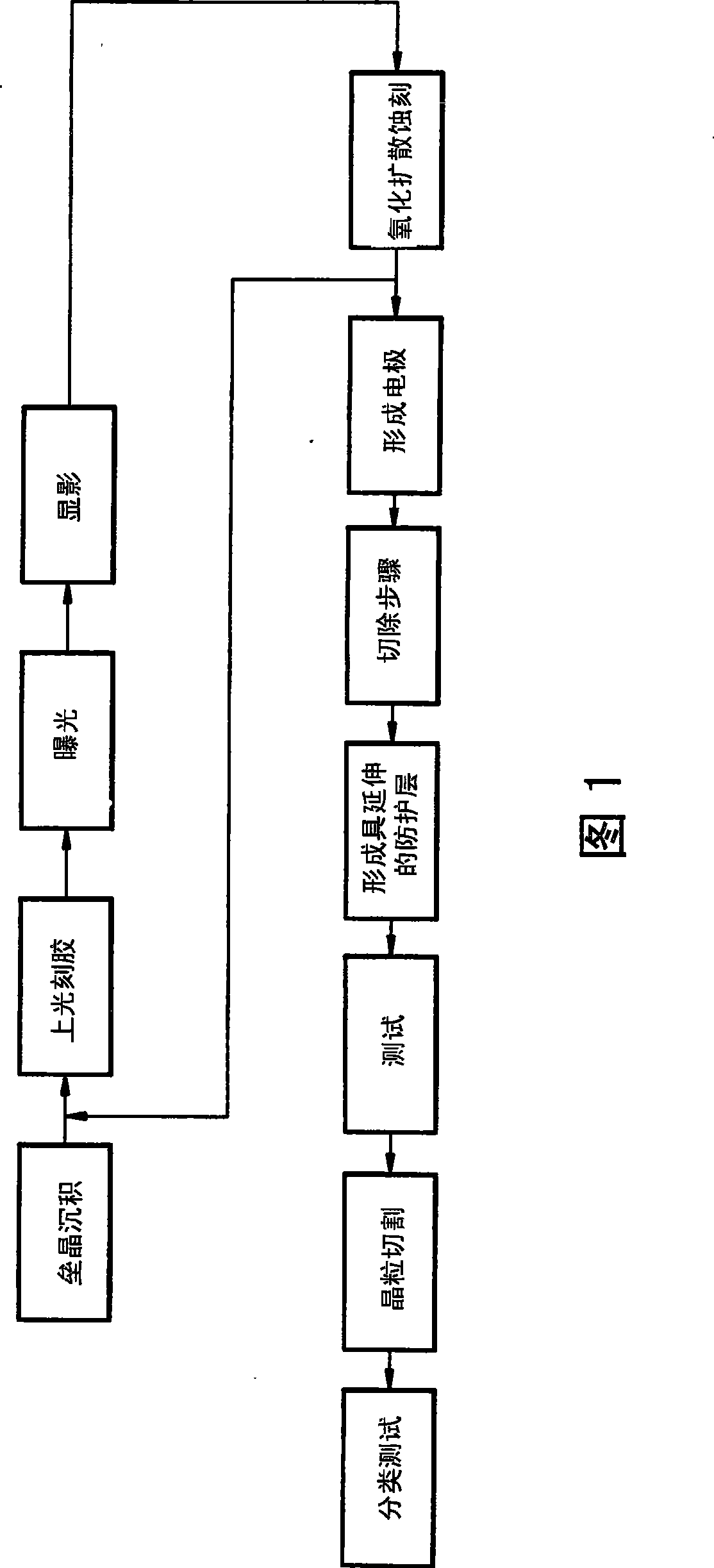

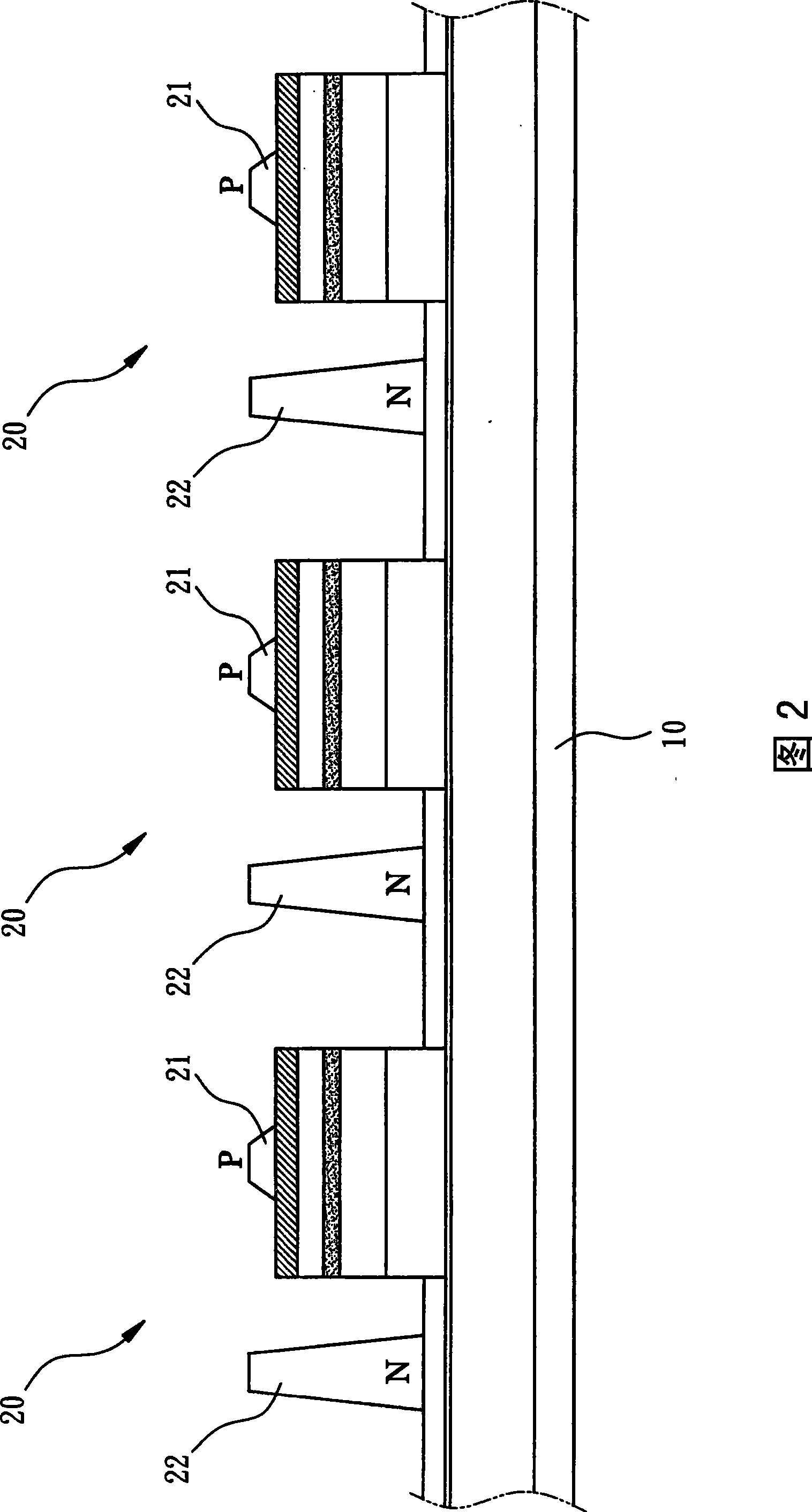

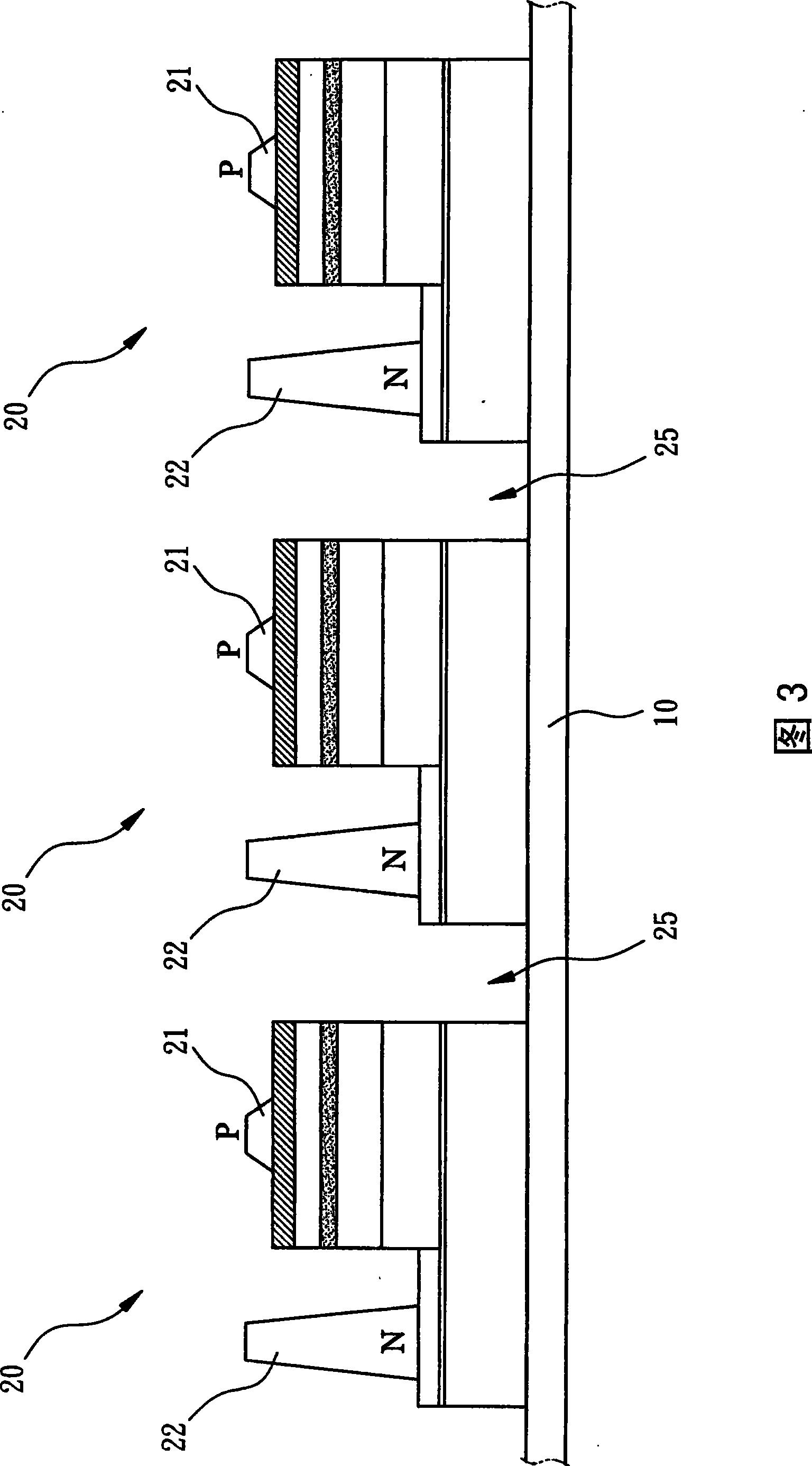

[0037] The present invention is a wafer-level packaged light-emitting diode chip and a manufacturing method thereof. As shown in FIGS. 1, 2, 5 and 8, the light-emitting diode chip (Light Emitting Diodes, LED) is mounted on a wafer substrate (Wafer) utilizes steps such as photoresist, exposure, development and oxidation diffusion etching of the semiconductor process to form light-emitting diodes 20 (as shown in FIG. 2 ) with many connections. Each light-emitting diode 20 has a positive surface electrode 21 (P pole electrode) and a negative electrode 22 (N pole electrode), and utilize a cutting step to remove the epitaxial layer connected to the adjacent light emitting diode 20 to form a cutout region 25 ( As shown in FIG. 3 ), and utilize a step of forming an extended protective layer to form a protective layer 30 (as shown in FIG. shown), the protective layer 30 is an insulating material with high light transmittance or high reflectivity and has protective functions such as mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com