Magnetic steel magnetization and magnetic flux detection integrated equipment

A magnetic flux, magnetic flux measurement technology, applied in magnetic objects, transportation and packaging, the size/direction of the magnetic field, etc., can solve the problems of increasing the splitting time, restricting the production efficiency, extending the production cycle, etc. The effect of saving packaging process and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

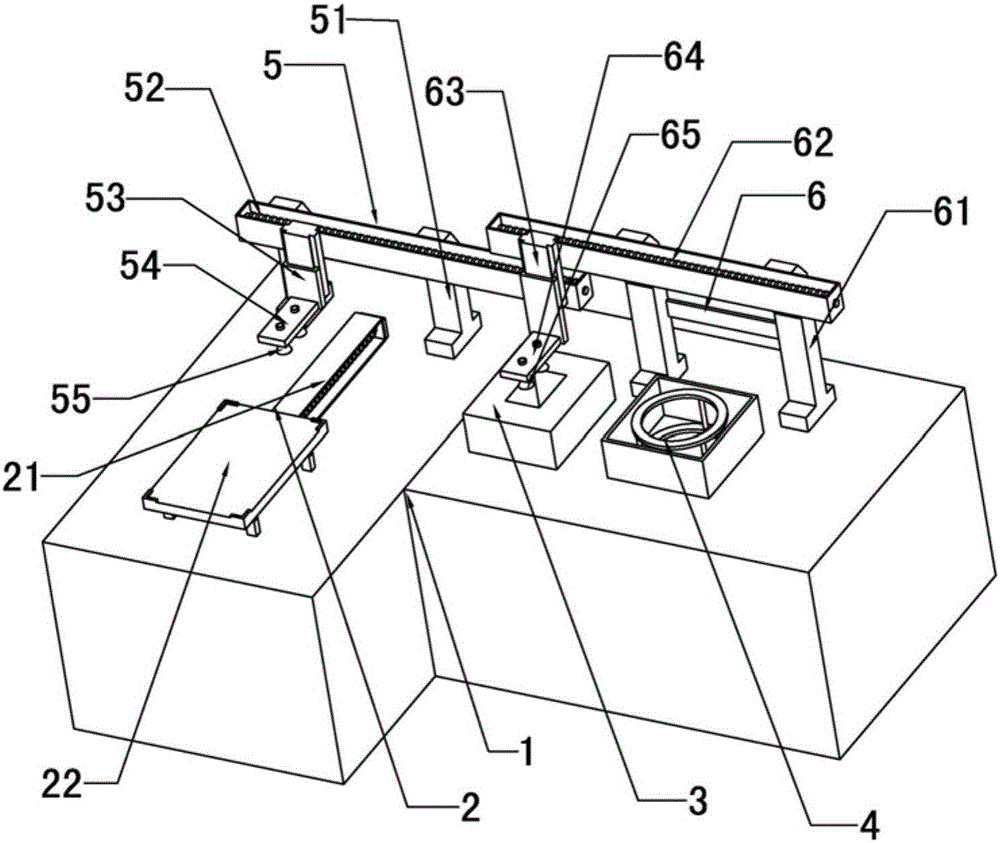

Embodiment 1

[0020] Embodiment one: if figure 1 As shown, an integrated equipment for magnetic steel magnetization and magnetic flux detection, including a worktable, on which a feeding station, a magnetizing station and a magnetic flux detection station are arranged in sequence, and a feeding device is arranged at the feeding station 2. The magnetizing station is equipped with a magnetizing coil 3 connected to the magnetizing machine, the magnetic flux detection station is provided with a magnetic flux measuring instrument 4, and a magnet is installed between the feeding station and the magnetizing station. The feeding station is transported to the first conveying device 5 of the magnetizing station, and the second conveying device 6 is arranged between the magnetizing station and the magnetic flux detection station to convey the magnetized magnetic steel to the magnetic flux detection station .

[0021]In this embodiment, the first conveying device 5 includes a first bracket 51 installe...

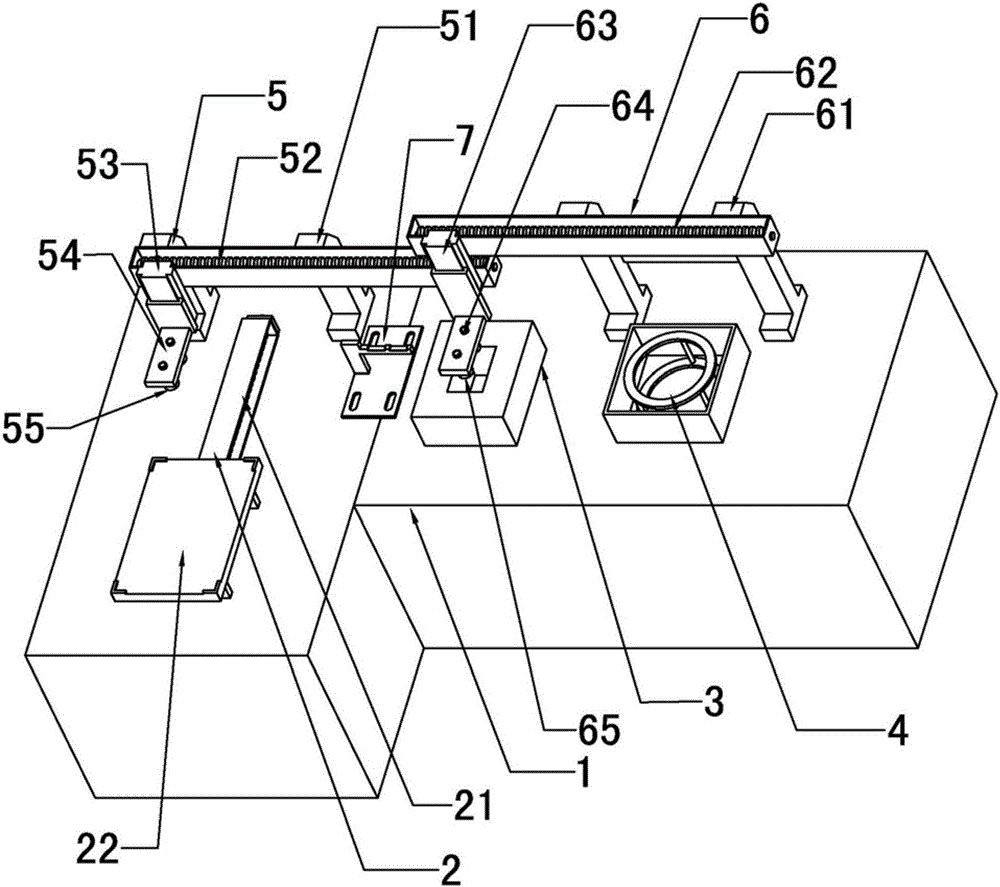

Embodiment 2

[0022] Embodiment two: if figure 2 As shown, an integrated equipment for magnetic steel magnetization and magnetic flux detection, including a worktable, on which a feeding station, a magnetizing station and a magnetic flux detection station are arranged in sequence, and a feeding device is arranged at the feeding station 2. A magnetizing coil 3 is installed at the magnetizing station, a magnetic flux measuring instrument 4 is installed at the magnetic flux detection station, and a device is installed between the feeding station and the magnetizing station to transport the magnetic steel from the feeding station to the charging station. The first conveying device 5 of the magnetic station, and the second conveying device 6 for conveying the magnetized magnetic steel to the magnetic flux detecting station is arranged between the magnetizing station and the magnetic flux detecting station.

[0023] In this embodiment, a marking station is also provided between the feeding stati...

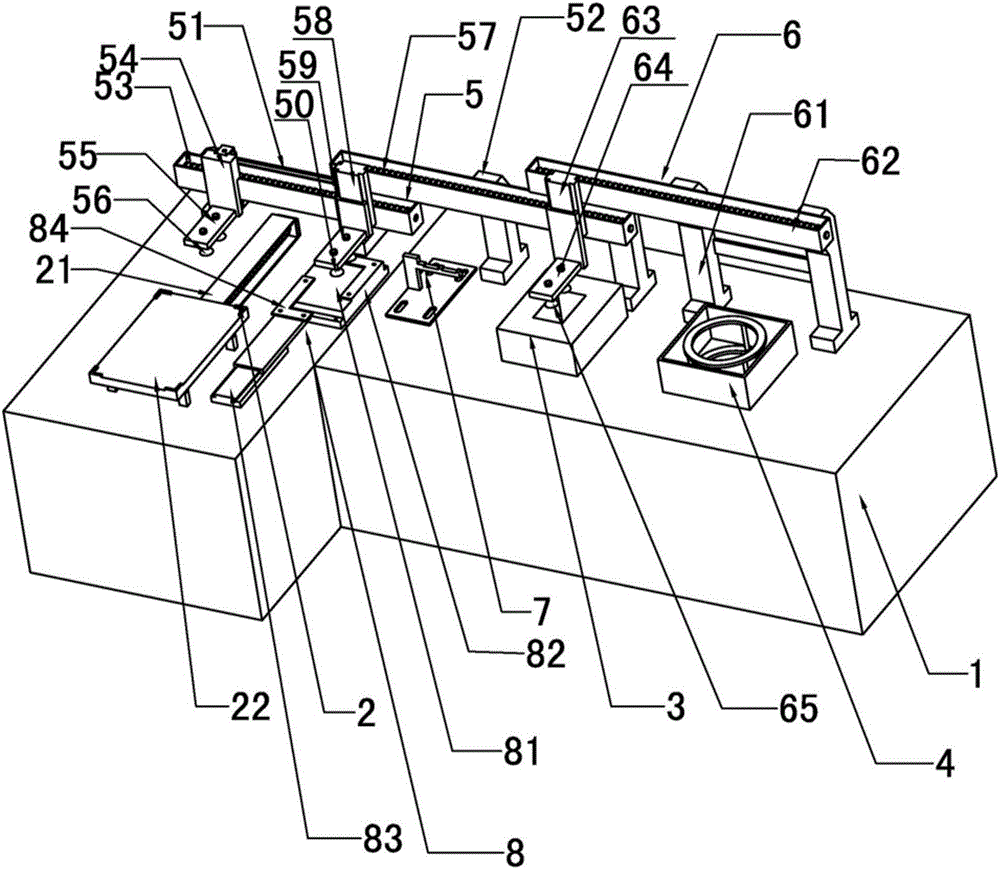

Embodiment 3

[0025] Embodiment three: as image 3 As shown, an integrated equipment for magnetic steel magnetization and magnetic flux detection, including a worktable, on which a feeding station, a magnetizing station and a magnetic flux detection station are arranged in sequence, and a feeding device is arranged at the feeding station 2. A magnetizing coil 3 is installed at the magnetizing station, a magnetic flux measuring instrument 4 is installed at the magnetic flux detection station, and a device is installed between the feeding station and the magnetizing station to transport the magnetic steel from the feeding station to the charging station. The first conveying device 5 of the magnetic station, and the second conveying device 6 for conveying the magnetized magnetic steel to the magnetic flux detecting station is arranged between the magnetizing station and the magnetic flux detecting station.

[0026] In this embodiment, a marking station is also provided between the feeding stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com