Method for treating rubbish percolates of different times for deep denitrification by using bipolar USAB+A/O+SBR process

A technology for deep denitrification of landfill leachate, applied in the field of deep denitrification of landfill leachate, can solve the problems of rare successful application of biological denitrification, complex control factors of nitrite accumulation, and few researches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

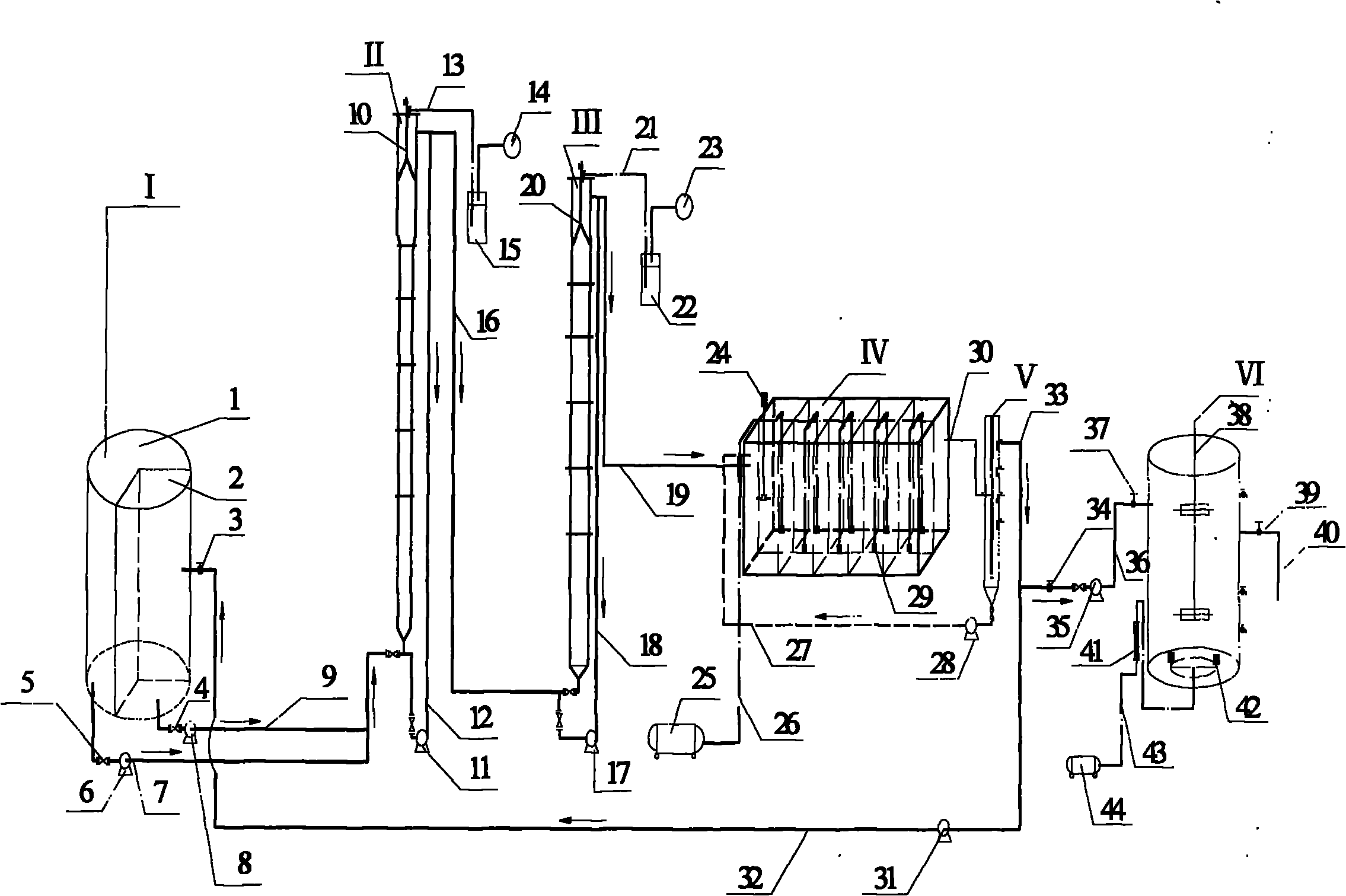

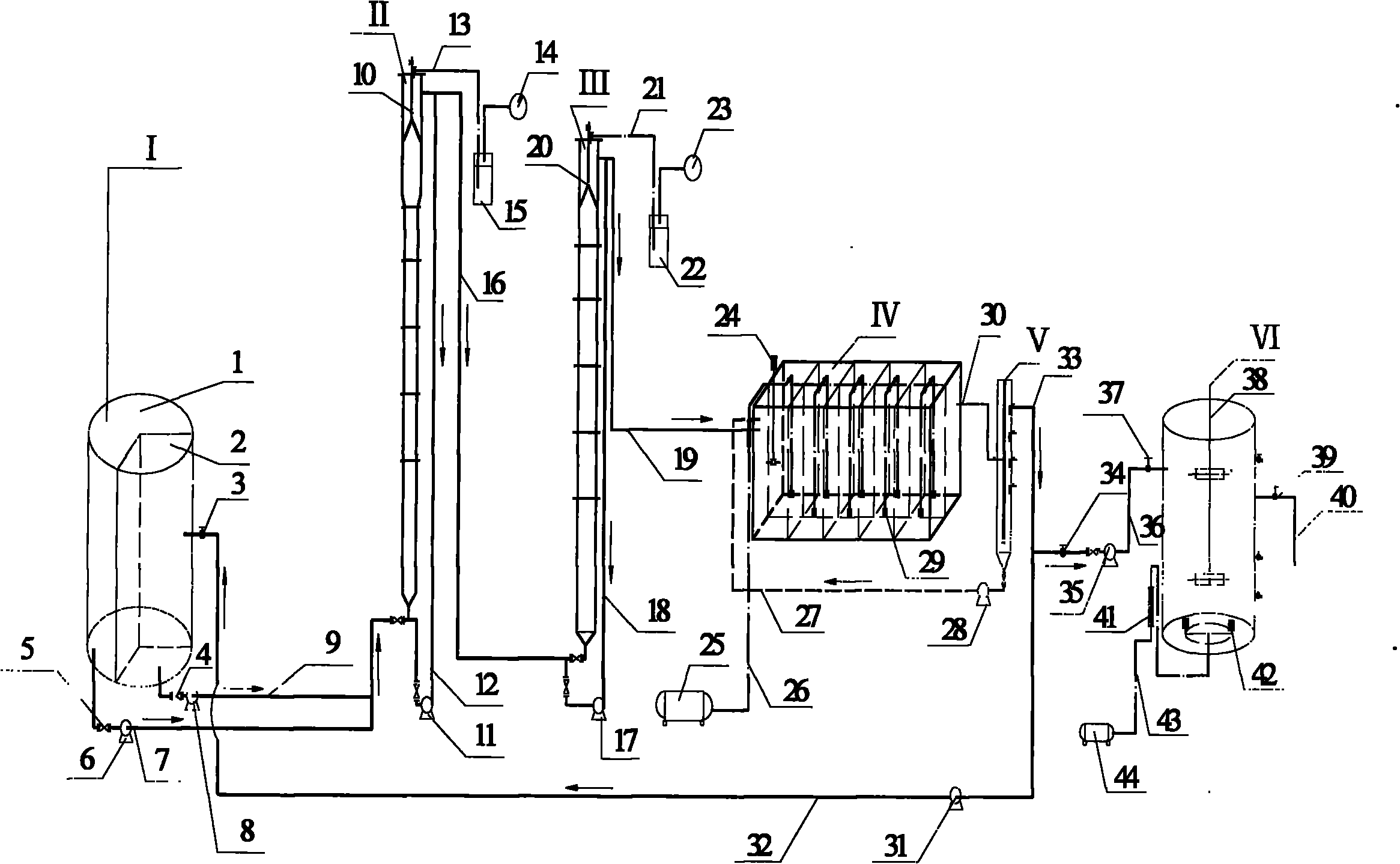

[0052] Combined example: the experimental water is taken from Beijing Liulitun landfill, and its water quality is as follows: COD=3000~5000mg·L-1, NH 4 + -N=1600~2400mg·L -1 , TP=9~15mg·L -1 , TN=1700~2700mg·L -1 , NO x - -N=0.5~15mg·L -1 , pH=7~8. COD, ammonia nitrogen, nitrite nitrogen, nitrate nitrogen and other routine water quality indicators all adopt national standard methods. TON, TN, TOC, IC, TC, etc. adopt TN / TOC analyzer (Multi N / C3000, Jena, Germany). The effective volumes of UASB1 and UASB2 are 4.25L and 8.25L, respectively. The A / O reactor is made of plexiglass and has an effective volume of 15L. It is divided into 10 compartments on average. The first compartment is an anoxic zone, and the rest are aerobic zones. The SBR reactor is 8L and processes 3L of water per cycle.

[0053] Such as figure 1 Shown, the concrete steps that the present invention handles landfill leachate are as follows:

[0054] (1) The leachate used in the test enters the primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com