Quick start method for short-range deep denitrification by SBR (Sequencing Batch Reactor) process at low temperature

A technology of deep denitrification and low temperature conditions, which is applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., to achieve nitrification reaction, stable operation, and remarkable effects of energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

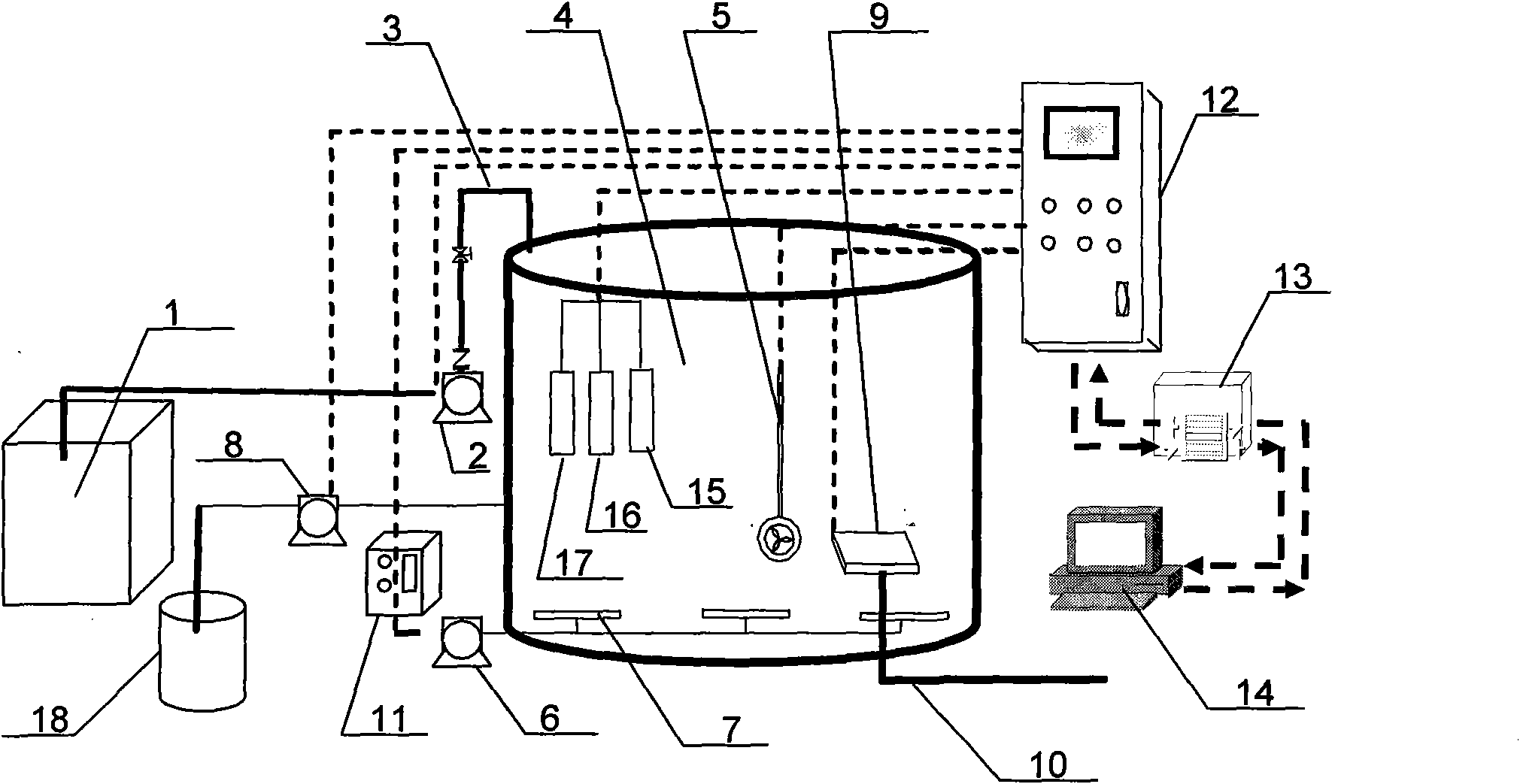

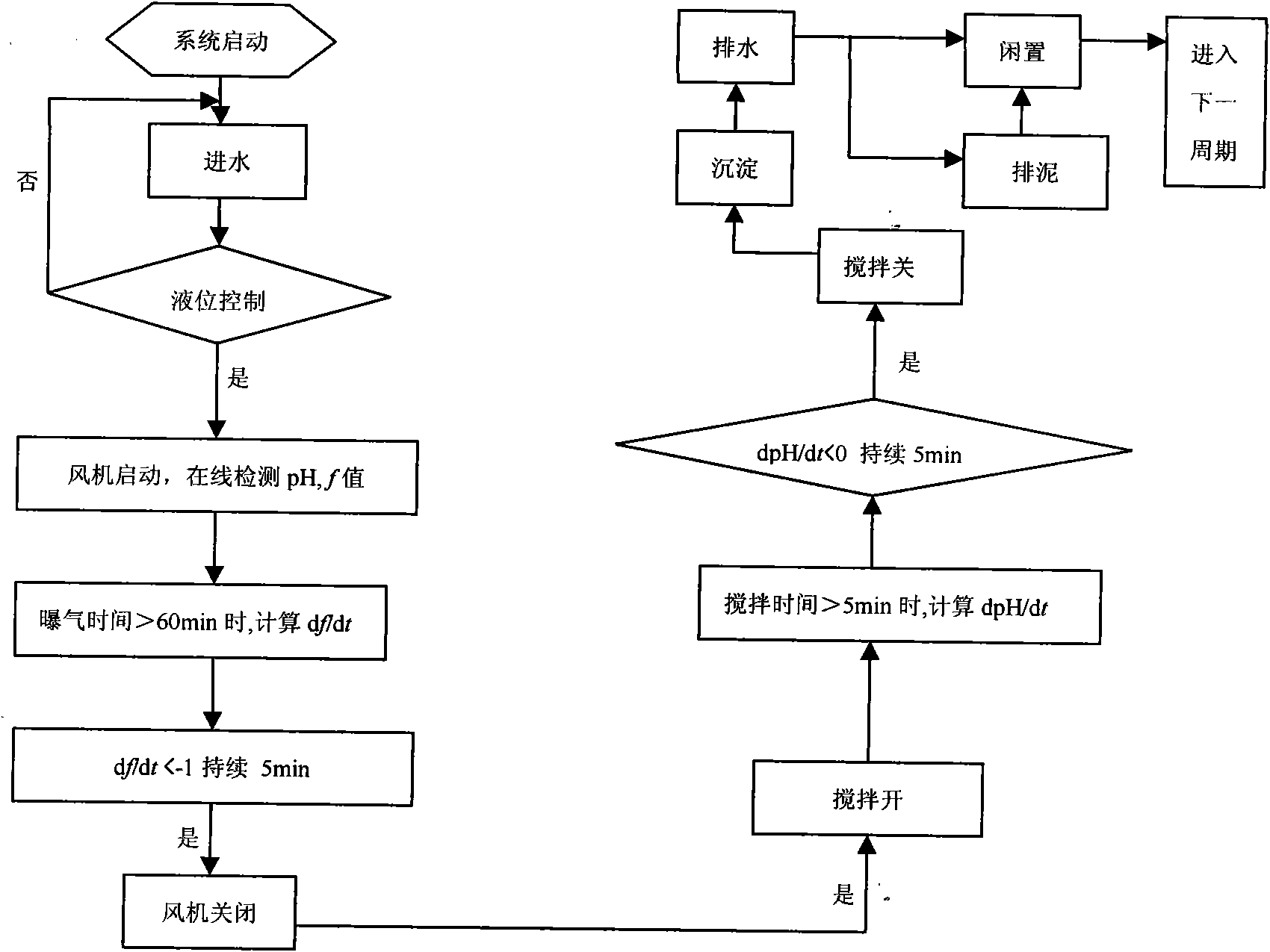

Method used

Image

Examples

Embodiment 1

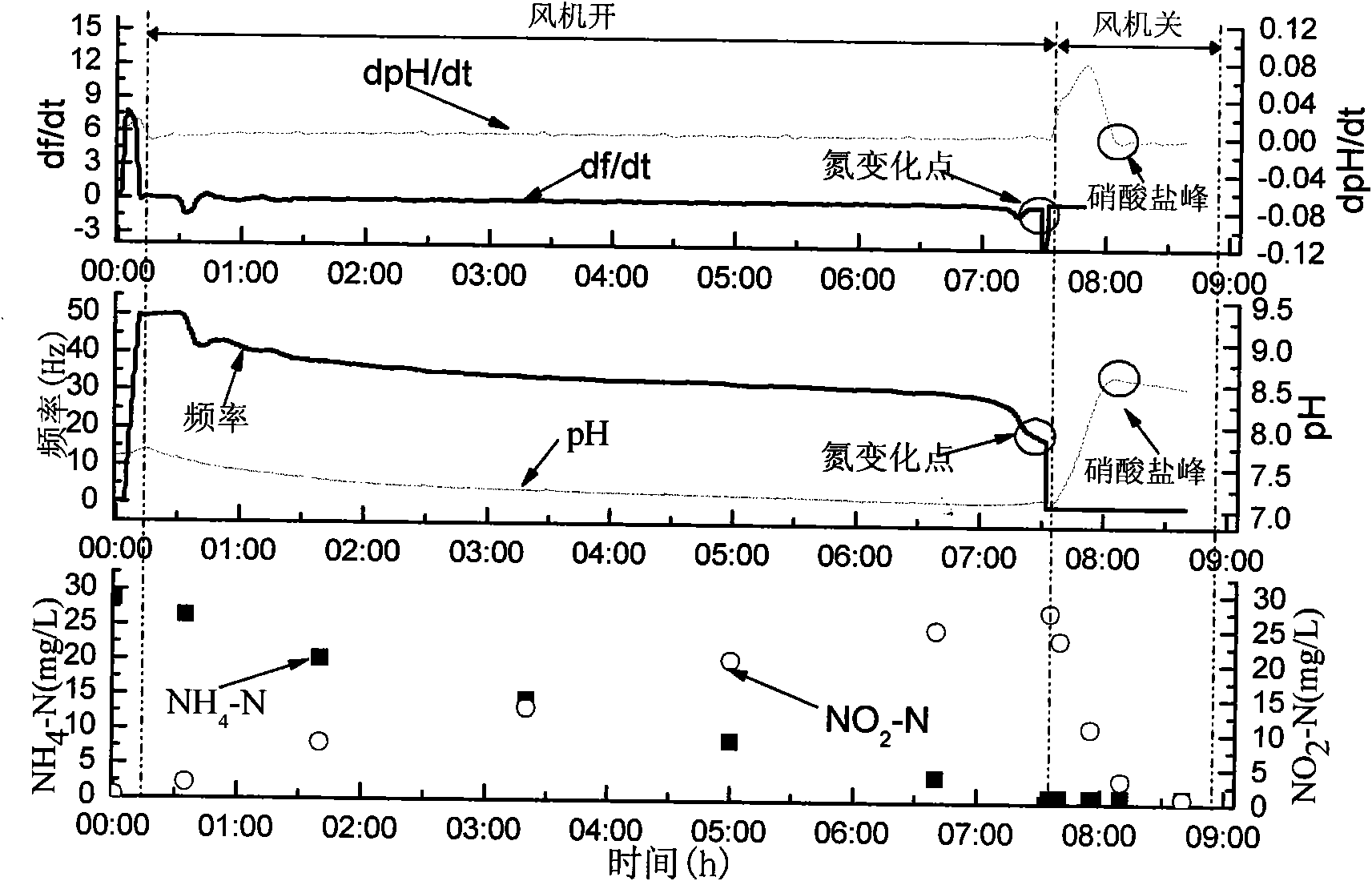

[0034] The SBR short-range deep denitrification quick start process runs continuously for 45 cycles, the SRT is controlled at about 35 days, and the temperature is within the range of 11-17 °C;

[0035] Taking domestic sewage discharged from a university as the research object (pH=7-7.8, COD=160-320mg / L, NH 4 + -N=75-90 mg / L). The test device adopts an effective volume of 7.0m 3 The pilot scale SBR reactor, the water volume per cycle is 2.5m 3 , after the water inflow is completed, the COD concentration of the mixed liquid in the reactor is maintained at 120-240mg / L, and the NH 4 + -N concentration is 20-35mg / L. In the rapid start-up stage of the short-range deep denitrification process, since the pilot-scale SBR reactor is used, the temperature control device cannot be used to control the reaction temperature, and the reactor temperature can only change with the change of the ambient temperature. The time of the rapid start-up phase is the period of transition from wint...

Embodiment 2

[0047] The SBR short-range deep denitrification rapid start-up process runs continuously for 55 cycles, the SRT is controlled at about 30 days, and the temperature is within the range of 11-17°C;

[0048] Taking domestic sewage discharged from a family area of a university as the research object (pH=7-7.8, COD=160-320mg / L, NH 4 + -N=75-90 mg / L). The test device adopts a small-scale SBR reactor with an effective volume of 10L, and the water treatment volume per cycle is 4L. After the water intake is completed, the COD concentration of the mixed liquid in the reactor is maintained at 150-260mg / L, and the NH 4 + -N concentration is 25-45mg / L. In the rapid start-up stage of the short-range deep denitrification process, the temperature is controlled within the range of 11-17°C. The external carbon source is ethanol with a volume fraction of 99.5%. The specific operation steps of each cycle are as follows:

[0049] I use the SBR reactor with an effective volume of 10L for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com