Production method of quantum dot light bar

A production method and technology of quantum dots, applied in the field of quantum dot light bars, can solve the problem that glass tubes cannot contain moisture and air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

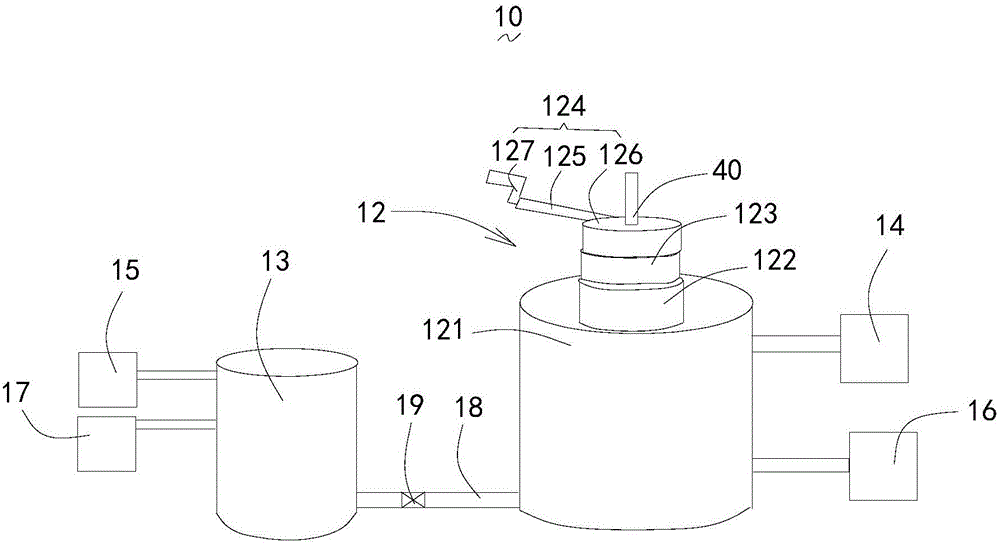

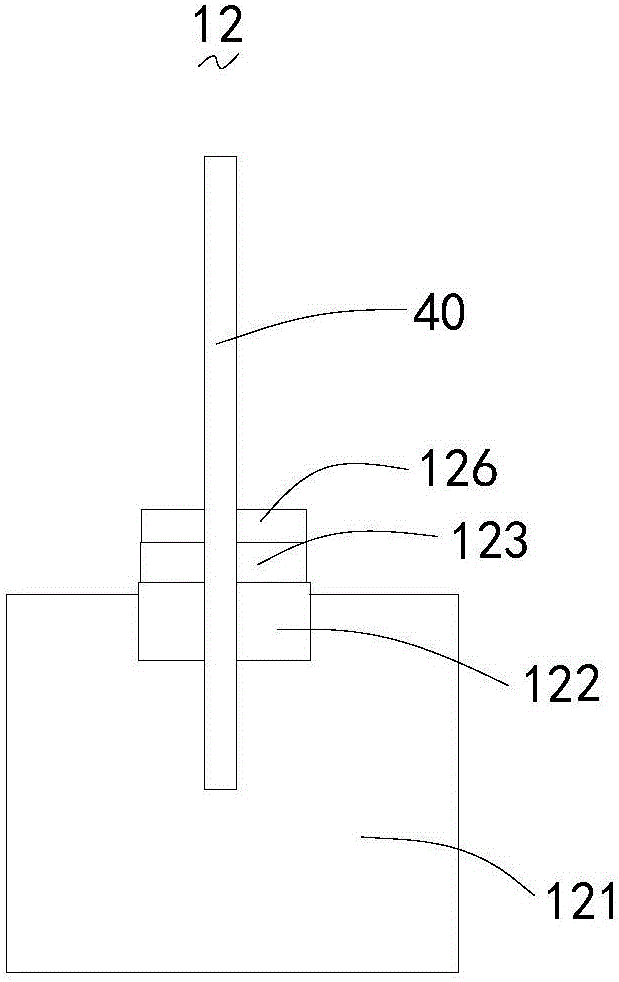

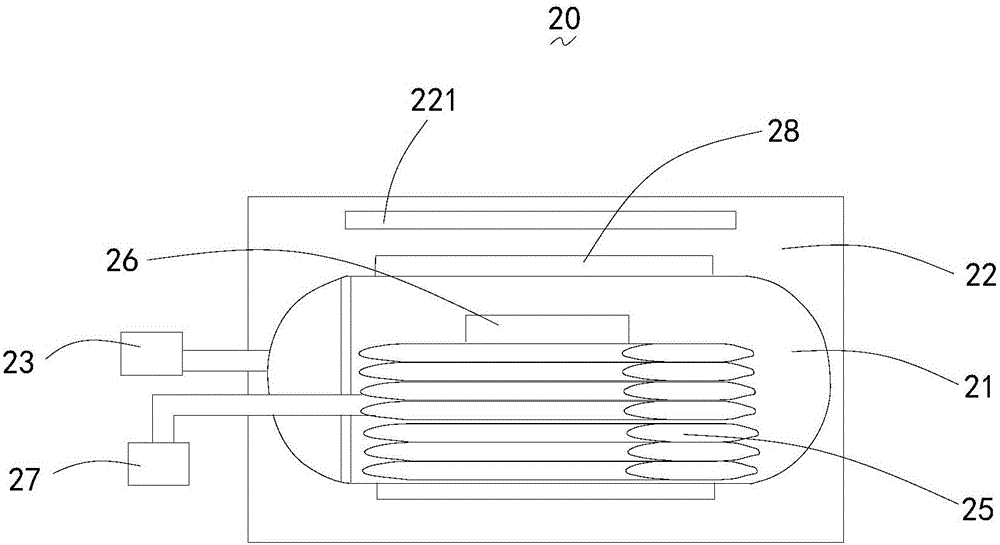

[0053] Please refer to Figure 1 to Figure 5 , providing a production device for quantum dot light strips, including: a filling mechanism 10 , a baking mechanism 20 and a sealing mechanism 30 . The filling mechanism 10 is used for filling the quantum dot glue into the glass tube, the baking mechanism 20 is used for baking the glass tube 40 , and the sealing mechanism 30 is used for sealing the open end of the glass tube.

[0054] Please refer to figure 1 and figure 2 , the filling mechanism 10 includes a filling tank 12, a liquid supply tank 13, a first vacuum pump 14, a second vacuum pump 15, a first shielding gas tank 16 and a second shielding gas tank 17, and the filling tank 12 includes a tank body 121 and a sealing Block 122, the tank body 121 has an opening, the sealing block 122 is located at the opening of the tank body 121 and the middle part of the sealing block 122 is provided with a first perforation, the first perforation is coaxially arranged with the opening,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com