Broadband wide temperature range high-power density low-loss manganese-zinc soft magnetic ferrite material and preparation method thereof

A high-power density, manganese-zinc soft magnet technology, applied in the direction of inorganic material magnetism, etc., can solve the problems of undisclosed power loss, inability to achieve low loss, etc., and achieve low-temperature start-up response, excellent working performance, and high initial permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

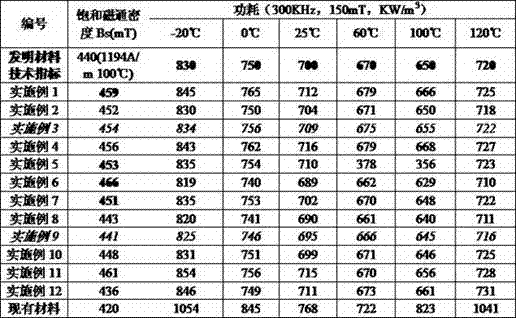

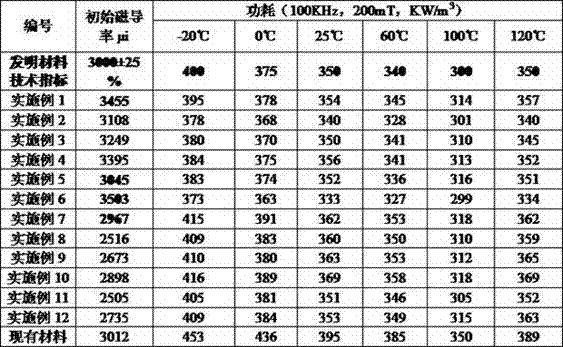

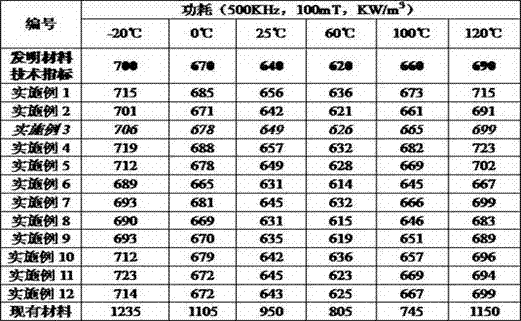

Examples

Embodiment 1

[0043] A manganese-zinc soft magnetic ferrite material with wide frequency, wide temperature, high power density and low loss, including main component, auxiliary component A and auxiliary component B, calculated by weight percentage, the main component includes 70.05% Fe 2 o 3 , 24.15% MnO and 5.80% ZnO;

[0044] Based on the weight of the main component, the auxiliary component A is CaCO 3 0.02%, Nb 2 o 5 0.05%, NiO 0.20%, Co 3 o 4 0.32%;

[0045] Based on the weight of the main component, the auxiliary component B is SiO 2 0.01%, CuO 0.05%, MoO 0.01%, Bi 2 o 3 0.05%.

[0046] A method for preparing a manganese-zinc soft ferrite material with wide frequency, wide temperature, high power density and low loss, comprising the following steps:

[0047] (1) Primary ingredients: In this embodiment, it is Fe by weight percentage 2 o 3 :MnO:ZnO= 70.05: 24.15:5.80 for batching; based on the weight of the main component, the auxiliary component A is: CaCO 3 0.02%, ...

Embodiment 2

[0067] In the same situation as in Example 1, the auxiliary component A added in step (1) is: CaCO 3 0.03%, Nb 2 o 5 0.03%, SnO 2 0.15%, Co 3 o 4 0.25%; In step (4), auxiliary component B is added as Y in the second batch 2 o 3 0.01%, K 2 CO 3 0.01%, MoO 0.03%.

Embodiment 3

[0069] In the same situation as in Example 1, the auxiliary component A added in step (1) is: CaCO 3 0.10%, NiO0.50%, SnO 2 0.01%, Co 3 o 4 0.2%; in step (4), the auxiliary component B is added to the secondary ingredients: SiO 2 0.01%, Al 2 o 3 0.01%, MoO 0.07%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com