Superheated steam fixation device and method

A technology of superheated steam and degreening equipment, which is applied in lighting and heating equipment, steam superheating, steam generation, etc. It can solve the problems of high water content of tea, easy to stuffy yellow water, dull taste, and reduced quality of tea, so as to achieve uniform degreening and drying, The effect of enhancing heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

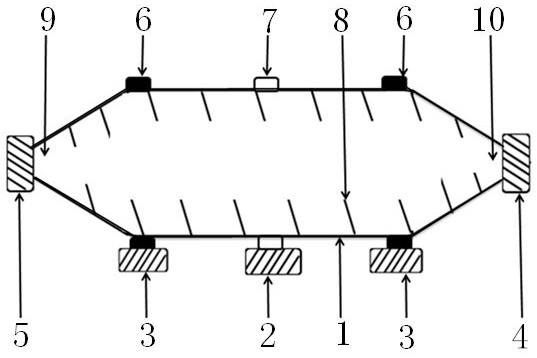

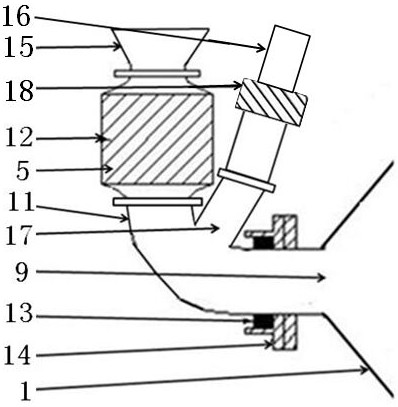

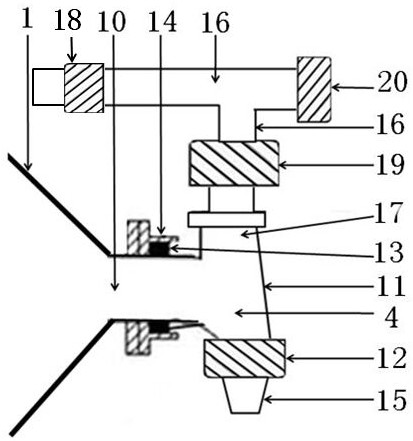

[0054] like figure 1 , figure 2 , image 3 The shown superheated steam fixing equipment includes a fixing drying bin 1, a driving device 2, a supporting roller 3, a discharging device 4, a feeding device 5, an air duct 16, a steam device 19, an exhaust device 20, and a duct fan 18.

[0055] The diameter of the said finishing and drying bin 1 is 1200mm, and the length is 8000mm.

[0056] The said finishing drying bin 1 includes a drum, a raceway 6 , a gear ring 7 , and a helical blade 8 . The helical blade 8 is fixed on the inner drum body; the gear ring 7 and the raceway 6 are installed on the drum.

[0057] The roller 3 supports the raceway 6 , and the drying bin 1 rotates on the roller 3 driven by the driving device 2 .

[0058] The driving device 2 is a combination of a motor and a speed changer. The driving wheel of the speed changer of the driving device 2 is engaged to drive the gear teeth of the gear ring 7, and the gear ring 7 drives the drying chamber 1. rotati...

Embodiment 2

[0080] The similarities between the superheated steam fixing equipment of the second embodiment and the superheated steam fixing equipment introduced in the embodiment 1 will not be repeated.

[0081] like figure 1 , figure 2 , image 3 , Figure 4 The shown superheated steam fixing equipment includes a fixing drying bin 1, a driving device 2, a supporting roller 3, a discharging device 4, a feeding device 5, an air duct 16, a steam device 19, an exhaust device 20, a heat exchanger, and a pipeline fan. 18.

[0082] The exhaust device 20 is a Roots blower.

[0083] Said feeding device 12 is a screw feeder.

[0084] The similarities between the superheated steam fixing method of the present embodiment 2 and the superheated steam fixing method introduced in the embodiment 1 will not be repeated.

[0085] A kind of continuous superheated steam fixing method, its work flow is as follows:

[0086] The temperature of the superheated steam heated by the steam heater of the ste...

Embodiment 3

[0090] The similarities between the superheated steam fixing equipment of the present embodiment 3 and the superheated steam fixing equipment introduced in the embodiment 1 will not be repeated.

[0091] like figure 1 , figure 2 , image 3 , Figure 4 The shown superheated steam fixing equipment includes a fixing drying bin 1, a driving device 2, a supporting roller 3, a discharging device 4, a feeding device 5, an air duct 16, a steam device 19, an exhaust device 20, a heat exchanger, and a pipeline fan. 18.

[0092] The exhaust device 20 is a vacuum pump.

[0093] The conveying device 12 is a high air-tight discharge valve.

[0094] The similarities between the superheated steam fixing method of the present embodiment 3 and the superheated steam fixing method introduced in the embodiment 1 will not be repeated.

[0095] A kind of continuous superheated steam fixing method, its work flow is as follows:

[0096] The relative pressure in the drying warehouse 1 is -0.98M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com