Methanol electro-oxidizing-catalyzing electrode, preparing process and application thereof

A catalytic electrode and electro-oxidation technology, applied in the direction of material electrochemical variables, etc., can solve the problems of low polymerization oxidation potential, difficulty in molecular chain growth, polymer peroxidation, etc., and achieve small adsorption capacity, lower methanol oxidation potential, and conductivity small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

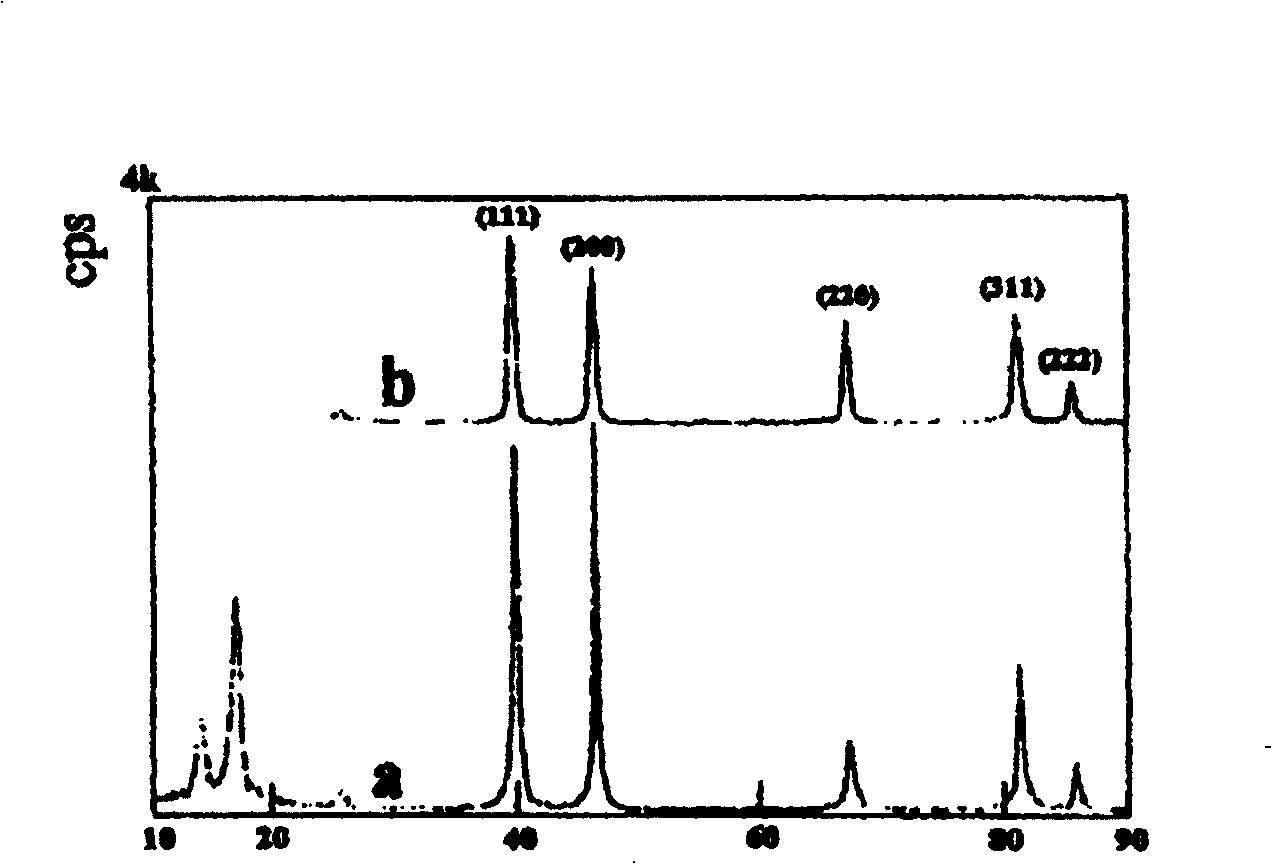

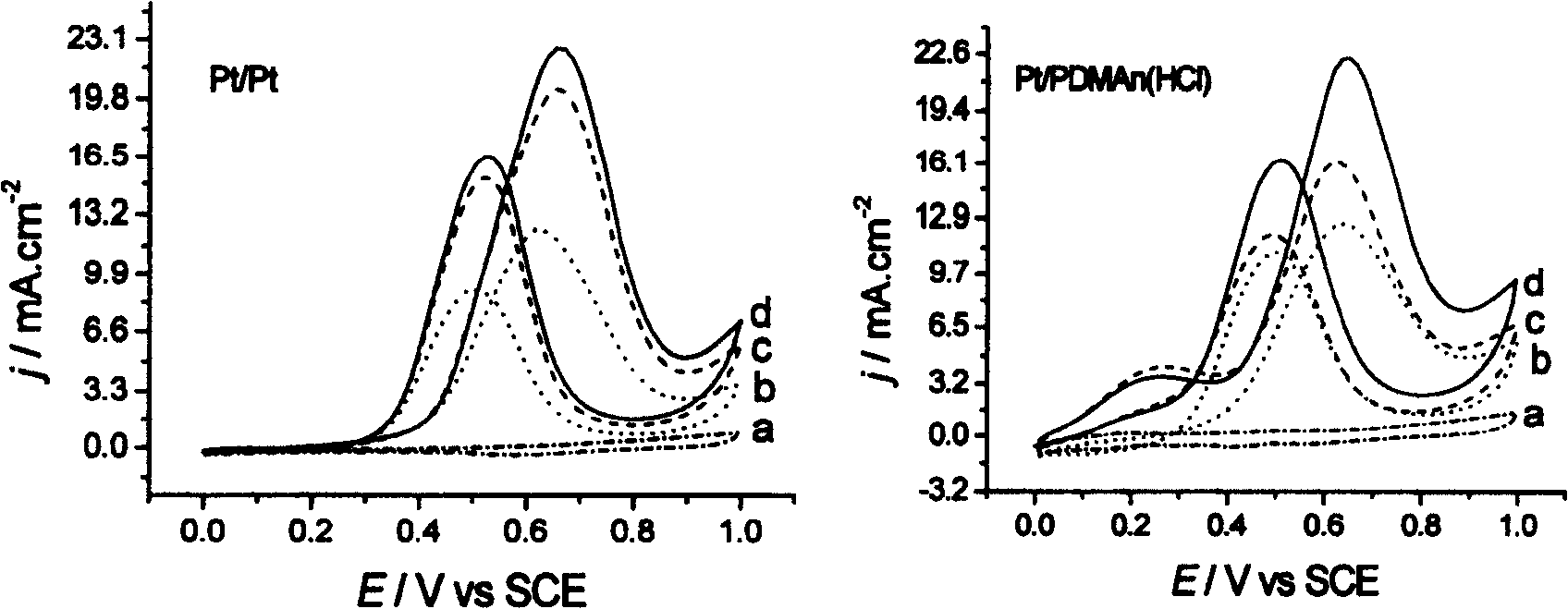

[0031] Dissolve PDMAn(HCl) in DMF to make a DMF solution with a concentration of 3.0mg / mL, and use a micro-vortex mixer to aid in dissolution; take a certain amount of polymer solution and coat it on the surface of a platinum disk electrode, and place it in an infrared rapid drying box Internal drying for 15 minutes, the polymer film modified electrode is obtained, and the adhesion amount of the polymer on the electrode surface is 0.3 mg·cm -2 .

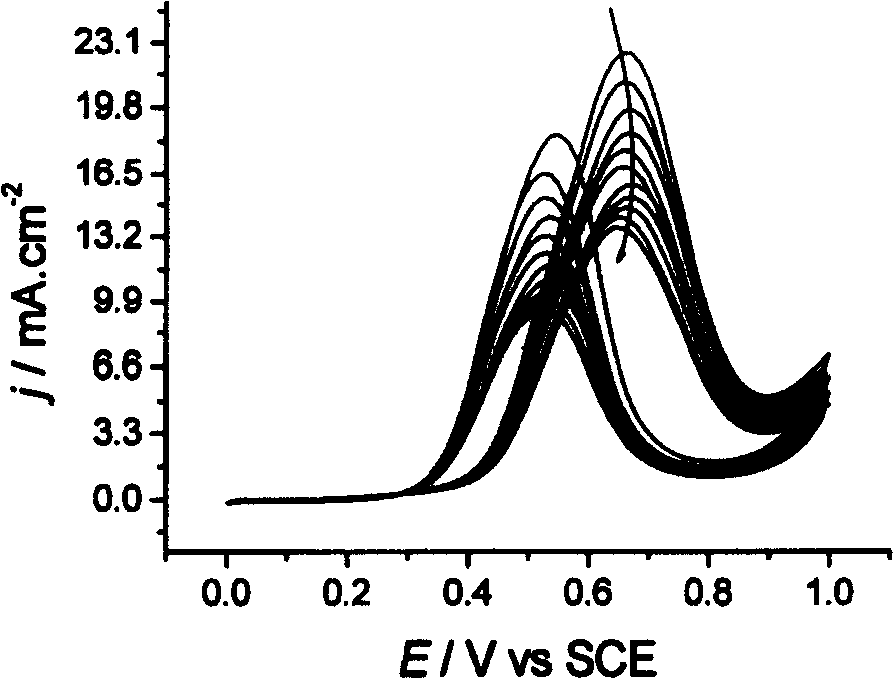

[0032] In the single-chamber electrolytic cell, the polymer membrane modified electrode is used as the working electrode, the platinum sheet electrode is used as the auxiliary electrode, and the saturated calomel electrode is used as the reference electrode. The experiment was carried out on a CHI660 electrochemical comprehensive tester, and its attached computer software can be used for the collection and processing of experimental data. The above-mentioned PDMAn(HCl) polymer membrane modified electrode was placed in 1.0mg / mLH 2 P...

Embodiment 2

[0037] PDMAn(HClO 4 ) was dissolved in DMF, and dissolved with a micro-vortex mixer with a concentration of 5.0 mg / mL; a certain amount of polymer solution was coated on the surface of a platinum disk electrode, and dried in an infrared rapid drying oven for 15 minutes to obtain the polymer Membrane modified electrode, the adhesion amount of polymer on the electrode surface is 0.6mg·cm -2 .

[0038] In the single-chamber electrolytic cell, the polymer membrane modified electrode is used as the working electrode, the platinum sheet electrode is used as the auxiliary electrode, and the saturated calomel electrode is used as the reference electrode. The experiment was carried out on a CHI660 electrochemical comprehensive tester, and its attached computer software can be used for the collection and processing of experimental data. The above PDMAn (HClO 4 ) polymer membrane modified electrode placed in 1.0mg / mL H 2 PtCl 6 In the 1.0mol / L HCl solution, the potential cycle scann...

Embodiment 3

[0040] Dissolve PDMAn (TSA) in DMF, and use a micro-vortex mixer to aid dissolution, with a concentration of 13.0 mg / mL; take a certain amount of polymer solution and coat it on the surface of a platinum disk electrode, and dry it in an infrared rapid drying oven for 15 minutes. The polymer film modified electrode was obtained, and the adhesion amount of the polymer on the electrode surface was 0.8 mg·cm -2 .

[0041] In the single-chamber electrolytic cell, the polymer membrane modified electrode is used as the working electrode, the platinum sheet electrode is used as the auxiliary electrode, and the saturated calomel electrode is used as the reference electrode. The experiment was carried out on a CHI660 electrochemical comprehensive tester, and its attached computer software can be used for the collection and processing of experimental data. The above-mentioned PDMAn (TSA) polymer membrane modified electrode was placed in 1.0 mg / mL H 2 PtCl 6 In a 1.0mol / L HCl solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com