Nanocrystalline soft magnetic alloy and preparation method and application thereof

A nanocrystalline soft magnetic and alloy technology, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of high saturation magnetic induction intensity, high and high frequency permeability, etc., and achieve low preparation difficulty, high density, The effect of reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a nanocrystalline soft magnetic alloy, its composition and the atomic percentage of each component are: 76.5at% Fe, 1.5at% Cu, 10at% Si, 8.5at% B, 2.5at% Nb, 0.8at%V and 0.2at%Pr;

[0048] The preparation method of the above-mentioned nanocrystalline soft magnetic alloy comprises the following steps,

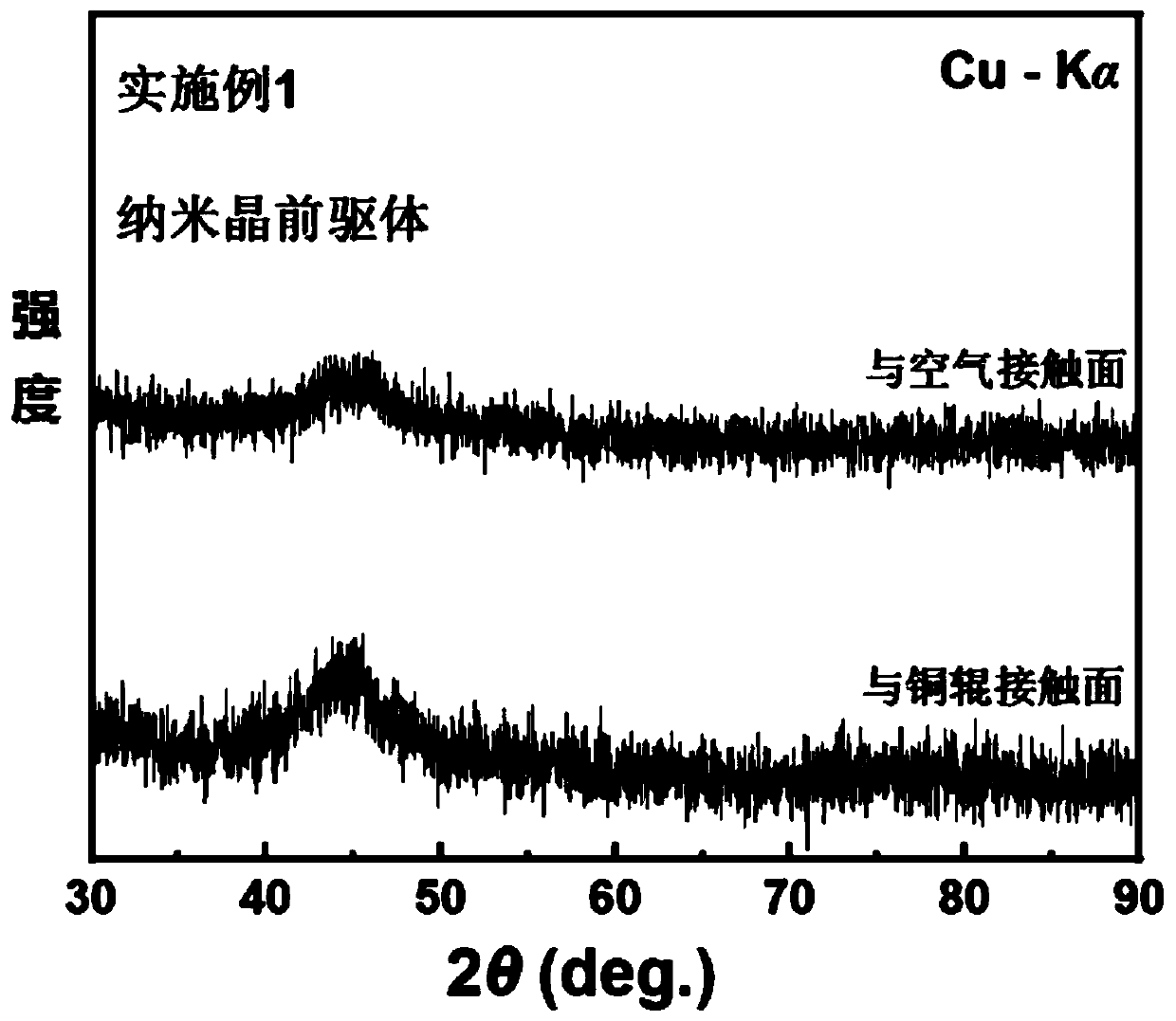

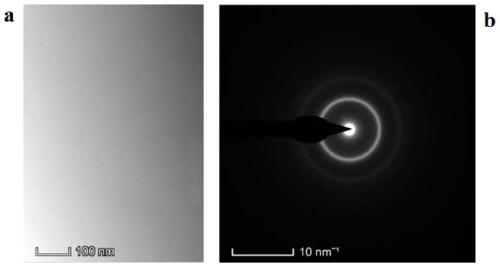

[0049] Mix iron raw materials, copper raw materials, silicon raw materials, boron-iron alloy ingot raw materials, niobium-iron alloy ingot raw materials, vanadium-iron-iron alloy ingot raw materials, and praseodymium-iron-iron alloy ingot raw materials according to the above proportions, keep warm at 1320°C for 45 minutes and cool to obtain alloy ingots, and then After the alloy ingot was heated to a molten liquid state at 1350 °C, it was sprayed onto a rotating copper roller through a narrow nozzle to obtain a nanocrystalline precursor with a width of 60 mm and a strip thickness of 18 μm.

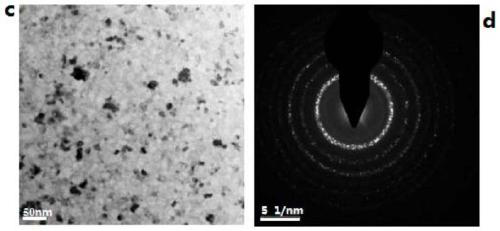

[0050] Put the nanocrystalline precursor into a heat tr...

Embodiment 2

[0055] This embodiment provides a nanocrystalline soft magnetic alloy, its composition and the atomic percentage of each component are: 78.5at% Fe, 1.2at% Cu, 10at% Si, 6.5at% B, 1.5at% Nb, 0.8at%V and 1.5at%La;

[0056] The preparation method of the above-mentioned nanocrystalline soft magnetic alloy comprises the following steps,

[0057] Mix iron raw materials, copper raw materials, silicon raw materials, ferroboron alloy ingot raw materials, niobium ferroalloy ingot raw materials, vanadium ferroalloy ingot raw materials and lanthanum ferroalloy ingot raw materials according to the above ratio, keep warm at 1350°C for 30 minutes and cool to obtain alloy ingots, and then After the alloy ingot was heated to a molten liquid state at 1380 ° C, it was sprayed onto a rotating copper roller through a narrow nozzle to obtain a nanocrystalline precursor with a width of 80 mm and a strip thickness of 20 μm.

[0058] Put the nanocrystalline precursor into a heat treatment furnace, he...

Embodiment 3

[0063] This embodiment provides a nanocrystalline soft magnetic alloy, its composition and the atomic percentage of each component are: 77.3at% Fe, 1.2at% Cu, 9.5at% Si, 8.5at% B, 1.5at% Nb , 0.8at%V and 1.2at%Ce;

[0064] The preparation method of the above-mentioned nanocrystalline soft magnetic alloy comprises the following steps,

[0065] Mix iron raw materials, copper raw materials, silicon raw materials, ferroboron alloy ingot raw materials, niobium ferroalloy ingot raw materials, vanadium ferroalloy ingot raw materials and cerium ferroalloy ingot raw materials according to the above proportions, keep warm at 1320°C for 40 minutes and cool to obtain alloy ingots, and then After the alloy ingot was heated to a molten liquid state at 1350 °C, it was sprayed onto a rotating copper roller through a narrow nozzle to obtain a nanocrystalline precursor with a width of 100 mm and a strip thickness of 19 μm.

[0066] Put the nanocrystalline precursor into a heat treatment furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com