Rare earth/alkaline earth metal and transition metal doped bismuth ferrite nano multiferroic material and preparation method thereof

A technology of multiferroic materials and transition metals, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems that BiFeO3 is difficult to apply, it is difficult to observe electric hysteresis loops, and magnetic hysteresis loops cannot be observed. Achieve excellent magnetic properties, excellent magnetic permittivity, easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

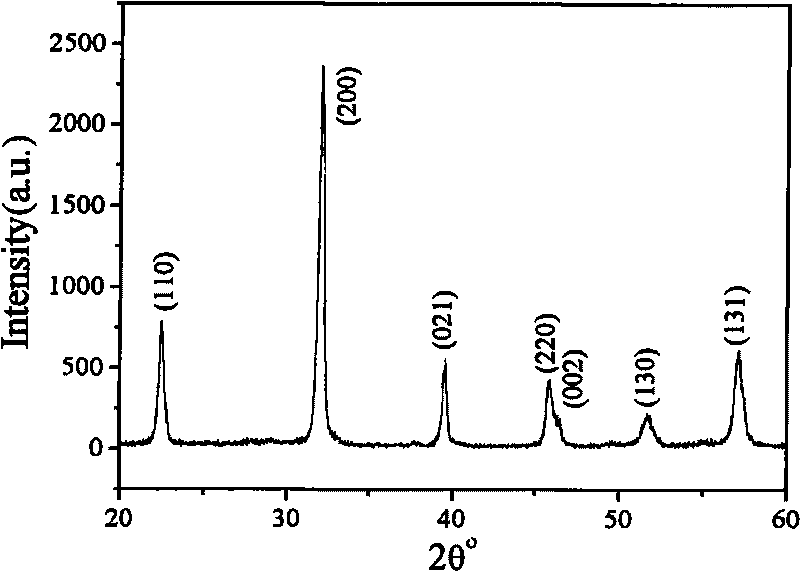

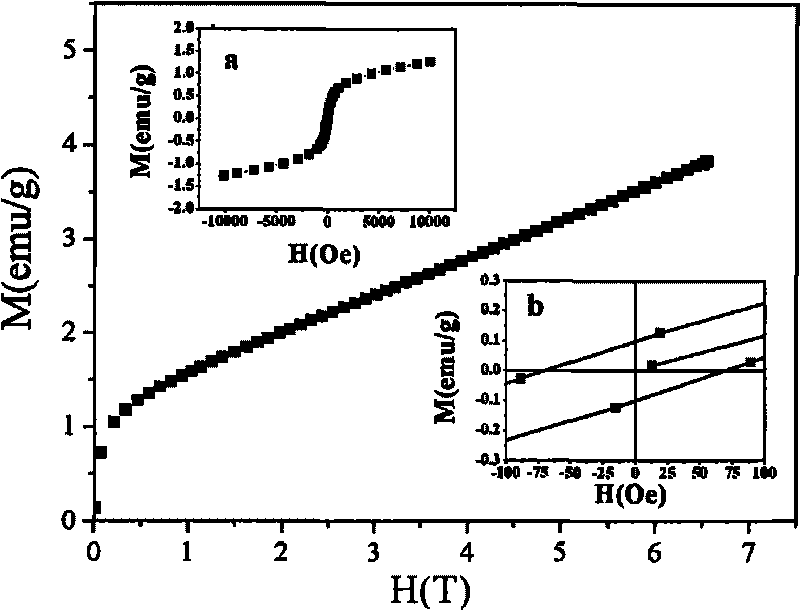

[0039] Weigh a certain stoichiometric ratio of solid Fe(NO 3 ) 3 9H 2 O, Bi(NO 3 ) 3 ·5H 2 O and Dy 2 o 3 ; put Dy first 2 o 3 Dissolve in an appropriate amount of concentrated nitric acid, then add the reaction materials into 48ml of ethylene glycol, and mechanically stir at 80°C for 3 hours to form a wine-red complex solution of metal cations and ethylene glycol. The total molar concentration of metal cations in the solution is 0.4 mol / L, and the molar ratio of Bi:Dy:Fe is 0.8:0.2:1. After cooling at room temperature, pour it into a beaker and let it age for 2 hours, then put the aged solution into 160°C to evaporate and dry for 13 hours to obtain a dry gel, grind it into powder, and put it into a muffle furnace for heat treatment: first, heat it at 400 ℃ for three times, followed by calcination at 600 ℃ for 0.5h to obtain nano powder. The product is 34nm Bi 0.8 Dy 0.2 FeO 3 (A site doping) powder.

Embodiment 2

[0041] Weigh a certain stoichiometric ratio of solid Fe(NO 3 ) 3 9H 2 O, Bi(NO 3 ) 3 ·5H 2 O and Dy 2 o 3 ; put Dy first 2 o 3 Dissolve in an appropriate amount of concentrated nitric acid, then add the reaction materials into 48ml of ethylene glycol, and mechanically stir at 80°C for 3 hours to form a wine-red complex solution of metal cations and ethylene glycol. The total molar concentration of metal cations in the solution is 0.5 mol / L, and the molar ratio of Bi:Dy:Fe is 0.8:0.2:1. After cooling at room temperature, pour it into a beaker and let it age for 2 hours, then put the aged solution into 160°C to evaporate and dry for 13 hours to obtain a dry gel, grind it into powder, and put it into a muffle furnace for heat treatment: first, heat it at 400 ℃ for three times, followed by calcination at 600 ℃ for 0.5h to obtain nano powder. The product is 34nm Bi 0.8 Dy 0.2 FeO 3 (A site doping) powder.

Embodiment 3

[0043] Weigh a certain stoichiometric ratio of solid Fe(NO 3 ) 3 9H 2 O, Bi(NO 3 ) 3 ·5H 2 O and Dy 2 o 3 ; put Dy first 2 o 3 Dissolve in an appropriate amount of concentrated nitric acid, then add the reaction materials into 48ml of ethylene glycol, and mechanically stir at 80°C for 3 hours to form a wine-red complex solution of metal cations and ethylene glycol. The total molar concentration of metal cations in the solution is 0.4 mol / L, and the molar ratio of Bi:Dy:Fe is 0.8:0.2:1. After cooling at room temperature, pour it into a beaker and let it age for 2 hours, then put the aged solution into 160°C to evaporate and dry for 13 hours to obtain a dry gel, grind it into powder, and put it into a muffle furnace for heat treatment: first, heat it at 400 ℃ for three times, followed by calcination at 750 ℃ for 0.5h to obtain nano powder. The product is 75nm Bi 0.8 Dy 0.2 FeO 3 (A site doping) powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com