Method for preparing rare-earth permanent magnets by infiltration process and graphite box utilized in method

A technology of rare earth permanent magnet and infiltration method, which is applied in the field of graphite box, can solve the problems of magnet coercive force drop and damage structure, and achieve the effects of reducing usage, simple process operation and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

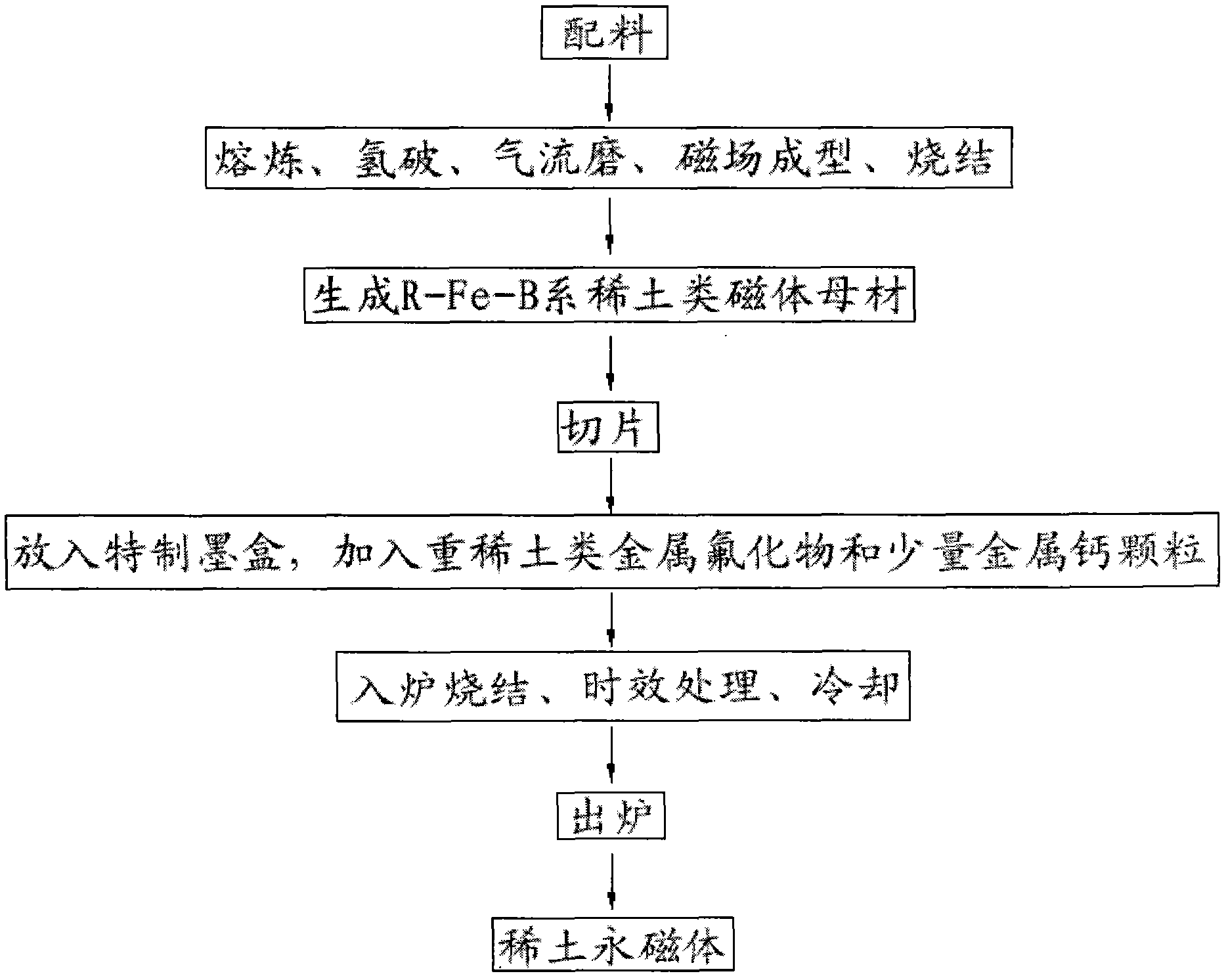

[0029] Produce according to the steps of the example:

[0030] (1) The raw materials of the following atomic percentages: Nd: 13.78%; Al: 0.3%; Nb: 0.2%; B: 5.9% and Fe of the remaining content and impurities introduced by the raw materials are mixed together for batching;

[0031] (2) Put the raw material prepared in step (1) into a vacuum intermediate frequency quick-setting induction furnace, vacuumize to less than 1Pa, fill it with Ar gas protection for heating and melting, and pour the NdFeB alloy liquid into the rotating furnace after refining On the cooling copper roll, the alloy casting sheet with a thickness of 0.25-0.35mm is prepared, and then the hydrogenated NdFeB alloy casting sheet is carried out in the hydrogen crushing furnace, and the hydrogenated alloy casting sheet is ground in the jet mill to have an average particle size of 3.0 -5.0μm material powder, orientated in a magnetic field with a magnetic field strength of 1.8T and pressed to form a green body, th...

Embodiment 2

[0038] Produce according to the steps of the example:

[0039] (1) The production method of the magnet base material (substrate) is as in Example 1. The magnet block material prepared by the above method is cut to make a Nd-Fe-B rare earth magnet with a length of 30 mm, a width of 10 mm, and a thickness of 2 mm;

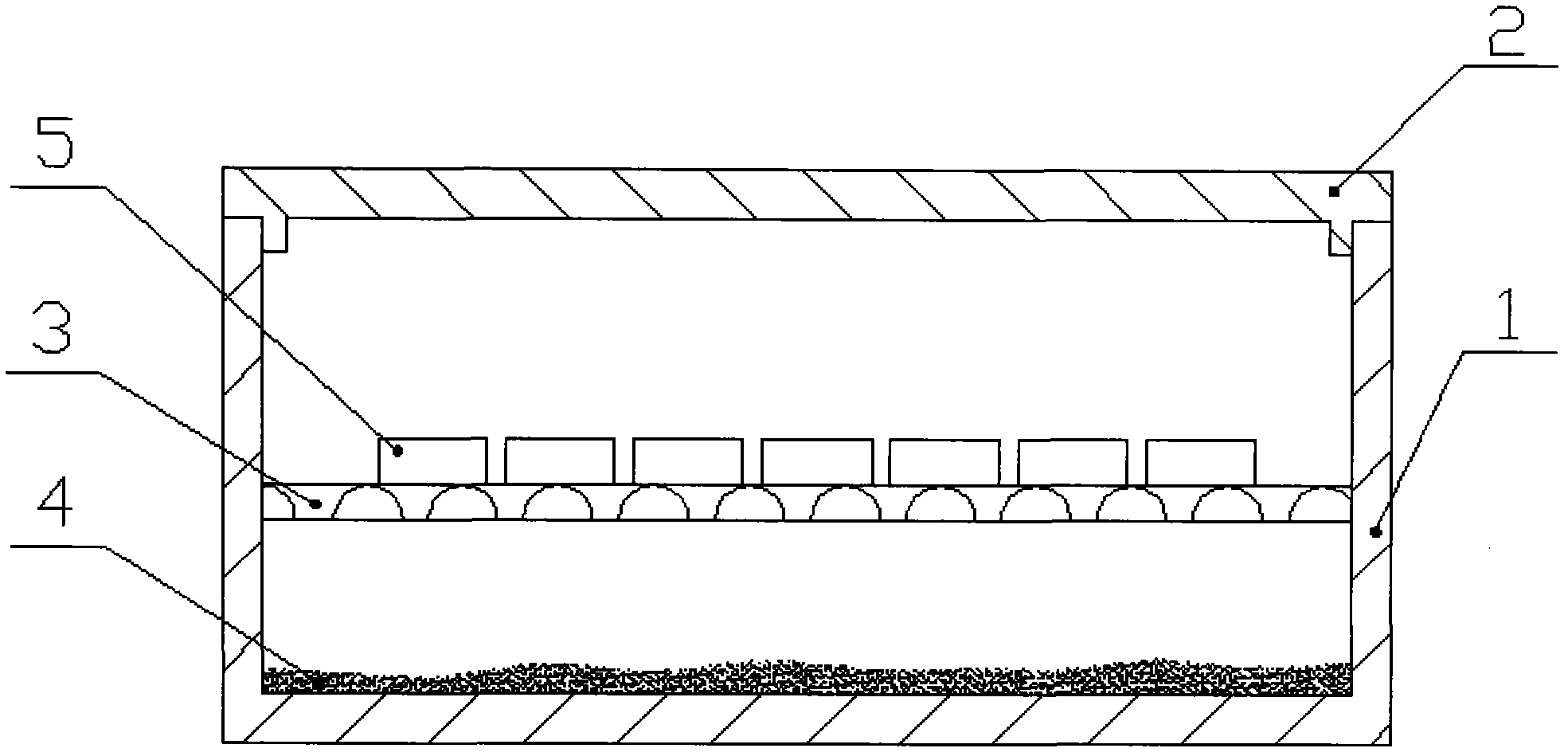

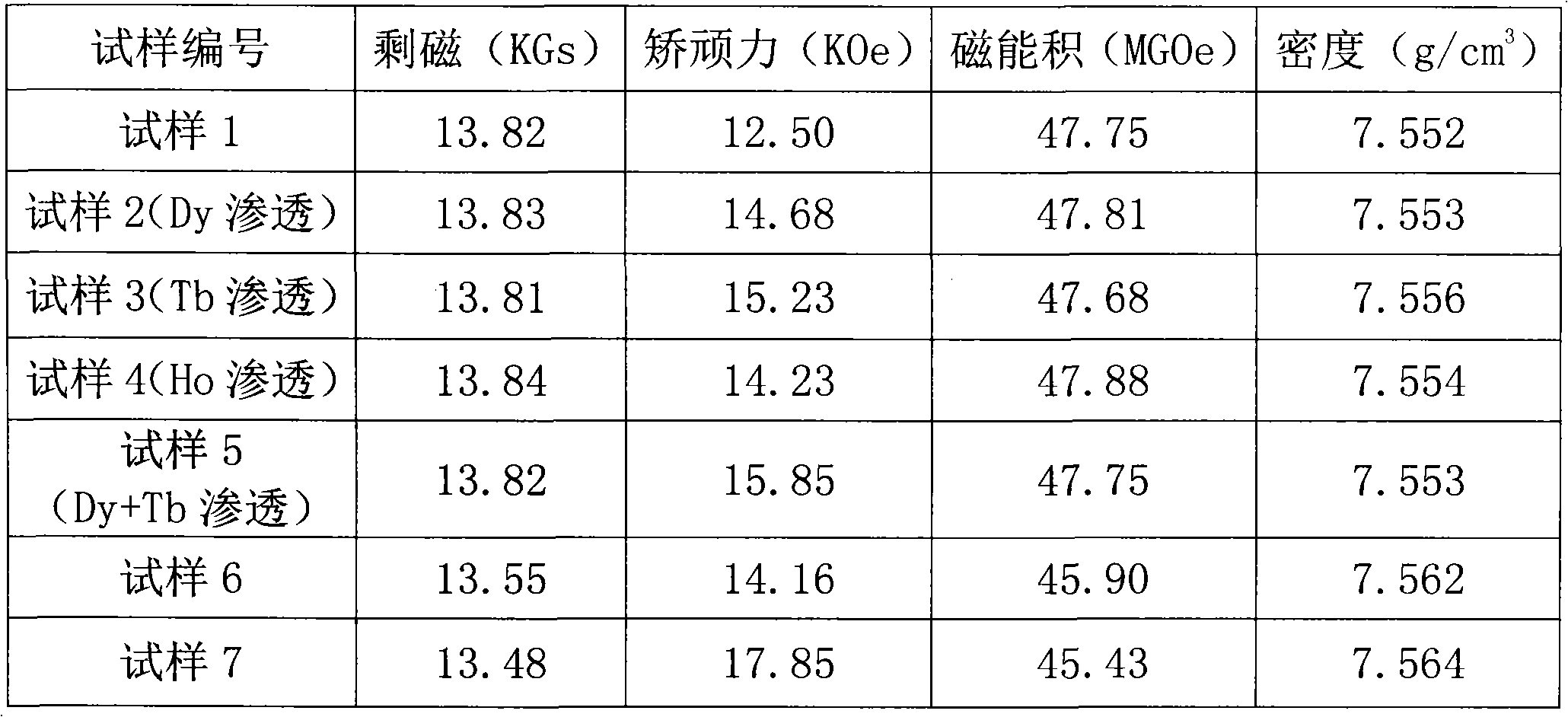

[0040] (2) Put the prepared samples into the attached figure 2 On the bracket 3 with holes in the special graphite box shown, the bottom of the graphite box is placed white powder uranium fluoride (TbF 3 ) and a small amount of metal calcium particles, put the device in a vacuum sintering furnace; vacuumize to less than 5.0×10 -3 At Pa, start heating to 600°C, keep it warm for 1.5 hours, the purpose is to remove the oxide layer on the surface of the magnet; then adjust the temperature to 950°C, fill it with Ar gas at an atmospheric pressure after holding it for 3 hours, cool it to 60°C, and then in high vacuum Aging treatment in the furnace: the aging temperature ...

Embodiment 3

[0043] Produce according to the steps of the example:

[0044] (1) The production method of the magnet base material (substrate) is as in Example 1. The magnet block material prepared by the above method is cut to make a Nd-Fe-B rare earth magnet with a length of 30 mm, a width of 10 mm, and a thickness of 2 mm;

[0045] (2) Put the prepared samples into the attached figure 2 On the special graphite box with hole bracket 3 shown, white powdered holmium fluoride (HoF 3 ) and a small amount of metal calcium particles, put the device in a vacuum sintering furnace; vacuumize to less than 5.0×10 -3 At Pa, start heating to 600°C, keep it warm for 1.5 hours, the purpose is to remove the oxide layer on the surface of the magnet; then adjust the temperature to 950°C, fill it with Ar gas at an atmospheric pressure after holding it for 3 hours, cool it to 60°C, and then in high vacuum Aging treatment in the furnace: the aging temperature is 480°C, after 4.5 hours of heat preservation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com