Comprehensive utilization method for red mud

A technology of red mud and roasting, applied in the direction of process efficiency improvement, sustainable waste treatment, solid waste management, etc., can solve the problem of no patent application, and achieve the effect of promoting development, good environmental protection and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

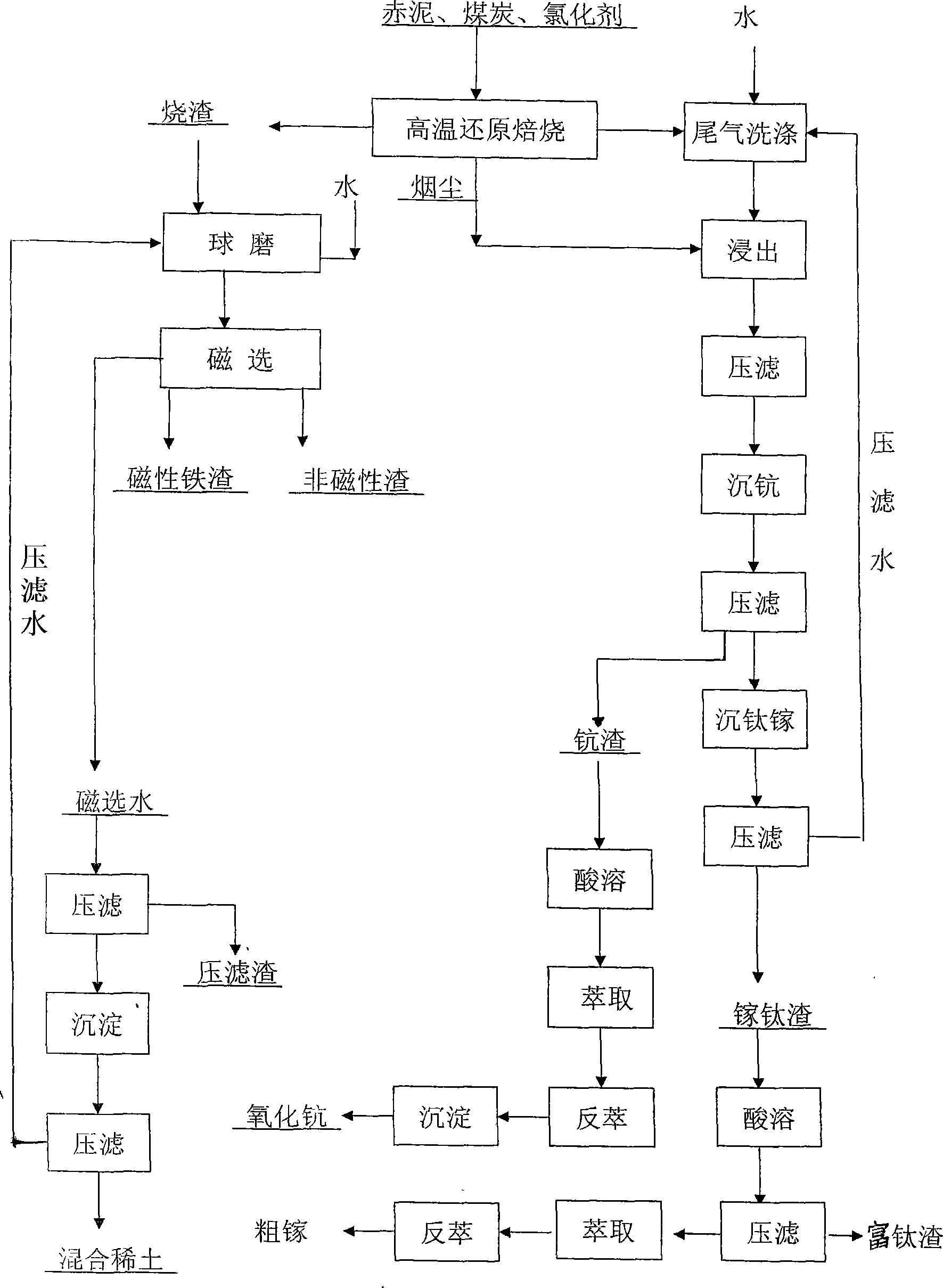

Method used

Image

Examples

Embodiment

[0029] Embodiment: adopt the present invention to carry out comprehensive utilization of red mud

[0030] The first step: chlorination roasting

[0031] The red mud is mixed with coal and calcium chloride and put into a rotary kiln for roasting. During the roasting process, the temperature is kept at 1100°C and the residence time is 3 hours.

[0032] The residue obtained after roasting the red mud is composed of:

[0033] Ingredient Content%

[0034] Fe 2 o 3 21.89

[0035] al 2 o 3 20.40

[0036] SiO 2 27.43

[0037] TiO 2 0.96

[0038] CaO 15.24

[0039] MgO 2.68

[0040] Cl - 0.017

[0041] K 2 O 0.62

[0042] Na 2 O 1.47

[0043] Sc 0.004

[0044] Ga 0.002

[0045] RE 2 o 3 0.35

[0046] Loss on ignition 2.04

[0047] The tail gas is washed by circulating water to absorb ScCl 3 , GaCl 3 and TiCl 4 Wait;

[0048] The second step of cinder d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com