Paint dipping method for bonding amorphous C type magnetic core by pure resin and special equipment

A kind of special equipment, epoxy resin paint technology, applied in the direction of surface coating liquid device, inductor/transformer/magnet manufacturing, electrical components, etc., to reduce damage and reduce shrinkage stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

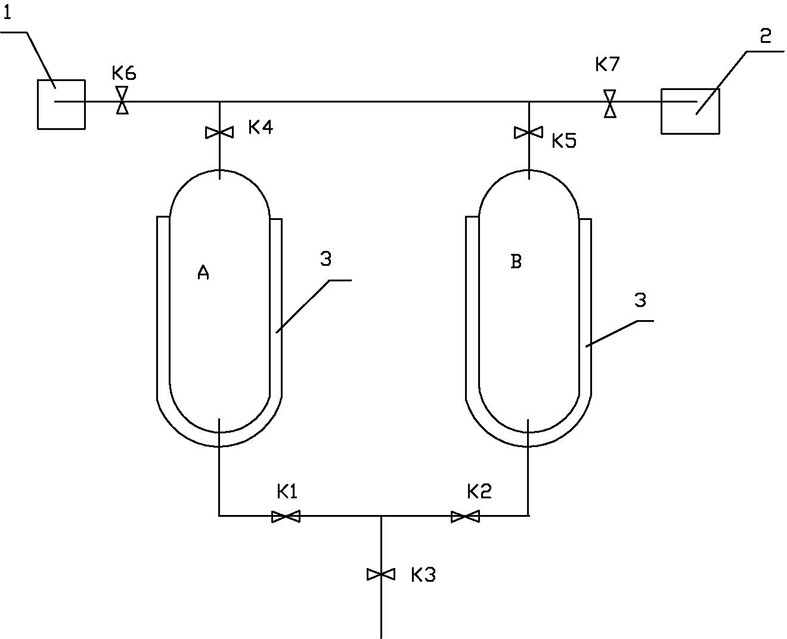

[0022] Such as figure 1 , figure 2 As shown, the special equipment for dipping paint of the present invention includes two sealable containers with lids provided with a heating device. In this embodiment, two sealable containers with lids (tank A, tank B) are arranged in a heatable water tank , Two sealable containers with lids (A tank, B tank) are connected with pipelines, and valves are installed on the pipelines, and two sealable containers with lids (A tank, B tank) are also connected with vacuum and pressurization pipelines .

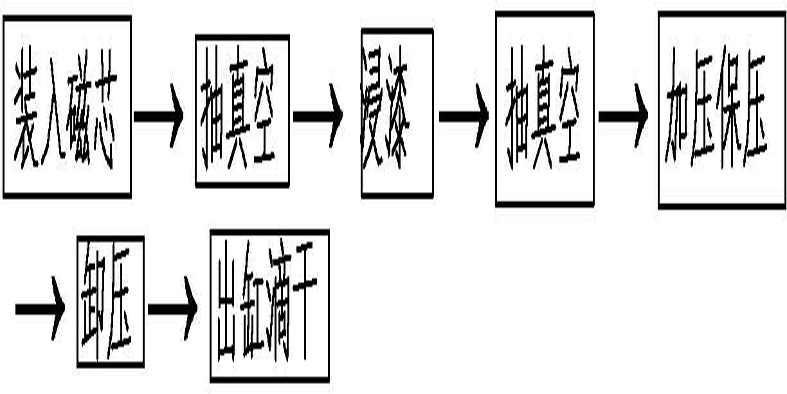

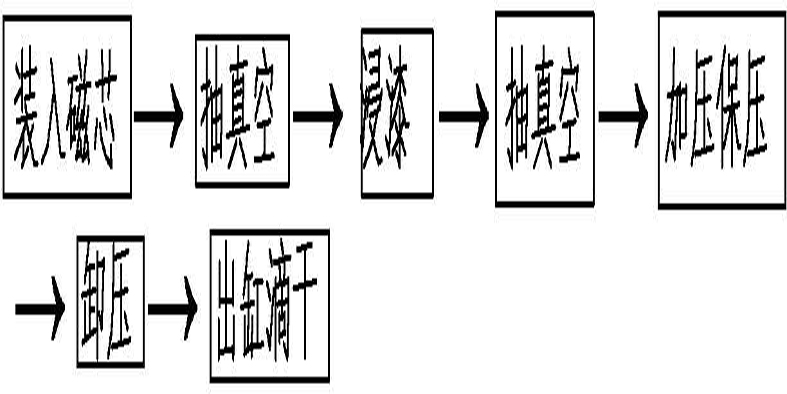

[0023] The inventive method comprises following processing steps:

[0024] a: prepare first figure 2 For the equipment shown, check whether the air compressor, vacuum pump, hot water device, solenoid valve, and instrument are working normally, and close the K1 and K3 valves.

[0025] b: Heat the hot water tank to the water bath.

[0026] c: Open the cover of oil tank A, add 180Kg and epoxy resin to tank A, and cover the cover of tank A.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com