Hard connection implementation method of optical module and optical module

An implementation method and hard connection technology, applied in the field of optical communication, can solve problems such as large insertion loss of optical signals, large signal attenuation of optical modules, unqualified module indicators, etc., and achieve the goal of reducing high-frequency loss, avoiding defects, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

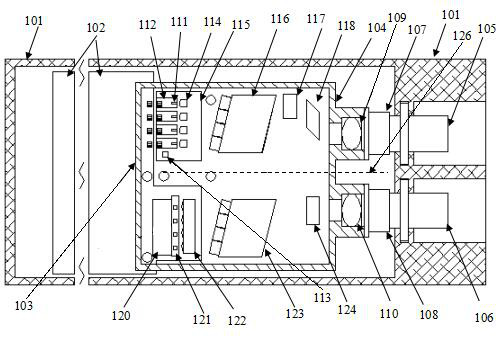

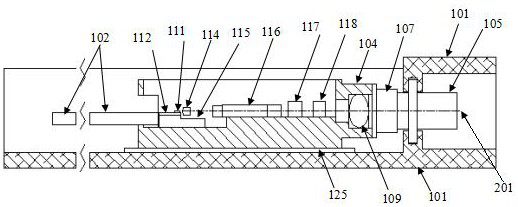

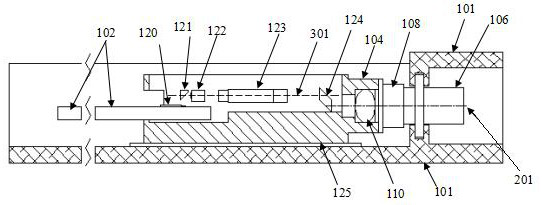

[0079] see Figure 1 to Figure 4 An embodiment of the present invention provides an optical module, including a module case 101, a PCBA 102, and an optical device 103. The optical device 103 includes a device case 104, a transmitting optical interface 105, a receiving optical interface 106, an adjustable sliding ring 107 at the transmitting end, Adjustable sliding ring 108 at the receiving end, optical port lens 109 at the transmitting end, optical port lens 110 at the receiving end, laser chipset 111, ceramic carrier group 112, thermistor 113, collimating lens group 114, TEC115, wavelength division multiplexing components 116 , an isolator 117 , a transmitter prism 118 , a detector chipset 119 , a TIA chip 120 , a triangular reflection prism 121 , an array lens 122 , a wave division multiplexing component 123 and a receiver prism 124 .

[0080] Among them, the transmitting optical interface 105, the adjustable sliding ring 107 at the transmitting end, the optical port lens 10...

Embodiment 2

[0090] see Figure 5 to Figure 11 , the embodiment of the present invention discloses a hard connection implementation method of an optical module, comprising the following steps:

[0091] Step 1: fixing part of the transmitting-end optical element and part of the receiving-end optical element inside the device case to form a first assembly. Such as Figure 5 , Figure 6 As shown, in this step, passive optics such as the optical port lens 109 at the transmitting end, the optical port lens 110 at the receiving end, the wavelength division multiplexing component 116 and the prism 118 at the transmitting end are bonded inside the device casing 104 . The order of bonding is not limited.

[0092] It should be noted here that three circular holes 501 , 502 , and 503 are processed in the device case 104 , and the contours of the circular holes are used as marks. The positions of the circular holes 501, 502, and 503 are strongly related to the mounting positions of the optical win...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com