NiCuZn ferrite material and manufacturing method thereof

A technology of ferrite materials and main components, applied in NiCuZn series ferrite materials with high magnetic permeability and low loss and its manufacturing field, can solve the problem of large material loss, unfavorable use of NFC antenna modules, small, thin and Lighten the problems of development and achieve the effect of high magnetic permeability and small magnetic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

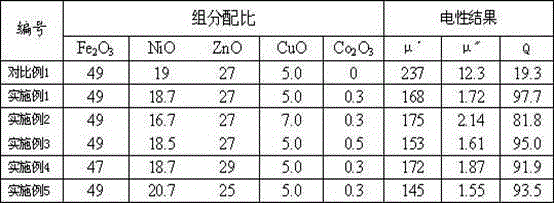

[0022] Embodiment 1-5, see table 1:

[0023] Using the sol-gel method, the raw material H 3 BO 3 , Bi(NO 3 ) 3 ·5H 2 O, Si(OC 2 h 5 ) 4 , Zn(CH 3 COO) 2 follow B 2 o 3 : Bi 2 o 3 :SiO2:ZnO molar ratio of 27:35:6:32 Synthetic glass powder A (BBSZ).

[0024] Take by weighing the initial raw material Fe according to the mole percentage of each component in Table 1 2 o 3 , ZnO, CuO, NiO and Co 2 o 3 , placed in a vibrating mill for dry mixing and vibrating for 1 hour.

[0025] The mixed dry powder is pre-fired in a sintering furnace at 900°C for 2 hours to obtain a preliminary reacted pre-fired powder.

[0026] Add 0.5wt% powder A and 0.2wt% SnO to the pre-fired powder 2 , and 0.2wt% Ta 2 o 5 , and mix and grind the mixture with deionized water until the average particle size of the powder is 1.0um, sieve after drying, and then add PVA solution to granulate.

[0027] Put the granulated powder in a designated mold, and press it into a magnetic ring under a pre...

Embodiment 6-12

[0034] Embodiment 6-12, see table 2:

[0035] Using the sol-gel method, the raw material H 3 BO 3 , Bi(NO 3 ) 3 ·5H 2 O, Si(OC 2 h 5 ) 4 , Zn(CH 3 COO) 2 follow B 2 o 3 : Bi 2 o 3 : SiO 2 : ZnO molar ratio of 18:30:12:40 synthetic glass powder A (BBSZ).

[0036] Weigh the initial raw material Fe by mole percentage 2 o 3 : 49.0mol%, ZnO: 27.0mol%, CuO: 5.0mol%, NiO: 18.7mol% and Co 2 o 3 : 0.3mol%, put into a vibration mill for dry mixing and vibration grinding for 1h.

[0037]The mixed dry powder is pre-fired in a sintering furnace at 900°C for 2 hours to obtain a preliminary reacted pre-fired powder.

[0038] Add different amounts of glass powder A and powder B to the pre-fired powder, see Table 2, where B is Ta 2 o 5 , SiO 2 , SnO 2 One or two of them, and then mix and grind the mixture with deionized water until the average particle size of the powder is 1.0um, sieve after drying, and then add PVA solution to granulate.

[0039] Put the granulated po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com