Water cooling soft magnet composite material disk type motor

A technology of soft magnetic composite materials and disc motors, which is applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve problems such as long processing cycle, large motor air gap, and large magnetic field leakage, and achieve Good cooling effect, good magnetic conductivity, and low high-frequency loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the present invention, the specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

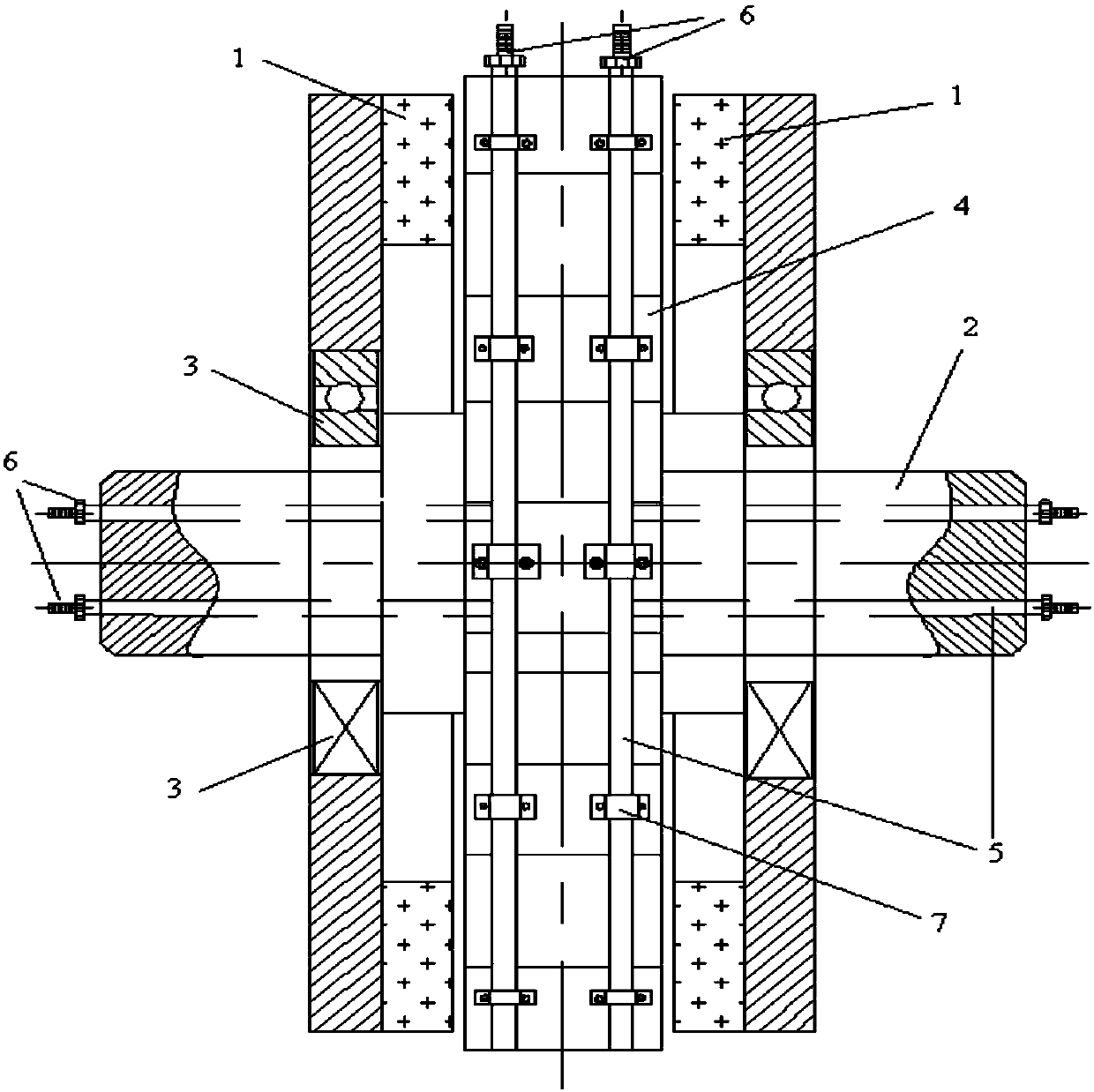

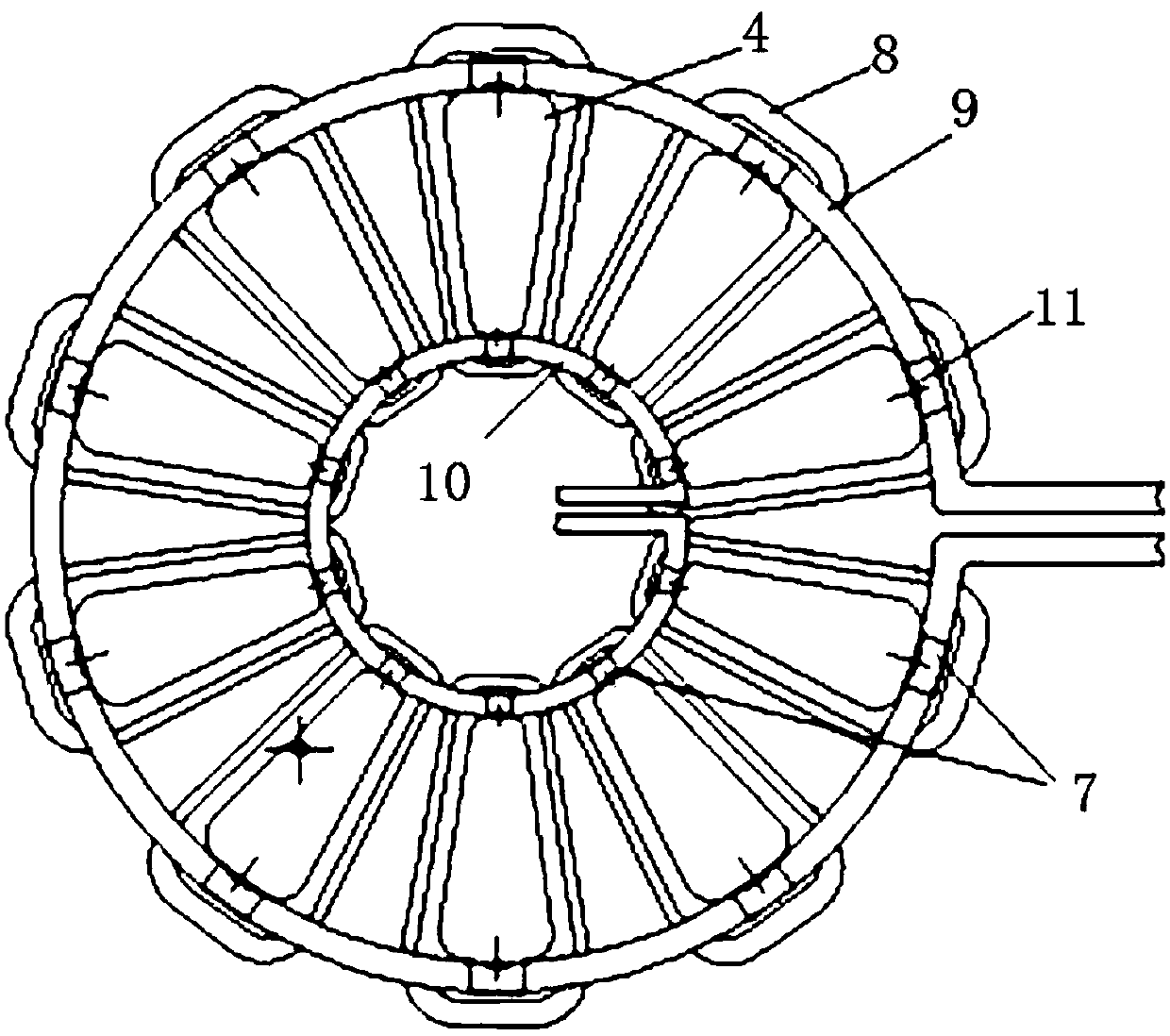

[0021] combined with figure 1 It is a structural schematic diagram of the water-cooled soft magnetic composite disc motor of the present invention, and the water-cooled soft magnetic composite disc motor includes a rotor 1, a fixed shaft 2, a bearing 3, a stator core module 4, a fixed ring 5, a stator, and a cooling nozzle 6 and a fixed clip 7; the stator of the motor of the present invention includes a stator core module 4, a coil winding 8, a fixed ring 5, a cooling nozzle 6 and a fixed clip 7; the stator core module 4 is formed by die-casting a soft magnetic composite material, Its appearance is characterized by a cylindrical module with a trapezoidal cross section, the four corners of the cylindrical body are rounded, and the coil winding 8 is directly wound on the stator core module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com