Wireless charging transceiver module preparation technology and wireless charging transceiver module

A technology of wireless charging and preparation process, applied in the direction of inductor/transformer/magnet manufacturing, circuits, electrical components, etc., can solve the problems of low charging efficiency, inability to achieve the ultimate power transmission efficiency, inability to meet application requirements, etc., to avoid excessive charging. The effect of multiple magnetic flux leakage, improving charging efficiency, and improving charging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

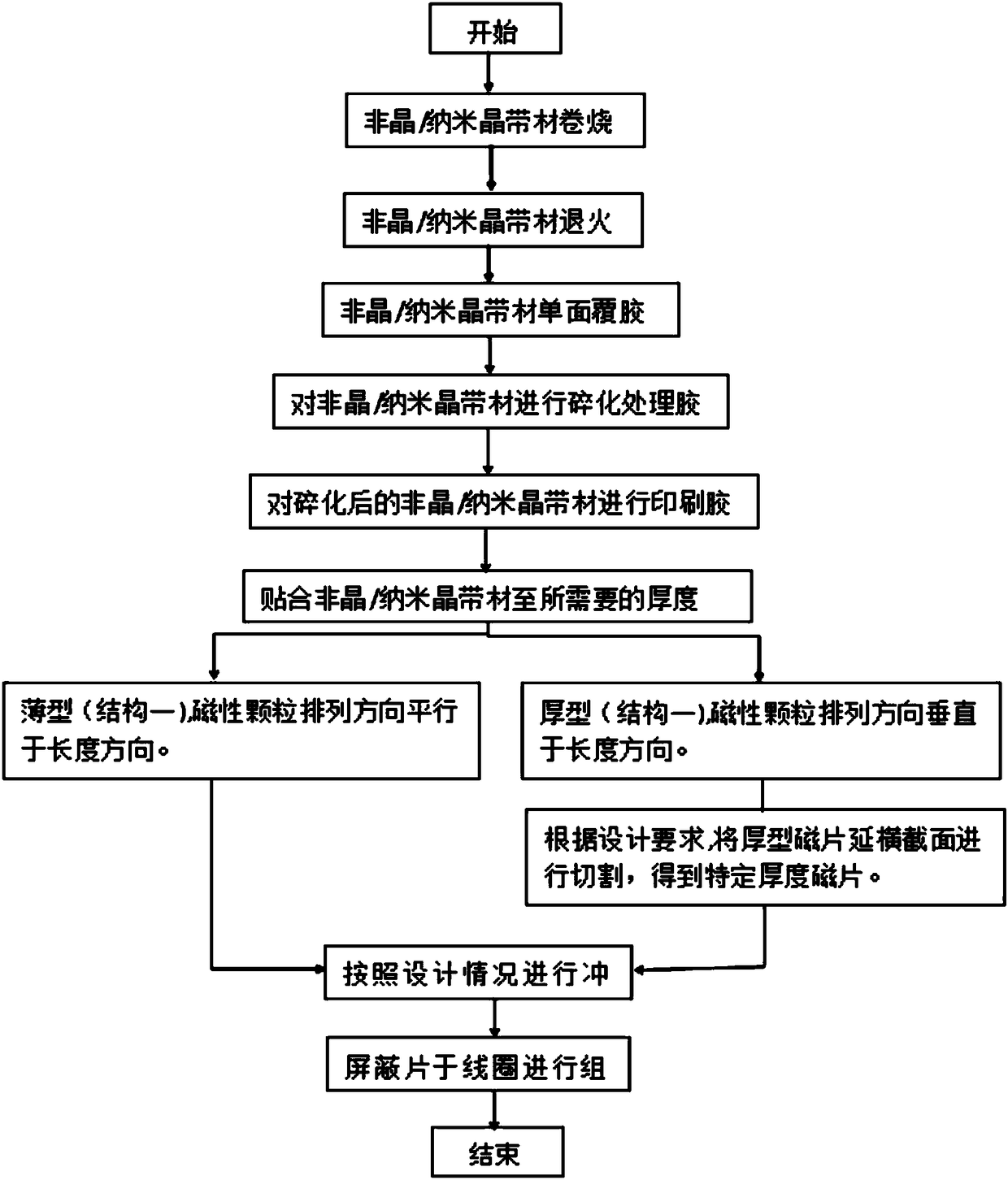

[0025] The invention discloses a preparation process of a wireless charging transceiver module, please refer to figure 1 , which includes the following steps:

[0026] Step S1, preparation of electromagnetic wave shielding sheet materials: preparing high magnetic permeability alloy strips;

[0027] Step S2, heat treatment: winding the high magnetic conductivity alloy strip to a preset size, and then putting the wound high magnetic conductivity alloy strip into a heat treatment furnace for heat treatment;

[0028] Step S3, applying single-sided adhesive: using a laminating machine to apply adhesive to one side of the heat-treated magnetically permeable alloy strip, and attaching a protective film with single-sided adhesive to the surface of the highly magnetically permeable alloy strip;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com