Simultaneous induction heating and quenching process for four planes of a commercial vehicle brake caliper bracket

A technology of a brake caliper bracket and a process method, which is applied to the four-plane simultaneous induction heating and quenching process of a commercial vehicle brake caliper bracket, can solve the problems of uneven distribution of surface hardness and depth of hardened layer, poor uniformity of heating temperature distribution, etc. Avoid quality fluctuations, work stability and service life guarantee, prolong the effect of aging cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

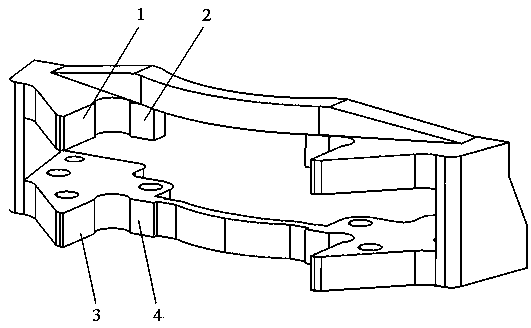

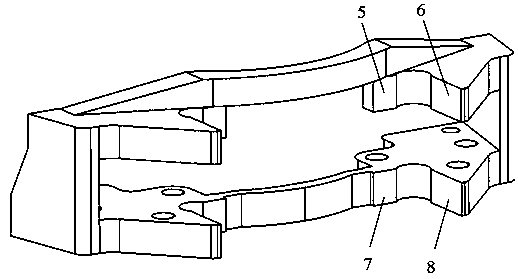

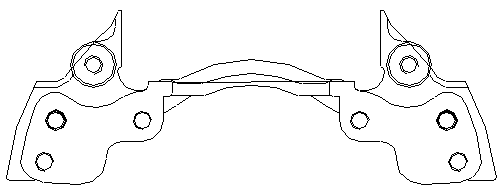

[0037] Below in conjunction with accompanying drawing, the present invention is described in detail: as Figure 1-7As shown, a commercial vehicle brake caliper bracket four-plane simultaneous induction heating and quenching process is characterized in that four adjacent limiting surfaces on one side of the brake caliper bracket are simultaneously heated and quenched, and each limiting surface is effectively heated. U-shaped structure is adopted, and the currents in the U-shaped double heating wires are equal in size and opposite in direction; one end of the brake caliper bracket is adjacent to four limit surfaces 1, 2, 3, 4 as a group, and the other end is adjacent to four limit surfaces 5, 6, 7, and 8 are a group, and the four U-shaped heating wires corresponding to the four adjacent limit surfaces of each group are welded in series as a whole to form a four-plane simultaneous heating sensor structure; two sets of four Plane simultaneous quenching sensor;

[0038] The quench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com