Heat-phonomotor driven by heat transfer through heat pipe

A thermoacoustic engine and heat pipe technology, applied in the direction of machines/engines, mechanisms that generate mechanical power, and mechanical equipment, can solve the problems of difficult heating power, pollution, noise, etc. The effect of expanding the application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

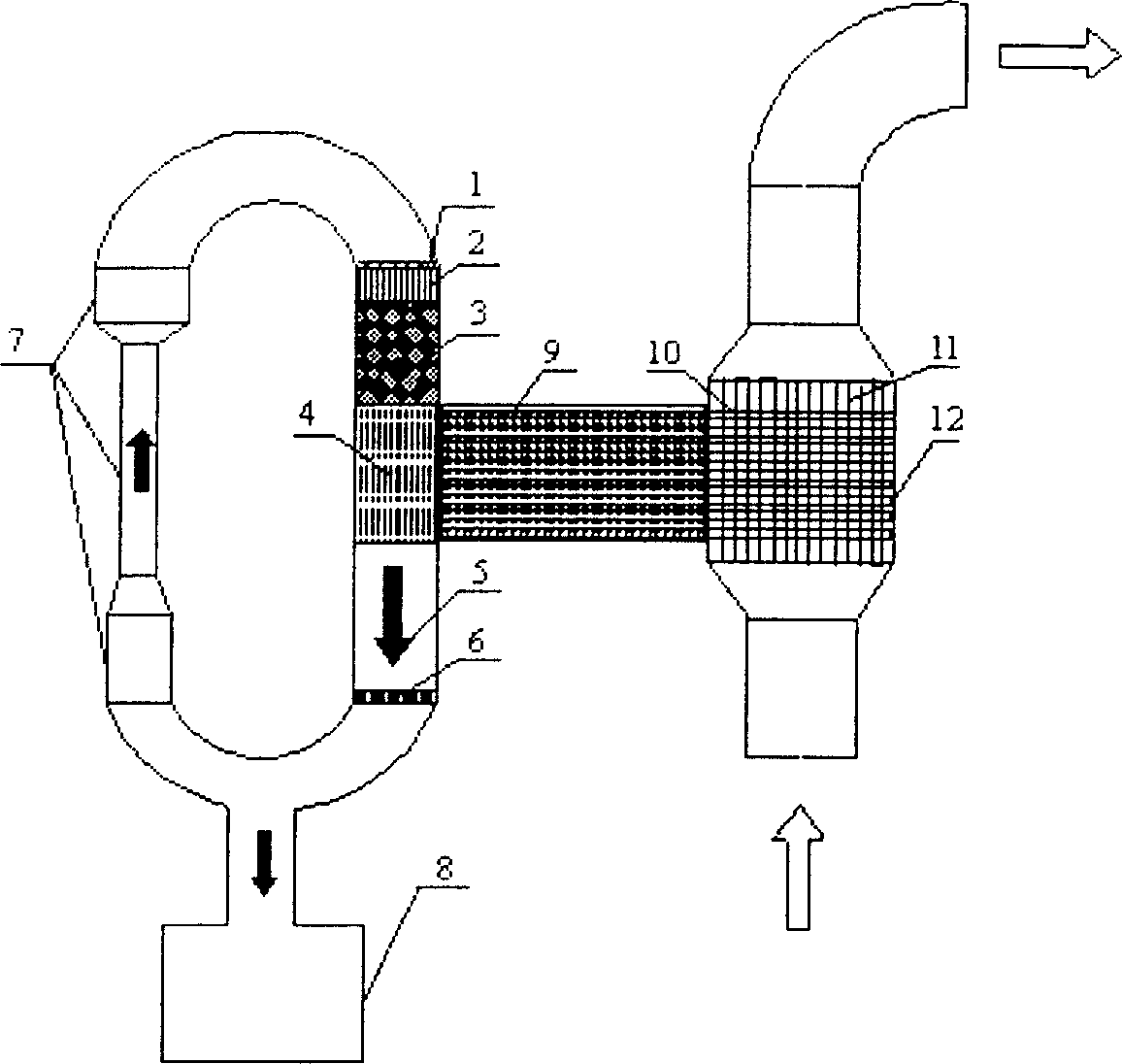

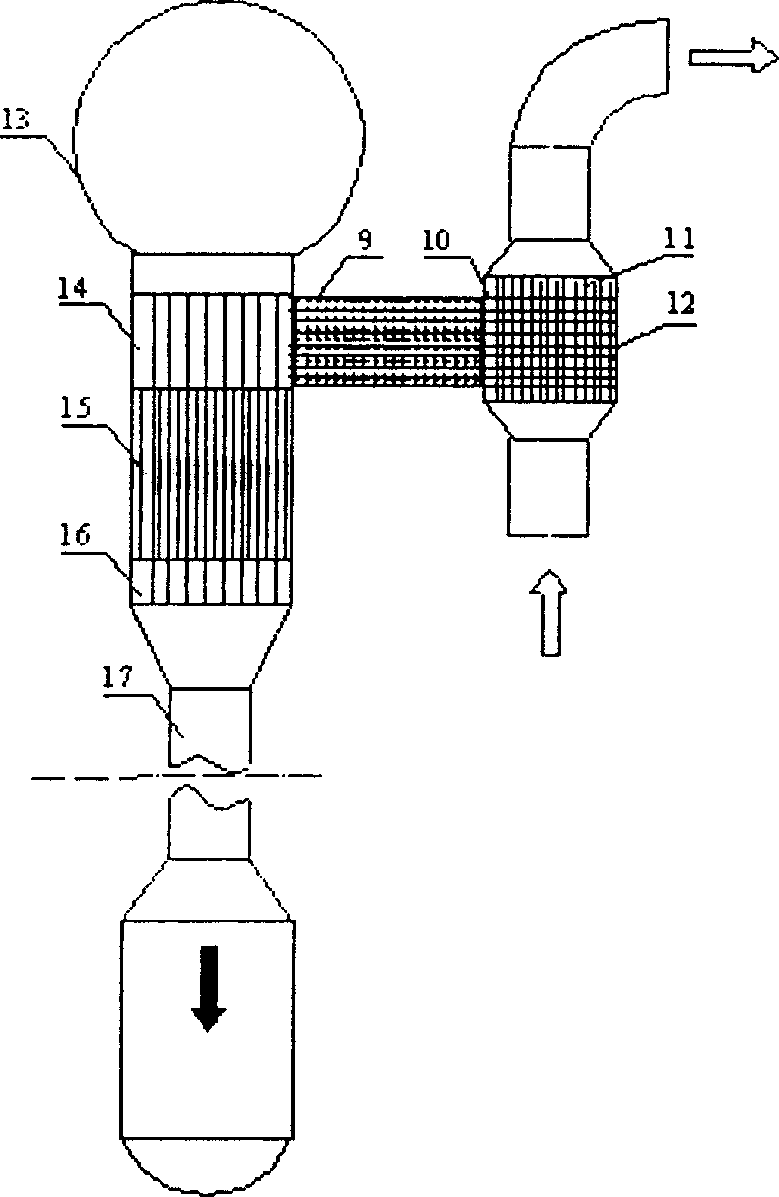

[0018] In fact, whether it is a traveling wave thermoacoustic engine or a standing wave thermoacoustic engine, heat pipe heating and driving technology can be used. In this patent, the traveling wave thermoacoustic engine and the standing wave thermoacoustic engine are used as examples for illustration.

[0019] like figure 1As shown, a thermoacoustic engine driven by heat pipe heat transfer has a traveling wave loop and a resonant branch 8. The traveling wave loop has a DC controller 1, a main cooler 2, a regenerator 3, and a heater connected in sequence. 4. Thermal buffer pipe 5 , sub cooler 6 , feedback loop 7 , the heater 4 of the thermoacoustic engine is connected to the heat exchanger 12 through the heat pipe 10 . The heat exchanger 12 is a shell-and-tube heat exchanger, and the shell side is filled with high-temperature flue gas or industrial steam.

[0020] The heat pipe heating device of the thermoacoustic engine includes the insulation layer 9 of the heat insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com