Horizontal rotating construction method for steel truss beam bridge

A construction method and steel truss technology, applied in truss bridges, erection/assembly bridges, bridges, etc., can solve the problem of limited bridge type promotion, large transverse spans of highway bridges, and difficult treatment of orthotropic plate steel bridge deck pavement, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0092] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

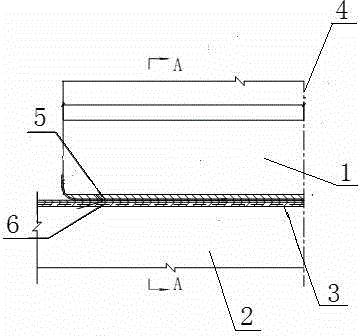

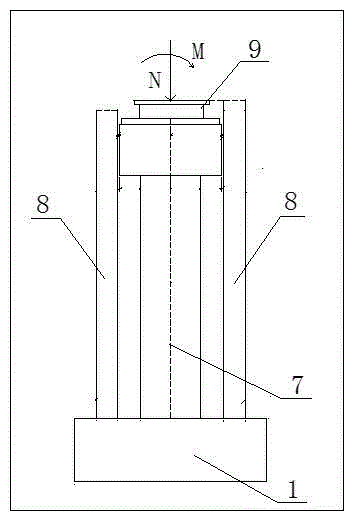

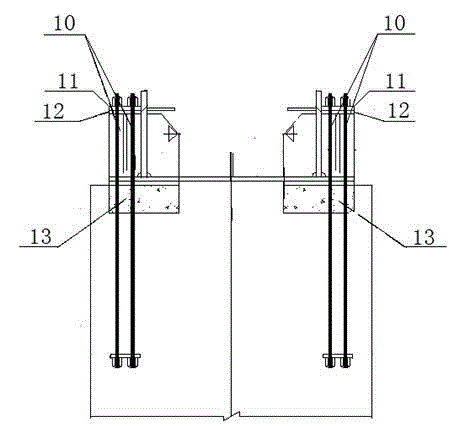

[0093] 1. Process principle

[0094] The fixed lower turntable support system consists of the main pier pile foundation, the lower cap (the main pier cap is divided into upper and lower parts), the slideway pile foundation and the slideway cap, the slideway and the lower spherical hinge of the rotating spherical hinge. The upper cap of the pier, the main pier, the cover beam, the permanent support, the steel beam (upper structure), the upper spherical hinge of the rotating spherical hinge and the legs of the upper cap slideway constitute a stable structure that can rotate around the lower spherical hinge. The upper turntable system that slides on the slide is temporarily locked and consolidated by the pier beam, so that when the upper cap, the main pier, and the cover beam rotate, it can drive the upper structure to rotate synchronously without relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com