PCB (Printed Circuit Board) component and light emitting component

A technology of light emitting components and PCB boards, applied in the field of communication, can solve the problems of high gold wire arch, large high frequency loss, poor transmission characteristics, etc., and achieve small gold wire arch height, low high frequency loss, and good transmission characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

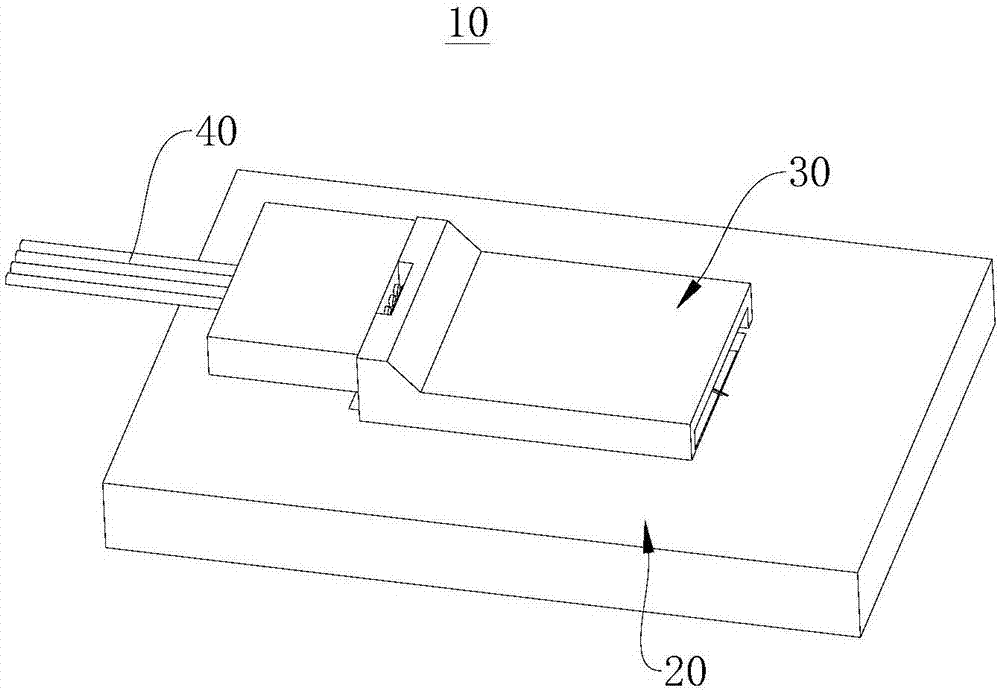

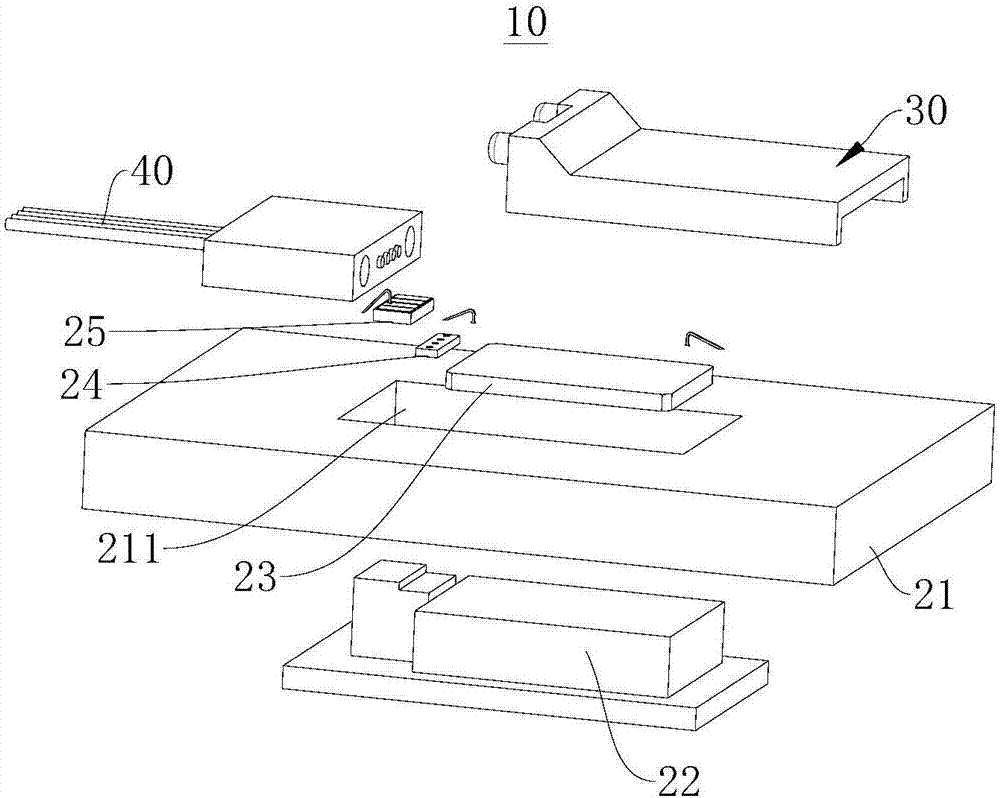

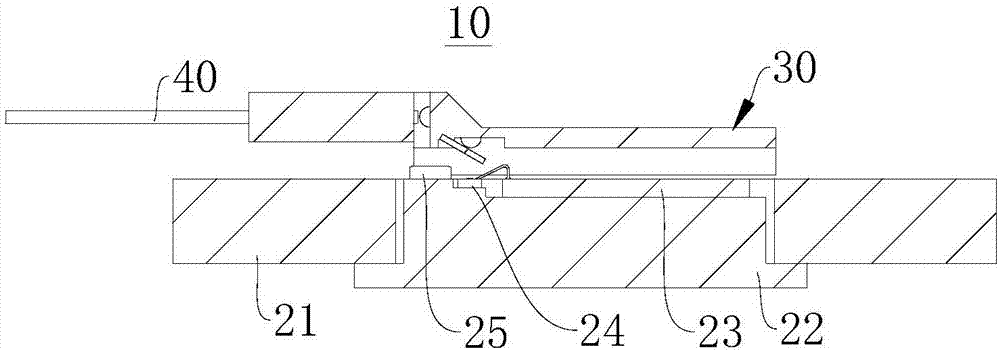

[0033] see Figure 1 to Figure 3 , the present embodiment provides a light emitting assembly 10, the light emitting assembly 10 includes a lens assembly 30 and a PCB board assembly 20, the PCB board assembly 20 includes a PCB substrate 21, a step gasket 22, a driver chip 23, a laser chip 24 and a monitoring The chip 25 and the PCB substrate 21 are provided with a mounting hole 211 , the mounting hole 211 is a through hole, and the step gasket 22 is assembled in the mounting hole 211 . The step spacer 22 includes a top surface constituting a mounting surface. The driver chip 23, the laser chip 24 and the monitoring chip 25 are all mounted on the mounting surface. The lens assembly 30 is arranged on the PCB board assembly 20, and the optical fiber 40 is connected to the lens assembly 30. The lens assembly 30 is used to divide the light emitted by the laser chip 24 into two paths of light directed to the monitoring chip 25 and the optical fiber 40 respectively.

[0034] The mon...

no. 2 example

[0059] This embodiment provides a light emitting assembly 10, which is similar in structure to the light emitting assembly 10 in the first embodiment, except that the structure of the PCB board assembly 20 is different.

[0060] see Figure 9 , in the PCB board assembly 20 provided by this embodiment, the mounting surface of the step gasket 22 only includes the first surface 221 and the second surface 222, the laser chip 24 is located on the first surface 221 of the step gasket 22, and the driver chip 23 is located on the first surface 221 of the step gasket 22. The second surface 222 of the step washer 22 . The height of the first surface 221 is higher than that of the second surface 222 , so that the height difference between the top surface of the driver chip 23 and the top surface of the laser chip 24 and the top surface of the PCB substrate 21 is smaller than the thickness of the driver chip 23 .

[0061] The monitoring chip 25 is mounted on the surface of the PCB substr...

no. 3 example

[0064] This embodiment provides a light emitting assembly 10, which is similar in structure to the light emitting assembly 10 in the first embodiment, except that the structure of the PCB board assembly 20 is different.

[0065] see Figure 10 , in the PCB assembly 20 provided in this embodiment, the mounting hole 211 is a blind hole, and the bottom of the mounting hole 211 is a mounting surface. The installation surface only includes the first surface 221 and the second surface 222 , the laser chip 24 is located on the first surface 221 of the stepped spacer 22 , and the driver chip 23 is located on the second surface 222 of the stepped spacer 22 . The height of the first surface 221 is higher than that of the second surface 222 , so that the height difference between the top surface of the driver chip 23 and the top surface of the laser chip 24 and the top surface of the PCB substrate 21 is smaller than the thickness of the driver chip 23 .

[0066] The monitoring chip 25 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com