Wire coil for electromagnetic rice cooker and coiling method

A rice cooker and electromagnetic technology, applied in applications, coil devices, household appliances, etc., can solve problems such as coil inter-turn short circuit, coil disk damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

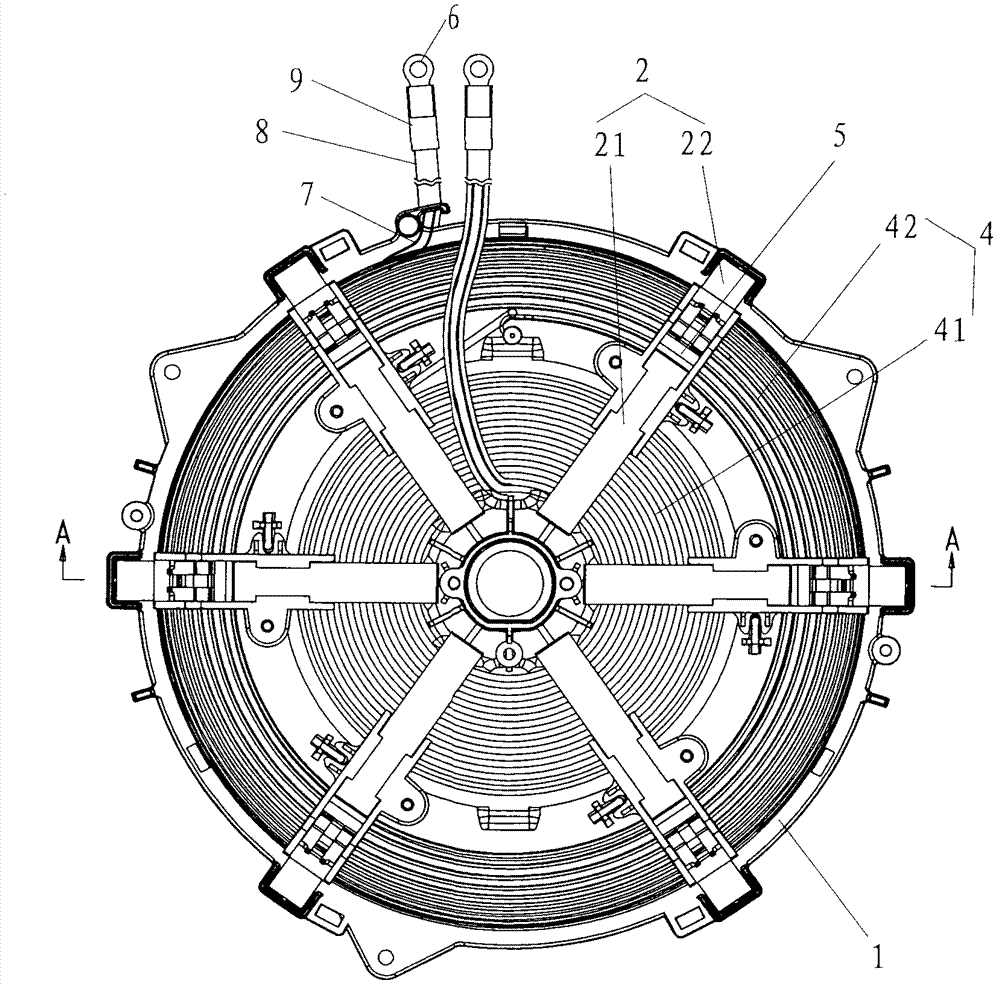

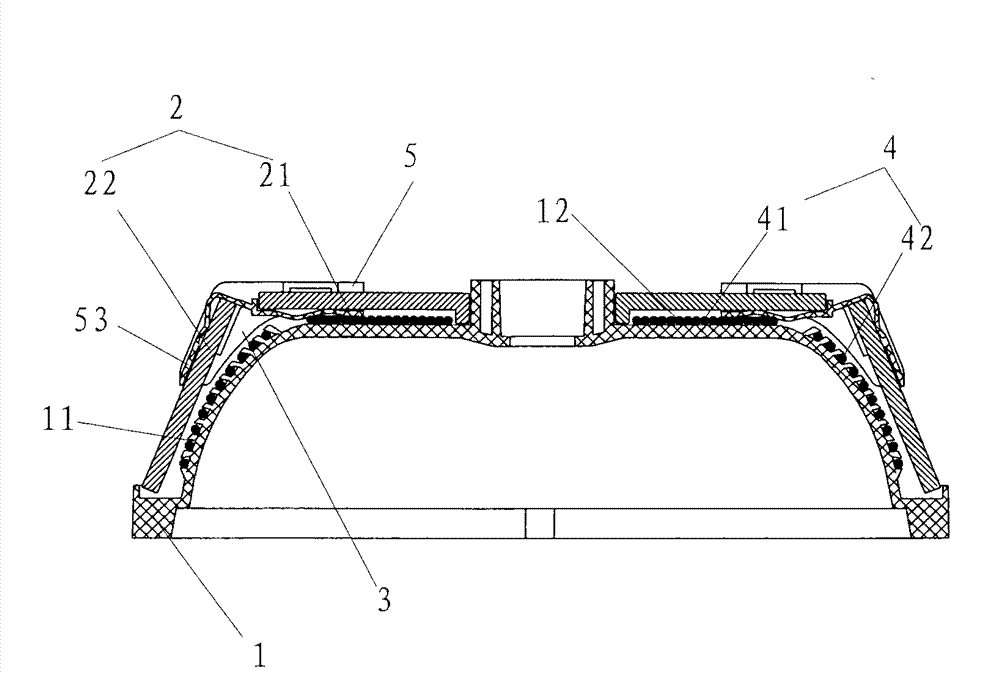

[0040] The invention discloses a coil winding method for an electromagnetic rice cooker. The coil of the electromagnetic rice cooker includes a bracket, a magnetic strip and a stranded wire, and comprises the following steps:

[0041] (1) Divide the twisted wire into two parts;

[0042] (2) wherein a part of the twisted wires are wound on the outer surface of the support;

[0043] (3) winding another part of the stranded wire on the bottom plane of the support;

[0044] (4) Install the magnetic strip on the support.

[0045] In the above step (2) or (3), the gap between the stranded coils formed by the stranded wires is 1-5mm.

[0046] When in use, since the twisted wires are separated from each other, there is a gap between each turn of the twisted wires. In this way, compared with the current one, its advantages lie in:

[0047] 1) Increase the insulation distance between each turn to reduce the probability of inter-turn short circuit under instantaneous overvoltage and o...

Embodiment 2

[0052] Compared with Embodiment 1, the difference lies in that in step (2), some of the above-mentioned stranded wires are shaped on the support in a sparsely wound manner.

Embodiment 3

[0054] Compared with its embodiment two, the difference is:

[0055] In step (3), the other part of the stranded wires is wound on the bottom plane of the support in a spaced winding manner.

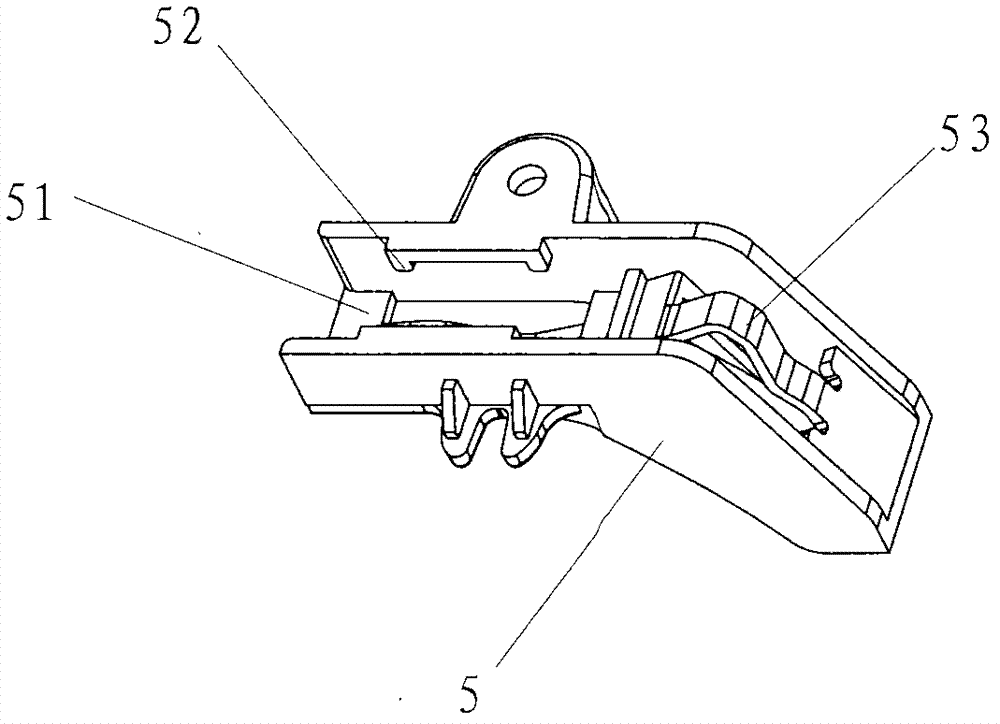

[0056] In addition, in this embodiment, the outer surface of the above-mentioned bracket is provided with a wire-holding groove, and the wire-holding groove is rotatably arranged on the outer surface of the bracket, and the twisted wire is wound in the wire-holding groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com