Fluctuant waveguide slow wave structure

A slow-wave structure, undulating technology, applied in the field of vacuum electronics, can solve the problems of difficult design of input and output structure of rectangular grid waveguide, high development cost of terahertz power source, and difficult processing of electronic injection channels, and achieves low processing difficulty and reflection. Small, low frequency loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

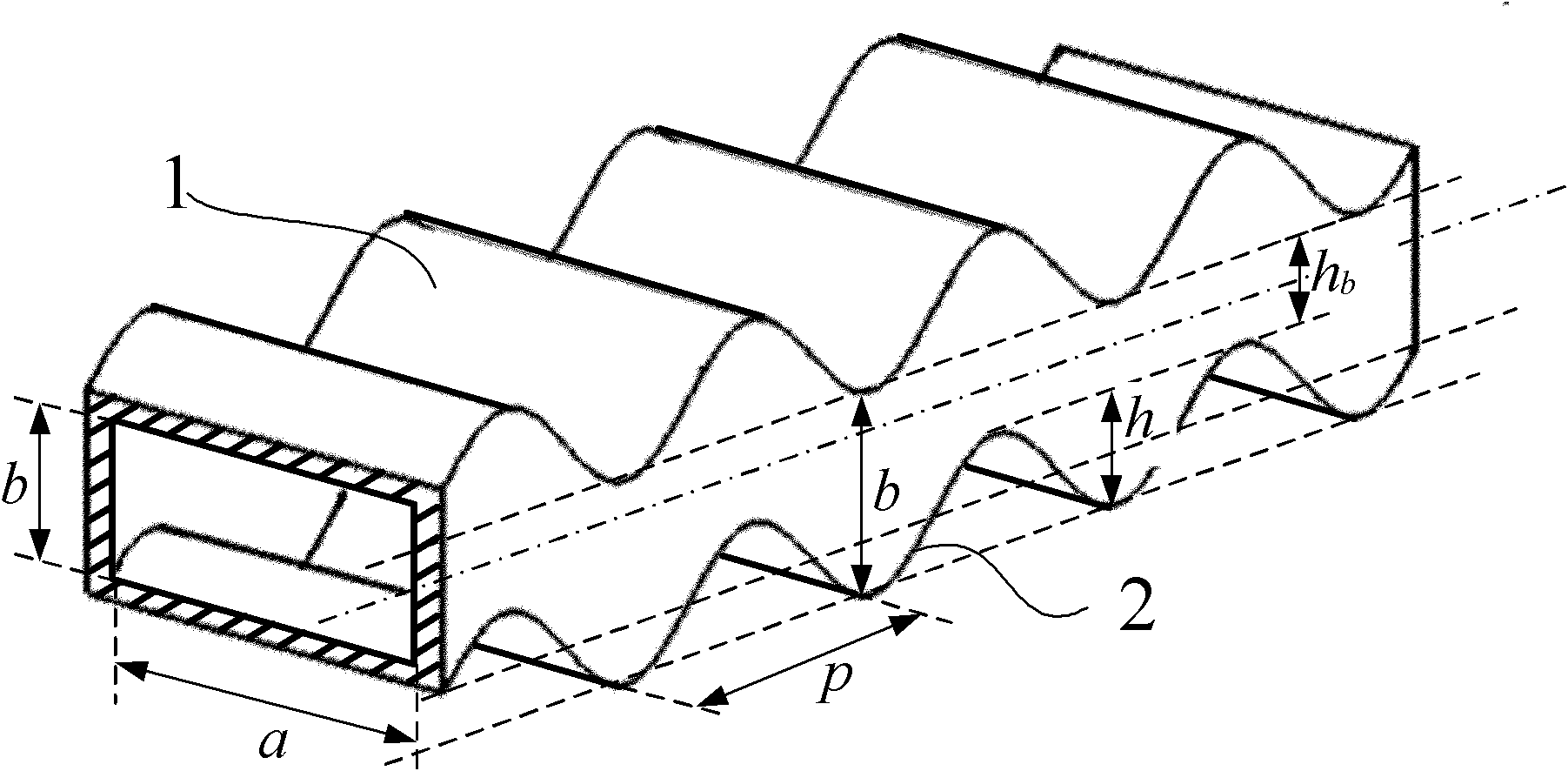

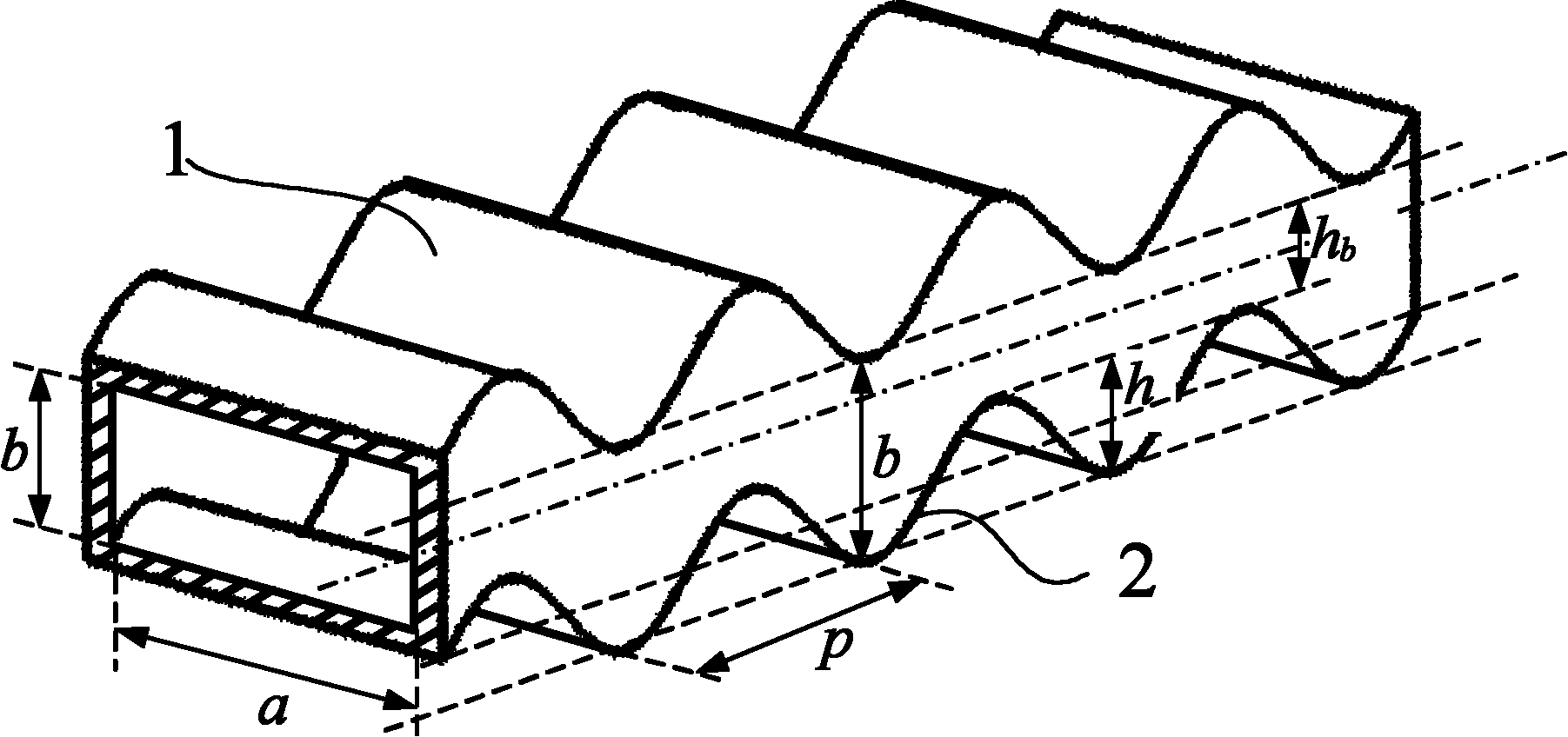

[0019] An undulating waveguide slow-wave structure, such as figure 1 As shown, it is formed by deforming a conventional rectangular waveguide whose broad side size is a and narrow side size is b; the E surface (ie, the electric field surface) of the undulating waveguide slow wave structure is periodically undulating, and the undulating waveguide The H surface (i.e. the magnetic field surface) of the waveguide slow wave structure is a plane, and the cross contour line of the E surface and the H surface is a periodically changing wave line; the period length of the periodically changing wave line is p, and the undulation height h is Dimension b of narrow side of rectangular waveguide and height h of electron beam channel b poor.

[0020] In the above technical solution, the periodically changing wavy line is a sine curve, a cosine curve, a triangular waveform curve or a semicircular arc curve.

[0021] Set the specific dimensions as follows: the wide side a of the conventional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com